Discover how polymer-based insulation systems can revolutionize the construction industry with their comprehensive solutions in this informative blog post.

As a construction worker, I’ve been on many job sites where the insulation system was either inadequate or non-existent. I remember one particular project where we had to halt construction for weeks because the insulation wasn’t up to code.

This experience made me realize just how crucial proper insulation is in any building project.

Over the years, I’ve seen various types of insulation systems come and go, but none have impressed me quite like polymer-based insulation systems. These solutions are not only comprehensive but also cost-effective and environmentally friendly.

In this article, we’ll dive into what makes polymer-based insulation systems so special and why they’re quickly becoming the go-to solution for construction professionals everywhere. Whether you’re a seasoned contractor or just starting in the industry, this article will provide valuable insights into how these innovative solutions can benefit your next project.

So let’s get started!

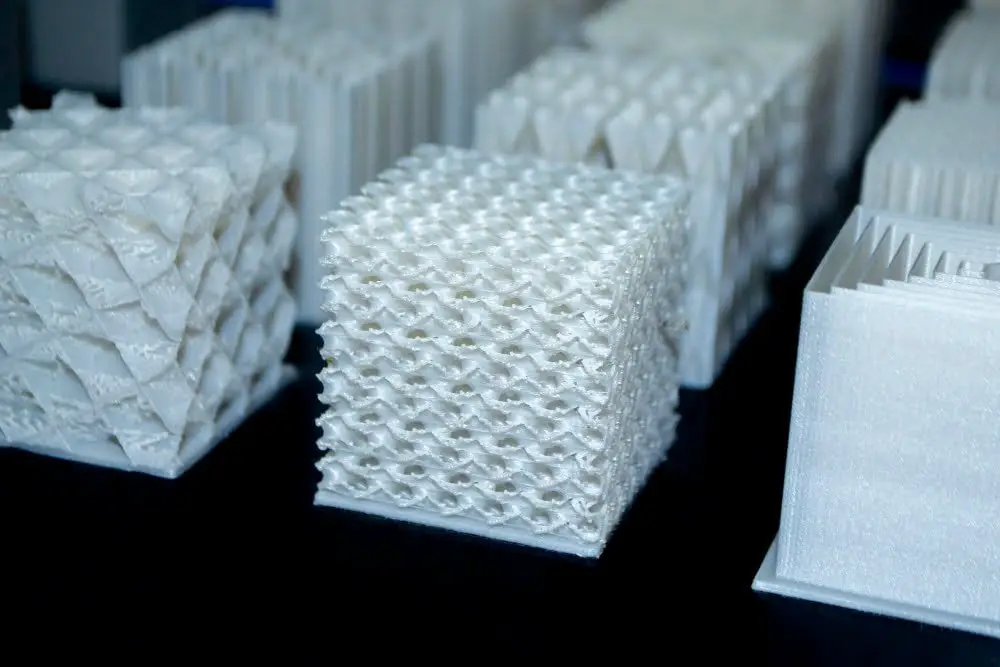

Polymer Insulation Types

Polymer-based insulation systems are a type of insulation that uses polymers, or long chains of molecules, to create a barrier between the interior and exterior of a building. These systems come in various types, each with its unique properties and benefits.

One such type is spray foam insulation. This type involves spraying liquid polyurethane foam onto surfaces, where it then expands to fill gaps and crevices.

Spray foam provides excellent thermal resistance while also acting as an air barrier.

Another popular polymer-based insulation system is rigid board insulation. This type consists of panels made from materials like polystyrene or polyisocyanurate that are installed on walls or roofs before being covered with other materials like drywall or roofing tiles.

There’s blown-in cellulose fiber insulations which consist mainly recycled paper products treated with fire retardants for safety purposes; this option offers great soundproofing capabilities along with good thermal resistance properties.

Polymer-based Insulation Systems have become increasingly popular over the years due to their numerous advantages over traditional forms of insulations such as fiberglass batts which can be difficult to install correctly leading them not providing adequate coverage.

As construction professionals continue searching for more efficient ways to build structures without compromising quality standards Polymer-Based Insulation Systems will remain at the forefront offering comprehensive solutions that meet both environmental regulations and energy efficiency requirements while keeping costs low.

Thermal Performance

One of the most significant advantages of polymer-based insulation systems is their exceptional thermal performance. These solutions are designed to provide superior insulation, which helps maintain a comfortable indoor temperature while reducing energy consumption and costs.

I remember working on a project where we used traditional fiberglass insulation, and it was clear that it wasn’t doing its job correctly. The building’s occupants complained about drafts and inconsistent temperatures throughout the space.

We had to go back in and add more layers of fiberglass, which only added time and cost to the project.

Polymer-based insulation systems offer an alternative solution that eliminates these issues altogether. They’re made from high-quality materials that provide excellent thermal resistance without adding bulk or weight to your construction projects.

