Discover how lightweight polymer insulation revolutionizes sustainable construction and reduces energy costs with our expert insights.

As someone who cares deeply about our planet, it’s heartening to see builders and architects taking steps to reduce their environmental impact.

One area where this shift is particularly evident is in insulation. For decades, traditional materials like fiberglass and cellulose dominated the market.

But these options have some serious downsides: they’re bulky, messy to install, and can even pose health risks if not handled properly.

That’s why I was thrilled when I first heard about lightweight polymer insulation. This game-changing material offers all the benefits of traditional insulation (like keeping your home warm in winter), but with none of the drawbacks.

In this article, we’ll take a closer look at what makes polymer insulation so special and why it’s poised to become an essential part of sustainable construction practices. Whether you’re a builder or just someone interested in making your home more eco-friendly, you won’t want to miss this!

Key takeaways:

- Lightweight polymer insulation offers all the benefits of traditional insulation without the drawbacks.

- It is easy to install, customizable, and creates an airtight seal.

- Polymer insulation is made from recycled plastics, making it more sustainable than traditional options.

- It has superior thermal performance and helps reduce energy costs.

- Polymer insulation is fire-resistant, low-maintenance, and environmentally friendly.

Polymer Insulation: An Overview

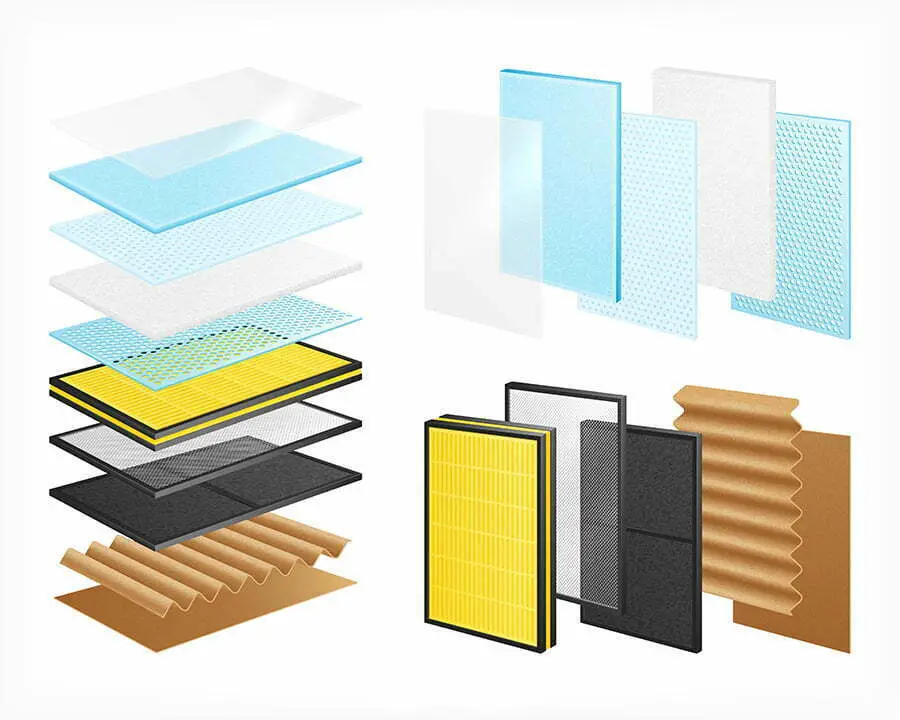

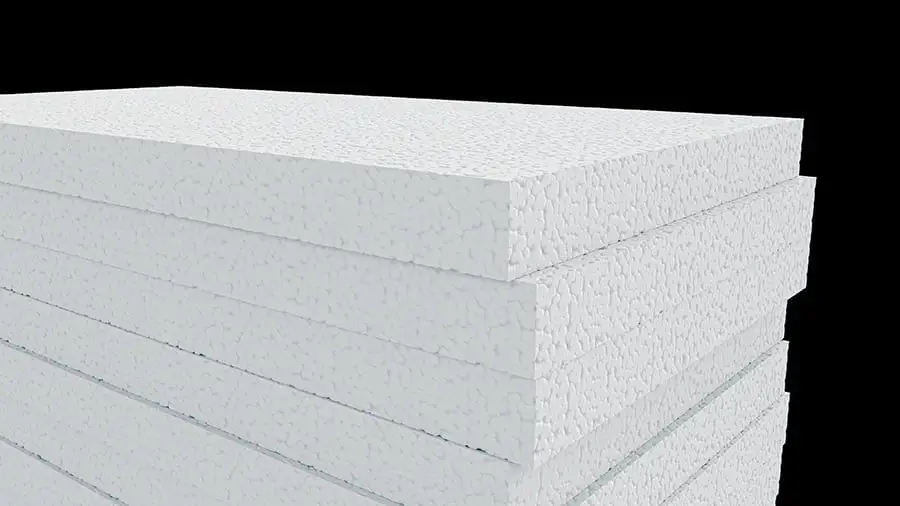

Polymer insulation is a relatively new type of insulation that has been gaining popularity in recent years. It’s made from lightweight, synthetic materials like polyurethane foam or expanded polystyrene (EPS).

