In this article, we delve into the fascinating world of plastic extrusion to discover a variety of everyday items that are produced using this versatile manufacturing process.

Plastic extrusion, a high-volume manufacturing process, is instrumental in producing a variety of everyday items. From plastic pipes, wire insulation, and window frames to weather stripping, adhesive tape, and plastic films, the list is extensive.

This process involves melting raw plastic and forming it into a continuous profile, offering immense versatility in creating products of various shapes and sizes.

As you delve into this article, you will discover the intricacies of the plastic extrusion process, its significance in the construction industry, and the vast array of products it helps create.

The details that follow will provide a comprehensive understanding of this fascinating subject.

Key takeaways:

- Plastic extrusion is used to make a wide range of everyday items such as pipes, window frames, films, wire insulation, and weather stripping.

- The process involves melting raw plastic, shaping it into a continuous profile, cooling it, and cutting it into the desired lengths.

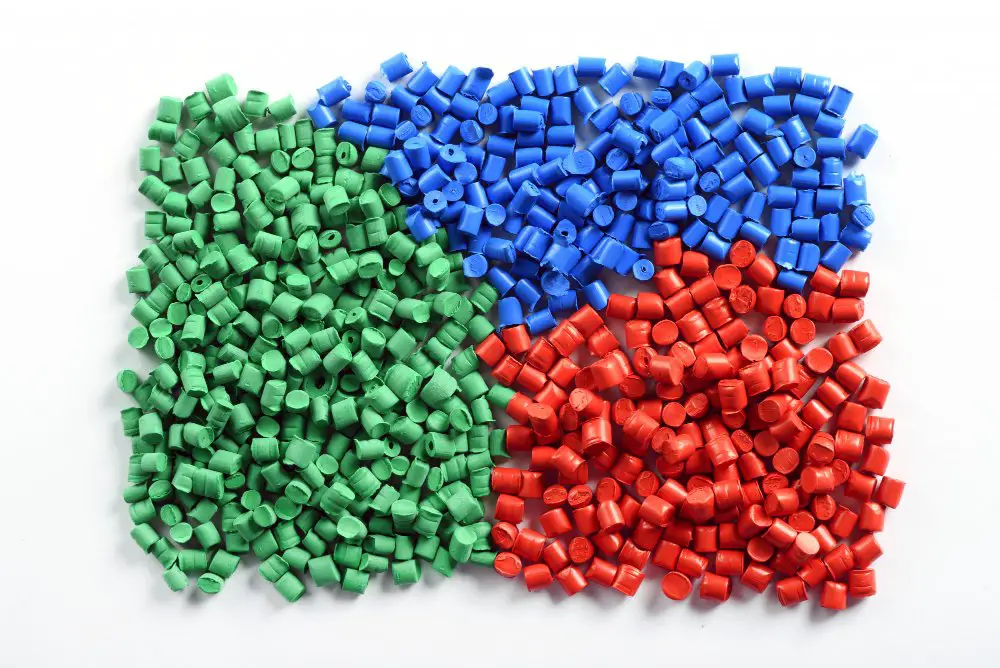

- Popular materials used in plastic extrusion include HDPE, LDPE, PVC, PP, PS, and PET, each with their own specific characteristics and applications.

- Different types of extruders, such as single screw, twin screw, and multiple screw extruders, are used depending on the complexity of the material and the desired end product.

- Plastic extrusion offers advantages such as lower costs, high production rates, custom shapes, efficient manufacturing, scrap reusability, and recyclability.

Understanding Plastic Extrusion

Plastic extrusion is a crucial process that transforms raw plastic material, often in the form of pellets, into a continuous profile. The process finds extensive application in the manufacture of a host of items, from drinking straws and piping to window frames and plastic sheeting.

Essential components of the plastic extrusion process are:

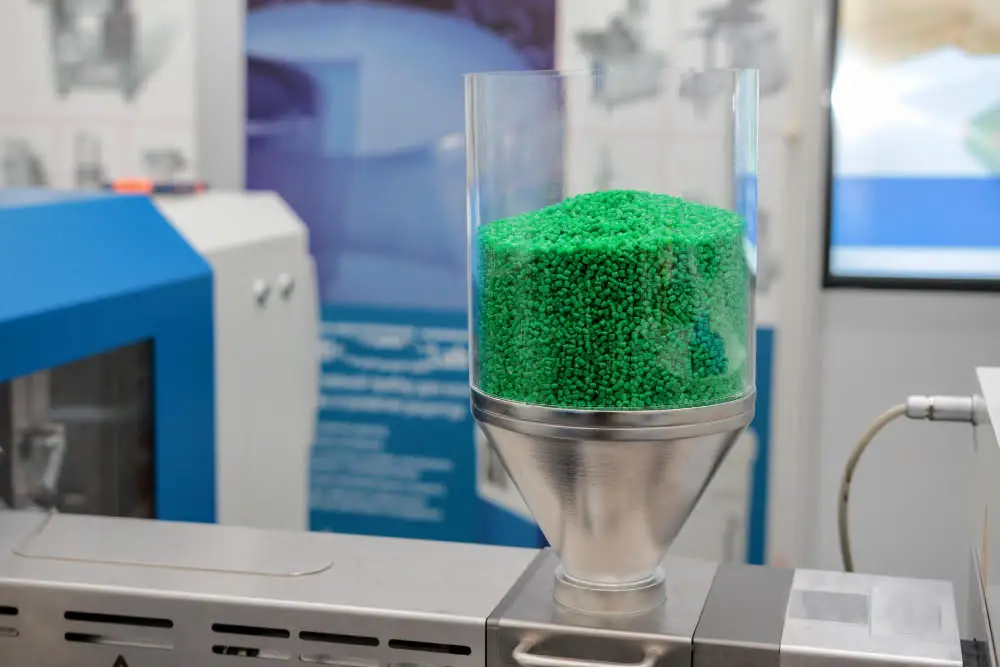

- Raw Material: Where the journey begins. The raw plastic, usually in pellet form, is fed into an extruder.

