Incorporating polymer insulation in construction projects is revolutionizing the industry, and this article will explore its innovative uses for a more energy-efficient and sustainable future.

It’s hard to believe that something so simple as polymers could have such a massive impact on construction projects across the globe. But it’s true! In fact, I recently had an experience that drove home just how important polymer insulation can be.

I was working on a project in an area of the country known for its extreme weather conditions – hot summers and freezing winters. The building we were constructing needed to be able to withstand both without causing undue strain on heating and cooling systems or driving up energy bills for occupants.

That’s where polymer insulation came in. We used this innovative material throughout the building’s walls and roof, creating an impermeable barrier against outside temperatures while providing excellent soundproofing.

The result? A building that remained comfortable year-round with minimal energy usage – all thanks to polymer insulation! Intrigued? Read on to learn more about this exciting material and its countless applications in today’s construction industry.

Key takeaways:

- Polymer insulation offers superior thermal and acoustic performance.

- It improves energy efficiency and reduces utility bills.

- Polymer insulation is versatile and can be used in various construction projects.

- It provides excellent moisture control and fire resistance.

- Retrofitting existing buildings with polymer insulation is cost-effective and sustainable.

Polymer Insulation Types

Polymer insulation is a type of insulation made from synthetic materials that are designed to provide superior thermal and acoustic performance. There are several different types of polymer insulation available, each with its own unique properties and applications.

For example, expanded polystyrene (EPS) is a lightweight foam material that offers excellent thermal resistance and moisture resistance. It’s commonly used in walls, roofs, floors, and foundations.

Extruded polystyrene (XPS), on the other hand, has a higher compressive strength than EPS which makes it ideal for use in heavy-duty applications such as under concrete slabs or roads.

Polyisocyanurate (PIR) foam boards have high fire-resistance properties making them suitable for use in buildings where fire safety is critical like hospitals or schools.

The versatility of polymer insulation means it can be used across many construction projects regardless of size or complexity – just like the project I mentioned earlier! By using this innovative material throughout our building’s structure, we created an energy-efficient space without sacrificing comfort levels for occupants. Polymer Insulation Types offer various benefits depending on their application areas; therefore choosing the right one will ensure optimal results while keeping costs low.

Energy Efficiency Benefits

One of the most significant benefits of using polymer insulation in construction projects is its energy efficiency. As I mentioned earlier, the building we constructed with polymer insulation was able to maintain a comfortable temperature year-round without putting undue strain on heating and cooling systems or driving up energy bills for occupants.

This is because polymer insulation creates an impermeable barrier against outside temperatures, preventing heat from escaping during cold weather and keeping cool air inside during hot weather. This means that less energy is required to maintain a comfortable indoor environment, resulting in lower utility bills for building owners and tenants.

But it’s not just about saving money – using less energy also has environmental benefits by reducing greenhouse gas emissions associated with traditional heating and cooling methods. In fact, buildings are responsible for around 40% of global carbon emissions! By incorporating innovative materials like polymer insulation into our construction projects, we can help reduce this impact while still providing high-quality structures that meet the needs of modern society.

In short: Polymer insulation isn’t just good news for your wallet – it’s also great news for the planet!

Thermal Performance

One of the most significant benefits of polymer insulation is its thermal performance. As I mentioned earlier, the building we constructed using this material remained comfortable year-round with minimal energy usage.

This is because polymer insulation creates an airtight seal that prevents heat transfer between inside and outside environments.

In addition to reducing heating and cooling costs for occupants, this also means that HVAC systems can be downsized without sacrificing comfort levels. And in areas where extreme temperatures are common, such as the location of our project site, this can make a massive difference in overall energy consumption.

But it’s not just about keeping buildings warm or cool – polymer insulation also helps regulate temperature fluctuations within individual rooms or spaces. This makes it ideal for use in areas like recording studios or medical facilities where precise temperature control is essential.

When it comes to thermal performance and energy efficiency in construction projects today, there are few materials more innovative than polymer insulation!

Acoustic Insulation

In addition to its thermal insulation properties, polymer insulation is also an excellent choice for acoustic insulation. In fact, the same project I mentioned earlier required us to address noise pollution from nearby traffic and other sources.

