In this article, we will explore the significance of polymer insulation standards in construction and how regulations play a crucial role in ensuring safety and quality.

As a construction worker, I’ve seen my fair share of buildings go up. From towering skyscrapers to humble family homes, each project is unique in its own way.

But there’s one thing that remains constant across all constructions: the importance of insulation.

Insulation is what keeps us warm in the winter and cool in the summer. It’s what helps us save money on energy bills and reduces our carbon footprint.

And when it comes to insulation standards, there are a lot of regulations to keep in mind.

One type of insulation that has been gaining popularity over the years is polymer insulation. As an expert in the industry, I’ve seen firsthand how effective this type of insulation can be when installed correctly.

But with so many different regulations and standards surrounding polymer insulation, it can be challenging to know where to begin. That’s why I’m here today – to help you understand the role of regulations in construction and how they impact your building project.

So grab a cup of coffee (or tea) and let’s dive into everything you need to know about polymer insulation standards!

Key takeaways:

- Polymer insulation is an important component in construction for energy efficiency.

- Regulations ensure safety and quality control in polymer insulation.

- Regulatory bodies like ICC and ASTM set standards for polymer insulation.

- Compliance with regulations avoids fines and legal issues.

- Polymer insulation has environmental benefits when produced sustainably.

Polymer Insulation Types

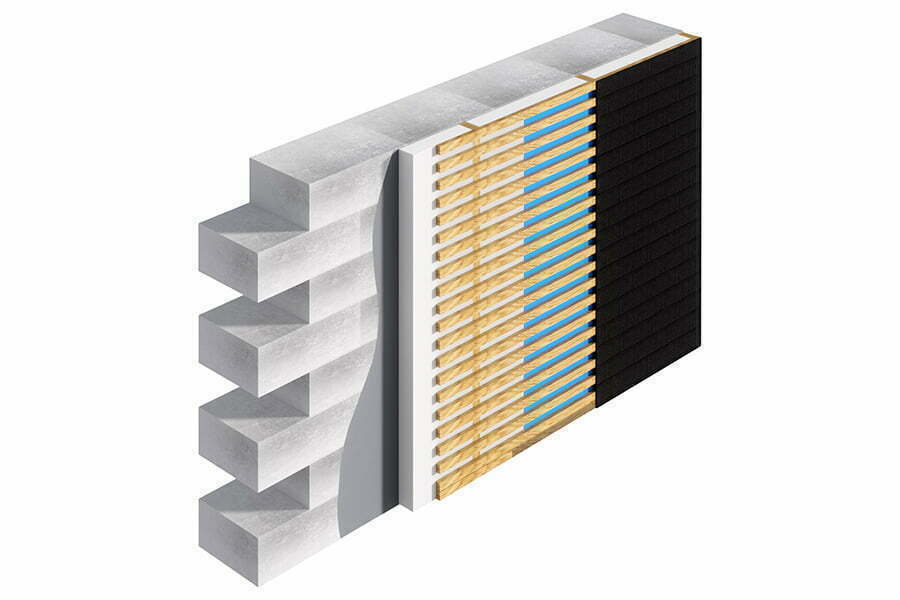

Now that we’ve established the importance of insulation in construction, let’s take a closer look at polymer insulation. This type of insulation is made from plastic materials and can come in various forms such as spray foam, rigid board, or blown-in loose-fill.

One significant advantage of polymer insulation is its ability to fill gaps and crevices that traditional fiberglass batts cannot reach. It also has a higher R-value (a measure of thermal resistance) than other types of insulations which means it provides better energy efficiency for your building.

However, with any type of material used in construction comes regulations and standards set by governing bodies to ensure safety and quality control. These regulations are put into place to protect both the workers installing the material as well as those who will be occupying the building once it’s completed.

In this article, we’ll explore these regulations further so you can understand how they impact your project when using polymer insulation types specifically.