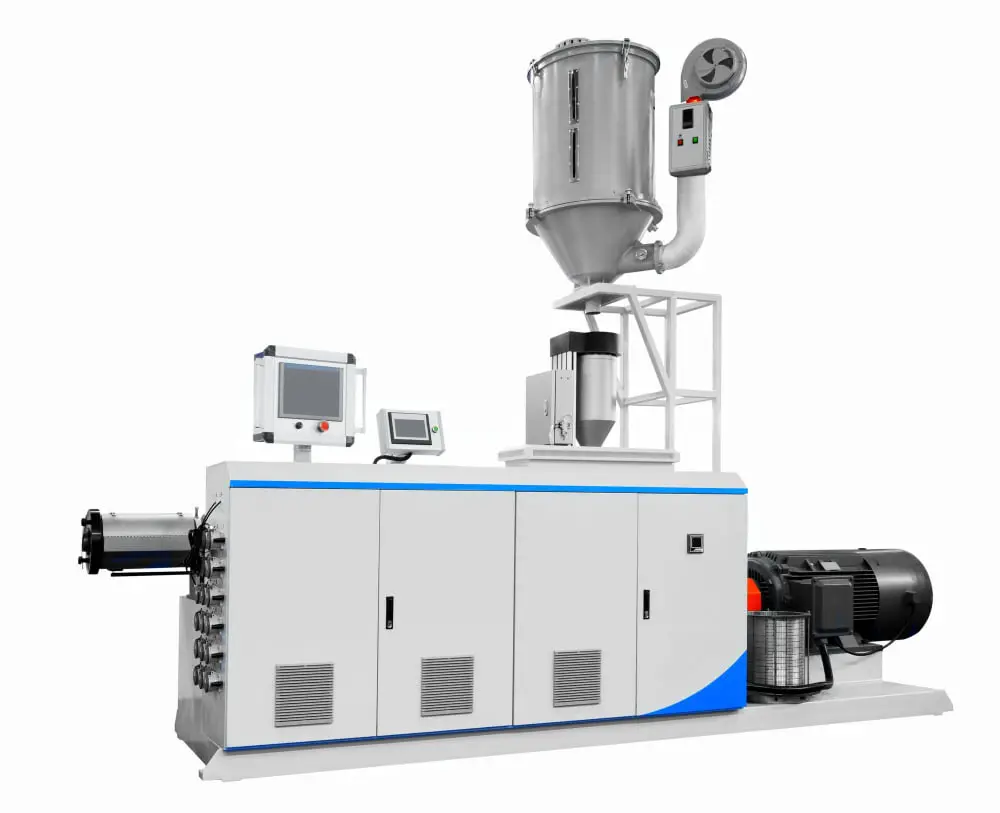

- Extruder: The heart of the process. This machine heats and melts the raw plastic under pressure, turning it into a molten form.

- Shape Determination: Where the magic happens. The molten plastic is then passed through a die, a metal plate with an opening that gives the plastic its final shape.

- Cooling and Cutting: The finishing touches. The plastic is then cooled and cut into lengths, ready for distribution or further processing.

This process simplifies the manufacture of various complex plastic shapes and is widely used due to its cost-effectiveness and versatility. Various adjustments, such as different dies and temperatures, can lead to an array of products with diverse characteristics, satisfying a broad range of applications.

Typical Extrusion Materials

Popular choices for plastic extrusion include High-Density Polyethylene (HDPE), Low-Density Polyethylene (LDPE), and Polyvinyl Chloride (PVC). Each of these options boasts specific characteristics that contribute significantly to their selection for various applications.

HDPE offers great strength and durability, making it an excellent choice for products requiring longevity, even under challenging environmental conditions. Items such as plastic lumber and geomembranes commonly use this material.

LDPE, on the other hand, is noted for flexibility and resistance to impact, chemicals, and UV radiation. Because of these properties, it is commonly used in film applications, flexible tubes, and plastic bags.

Then there’s PVC, a highly versatile material due to its ability to accept additives that adjust its properties, such as softeners, UV stabilizers, and flame retardants. Predominantly, it is used in creating profiles such as window frames and pipes.

Other materials frequently used in extrusion are Polypropylene (PP), ideal for heat resistance applications; Polystyrene (PS), suitable for rigid applications like packaging and building insulation, and Polyethylene Terephthalate (PET), typically used in the production of bottles and containers.

In making a choice of material for extrusion, factors to consider include product requirements, performance under specific conditions, and necessary adjustments via additives. It’s essential to match the correct polymer type to the intended use to maximize performance while ensuring durability and cost-effectiveness.

Types of Extruder

There are primarily two types: the single screw extruder and the twin screw extruder. The former, as its name suggests, consists of just one screw to carry out the function of extrusion. Known for its simplicity and cost-effectiveness, the single screw extruder is the most common extruder and ideal for processing basic materials.

On the other hand, the twin screw extruder, which contains two screws, is primarily used for more complex materials and operations. This includes tasks such as mixing, compounding, or reactive extrusion. Based on their configuration, twin screw extruders can be corotating or counter-rotating, and intermeshing or non-intermeshing.

