Discover effective strategies to identify and attract potential clients in the plastic extrusion industry.

Finding plastic extrusion clients can be a challenging task, but with the right strategies, it can become a straightforward process. This involves understanding the industry, identifying potential markets, networking, and leveraging digital platforms. This article will guide you through these steps, offering detailed insights to help you expand your client base in the plastic extrusion industry. By following these recommendations, you can reach out to potential clients who need your services, thereby growing your business.

Key takeaways:

- Understanding the plastic extrusion process and its components

- Importance of plastic extrusion in industries like construction and packaging

- Identifying and selecting reliable plastic extrusion suppliers

- Using B2B networks and digital marketing to find clients

- Effective networking techniques to expand client base

Understanding Plastic Extrusion

Plastic extrusion is a high-volume manufacturing process that involves melting raw plastic material and transforming it into a continuous profile. Applications of the resulting products are wide-ranging, including parts for construction, automotive industries, and consumer products, just to name a few. The simplicity and versatility of the process have made it a cornerstone of the polymer industry.

Here are some critical steps and components of plastic extrusion:

- Raw Material: The process starts with plastic granules, pellets, or powder. This could be a homogenous raw material or a blend for specific applications.

- Extruder: This is where the real magic happens. The raw material is fed into the extruder where it gets heated, turning into a molten state. The heated plastic is then forced through a die, a custom-made shape based on the required product.

- Shape Formation: The molten plastic that comes out of the extruder takes the desired continuous shape. It is then cooled and solidified, maintaining that shape.

- Cutting and Finishing: Once the plastic is cooled, it’s cut to the required length and finished if needed. The handling of the finished product may involve additional procedures like drilling, printing, or even assembly.

Reviewing a potential client’s requirement, matching it with your capabilities, and suggesting a viable solution can pave the way for successful partnership in the plastic extrusion industry. It doesn’t just stop at the manufacturing stage, value-added services and commitment to quality are also essential to attract and retain clients.

The Process of Plastic Extrusion

The process of plastic extrusion is fascinating, yet simple. It starts with raw plastic material, often in the form of granules, pellets, or powder. This raw material is loaded into a hopper.

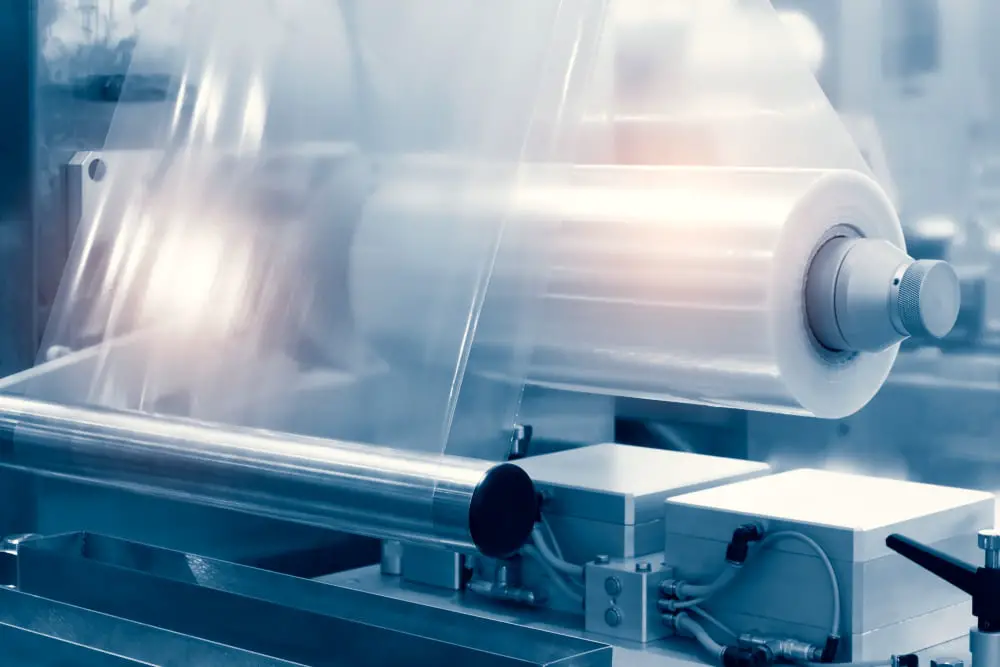

From the hopper, the plastic is transported to a heated barrel, where it is thrust forward by a screw mechanism. Here, the plastic reaches a melting point and turns into a liquid form, with heat generated by both the mechanical action and the heaters on the barrel.