These innovative solutions are incredibly versatile; they can be applied in various ways depending on your specific needs. Whether you’re looking for spray foam or rigid board options, there’s a polymer-based system out there for you.

If you want an efficient way to insulate your buildings while keeping costs low over time – look no further than polymer-based insulation systems!

Moisture Resistance

One of the most significant advantages of polymer-based insulation systems is their moisture resistance. As a construction worker, I’ve seen firsthand how water damage can wreak havoc on buildings and cause costly repairs.

Traditional insulation materials like fiberglass or cellulose are prone to absorbing moisture, which can lead to mold growth and structural damage over time.

Polymer-based insulation systems, on the other hand, are designed with moisture resistance in mind. They’re made from closed-cell foam that doesn’t absorb water or allow it to penetrate through the material.

This means that even if there’s a leak in your building’s roof or walls, your polymer-based insulation system will remain intact and continue providing excellent thermal protection.

In addition to being resistant to water damage, these innovative solutions also offer superior air sealing capabilities compared to traditional insulations like fiberglass batts or blown-in cellulose fibers. By creating an airtight seal around your building envelope with polymer-based insulations you’ll be able not only save energy but also improve indoor air quality by preventing drafts from entering into living spaces.

Overall when it comes down choosing an effective solution for both thermal protection as well as keeping out unwanted elements such as pests & allergens while maintaining good indoor air quality – Polymer-Based Insulation Systems should definitely be considered!

Fire Safety

When it comes to building construction, fire safety is a top priority. Inadequate insulation can lead to the rapid spread of flames and smoke, putting occupants at risk.

This is where polymer-based insulation systems shine.

Polymer-based insulation materials are inherently flame-resistant and have been tested extensively for their fire-retardant properties. They do not contribute to the spread of flames or release toxic gases when exposed to high temperatures.

In fact, some polymer-based insulations have even been designed specifically for use in areas with high fire risks such as commercial kitchens or industrial facilities.

As someone who has seen firsthand how devastating fires can be on a job site, I highly recommend considering polymer-based insulation systems for any project that requires superior fire safety measures. Not only will they provide peace of mind knowing your building is protected from potential fires but also ensure compliance with local regulations and codes related to building safety standards.

Acoustic Properties

Aside from their thermal insulation properties, polymer-based insulation systems also offer excellent acoustic performance. This is particularly important in buildings where noise reduction is a priority, such as hospitals or schools.

I remember working on a school project where the classrooms were located near busy roads. The noise levels were so high that it was difficult for students to concentrate and teachers had to raise their voices just to be heard.

We installed a polymer-based insulation system which significantly reduced the amount of external noise entering the building.

Polymer-based solutions are able to absorb sound waves due to their unique cellular structure which traps air pockets within its material composition. This results in an effective barrier against unwanted sounds and vibrations.

These systems can also improve indoor acoustics by reducing echo and improving speech intelligibility – making them ideal for auditoriums or conference rooms.

Incorporating polymer-based insulation systems into your construction projects not only provides superior thermal protection but also enhances acoustic comfort – creating healthier environments for occupants while meeting regulatory requirements at the same time.

Eco-friendly Solutions

One of the most significant advantages of polymer-based insulation systems is their eco-friendliness. As a construction worker, I’ve seen firsthand how much waste and pollution can result from traditional insulation methods.

However, with polymer-based solutions, there’s no need to worry about harmful chemicals or materials damaging the environment.

Polymer-based insulation systems are made from recycled materials and are themselves recyclable at the end of their lifespan. This means that not only do they reduce waste during installation but also have a minimal impact on the environment when it comes time for replacement.

In addition to being environmentally friendly, these solutions also offer energy-saving benefits that can help reduce carbon emissions in buildings over time. By providing superior thermal performance compared to traditional insulations like fiberglass or cellulose, polymer-based systems help keep indoor temperatures stable without relying heavily on heating or cooling equipment.

If you’re looking for an eco-friendly solution for your next construction project while still maintaining high-quality standards in terms of performance and durability – then look no further than polymer-based insulation systems!

Installation Techniques

When it comes to insulation, the installation process is just as important as the type of material used. Fortunately, polymer-based insulation systems are relatively easy to install and can be applied using a variety of techniques.

One popular method for installing polymer-based insulation is through spray foam application. This involves spraying a liquid mixture onto surfaces that then expands and hardens into an insulating layer.

Spray foam application allows for precise coverage in hard-to-reach areas and can also help seal any gaps or cracks in walls or ceilings.

Another technique commonly used with polymer-based insulation systems is blown-in installation. This involves blowing loose-fill materials such as cellulose or fiberglass into wall cavities or attics using specialized equipment.

Blown-in installation provides excellent coverage while minimizing waste and reducing labor costs.

The versatility of these innovative solutions makes them ideal for various construction projects regardless of size or complexity. With their ease-of-use during installations, coupled with their cost-effectiveness compared to traditional methods like batts & rolls, make them an attractive option among contractors looking at optimizing project timelines without compromising on quality standards.

Recap