The differences between these two types of extruders lie in their efficiency and applications. While a single screw extruder is suitable for basic tasks, twin screw extruders are necessary for more demanding projects. For instance, when handling heat-sensitive materials or undertaking processes that require a high level of shearing.

Another variant is the multiple screw extruder, which, although not very common, has uses in specific areas of the polymer, food, and powder coating industries. Multiple screw extruders contain more than two screws in their system, allowing for an even better degree of mixing.

When choosing an extruder, factors such as the type of material, product specifications, cost, and process flexibility should be carefully weighed. In turn, this would aid in ensuring the best results for every individual project.

Process of Plastic Extrusion

Plastic extrusion begins with the feeding of raw polymer material, often in the form of pellets or granules, into the extruder’s hopper. A rotating screw then conveys these materials through a heated barrel, melting them into a viscous, molten state at temperatures usually ranging from 200 to 275 degrees Celsius.

The melted plastic subsequently goes through a static screen pack which aims to filter out contaminants and refine overall consistency. In this process, pressure is built up which aids in pushing the molten plastic through the die, shaping it into the desired form.

Once exiting the die, the hot, soft extrudate encounters a set of cooling rolls, water bath, air, or other cooling mediums which solidify the plastic, giving it the necessary rigidity to maintain the form imparted by the die. After cooling, the plastic object is moved towards a take-up system, often a conveyor belt or pair of pinch rollers, that transport the product to the next stage such as cutting, wrapping, or further assembly.

The rate of extrusion, temperature at critical points, and the design of the die all play key roles in determining the size, shape, and surface texture of the extruded plastic product. The process can continuously run as long as there are materials being fed into the hopper, making plastic extrusion a cost-effective method for mass-producing uniform plastic items.

Screw Design in Plastic Extrusion

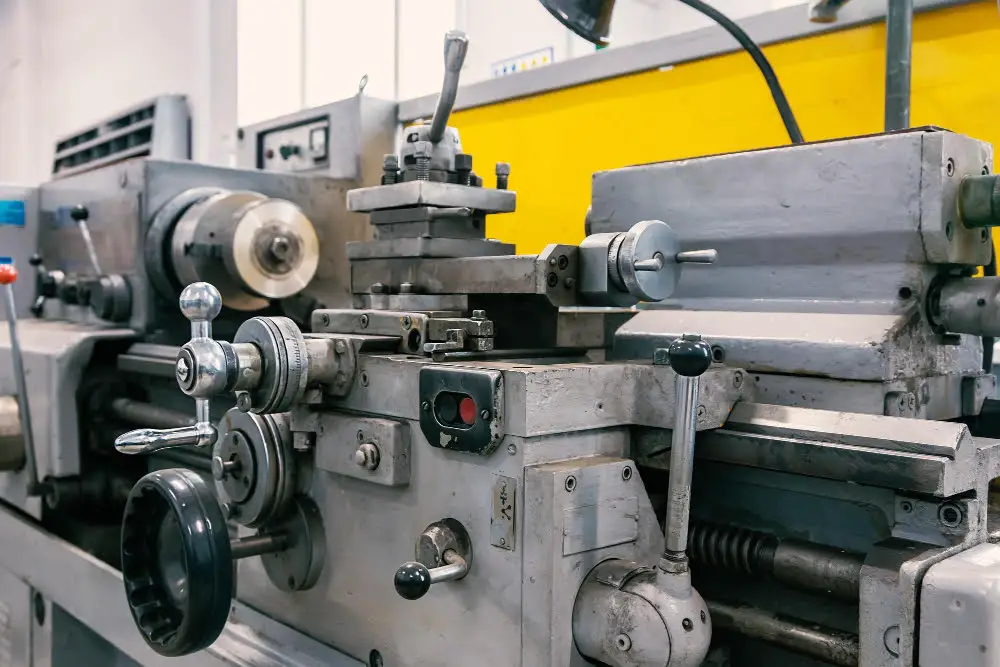

A main component in plastic extrusion, the screw serves integral functions. Firstly, it moves the raw plastic pellets into the extruder. Secondly, it applies heat to the material courtesy of its shearing action, leading to melting.

Constructed typically of steel, the screw boasts three distinctive segments. Its feed section is where the raw plastic is loaded, and its function is to take in and convey the pellets forward. Moving towards the compression section, the screw’s aesthetics change – the diameter of the thread enlarges while the depth sees reduction – resulting in compression of the plastic. The metering section, with its shallower and more consistent thread depth, serves to homogenize and melt the plastic efficiently.

The design of the screw varies depending on the specific material being used in extrusion. Ideal, consistent operating conditions can be achieved by aligning screw design to the unique characteristics of a plastic. It is crucial to note that when switching to a different material type in the same extruder, thorough cleaning must be performed to avoid contamination.

A plastic’s viscosity, melting temperature, and other physical properties dictate the optimal screw design. For instance, materials with high melt viscosities often use a longer feed section to avoid premature melting. Conversely, those with a low melt temperature require shorter feed sections.

A small alteration in screw design can have significant impacts on product quality and the efficiency of the extrusion process. Therefore, screw design plays an undeniably vital role in the plastic extrusion process.

Die Types Used in Plastic Extrusion

Die designs play an integral role in shaping the final product that comes out of the plastic extrusion process. The most common types include straight-through, spider, and coathanger dies.

The straight-through die, or also called the fish-tail die, has a straightforward design and operation, used often when simplicity and cost-effectiveness is a priority.

