Recycled polymers can then be used to create new construction products or incorporated into existing ones to reduce waste and promote sustainability.

Polymers are everywhere around us – from water bottles to plastic bags. But did you know that they can also be used in construction? Polymers have unique properties that make them ideal for certain applications in the building industry, such as sealants or coatings.

However, with so much plastic waste piling up around the world, it’s essential to find ways of reusing these materials instead of sending them to landfill sites.

Key takeaways:

- Polymers, found commonly in our lives, can be recycled for construction use, promoting sustainability.

- Key polymers in construction include polyethylene, polypropylene, polystyrene, and polyvinyl chloride.

- Recycling them is critical but complex.

- Recycled polymers enhance construction materials, serve as insulation, and create eco-friendly drainage systems.

- Despite recycling challenges, research is exploring innovative uses for recycled polymers in construction.

Polymer Types in Construction

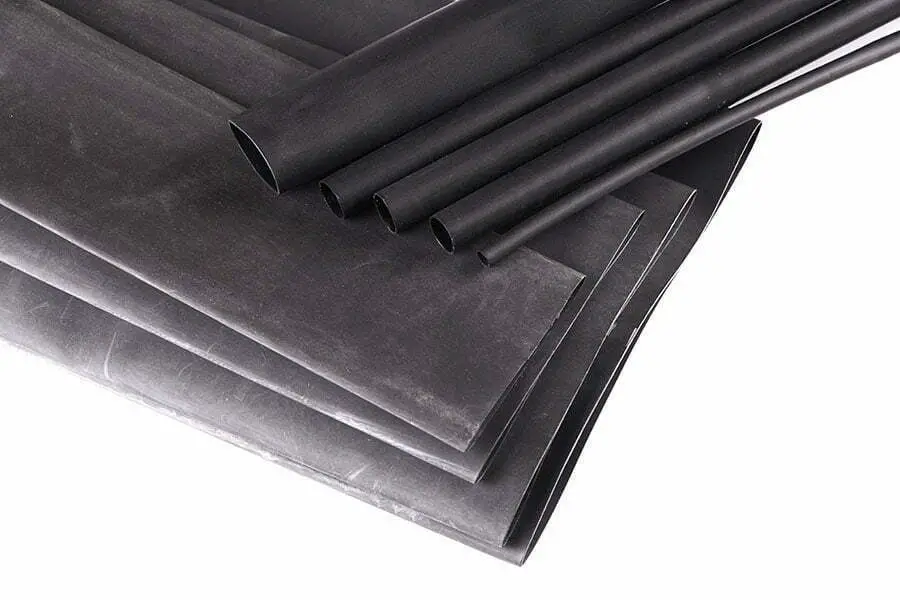

In the construction industry, polymers are used for a variety of purposes. They can be found in everything from adhesives and coatings to insulation and roofing materials.

The most common types of polymers used in construction include polyethylene (PE), polypropylene (PP), polystyrene (PS), and polyvinyl chloride (PVC).

While these materials have proven useful, they also contribute significantly to plastic waste pollution worldwide. That’s why many researchers are exploring ways to recycle these plastics into new products.

As I mentioned earlier, recycling is essential for reducing waste production globally. However, it’s not always easy or straightforward when it comes to certain types of plastics like those commonly found in the building industry.

Recycling Process of Polymers

The recycling process of polymers is complex, but it’s essential to understand how it works to appreciate the potential benefits. The first step in the process is sorting and cleaning.

This involves separating different types of plastics and removing any contaminants such as dirt or food residue.

Once sorted, the plastic waste goes through a shredding machine that breaks down large pieces into smaller ones. These small pieces are then washed again before being melted down into pellets or flakes.

The recycled polymer can now be used in various applications, including construction materials like insulation foam boards or roofing membranes.

It’s exciting to see how much progress has been made in recent years towards finding sustainable solutions for our planet’s waste problem. By reusing polymers instead of sending them to landfills, we can reduce our environmental impact while also creating new opportunities for innovation within the construction industry.

Reusing Recycled Polymers

As we discussed earlier, polymers have unique properties that make them ideal for certain applications in the construction industry. However, with so much plastic waste piling up around the world, it’s essential to find ways of reusing these materials instead of sending them to landfill sites.

Fortunately, recycled polymers can be reused in a variety of ways within the construction industry. For example, they can be used as an additive in concrete or asphalt mixtures to improve their strength and durability.

