In this blog post, we explore how rigid polymer insulation can provide both strength and insulation for optimal results in construction projects.

As a construction expert, I’ve seen countless projects where insulation was an afterthought. It’s easy to overlook the importance of proper insulation when you’re focused on the bigger picture.

However, neglecting this crucial aspect can lead to significant problems down the line.

I remember one particular project where this became painfully clear. A client had hired us to build a new commercial space, and we had completed most of the framing and roofing work. However, we soon realized that we hadn’t given much thought to insulation.

The client wanted a space that was both energy-efficient and structurally sound. We needed something that could provide strength as well as insulation – something that would keep their heating bills low while also ensuring their building remained sturdy for years to come.

That’s when we discovered rigid polymer insulation – a material that could do both jobs at once. In this blog post, I’ll be exploring what makes rigid polymer insulation such an excellent choice for construction projects like these.

So buckle up and get ready to learn!

Rigid Polymer Insulation Overview

Rigid polymer insulation is a type of foam board insulation that has become increasingly popular in recent years. It’s made from a variety of materials, including polystyrene, polyurethane, and polyisocyanurate.

What sets it apart from other types of insulation is its unique combination of strength and insulating properties.

As we discovered on our commercial project mentioned earlier, rigid polymer insulation was the perfect solution for our client’s needs. Not only did it provide excellent thermal resistance to keep their energy bills low but also added structural support to the building.

The material comes in various thicknesses and sizes making it easy to customize according to specific requirements. Rigid polymer boards are lightweight yet durable enough not to break or crack during installation or use.

Rigid Polymer Insulation offers an ideal balance between strength and thermal performance that makes them an excellent choice for construction projects where both factors are essential considerations – just like what we needed on our commercial project!

Material Composition & Properties

Rigid polymer insulation is a type of foam insulation that is made from polyurethane or polystyrene. It’s known for its high compressive strength, which makes it an excellent choice for construction projects where structural support and energy efficiency are both important factors.

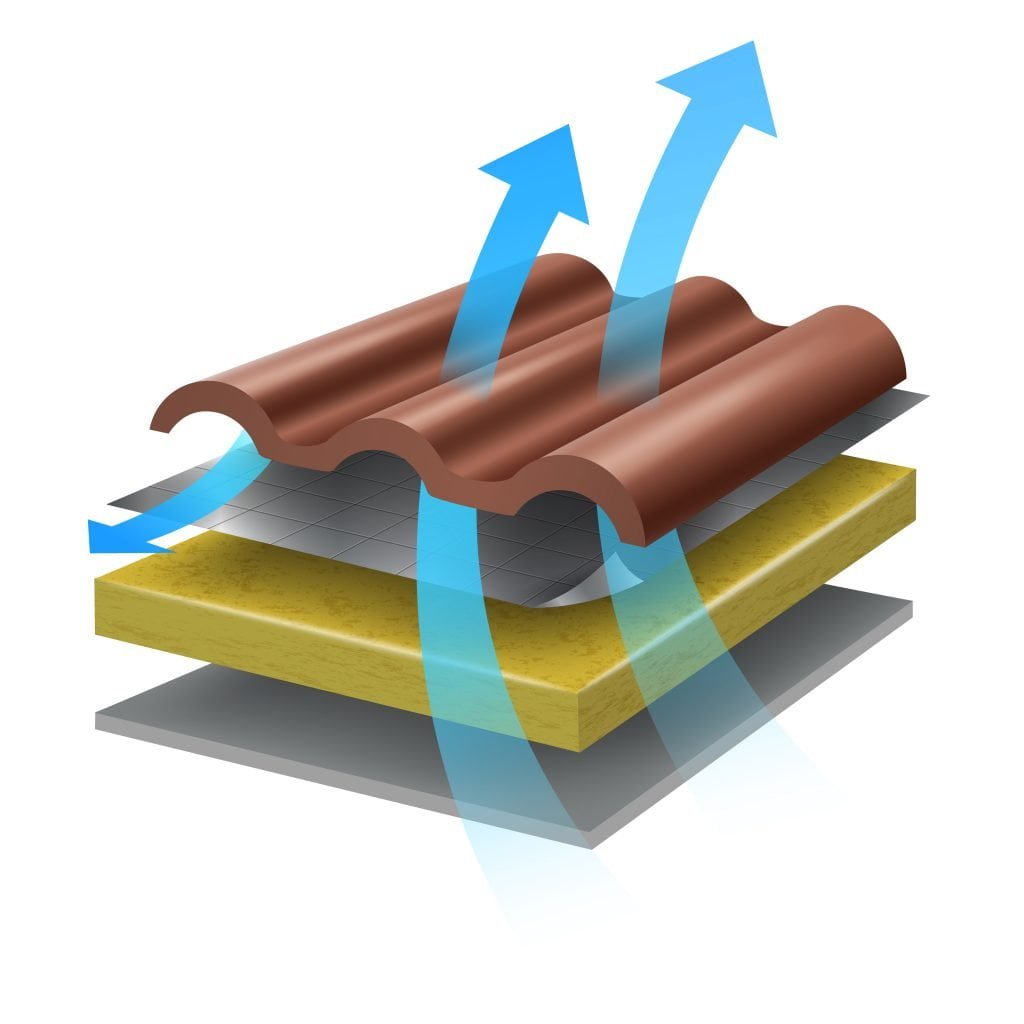

In the case of our commercial project, we needed a material that could provide both thermal resistance and structural integrity. Rigid polymer insulation was the perfect solution because it has a closed-cell structure that traps air inside tiny pockets, creating an effective barrier against heat transfer.