Moving onto spider dies. In this type, the polymer melt is segmented into several channels before being recombined. This process ensures a homogeneous output, making it a favorite when working with complex or expensive materials.

Lastly, there’s the coathanger die. Its name may sound peculiar but makes complete sense when one looks at its shape. Designed to spread the melt evenly across the width of the die, it offers unmatched uniformity, especially ideal for the production of films and sheets.

Understanding the application and operation of these die types allows manufacturers to fine-tune their plastic extrusion process for optimal results. These designs are often tailored specific to the material, product design, and other production factors.

Coextrusion Explained

Coextrusion is a process involving multiple extruders that simultaneously push different types of plastic through a single die. We can imagine it as layering different plastic materials in a single product, similar to a sandwich.

Commonly used in the production of packaging, coextrusion allows for the creation of a final product with diverse properties. One layer may provide strength, while others add barrier properties or a desirable surface finish. It’s a cunning way to combine the best attributes of multiple types of polymers.

In the process, the polymers must be compatible for proper bonding, and each layer’s thickness can be precisely controlled to meet specific functionality needs.

It’s the pulling together of different plastics, each adding its specialty, to form one superior product.

Coextrusion can also reduce manufacturing costs. Often, an expensive, high-performance polymer is used only as a thin outer layer, keeping the cost down while still having the essential properties at the surface.

In short, coextrusion is economy and efficiency rolled into one. It’s the clever use of multiple polymers to create cost-effective, high-functioning plastic products.

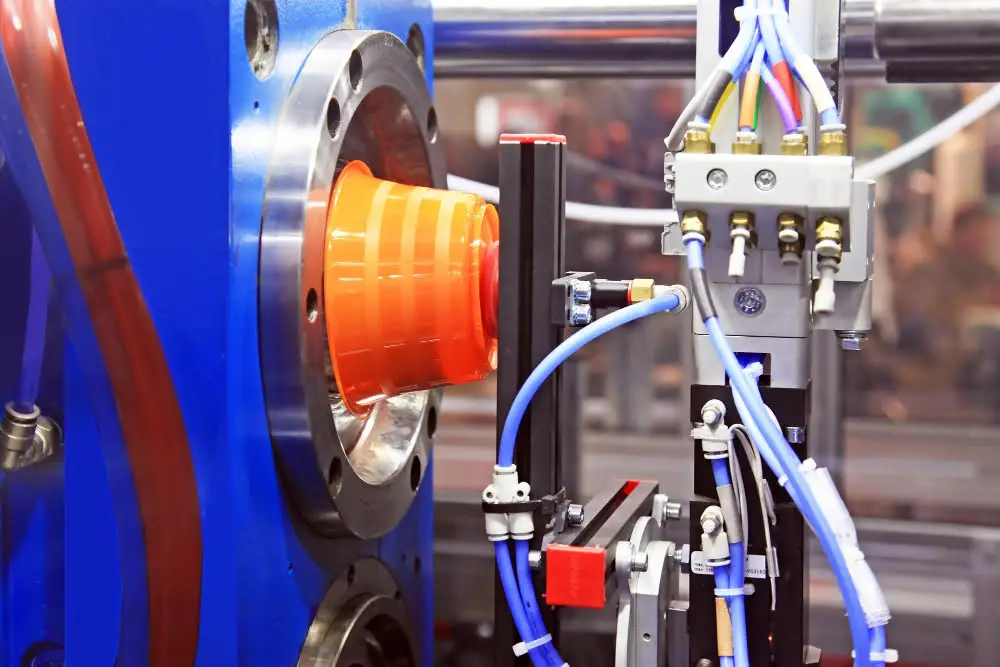

Blown Film Extrusion Insights

Blown film extrusion is a unique process leveraged in the manufacture of various plastic materials. At its core, it involves extruding molten thermoplastic, commonly Polyethylene, through a circular die, which then inflates to form a continuous tube of thin film. A chilling mechanism cools this tube, causing it to solidify, after which it is flattened and wound.

Key aspects of this method include:

- Use of various types of Polyethylene: Blown film extrusion commonly employs Low Density Polyethylene (LDPE), Linear Low Density Polyethylene (LLDPE), and High Density Polyethylene (HDPE). Each type produces films with varying degrees of strength, clarity, and barrier properties.

- Multilayer films: It’s conceivable to create composite structures by extruding multiple layers of different types of plastic simultaneously. This allows for films with a tailored balance of properties.

- Multiple applications: Resulting film finds widespread use in the packaging industry for bags, food coverings, and shrink wrapping, among others. They’re also used in agriculture for greenhouse coverings and soil moisture retention systems.

- Variability in thickness: The third key factor in the process is the cooling ring and air volume that influences the tube size and thickness of the film. Cooling too quickly could lead to a thicker, but weaker film, while slower cooling produces thinner yet stronger film.

- Control of the blow-up ratio: The ratio of the diameter of the inflated bubble to the diameter of the die is crucial in determining film properties. A higher ratio can improve film strength and resistance, but negatively affects the optical properties.

Understanding these factors offers efficiency in producing desired product specifications, reducing waste, and optimizing cost-effectiveness in the application of blown film extrusion.