We used a specialized type of polymer foam that not only blocked out unwanted sounds but also absorbed them. This resulted in a much quieter indoor environment for occupants – something that was especially important given the building’s location near a busy highway.

But it’s not just large commercial buildings that can benefit from this innovative material. Homeowners looking to reduce noise levels in their homes can use polymer acoustic insulation as well.

Whether you live near an airport or simply want some peace and quiet, this material is worth considering. It’s clear that polymer insulation has numerous applications beyond traditional thermal uses – making it one of the most versatile materials available today!

Moisture Control Solutions

In addition to its thermal and acoustic insulation properties, polymer insulation also offers excellent moisture control solutions. During my experience with the extreme weather conditions project, we encountered a significant amount of rain and humidity that could have caused serious damage to the building’s structure if not properly addressed.

Fortunately, our use of polymer insulation prevented any such issues from arising. The material’s closed-cell structure creates an effective barrier against water vapor infiltration while also preventing mold growth – a common problem in humid environments.

But it’s not just extreme weather conditions where moisture control is essential. In fact, many construction projects can benefit from using polymer insulation as part of their overall moisture management strategy.

From reducing condensation in HVAC systems to preventing water damage in basements or crawl spaces – this innovative material has countless applications when it comes to keeping buildings dry and structurally sound. So whether you’re working on a large-scale commercial project or simply looking for ways to improve your home’s energy efficiency and comfort levels – consider incorporating polymer insulation into your plans for optimal results!

Retrofitting Applications

But it’s not just new construction projects that can benefit from polymer insulation. Retrofitting existing buildings with this material is also a smart move, especially for those looking to improve energy efficiency and reduce costs.

In fact, I recently worked on a retrofit project where we used polymer insulation to upgrade an older building’s walls and roof. The results were impressive – the building was able to maintain comfortable temperatures year-round without relying as heavily on heating and cooling systems.

Not only did this save the owners money in energy costs, but it also made the space more attractive to potential tenants who valued sustainability and eco-friendliness.

Polymer insulation is versatile enough that it can be retrofitted into almost any type of structure – from homes to commercial buildings. And because of its lightweight nature, installation is often quick and easy compared with other types of insulation materials.

Retrofitting with polymer insulation offers an excellent return on investment for property owners while simultaneously reducing their carbon footprint. It’s just one more way that innovative materials like these are changing the face of modern construction!