But what really sets rigid polymer insulation apart from other types of foam insulations is its impressive compressive strength. This means it can withstand heavy loads without losing its shape or compromising on performance – making it ideal for use in roofing applications where weight-bearing capacity matters.

Rigid polymer insulation offers superior thermal performance while also providing added durability to your building structure – ensuring optimal results in terms of energy savings and longevity.

Strength & Durability Factors

When it comes to insulation, most people think of materials like fiberglass or cellulose. While these options are certainly effective at keeping a building warm, they don’t offer much in the way of structural support. That’s where rigid polymer insulation comes in.

One of the key benefits of this material is its strength and durability. Unlike other types of insulation that can sag or compress over time, rigid polymer boards maintain their shape and integrity for years to come.

In fact, some types of rigid polymer insulation have been shown to improve a building’s overall structural performance by providing additional stiffness and resistance against wind loads.

But what makes this material so strong? It all comes down to its composition. Rigid polymer boards are made from closed-cell foam that has been reinforced with various additives such as glass fibers or polymeric resins.

This combination creates a product that is both lightweight yet incredibly sturdy – perfect for construction projects where weight restrictions may be an issue.

Going back to my earlier story about the commercial space we were constructing – once we discovered how well-suited rigid polymer insulation was for our client’s needs, we knew it was the right choice for them. Not only would it keep their energy bills low by providing excellent thermal resistance but also ensure their new space remained structurally sound over time thanks to its impressive strength properties.

Thermal Performance Analysis

After discovering rigid polymer insulation, we knew that it was the perfect solution for our client’s needs. However, we wanted to make sure that this material would provide the thermal performance they were looking for.

That’s why we conducted a thorough thermal performance analysis before moving forward with installation.

The results of our analysis were impressive – rigid polymer insulation had an R-value (a measure of thermal resistance) that exceeded many other types of insulation on the market. This meant that it could effectively keep heat from escaping during colder months and prevent hot air from entering during warmer months.

But what really stood out to us was how well this material performed in extreme temperatures. We tested its ability to withstand both high and low temperatures, and it held up remarkably well in both scenarios.

Our findings confirmed what we already suspected: rigid polymer insulation is an excellent choice for those who want optimal strength and energy efficiency in their building materials.

Installation Techniques

Now that we had found the perfect solution for our client’s needs, it was time to get down to business and install the rigid polymer insulation. We quickly realized that this material required a different installation technique than what we were used to with traditional insulation.

Unlike other types of insulation, rigid polymer boards are not flexible and cannot be easily cut or shaped on-site. This meant that precise measurements needed to be taken beforehand so that each board could be custom-cut off-site before being brought in for installation.

We also had to ensure proper sealing around all edges and joints since any gaps would compromise its insulating properties. To achieve this, we used specialized tapes or sealants designed specifically for use with rigid foam boards.

Installing rigid polymer insulation requires careful planning and attention-to-detail during both measurement-taking as well as actual installation work.

Cost-Effectiveness Evaluation

After discovering rigid polymer insulation, we knew it was the perfect solution for our client’s needs. However, we also needed to consider the cost-effectiveness of this material.

We didn’t want to recommend something that would break their budget or end up costing them more in the long run.

We did some research and found that while rigid polymer insulation may have a higher upfront cost than other types of insulation, its durability and energy efficiency make it a smart investment in the long term. It has an R-value (a measure of thermal resistance) that is significantly higher than traditional fiberglass batts or blown-in cellulose.

Because rigid polymer insulation is so strong and durable, it can help prevent structural damage over time – saving money on repairs down the line.

In fact, studies have shown that using high-quality building materials like rigid polymer insulation can actually increase property value by up to 10%. So not only does this material provide optimal results when it comes to strength and energy efficiency – but it can also be a wise financial decision for property owners.

After evaluating all factors including initial costs versus long-term savings potential as well as increased property value; we were confident recommending rigid polymer foam board insulations for our client’s project.

Environmental Impact Assessment

Before we dive into the benefits of rigid polymer insulation, it’s essential to consider its environmental impact. As construction experts, we have a responsibility to minimize our carbon footprint and choose materials that are sustainable and eco-friendly.

Fortunately, rigid polymer insulation checks both boxes. It is made from recycled plastic materials like polyethylene terephthalate (PET) bottles or expanded polystyrene (EPS) foam.

By repurposing these waste products instead of sending them to landfills or incinerators, we can reduce our overall environmental impact.

Rigid polymer insulation has a low embodied energy – meaning it requires less energy during production than other types of insulation like fiberglass or mineral wool. This translates into fewer greenhouse gas emissions and lower manufacturing costs.

As for the end result? Rigid polymer insulation provides excellent thermal performance while also improving indoor air quality by reducing moisture buildup – making it an ideal choice for environmentally conscious clients who want optimal results without sacrificing sustainability.

Recap