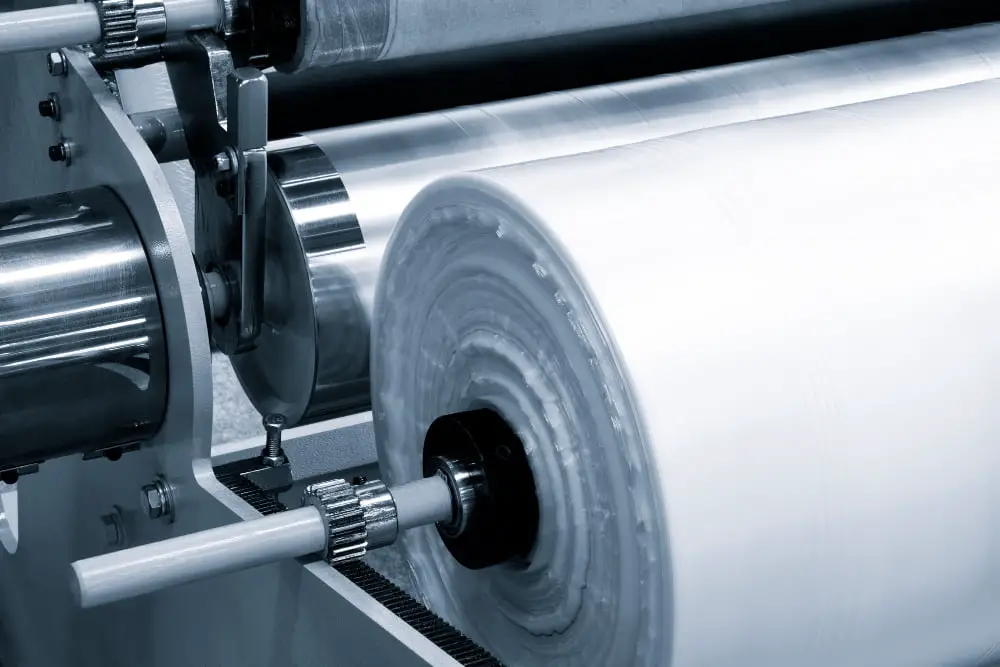

Sheet/Film Extrusion Details

In sheet or film extrusion, the molten plastic exits the extruder through a flat die, producing a wide, thin product. It’s an essential process in manufacturing items such as plastic bags, wraps, and films.

To begin, plastic pellets are fed into the extruder. The heat from the extruder transforms these pellets into a molten state. This fluid plastic is then pushed through the flat die, giving it the desired width.

Upon exit, position and cooling are critical. The sheet or film is drawn onto chill rolls which solidify the extrudate. These rolls not only cool the plastic but also determine the thickness of the end product.

For thickness, speed is key. The faster the cooling rolls draw, the thinner the product becomes. Conversely, drawing at slower speeds results in thicker products. This balance of rate, heat, and cooling allows for a range of product thicknesses, making this method highly versatile.

Once solidified and cooled, the plastic sheet or film can be wound onto rolls for future processing. The winding tension must be controlled to avoid defects and ensure a uniform roll.

Often, sheet or film are subjected to further treatments such as corona, flame or plasma treatment. These help improve the surface energy of the plastic, allowing for better printing or adhesion in later stages.

Overall, the process requires careful control of many elements to gain the desired results but when done correctly, results in a wide range of valuable products from heavy-duty construction wrap to plastic bags we use daily.

Over Jacketing Extrusion

Over jacketing extrusion, a special type of extrusion, is typically used when a finished product needs an additional layer or protection. A common example of a product made using this method is insulated electrical wires where the insulation serves as the protecting ‘jacket.’

When carrying out the over jacketing extrusion process, the original product, also identified as the ‘substrate,’ is fed into the extrusion equipment. Simultaneously, the plastic material, which will form the jacket, is introduced into the extruder.

The jacket material undergoes heating and pressurizing until it reaches a molten state, quite similar to regular extrusion methods. But in this case, the melt is formed around the substrate as both pass through a custom-built die. This encases the substrate in the plastic jacket, providing the desired additional layer or protection.

Remember that the type of plastic used for the jacket needs to be compatible with the substrate and the required external conditions. These could include factors like temperature resistance, chemical resistance, or UV resistance. Also, the design of the die, the rate of extrusion, and the cooling process must be carefully managed to ensure a high-quality, well-adhered jacket is formed around the substrate.

It’s also essential to note the process’s unique advantages: over jacketing allows multiple functionality layers in a single product and optimizes production by allowing continuous, high-speed manufacturing.

Compound Extrusions

Compound extrusions involve combining two or more materials, using different die positions, to create a final product with desirable properties. Here are key points of how this process works and the unique advantages it brings:

- Coupling two or more polymers allows the generation of products with combined attributes. This may result in products with enhanced strength, increased flexibility, or specialized functions.

- This process optimizes cost-efficiency by using less expensive materials in the core of the product and reserving high-quality, costlier materials for the surface where their beneficial properties are needed most.

- Deciding the right mix of materials is crucial in achieving desired outcomes. For example, a hard inner and a soft outer material can be combined to create a robust yet flexible tube.

- The process can include additional stages, such as cooling, or even introducing other elements like metals or ceramics at certain sections of the product for specific applications.

- Adjusting die positions has a significant effect on the final product’s quality and characteristics. The careful calibration of these positions helps control the thickening or thinning of different material layers, further manipulating the product’s properties.

- Blending all the materials through a single extruder or feeding them through individual extruders may significantly impact the production process, influencing factors such as production speed and output quality.

Remember, optimal results in compound extrusions come from careful consideration of all the previously mentioned factors, in addition to meticulous planning and precise execution. Engaging a professional with extensive knowledge in polymers and extrusion processes can greatly assist in producing the best outcomes.