Unlike traditional insulation materials, polymer insulation is incredibly easy to install and can be cut to fit any space.

But what really sets polymer insulation apart is its impressive insulating properties. Because it’s so lightweight, it creates an airtight seal around your home that helps keep warm air inside during the winter and cool air inside during the summer.

This means you’ll spend less money on heating and cooling bills over time.

As I mentioned earlier, one of the biggest advantages of polymer insulation is its sustainability factor. Traditional fiberglass or cellulose options are often made from non-renewable resources like petroleum products or wood pulp – not exactly eco-friendly choices! Polymer-based options are much more sustainable because they’re typically made from recycled plastics.

There are many reasons why builders and homeowners alike should consider using lightweight polymer-based insulations in their construction projects moving forward – especially if they want to reduce their environmental impact while still enjoying all the benefits of traditional insulations!

Sustainable Construction Benefits

Sustainable construction practices are becoming increasingly popular, and for good reason. By using materials and techniques that minimize environmental impact, builders can create structures that are both eco-friendly and cost-effective in the long run.

One of the most exciting developments in sustainable construction is lightweight polymer insulation. As I mentioned earlier, this material offers a host of benefits over traditional options like fiberglass or cellulose.

For one thing, it’s much easier to install. Because polymer insulation is so lightweight (hence the name), it doesn’t require any special equipment or heavy lifting to get into place.

This means less time spent on installation – which translates to lower labor costs for builders.

But perhaps even more importantly from an environmental standpoint: polymer insulation has a much smaller carbon footprint than other types of insulation. That’s because it requires fewer resources (like energy) to manufacture and transport – all while still providing excellent thermal performance once installed.

All these factors make lightweight polymer insulation an ideal choice for anyone looking to build sustainably without sacrificing quality or comfort inside their home or building.

Types of Lightweight Polymers

Now that we’ve established why lightweight polymer insulation is such an exciting development in sustainable construction, let’s take a closer look at the different types of polymers available.

One popular option is expanded polystyrene (EPS), which is made from small beads of polystyrene that are heated and then fused together. EPS has been used for decades in packaging materials, but it’s also an excellent choice for insulation due to its low thermal conductivity and high compressive strength.

Another type of polymer insulation gaining popularity is polyurethane foam (PUF). PUF can be sprayed or injected into walls, floors, and ceilings to create a seamless layer of insulation.

It offers excellent thermal resistance while taking up minimal space compared to traditional options like fiberglass batts.

There’s extruded polystyrene (XPS), which starts as solid blocks before being melted down and reshaped into sheets or boards. XPS has similar properties to EPS but with added benefits like increased moisture resistance.

No matter what type you choose, lightweight polymer insulations offer numerous advantages over traditional materials. They’re easy to install without creating any messes or health hazards during installation; they don’t settle over time; they’re resistant against mold growth; they have higher R-values than other insulating products on the market today – all while being eco-friendly!

Thermal Performance Analysis

One of the most important factors to consider when choosing insulation is its thermal performance. After all, the whole point of insulation is to keep your home at a comfortable temperature year-round.

So how does lightweight polymer insulation stack up in this regard?

The answer: very well indeed! In fact, some studies have shown that polymer insulation can outperform traditional materials like fiberglass and cellulose by a significant margin.

This superior thermal performance comes down to two key factors: first, polymers are excellent insulators thanks to their low thermal conductivity (i.e., they don’t transfer heat as easily as other materials). Second, because polymer insulation is so lightweight and easy to install, it’s possible to achieve better coverage with fewer gaps or air leaks – both of which can compromise an insulating material’s effectiveness.

Of course, every building project has unique requirements when it comes to energy efficiency and comfort levels. That’s why it’s always best practice for builders or homeowners alike consult with experts before making any decisions on what type of material will be used for their construction projects.

Cost and Energy Savings

One of the most significant benefits of lightweight polymer insulation is its cost-effectiveness. While traditional insulation materials may be cheaper upfront, they often require more maintenance and replacement over time.

In contrast, polymer insulation has a longer lifespan and requires less upkeep.

But that’s not all: using this innovative material can also lead to significant energy savings in the long run. Because it’s so effective at trapping heat (or cool air), you’ll need less energy to keep your home at a comfortable temperature year-round.

As someone who cares about sustainability, I’m always looking for ways to reduce my carbon footprint without breaking the bank. That’s why I’m excited about how much money homeowners can save by switching to lightweight polymer insulation – both in terms of installation costs and ongoing energy bills.