Regulatory Bodies and Standards

When it comes to polymer insulation standards, there are several regulatory bodies and standards that construction workers need to be aware of. These organizations set guidelines for the use of polymer insulation in buildings, ensuring that they meet safety and performance requirements.

One such organization is the International Code Council (ICC), which develops codes and regulations for building safety. The ICC’s International Energy Conservation Code (IECC) sets minimum requirements for energy efficiency in buildings, including insulation materials like polymers.

Another important standard is ASTM C578 – Standard Specification for Rigid Cellular Polystyrene Thermal Insulation. This specification outlines the physical properties required of rigid cellular polystyrene thermal insulation products used in construction applications.

It’s essential to understand these regulations when working with polymer insulation because failure to comply can result in costly fines or even legal action if a building fails inspection due to inadequate or unsafe installation practices.

As an expert in the industry, I’ve seen firsthand how crucial it is not only to follow these regulations but also stay up-to-date on any changes or updates made by regulatory bodies over time. By doing so, we can ensure our constructions are safe and efficient while meeting all necessary compliance measures set forth by governing agencies.

Construction Compliance

When it comes to construction compliance, there are a lot of regulations and standards that must be followed. These rules are in place to ensure the safety and quality of buildings, as well as protect the environment.

Failure to comply with these regulations can result in costly fines or even legal action.

Polymer insulation is no exception when it comes to compliance. There are specific standards that must be met during installation, such as ensuring proper ventilation and fire resistance ratings.

It’s important for contractors and builders alike to stay up-to-date on these requirements so they can avoid any potential issues down the line.

As an expert in the industry, I’ve seen firsthand how non-compliance with polymer insulation standards can lead to problems later on – from decreased energy efficiency due to improper installation techniques all the way up through building code violations resulting from inadequate fire protection measures.

That’s why understanding construction compliance is crucial for anyone involved in a building project – whether you’re a contractor or homeowner looking into DIY projects around your home! By staying informed about polymer insulation regulations (and other relevant codes), you’ll help ensure your project meets all necessary requirements while also keeping everyone safe throughout its lifespan!

Thermal Performance

Thermal performance refers to how well the insulation material can resist heat flow and maintain a consistent temperature inside a building.

The higher the thermal performance, the more effective your insulation will be at keeping your home or office comfortable year-round.

Polymer insulation has been shown to have excellent thermal performance when installed correctly. However, there are regulations in place that dictate how much heat loss is acceptable for different types of buildings and climates.

As an expert in construction, I’ve seen firsthand how important it is for builders and contractors to stay up-to-date on these regulations. Failure to comply with them could result in costly fines or even legal action down the line.

That’s why understanding polymer insulation standards isn’t just about ensuring optimal energy efficiency – it’s also about staying compliant with local laws and codes. By doing so, you can ensure that your building project meets all necessary requirements while still providing top-notch comfort for its occupants.

Fire Safety Regulations

Fire safety is a top concern. That’s why strict regulations are in place to ensure that all insulation materials meet certain standards for fire resistance. Polymer insulation is no exception.

Fire safety regulations require that polymer insulation be tested and certified for its ability to resist flames and prevent the spread of fires. This means that before any polymer insulation can be used in construction projects, it must undergo rigorous testing by independent laboratories.

I once worked on a project where we had initially planned on using a cheaper type of polymer foam as our primary insulator – until we discovered that this particular foam did not meet fire safety standards.

We quickly switched gears and opted for a more expensive but safer option instead – one which met all necessary certifications and provided peace of mind knowing our building was protected against potential fires.

In short: while adhering to fire-safety regulation may add some extra cost or time upfront during your construction project planning phase; ultimately you’ll have greater confidence knowing your structure will withstand unexpected events like fires with minimal damage or loss due largely imparted by proper installation techniques meeting regulatory requirements!

Environmental Impact

When it comes to insulation, we often think about how it affects our comfort and energy bills. But there’s another crucial factor to consider: the environmental impact.