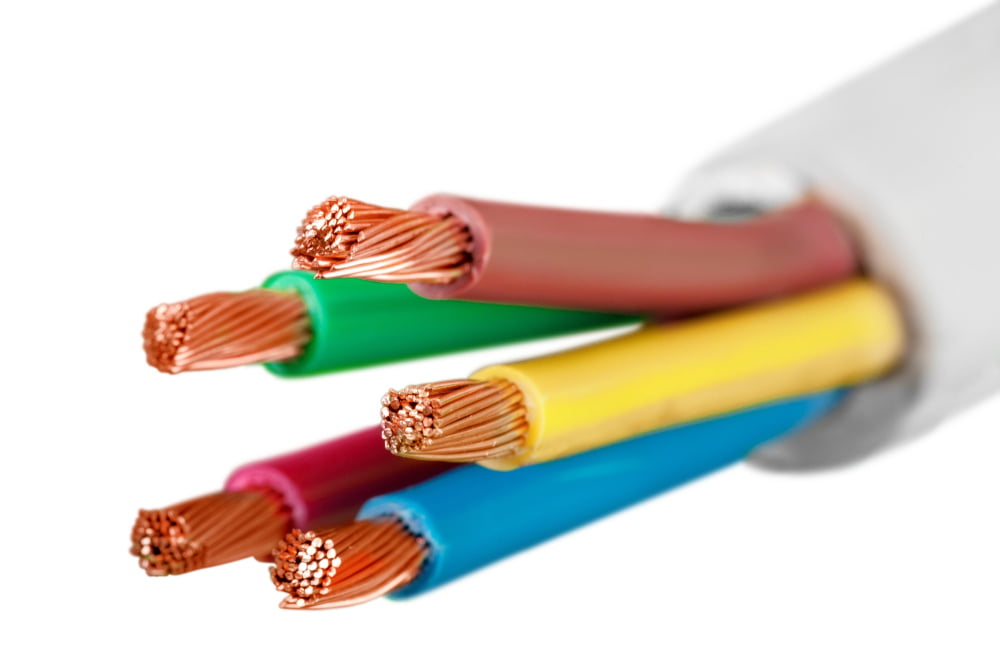

Insulated Wire Made By Plastic Extrusion

Insulated wiring plays a critical role in transmitting electricity while minimizing risks. The isolation is achieved by plastic extrusion – a high-heat process that uses various polymers around the conducting wire.

Key polymers for this process include PVC, polyethylene, and thermoplastic rubber, each offering unique levels of flexibility, resilience, and resistance to environmental factors.

In the extrusion process, the selected polymer is first warmed to a fluid state. The bare wire, fed from a spool, passes through a cross-head die, where polymer coats it seamlessly. The newly coated wire then takes a chilling bath to solidify the insulation.

The thickness of the insulation can be adjusted according to the wire’s intended use. For instance, wires exposed to harsh environmental conditions or high voltage will require thicker insulation.

Visual inspection and rigorous testing assure that the insulation has been evenly applied, without pinholes or thin spots. This process ensures electrical safety and high performance across various settings, including household wiring, automotive, and industrial usage.

The plastic extrusion process for wire insulation not only enhances electricity conduction but also reduces potential dangers, making it a pivotal component in modern day construction and electromechanical devices.

Extruded Car Parts

Plastic extrusion finds substantial application in the automobile industry because of its versatility and cost-effectiveness. Extruded parts help minimize a vehicle’s weight, improving fuel efficiency and overall performance.

The process works by heating and forcing plastic through a die in the shape of the desired car part, allowing vast production quantities. A cooling process solidifies these parts, which then undergo post-extrusion processes if needed, such as punching, sealing, or embossing.

Commonly extruded car parts include door and window seals. These are typically composed of a harder plastic exterior for durability and a softer interior for flexibility.

Another commonly extruded part is plastic trim, which enhances car aesthetics. This durable and lightweight plastic trim can come in varying colors and finishes to match vehicle designs.

Extrusion can also fabricate automotive tubing. Coolant and fuel lines, air conditioning tubing, and windshield washer lines are all possible through plastic extrusion. These tubes carry essential fluids and gases, so their durability is critical.

Additionally, plastic extrusion can produce car bumpers. These parts played a vital role in absorbing impact and protecting the vehicle in case of collisions. They are made of thermoplastic olefins, defining their strength and elasticity.

Highlighting these examples, it’s clear to see how plastic extrusion plays an integral role in vehicle production and function.

Pipes and Tubes Made Through Plastic Extrusion

Using the plastic extrusion process, an impressive array of pipes and tubes, both flexible and rigid, can be produced. A primary ingredient in the production process is granulated or powdered thermoplastic material, which gets melted down and pumped through a die. This die is specifically designed to give the final product its distinctive tube or pipe shape.

To maintain uniformity, the plastic is cooled and solidified post-extrusion before being cut to the desired length. From there, they can undergo further processes to add specific features or markings, if required. Primarily, these pipes and tubes find their application in several sectors:

- Plumbing: Plastic pipes are resistant to corrosion, making them ideal for carrying water in both residential and commercial uses.

- Gas Lines: Due to their durability and flexibility, plastic tubes are often used to transport gases safely.

- Industrial Applications: From carrying materials in a factory setting to serving as protective sheathing for wires and cables, plastic pipes and tubes are diverse in application.

- Medical Use: In the medical field, small diameter plastic tubes are used in various surgical procedures and biomedical equipment.

Remember, the versatility of plastic extrusion allows for pipes and tubes of different sizes, flexibilities, and color to be produced quite efficiently for these varied applications.