Recycled polymers are also commonly used as insulation material due to their excellent thermal properties.

Moreover, recycled polymer products such as pipes and drainage systems are becoming increasingly popular because they offer a cost-effective alternative while being environmentally friendly at the same time.

Benefits of Polymer Recycling

The benefits of polymer recycling are numerous, and they extend far beyond just reducing waste. By reusing polymers in construction, we can conserve natural resources and reduce our carbon footprint.

Recycling also helps to create a circular economy where materials are continually reused instead of being discarded after one use.

The construction industry generates a significant amount of waste each year. By incorporating recycled polymers into building projects, we can divert some of this waste from landfills and reduce the environmental impact associated with traditional disposal methods.

But it’s not just about reducing waste; using recycled polymers in construction also has practical benefits. For example, these materials often have unique properties that make them ideal for specific applications such as insulation or waterproofing.

There is no denying that polymer recycling offers many advantages for both the environment and the building industry itself.

Challenges in Polymer Recycling

While the idea of recycling polymers in construction sounds promising, it’s not without its challenges. One significant challenge is that many polymers are difficult to recycle due to their complex chemical makeup.

For example, some types of plastics cannot be recycled because they contain additives or contaminants that make them unsuitable for reuse.

Another issue is the lack of infrastructure and technology needed for polymer recycling on a large scale. While there are some companies and facilities dedicated to polymer recycling, they’re still relatively few and far between compared to traditional waste management systems.

Despite these challenges, there’s hope on the horizon as more research is being done into developing new methods for polymer recycling in construction. Some innovative solutions include using enzymes or bacteria to break down certain types of plastics or creating new materials from recycled polymers.

As we continue our journey towards a more sustainable future, finding ways to recycle and reuse materials like polymers will be crucial in reducing waste and preserving our planet’s resources.

Innovative Applications in Construction

As I mentioned earlier, polymers have unique properties that make them ideal for certain applications in the construction industry.

For example, researchers are exploring ways to use recycled plastic waste as a replacement for traditional aggregates like sand and gravel. These plastic aggregates can be used to create lightweight concrete blocks or even road surfaces.

Another innovative application is using polymer-based coatings on buildings’ exteriors. These coatings can help protect against weather damage and reduce energy consumption by reflecting sunlight away from the building’s surface.

But perhaps one of the most promising uses of recycled polymers in construction is creating insulation materials. By shredding and melting down plastic waste, it can be transformed into an insulating foam that has excellent thermal properties while being lightweight and easy to install.

These innovative applications provide solutions for reducing waste and offer cost-effective alternatives with improved performance compared to traditional materials.

It’s clear that there are many potential benefits when it comes to recycling plastics within construction projects – both environmentally friendly practices as well as economic advantages!

Case Studies of Successful Polymer Recycling in Construction

Several case studies have demonstrated the successful recycling and reuse of polymers in construction projects. One such example is the use of recycled polyethylene terephthalate (PET) bottles to create polyester fibers for insulation materials.

This innovative approach not only reduces waste but also provides a cost-effective solution for improving energy efficiency in buildings.

Another notable case study involves the recycling of high-density polyethylene (HDPE) pipes used for water distribution systems. These pipes are often replaced due to aging or damage, but instead of disposing them, they can be collected and processed into new HDPE products like drainage pipes or plastic lumber.

Furthermore, some construction companies have adopted a closed-loop system where polymer waste generated during construction activities is collected on-site and sent back to manufacturers for reprocessing into new building materials. This circular economy approach minimizes resource consumption while promoting sustainability within the industry.

These successful case studies highlight how polymer recycling can contribute to reducing environmental impact, conserving resources, and creating economic value within the construction sector.

Future Perspectives of Polymer Recycling in the Construction Industry

With advancements in technology and growing awareness about the benefits of recycling, there are several exciting perspectives for polymer recycling in construction.

One key aspect is the development of more efficient and cost-effective methods for separating different types of polymers during the recycling process. This will enable a wider range of polymers to be recycled and reused in various construction applications.

Researchers are exploring ways to enhance the mechanical properties and durability of recycled polymers so that they can meet or even exceed those of virgin materials. By improving their performance characteristics, recycled polymers can become a viable alternative for use in structural elements such as beams, columns, or even entire building components.