Polymer insulation is known for its eco-friendliness, as it can be made from recycled materials and has a low carbon footprint. However, not all polymer insulations are created equal in terms of sustainability.

That’s where regulations come into play. By setting standards for the production and installation of polymer insulation, regulatory bodies ensure that only environmentally friendly options are used in construction projects.

As someone who cares deeply about the environment (and I hope you do too!), I always make sure to follow these regulations when working on a project involving polymer insulation. It may require some extra effort or cost upfront but knowing that my work is contributing positively towards our planet makes it all worth it in the end!

Installation Guidelines

Proper installation is crucial. Not only does it ensure that the insulation performs as intended, but it also ensures that your building meets all necessary regulations and standards.

Installation guidelines for polymer insulation can vary depending on the specific product being used. However, there are some general principles that apply across the board.

Firstly, before installing any type of insulation material in a building project, you must ensure that all surfaces are clean and free from debris or contaminants. This will help to create a smooth surface for installation and prevent any potential issues down the line.

Secondly, when installing polymer insulation materials such as spray foam or rigid boards, be sure to follow manufacturer instructions carefully. These instructions will provide guidance on everything from application techniques to recommended thicknesses based on climate zones.

Lastly – but certainly not least – always make sure you’re following local regulations regarding fire safety when using any type of insulating material in construction projects.

By following these guidelines closely during installation processes with Polymer Insulation Standards products like spray foam or rigid boards; we can guarantee optimal performance while ensuring compliance with relevant codes & standards!

Exploring Common Issues and Solutions in Polymer Insulation

Polymer insulation is widely used in construction due to its excellent thermal properties and versatility. However, like any other building material, it can face certain issues that need to be addressed for optimal performance.

One common issue is moisture absorption, which can lead to reduced insulation effectiveness over time. To combat this problem, manufacturers have developed polymer insulations with improved moisture resistance or added vapor barriers during installation.

Another challenge faced by polymer insulation is its susceptibility to fire hazards. While some polymers are inherently flame-resistant, others may require the addition of fire-retardant additives or coatings for enhanced safety.

It’s crucial for builders and contractors to select the appropriate type of polymer insulation based on local fire safety regulations and project requirements.

Furthermore, proper installation techniques play a vital role in maximizing the benefits of polymer insulation while minimizing potential issues such as air gaps or compression that could compromise its thermal efficiency.

Comparison of Different Polymer Insulation Material Properties

Each material has its own unique properties that make it suitable for different applications. Understanding these differences can help builders and contractors choose the right polymer insulation for their specific needs.

One commonly used polymer insulation material is expanded polystyrene (EPS). EPS is known for its excellent thermal performance and moisture resistance.

It is lightweight, easy to install, and offers good compressive strength. However, EPS may not be as effective in fire-resistant applications compared to other materials.

Another popular option is extruded polystyrene (XPS) foam board insulation. XPS provides high thermal resistance and superior moisture resistance due to its closed-cell structure.

It also offers better compressive strength than EPS, making it ideal for heavy-duty applications such as under concrete slabs or on roofs.

Polyisocyanurate (PIR) foam boards are another type of polymer insulation with exceptional thermal performance properties. PIR has a higher R-value per inch compared to other materials like EPS or XPS foam boards, providing enhanced energy efficiency benefits.

Polyurethane spray foams offer versatility in application due to their ability to conform around irregular shapes and fill gaps effectively while providing excellent air sealing capabilities.

The Role and Impact of Local Building Codes On Polymer Insulation

These codes are put in place to ensure that buildings meet certain safety and performance standards. They outline specific requirements for materials, including polymer insulation, to be used in various applications.

The impact of local building codes on polymer insulation is significant as they dictate the minimum thickness, fire resistance rating, and other properties that must be met by these materials. Compliance with these regulations helps ensure that buildings are safe from potential hazards such as fire or structural failure.