Building Envelope Innovations

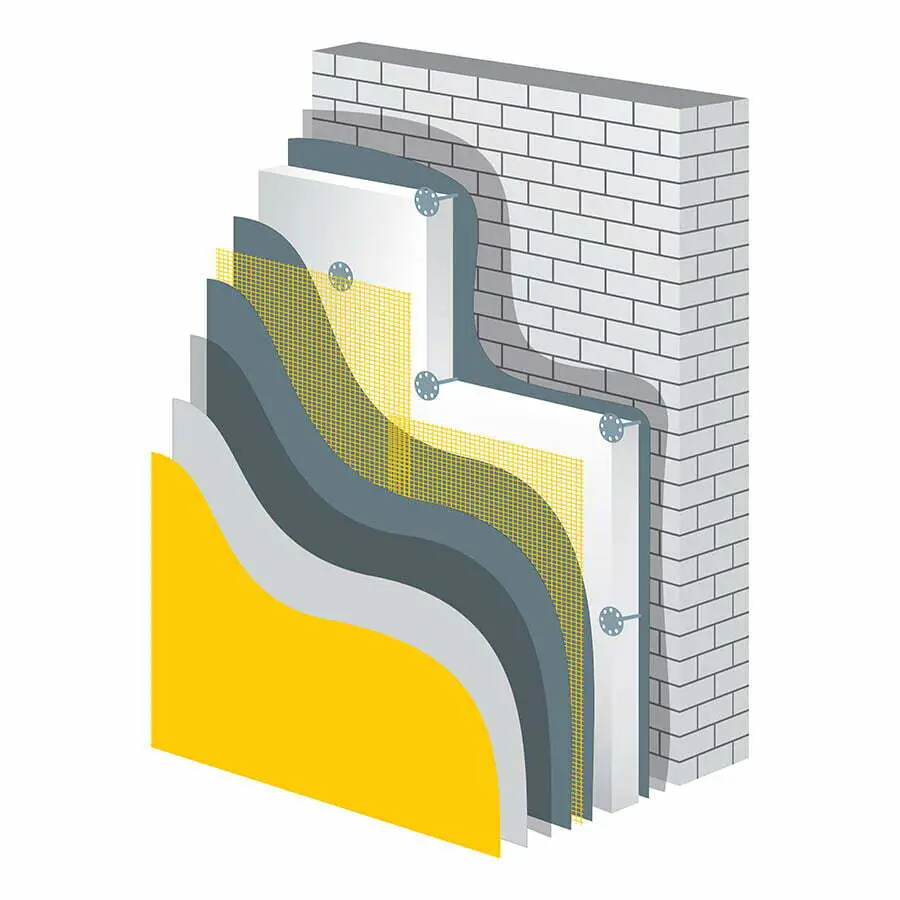

One of the most exciting applications of polymer insulation is in building envelopes. As I mentioned earlier, we used this material extensively in the walls and roof of a recent project to create an impermeable barrier against outside temperatures.

But that’s just scratching the surface when it comes to what polymer insulation can do for building envelopes.

In fact, there are now entire systems built around this innovative material that take envelope performance to new heights. These systems typically include not only insulation but also air barriers, vapor retarders, and other components designed to work together seamlessly.

The result is a building envelope that provides superior thermal performance while also preventing moisture infiltration and reducing air leakage – all critical factors for energy efficiency and occupant comfort.

But perhaps even more impressive than these individual benefits is how they all come together as part of a holistic approach to construction. By using advanced materials like polymer insulation alongside other innovations such as smart controls or renewable energy sources, we can create buildings that are truly sustainable – both environmentally and economically speaking.

So if you’re looking for ways to improve your next construction project’s performance while also reducing its environmental impact (and who isn’t?), be sure not overlook the potential offered by today’s cutting-edge building envelope innovations!

Fire Resistance of Polymer Insulation

Polymer insulation offers excellent fire resistance properties, making it a valuable choice for the construction industry. The unique chemical composition of polymers allows them to withstand high temperatures without melting or releasing toxic fumes.

This is particularly important in buildings where fire safety is a top priority.

Polymer insulation materials are designed to have low flammability and high ignition resistance, reducing the risk of fires spreading rapidly within structures. They can effectively slow down the spread of flames and limit their intensity, providing crucial time for occupants to evacuate safely.

In addition to their inherent fire-resistant properties, polymer insulations can also be treated with flame retardant additives during manufacturing processes. These additives further enhance their ability to resist combustion and reduce smoke generation in case of a fire incident.

Furthermore, polymer insulation’s ability to retain its structural integrity even under extreme heat conditions makes it an ideal choice for applications such as electrical wiring protection or thermal barriers around heating systems.

Environmental Impacts and Sustainability

One key advantage is its energy efficiency, which helps reduce greenhouse gas emissions by minimizing heat loss or gain in buildings. This leads to lower energy consumption for heating and cooling, resulting in reduced carbon footprint.

Polymer insulation materials are often made from recycled or renewable sources such as recycled plastics or bio-based polymers derived from plants. By utilizing these sustainable resources, the production of polymer insulation reduces reliance on fossil fuels and decreases overall environmental impact.

Furthermore, polymer insulation has a longer lifespan compared to traditional insulating materials like fiberglass or mineral wool. This durability means less frequent replacement is required over time, reducing waste generation and landfill usage.

Moreover, many types of polymer insulations are recyclable at the end of their life cycle. They can be processed into new products instead of being discarded as waste material.

Recycling not only minimizes environmental impact but also conserves valuable resources that would otherwise be used for manufacturing new materials.

Installation Considerations and Methods

One key factor is ensuring proper surface preparation before installation. This involves cleaning the substrate and removing any loose debris or contaminants that could affect adhesion.