Furthermore, collaborations between academia, industry stakeholders,and government bodies play an essential role in driving innovation within polymer recycling technologies. These partnerships facilitate knowledge sharing,research funding,and regulatory support necessary for scaling up sustainable practices across all stagesoftheconstruction lifecycle.

Policies and Regulations Impacting Polymer Recycling

Governments around the world are recognizing the importance of sustainable practices and are implementing measures to encourage or enforce polymer recycling.

One key aspect is waste management policies that prioritize recycling over landfilling or incineration. These policies often include specific targets for reducing plastic waste, promoting circular economy principles, and encouraging industries to adopt more sustainable practices.

In addition to waste management policies, there may be specific regulations governing the use of recycled polymers in construction materials. These regulations ensure that recycled polymers meet certain quality standards and performance criteria before they can be used in building projects.

This helps maintain safety standards while also promoting sustainability.

Furthermore, some governments offer incentives such as tax breaks or grants for companies that invest in technologies or processes related to polymer recycling. These incentives help drive innovation and investment into research on improving recyclability rates as well as developing new applications for recycled polymers within construction.

Comparative Analysis of New Versus Recycled Polymer Performance in Construction

A comparative analysis can shed light on how these two types of materials stack up against each other.

In terms of strength and durability, both new and recycled polymers have been found to perform well in construction applications. Studies have shown that properly processed and treated recycled polymer materials can exhibit similar mechanical properties as their virgin counterparts.

However, there are some differences between the two. Recycled polymers may have slightly lower tensile strength or impact resistance compared to new ones due to potential degradation during previous use or recycling processes.

This variation depends on factors such as the quality of sorting, processing techniques employed during recycling, and any additives used in the original polymer formulation.

It’s worth noting that advancements in recycling technologies are continuously improving the quality and consistency of recycled polymer materials for construction purposes. Researchers are exploring various methods like melt filtration systems or compatibilizers that enhance compatibility between different types of plastics when mixed together for recycling.

Ultimately, choosing between new or recycled polymers will depend on specific project requirements such as load-bearing capacity needs, environmental considerations (e.g., carbon footprint reduction), cost-effectiveness goals,and local regulations governing material usage.

Environmental Impact of Polymer Recycling in Construction

Firstly, by recycling and reusing polymers in construction projects, we can significantly reduce the amount of waste that ends up in landfills. This helps conserve valuable landfill space and reduces the need for new landfills.

Recycling polymers requires less energy compared to producing virgin materials from scratch. The process of manufacturing new polymers involves extracting raw materials and consuming large amounts of energy.

By opting for recycled polymers instead, we can save on energy consumption and reduce greenhouse gas emissions.

Furthermore, using recycled polymers also helps mitigate pollution associated with traditional disposal methods such as incineration or landfilling. These methods release harmful pollutants into the air or soil which can have detrimental effects on human health and ecosystems.

Lastly, incorporating recycled polymers into construction projects promotes a circular economy where resources are reused rather than discarded after single use. This contributes towards a more sustainable future by reducing our reliance on finite resources while minimizing environmental degradation caused by extraction processes.

Considering these environmental benefits makes it clear that polymer recycling has a positive impact on sustainability within the construction industry.

FAQ

How can polymers be recycled?

Polymers can be recycled by either undergoing mechanical recycling – which involves washing, grinding, and melting the material – or through chemical recycling that breaks down the polymer into monomers to form new polymers for reuse.

What can recycled plastic be used for in construction?

Recycled plastics, once treated with gamma radiation and converted into a powder, can be mixed into cement paste to produce stronger concrete structures, such as sidewalks and driveways.

Can polymer be reused?

Yes, polymer can be reused, with thermoplastic polymers being easily recyclable while thermosetting polymers posing more difficulty; however, it’s important to note that properties of thermoplastic polymers degrade with each reuse.

What specific construction materials can be substituted with polymers and why?

Polymers can substitute traditional construction materials like concrete, wood, and steel due to their durability, corrosion resistance, insulation properties, and reduced weight.

How does the properties of polymers contribute to energy efficiency in buildings?

The properties of polymers, such as thermal insulation, light transmission, durability, and flexibility, contribute to energy efficiency in buildings by reducing heat loss, maximizing natural lighting, extending lifespan of structures, and enabling innovative architectural designs.

Are there any notable challenges in using recycled polymers in construction?

The notable challenges in using recycled polymers in construction include ensuring consistent quality and performance, dealing with contamination, and overcoming regulatory constraints.

Recap