By adhering to local building codes, contractors can guarantee that their construction projects meet the necessary safety standards set by regulatory authorities. This not only protects occupants but also ensures compliance with legal requirements.

It’s important for builders and architects to stay updated on any changes or updates made to local building codes regarding polymer insulation. By doing so, they can make informed decisions about which products will best suit their project needs while meeting all relevant regulations.

How to Meet and Exceed Fire Safety Standards With Polymer Insulation

Polymer insulation can play a crucial role in ensuring the safety of buildings. To meet and exceed fire safety standards with polymer insulation, several factors need to be considered.

Firstly, selecting the right type of polymer insulation material is essential. Some polymers have inherently better fire-resistant properties than others.

For example, materials like polyisocyanurate (PIR) or phenolic foam are known for their excellent resistance to flames and high temperatures.

Secondly, proper installation techniques should be followed to maximize fire resistance. This includes ensuring that all joints are tightly sealed and using appropriate adhesives or fasteners as recommended by manufacturers.

Incorporating additional protective measures such as intumescent coatings or flame retardant additives can further enhance the fire performance of polymer insulation materials.

It’s also important to consider local building codes and regulations related to fire safety when choosing polymer insulation products for construction projects. These codes often specify minimum requirements for flame spread ratings and smoke development during a potential fire event.

Lastly, regular inspections should be conducted throughout the lifespan of a building with polymer insulation installed. This helps identify any damage or degradation that may compromise its ability to withstand fires effectively.

Sustainability Efforts in Polymer Insulation Production

They understand the importance of reducing environmental impact and meeting the growing demand for eco-friendly construction materials.

One key aspect of sustainability is using recycled or renewable materials in polymer insulation production. Many manufacturers now incorporate recycled polymers into their products, reducing waste and conserving resources.

Some companies have started exploring bio-based polymers derived from renewable sources like plants or algae.

Energy efficiency is another crucial factor in sustainable polymer insulation production. Manufacturers are adopting energy-saving technologies to minimize greenhouse gas emissions during manufacturing processes.

This includes optimizing equipment, implementing efficient heating and cooling systems, and utilizing renewable energy sources wherever possible.

Furthermore, efforts are being made to reduce water consumption throughout the manufacturing process by implementing recycling systems that treat wastewater for reuse within the facility.

To ensure transparency and accountability regarding sustainability claims, industry organizations have developed certification programs that assess a manufacturer’s adherence to specific environmental standards. These certifications provide assurance to builders and consumers that they are choosing a sustainable product when selecting polymer insulation for their projects.

By prioritizing sustainability initiatives throughout all stages of production – from material sourcing to final product delivery – polymer insulation manufacturers contribute towards creating a more environmentally friendly construction industry while still providing high-quality thermal performance solutions.

FAQ

What is the IEC standard for polymer insulators?

The IEC standard for polymer insulators is IEC 62217:2012.

What is polymer insulation?

Polymer insulation is a type of insulator used both in transmission and distribution power lines and substations, offering improved mechanical resistance against shocks due to the flexibility and behavior of the polymeric material.

What is the lifespan of polymer insulators?

The expected service life of fourth-generation Quadri*Sil™ polymer transmission insulators is more than 50 years.

What is the best plastic for thermal insulation?

The best plastic for thermal insulation is Polybenzimidazole (PBI), due to its superior heat and wear resistance, strength, and mechanical property stability.

How does the environment affect the durability of polymer insulators?

The durability of polymer insulators is affected by environmental factors such as UV radiation, temperature fluctuations, and humidity.

How is thermal conductivity measured in polymer insulation materials?

Thermal conductivity in polymer insulation materials is measured using a technique known as the heat flow meter method, which determines the amount of heat transfer through the material.

What role does polymer reinforcement play in the construction industry?

Polymer reinforcement in the construction industry enhances the strength, durability, and flexibility of building materials, enabling the design of structures resistant to environmental stress and physical damage.

Recap