Of course, every building project is unique – but if you’re considering sustainable construction practices or want an eco-friendlier way to insulate your home or office space, it’s worth exploring whether this game-changing material could work for you!

Environmental Impact Reduction

One of the most significant benefits of lightweight polymer insulation is its positive impact on the environment. As we discussed earlier, traditional insulation materials like fiberglass and cellulose can be bulky and messy to install.

This means that they often require more energy to transport and handle, which contributes to their overall carbon footprint.

In contrast, polymer insulation is incredibly lightweight and easy to work with. It can be cut into custom shapes on-site without generating any waste or debris.

Plus, because it’s so efficient at trapping heat inside a building (or keeping it out in warmer climates), homeowners may even see a reduction in their energy bills over time.

But perhaps most importantly for those concerned about sustainability: many types of polymer insulation are made from recycled materials themselves! By using this type of product instead of traditional options that rely heavily on virgin resources like sand or glass fibers – builders can significantly reduce their environmental impact while still achieving excellent results.

I believe that lightweight polymer insulation represents an exciting step forward for sustainable construction practices – one that will benefit both builders and homeowners alike for years to come!

Installation and Maintenance

One of the most significant advantages of lightweight polymer insulation is its ease of installation. Unlike traditional materials, which can be messy and time-consuming to install, polymer insulation is quick and straightforward.

It comes in pre-cut panels that fit snugly between studs or rafters, making it easy for builders to achieve a tight seal without any gaps.

But what about maintenance? Here’s where things get even better: once installed correctly, lightweight polymer insulation requires virtually no upkeep. Unlike fiberglass or cellulose options that can settle over time (leading to reduced effectiveness), this material maintains its shape and insulating properties indefinitely.

In fact, some manufacturers claim that their products are so durable they’ll last as long as the building itself! That means you won’t have to worry about replacing your insulation every few years or dealing with costly repairs due to wear-and-tear.

If you’re looking for an eco-friendly option that’s both easy-to-install and low-maintenance – look no further than lightweight polymer insulation!

Fire Resistance Properties

One of the most important factors to consider when choosing insulation is fire resistance. Traditional materials like fiberglass and cellulose can be highly flammable, which poses a serious safety risk in the event of a fire.

But with lightweight polymer insulation, you don’t have to worry about this issue.

Polymer insulation is made from non-combustible materials that are designed to withstand high temperatures without catching on fire. This makes it an ideal choice for buildings where safety is a top priority.

But that’s not all: because polymer insulation doesn’t burn or release toxic fumes when exposed to flames, it can actually help slow down the spread of fires and give occupants more time to evacuate safely.

When I first learned about these impressive fire-resistant properties, I knew that lightweight polymer insulation was truly a game-changer for sustainable construction practices.

It offers superior thermal performance compared with traditional options – meaning you’ll save money on heating and cooling costs over time – and it also provides peace of mind knowing your home or building is safer in an emergency.

Recycling and Disposal Options

One of the most significant advantages of lightweight polymer insulation is its eco-friendliness. Not only does it reduce energy consumption and greenhouse gas emissions, but it’s also recyclable at the end of its life cycle.

Unlike traditional insulation materials that often end up in landfills, polymer insulation can be repurposed into new products or even used as fuel for energy generation.

In addition to recycling options, disposal methods are also much safer with this type of insulation. Traditional materials like fiberglass and cellulose can release harmful particles into the air if not disposed of properly.

But because polymer foam is chemically inert and doesn’t contain any hazardous substances, there’s no risk to human health or the environment during disposal.

Lightweight polymer insulation offers a sustainable solution for builders looking to reduce their environmental impact without sacrificing performance or safety standards. As more people become aware of these benefits and demand greener building practices from construction companies worldwide – we’ll see a shift towards more sustainable solutions across all aspects within our industry!

Innovative Applications of Lightweight Polymer Insulation in Commercial Buildings

In commercial buildings, the innovative applications of lightweight polymer insulation have revolutionized the construction industry. These advanced materials offer a range of benefits that make them highly desirable for various building projects.

One key advantage is their exceptional thermal performance. Lightweight polymer insulation effectively reduces heat transfer through walls, roofs, and floors, resulting in improved energy efficiency and reduced heating or cooling costs for commercial buildings.

This not only helps businesses save money but also contributes to overall sustainability by reducing carbon emissions.

Another notable feature is their lightweight nature. Compared to traditional insulation materials like concrete or fiberglass, polymers are significantly lighter while still providing excellent insulating properties.

This makes them easier to handle during installation and reduces structural load on the building itself.

Lightweight polymer insulation offers superior moisture resistance compared to other options available in the market today. Moisture can be a significant concern in commercial buildings due to factors such as weather conditions or high occupancy levels leading to increased humidity levels inside the structure.