Film and Sheeting Products and Their Applications

Film and sheeting products have a broad spectrum of applications, ranging from packaging to construction, due to their desirable characteristics such as flexibility, versatility, and durability.

In the realm of packaging, shrink wrap, food packaging films, carrier bags, and liners are all classic examples of film and sheet applications. Shrink wrap is effective for keeping items secure and protected, while food packaging ensures freshness and extends the shelf life of perishables. Liners and carrier bags offer convenience and portability.

But it’s not just the packaging industry that benefits from these plastic extrusions. In construction, plastic sheets are often utilized for their insulation properties and resistance to weather conditions. They serve as vapour barriers in walls, roofs, and floors, preventing moisture ingress that could potentially lead to mould or structural damage.

In the automotive industry, protective films are widely employed to guard against scratches and other external damage. This durable layer of plastic helps preserve the vehicle’s aesthetic appeal and maintain its resale value. The medical field also extensively uses plastic sheeting in a variety of disposable items like bed linens, gowns, gloves, and so forth.

Moreover, they play a pivotal role in agricultural setups, where they serve as coverings for greenhouses and soil fumigation films, helping to optimize crop yield by controlling temperature and moisture content.

Utility aside, a notable advantage of film and sheeting products is that they can be custom-designed to fit specific needs. Factors such as thickness, transparency, colour, resistance levels, and other physical properties can be adjusted to match the intended application. This customization ensures optimal performance in the targeted use, whether that’s for strength, barrier properties, sealability, or printability.

Sports Equipment Made By Plastic Extrusion

Among the variety of products birthed by plastic extrusion is sports equipment, demonstrating the versatility and resilience of polymers within this sector. Hockey sticks, ski equipment, and gymnasium fixtures are some of the items created through this method.

Hockey sticks, for instance, utilize plastic extrusion in the creation of their shaft and blade. Polymers known for their high-impact resistance, such as High-Density Polyethylene (HDPE), are extruded into the desired shape, creating a product that withstands the harsh conditions of the sport.

Ski equipment, including boots and bindings, also reap the benefits of extrusion. Durable polymers like Polyurethane (PU) ensure the equipment’s integrity even in the harshest of winter conditions while allowing for flexible designs that enable the user’s comfort and mobility.

In the world of fitness and gymnasiums, plastic extruded items range from parts of exercise machines to protective railings and fixtures. Given the wear and tear these items can encounter, polymers such as Polypropylene (PP) are often used due to their toughness, versatility, and easy moldability into unique designs and shapes.

Understanding the role of plastic extrusion in sports equipment not only highlights the process’s versatility but also illustrates the durability and adaptability that these polymer materials afford across diverse sectors.

Bottles and Straws Made Through Extrusion

Plastic extrusion plays a pivotal role in the production of everyday items such as bottles and straws. A variety of resin types including polyethylene terephthalate (PET), high-density polyethylene (HDPE), and polypropylene (PP) are used to meet the requirements of different products.

The process unfolds as described:

- Plastic pellets are first melted in the extruder. The extrusion process turns these pellets into a viscous liquid. This step ensures the easy shaping of the plastic into various forms.

- The molten plastic is then forced through a die, a specialized tool that shapes the plastic into a continuous profile. In this case, the die is designed to mold the plastic into the shape of straws or bottle preforms.

- Following the shaping process, the plastic is cooled down. This phase solidifies the shape, creating a rigid structure that maintains the design of the die. Cool water or air is typically used in this cooling phase.

- The final step involves cutting or winding the products. Straws need to be cut to the desired length. As for bottles, they start out as preforms which later undergo a process called blow molding where they’re heated and inflated into their final shape.

There are, of course, variations to this process depending on the manufacturer, the specific type of product, and the grade or type of plastic used. However, the fundamental steps remain consistent. Even within our homes, reminders of plastic extrusion are as commonplace as a straw in a juice box or a bottle of water.

Solid Shapes Produce Through Plastic Extrusion

Plastic extrusion can produce diverse solid shapes, limited only by the design of the die a material passes through. This technique is widely used to manufacture items we encounter daily.

Primarily, decorative and functional items like moldings, trims, weather stripping, and seals derive from this method. Construction materials, including vinyl fencing, window frames, and plastic lumber, are also a result of extruding solid shapes.

For toy manufacturing, tiny pieces and intricate shapes are made using this process. In the medical industry, small yet vital parts like IV components and surgical devices also come from solid shape extrusion.

Apart from the process’s general steps, the creation of solid shapes necessitates a cooling phase to ensure that the shape holds once it comes out of the die. This cooling can be done either by air or water immersion, depending on the nature of the polymer used and the complexity of the shape.

Remember, die selection is fundamental to determine the form and size of the solid shape. Its proper maintenance, along with pressure regulation and temperature control, counts for producing consistent, quality plastic items.

Connectivity accessories in electronics, like cable trays, are also plastic extrusions, while smaller parts on larger devices such as washing machines and refrigerators are often extruded as well.

Hollow Pipe and Tubing: A Product of Plastic Extrusion

Hollow pipes and tubing, widely seen in the plumbing and medical industries, are critical products of the plastic extrusion process.

Primarily created using an extruder equipped with a circular die, these products exhibit durability, and resistance against different temperature variants and chemical interactions, making them ideal for fluid transportation.

The plastic extrusion process for making these items involves the following steps:

- The selected polymer, heated and pressurized, is fed into the extruder.

- This molten polymer is then passed through a die, shaping it into a hollow tube due to the introduction of air pressure.