Another crucial aspect is selecting the appropriate adhesive or fastening method for securing the insulation panels. Depending on the specific application, options may include mechanical fasteners, adhesives, or both.

Proper handling and storage of polymer insulation materials are also essential to maintain their integrity. It’s important to protect them from extreme temperatures, moisture, and direct sunlight during transportation and on-site storage.

During installation itself, following manufacturer guidelines regarding panel orientation and joint sealing is vital for achieving optimal thermal performance. Attention should be given to maintaining consistent thickness throughout the entire insulated area by using appropriate cutting techniques when necessary.

Lastly but importantly: safety precautions must always be observed during installation procedures involving polymer insulation materials. This includes wearing protective gear such as gloves and goggles when handling certain products that may release particles or fumes during cutting or shaping processes.

Life Cycle Cost Benefits

While the upfront cost may be slightly higher compared to traditional materials, such as fiberglass or mineral wool, polymer insulation offers significant long-term savings.

One key advantage is its durability and longevity. Polymer insulations have a longer lifespan than many other types of insulation materials.

They are resistant to moisture damage, mold growth, and pests. This means that once installed properly, they require minimal maintenance or replacement over time.

Polymer insulations provide excellent thermal performance and energy efficiency. They effectively reduce heat transfer through walls and roofs which can result in substantial energy savings throughout the lifetime of a building.

Lower heating and cooling costs translate into reduced utility bills for homeowners or businesses.

Furthermore, using polymer insulation can contribute positively towards achieving green building certifications like LEED (Leadership in Energy & Environmental Design). These certifications recognize sustainable construction practices that minimize environmental impact while maximizing resource efficiency.

Polymer insulation’s life cycle cost benefits include its durability, longevity and low maintenance requirements, energy efficiency leading to lower utility bills, and potential eligibility for green building certifications.

Health and Safety Aspects in Usage

Polymer insulation materials are designed to be safe for use in buildings, but it is still crucial to follow proper handling procedures.

One key aspect is the potential release of volatile organic compounds (VOCs) during installation or when exposed to high temperatures. It’s important for workers and occupants alike to be aware of any potential risks associated with VOC emissions and take necessary precautions such as ensuring adequate ventilation during installation.

Some polymer insulation materials may contain additives that could pose health risks if not handled properly. It’s essential for construction professionals and installers to carefully read product labels, follow manufacturer guidelines, wear appropriate personal protective equipment (PPE), and dispose of waste material responsibly.

Furthermore, fire safety should always be a top priority when using any type of insulation material. While many polymer insulations have excellent fire resistance properties due to their chemical composition or added flame retardants, it is crucial that they meet local building codes and regulations regarding fire performance.

By being mindful about these health and safety aspects throughout the usage process – from handling the materials safely during installation through regular maintenance – we can ensure a safer working environment for construction professionals as well as healthier indoor air quality for building occupants.

FAQ

What are the applications of polymer insulators?

Polymer insulators are extensively applied in the electrical and electronics sectors, serving as vital components to isolate electricity in protective gear for humans and in electrical circuitries.

What is plastic insulation used for?

Plastic insulation is used for creating an electricity-resistant barrier in various applications such as electrical wiring, circuit boards, switches, and light fittings.

Is polymer a good insulator?

Yes, polymers are excellent insulators for both heat and electricity.

Which polymer is used as insulator?

The polymer used as an insulator in construction is usually silicone rubber, EPM, EPDM, CE, or polytetrafluoroethylene (PTFE or Teflon).

How do polymers enhance durability in construction materials?

Polymers enhance the durability of construction materials by providing increased robustness, resistance to environmental conditions, corrosion, and wear and tear, ultimately extending their lifespan.

What are the environmental impacts of using polymer-based insulation?

The environmental impacts of using polymer-based insulation include potential harm to wildlife due to non-biodegradability, increased waste in landfills, and carbon emissions during manufacturing.

How do thermal properties of polymers affect their insulation capabilities?

The thermal properties of polymers, specifically their low thermal conductivity, contribute to their high insulation capabilities by slowing down the transfer of heat.

Recap