Polymer-based insulations help prevent moisture buildup within walls and ceilings which can lead to mold growth or structural damage over time.

Furthermore, these innovative materials provide enhanced soundproofing capabilities when used as part of an acoustic system within commercial spaces such as offices or conference rooms where noise reduction is crucial for productivity and comfort.

Weather Resistance Properties of Polymer Insulation

Unlike traditional insulation materials such as fiberglass or mineral wool, polymers are inherently resistant to moisture and do not absorb water. This is particularly advantageous in regions with high humidity levels or areas prone to heavy rainfall.

The hydrophobic nature of polymer insulation prevents the absorption of water molecules, ensuring that its thermal performance remains unaffected over time. Moisture can compromise the effectiveness of other types of insulating materials by reducing their R-value (thermal resistance) and promoting mold growth.

However, polymer insulation maintains its structural integrity even when exposed to wet conditions.

Polymer-based insulations have low thermal conductivity which helps minimize heat transfer through walls and roofs during extreme weather conditions like hot summers or cold winters. This property contributes significantly towards energy efficiency in buildings by reducing heating and cooling costs.

Furthermore, the durability of lightweight polymer insulation allows it to withstand harsh environmental factors such as UV radiation from sunlight without degradation over time. It does not become brittle or crack under prolonged exposure to sunlight like some traditional insulating materials might.

Comparative Analysis: Lightweight Polymer Insulation Versus Traditional Insulation Materials

Compared to traditional insulation materials, such as fiberglass and mineral wool, lightweight polymer insulation offers several advantages.

Firstly, one of the key benefits of lightweight polymer insulation is its superior thermal performance. It provides excellent heat resistance and effectively prevents heat transfer through walls and roofs.

This helps maintain a comfortable indoor temperature while reducing the need for excessive heating or cooling systems.

Secondly, unlike traditional insulations that can be bulky and difficult to install, lightweight polymer insulations are much easier to handle due to their light weight. This makes them more convenient during installation processes while also saving time and labor costs.

Another advantage is that lightweight polymer insulations have better moisture resistance properties compared to some traditional options like cellulose or foam board insulations. They do not absorb water easily which helps prevent mold growth or structural damage caused by moisture infiltration over time.

Furthermore, these innovative polymers offer improved soundproofing capabilities when compared with other conventional materials like fiberglass batts or loose-fill cellulose fibers. The dense structure of the polymers absorbs sound waves effectively resulting in reduced noise transmission between rooms within buildings.

Lastly but importantly from an environmental standpoint – many types of modern-day polymers used for this purpose are recyclable which contributes towards sustainability efforts by reducing waste generation during construction projects.

Health and Safety Factors With Polymer Insulation

The good news is that lightweight polymer insulation offers several advantages in this regard. Firstly, polymer insulation does not contain harmful substances such as formaldehyde or volatile organic compounds (VOCs), which can be found in some traditional insulation materials.

This means that using lightweight polymer insulation reduces the risk of indoor air pollution and potential health issues for occupants.

Polymer insulations are non-toxic and do not release any hazardous particles into the air during installation or throughout their lifespan. This makes them a safer choice for both construction workers and building occupants.

Furthermore, lightweight polymer insulations have excellent fire-resistant properties compared to other types of insulation materials. They have high ignition temperatures and low flame spread rates, making them less likely to contribute to fires or emit toxic smoke if a fire occurs.

Future Perspective: Emerging Trends in Lightweight Polymer Insulation

With ongoing advancements in technology and research, several emerging trends are shaping the landscape of lightweight polymer insulation.

One notable trend is the development of enhanced thermal performance. Manufacturers are constantly working on improving the insulating properties of polymers, allowing for even greater energy savings in buildings.

This includes optimizing factors such as thermal conductivity and R-value to provide superior insulation capabilities.

Another promising trend is increased focus on fire resistance. Polymer-based insulations have traditionally faced challenges when it comes to fire safety standards.

However, recent innovations have led to improved flame retardant additives that enhance their ability to withstand high temperatures without compromising their insulating properties.

Furthermore, there is growing interest in incorporating sustainable materials into lightweight polymer insulation products. Researchers are exploring options such as bio-based polymers derived from renewable sources or recycled content that can reduce environmental impact while maintaining excellent performance characteristics.

Advancements in manufacturing techniques like 3D printing offer exciting possibilities for customized designs and shapes with precise dimensions tailored specifically for each project’s requirements.

These emerging trends indicate a bright future for lightweight polymer insulation within sustainable construction practices. As technology continues advancing and awareness about environmental concerns grows stronger among builders and consumers alike; we can expect further breakthroughs that will make this material an even more attractive choice moving forward.

Recap