- As the extruded tube leaves the die, it is cooled, typically with water, solidifying the shape.

- The solidified tube is then cut into required lengths for final use.

One can manipulate the diameter of the pipe or tube by adjusting the air pressure and the speed at which the material is extruded. This allows for different sizes of hollow pipes and tubes to be made, catering to a wide range of applications.

In medical applications, tubing is utilized for IV lines and catheters, while in construction, plastic pipes are a vital component in plumbing systems. This truly illustrates the versatility of plastic extrusion in manufacturing a variety of products across multiple industries.

Profile Shapes Obtained By Plastic Extrusion

Plastic extrusion plays a crucial role in the production of profile shapes. These shapes can range from simple, straight forms to more complex, contoured profiles. Commonly, extrusion is used to create profiles like seals, gaskets, and weather stripping for building and construction. Even items like plastic trim and gutters for homes can be created through this process.

In profile extrusion, the plastic material, typically in the form of small beads called resin, is melted and continuously pushed through a die cut into the shape of the desired profile. The extruded profile is then cooled, typically through a water bath, and cut to the required length.

For practical steps, consider:

- Choosing the correct resin: The type of plastic resin used will determine the properties of the final product.

- Setting the correct temperature: The resin needs to be heated to its melting point to allow it to flow properly. Too much heat can degrade the resin, too little can result in an uneven profile.

- Correct die setup: The die must be cut accurately to the desired profile shape.

- Controlling the cooling process: Rapid cooling can lead to warping, while slow cooling can result in a distorted profile.

- Proper system calibration: The extruder machine needs regular calibration to ensure accurate profiles.

The versatility of plastic extrusion in creating different profiles makes it beneficial for an array of industries, such as construction, automotive, and consumer products. However, it also necessitates a precise understanding of process parameters to achieve the desired product quality and performance.

Extruded Blow Molded Items Examined

Blow molding, an integral part of the plastic extrusion process, involves forming hollow plastic parts. It differs from injection molding (used in solid plastic parts) and is most commonly seen in the production of containers and bottles for beverages, cosmetics, and cleaning products among others.

Manufacturing using blow molding involves three main steps:

- Parison Formation: A parison, essentially a plastic tube with a hole in one end, is formed from the heated plastic material. The sizing of the parison directly affects the final product.

- Blowing: The parison is enclosed within a two-part mold. Compressed air is then sent into the parison, expanding it to fit the mold’s interior.

- Ejection: Once the hollow part has been cooled and hardened, it is ejected from the mold for further processing or packaging.

Each blow-molded item retains a mark or seam where the mold halves met, which differentiates these products from those made by other processes. Blow molding facilitates production of complex shapes, one of the reasons it is prevalent in various industrial sectors. Most pipelines, gas and water tanks, and plastic drums are manufactured using this practice. Blow-molded items are also recurrent in daily-use products such as toys and household appliances.

To increase understanding, imagine an inflated balloon in the shape of an animal – consider this the plastic, initially heated and flexible. The balloon artist’s twisting and bending represents the mold, shaping the warmed plastic. Upon cooling (deflating, in our analogy), the shape remains intact, much like a finished blow-molded product.

Advantages of Plastic Extrusion

Plastic extrusion has a key role in contemporary manufacturing processes. Its advantages are multiple:

Firstly, Lower Costs. The polymer used in plastic extrusion is cost-effective. Unlike other materials, it allows for a higher output at lower costs, which favorably impacts the final price of the product.

High Production Rates also play a role. Plastic extrusion can create continuous lengths of product, leading to high production rates. This makes it an excellent choice for large-scale manufacturing.

Custom Shapes are another advantage. Extrusion allows the creation of intricate, custom shapes while maintaining structural integrity. From tiny medical tubes to large pipes, the range is vast.

Efficient Manufacturing is a key feature. Once the extrusion tooling is in place, plastic extrusion runs continuously, increasing efficiency and throughput.

Scrap Reusability is another perk. The manufacturing process allows for the in-house regrinding and reusing of scrap materials, contributing to environmental sustainability. It also reduces the overall production cost.

Recyclability aids sustainability. Most materials used in plastic extrusion are recyclable, which helps in reducing environmental pollution.

FAQ

What products are made from plastic extrusion?

Plastic extrusion manufactures products such as pipe/tubing, weatherstripping, fencing, deck railings, window frames, plastic films and sheeting, thermoplastic coatings, and wire insulation.

What are some examples of products that are extruded?

Examples of extruded products include pipes, tubing, wire insulation, thermoplastic coatings, sheeting, plastic films, window frames, deck railings, fencing, and weather stripping.

What materials are formed by extrusion?

Materials formed by extrusion include metals, polymers, ceramics, concrete, modeling clay, and foodstuffs.

What are some everyday examples of extrusion?

Everyday examples of extrusion encompass pasta, pipes, window panes, gears, various snack foods, aluminum cans, railings, shower stalls and windshield wipers.

What is the impact of plastic extrusion on the environment?

Plastic extrusion, a common manufacturing process for many construction materials, contributes to environmental degradation due to its energy-intensive nature and the greenhouse gases it generates.

How has the technology of plastic extrusion evolved over time?

The technology of plastic extrusion has evolved over time through advancements in machinery design and process control, enabling more precise and efficient creation of complex, high-quality polymer products with varied shapes, sizes, and compositions.

In what ways does plastic extrusion contribute to the construction industry?

Plastic extrusion contributes to the construction industry by providing durable, lightweight, and cost-effective materials for various construction applications, including insulation, cladding, pipework, and window frames.

Recap