Then comes the shaping phase. The molten plastic is forced through a die – the specialized, custom-made tool that gives the plastic its final shape. This could be anything from a thin sheet to a complex profile, depending on the end product.

Upon exiting the die, the plastic heads into a set of cooling tanks, where it solidifies while maintaining the shape given by the die. Cooling is often achieved by a combination of fans, chilled air or water.

It doesn’t end here! The plastic must be cut into the desired lengths to be suitable for use. Following taking the correct dimensions, the output is then cut using a mechanical cutter.

Recap: The process includes feeding raw material, heating and melting, shaping with a custom die, cooling, and finally cutting. This straightforward yet adaptable process allows for the creation of a remarkable array of plastic items we come across daily. Understanding this process is the first step for anyone venturing into plastic extrusion business.

Importance of Plastic Extrusion in Various Industries

Plastic extrusion plays a vital role across various sectors, owing to its versatile application and cost effectiveness.

In the construction sector, the process is essential for creating components such as piping, window frames and even insulation materials. These plastic extruded products offer enhanced durability and resistance to environmental stresses, contributing to the construction of robust structures.

The automotive industry benefits from plastic extrusion as well, utilizing it in the production of interior and exterior parts like bumpers, trim, and car door seals. These parts are lightweight, reducing the overall weight of the vehicle, leading to improved fuel efficiency.

For the packaging industry, plastic extrusion is indispensable. It aids in the production of film, bags, and containers that help to protect, store and transport a myriad of products, from food to industrial equipment.

Medical sector utilizes plastic extrusion for the production of various items such as catheters, tubing, and other medical appliances. Here, plastic extrusion provides components that are safe, reliable, and easily sterilized.

To harness the benefits of plastic extrusion in these and other sectors, it is crucial to partner with reliable and experienced plastic extrusion companies. Having a clear understanding of the desired product specifications, coupled with good market research can aid significantly in this process.

Defining Plastic Extrusion Companies and Suppliers

Plastic extrusion companies specialize in the creation of continuous plastic profiles, employing a high-volume manufacturing process in which raw plastic materials are melted and formed into a continuous profile. The plastic extrusion process is utilized widely within multiple industries such as construction, packaging, and transportation sectors, where they manufacture items like pipes, tubing, weather stripping, window frames, and adhesive tape.

Suppliers, on the other hand, cater to plastic extruders by providing raw materials necessary for the process. They offer various types of plastic, including polyethylene, PVC, and ABS, to cater to diverse extrusion needs. They also supply necessary equipment – extrusion machines, dies, and other necessary machinery or components.

To understand this field better, let’s break down some defining characteristics and key concepts related to these businesses:

- Process Focus: Plastic extrusion companies essentially transform raw materials into finished products using the extrusion process.

- Equipment and Supplies: They require special machinery (such as extruders and dies) and materials (different types of plastic) – both of which are supplied by the suppliers.

- Diverse Product Offerings: The output of extrusion can range from mundane items such as plastic bags to specialized components like weather stripping or PVC piping.

- Sector-specific Applications: Different industries seek the services of extrusion companies and suppliers – construction favors extrusion for creating plastic pipes and window frames, transportation uses extruded parts for vehicles, and packaging industries opt for extrusion-made materials in their operations.

Recognizing and understanding these features can be beneficial in identifying potential clients in the plastic extrusion business.

Identifying the Right Plastic Extrusion Suppliers

Identifying the right plastic extrusion suppliers is integral to ensure a smooth and efficient production process. Here are key factors to consider:

Quality of Materials: The supplier should provide high-quality materials that can withstand different temperatures and pressures in the extrusion process. In not compromising quality, the end product’s integrity remains preserved.

Reputation: A supplier with a positive industry reputation is often a reliable choice. This can be verified via customer reviews, industry awards, or word-of-mouth recommendations.

Pricing: While price should not be the only deciding factor, the supplier’s pricing must be competitive without undermining material quality.

Delivery Consistency: A supplier’s ability to provide consistent, on-time deliveries is crucial to maintain the ongoing production schedules without unnecessary delays.

Technical Support: Ideally, a supplier should offer strong technical support to overcome potential challenges during the plastic extrusion process.

Capacity: The supplier’s capacity to meet the volume requirements of clients is another important consideration.

Regulatory Compliance: Lastly, ensuring the supplier adheres to the relevant industry standards and regulations guarantees safety and increases clients’ trust.

These factors will guide you towards a strategic decision in selecting the right plastic extrusion supplier, bringing you one step closer to a successful venture in the industry.

Searching for Plastic Extrusion Clients On B2B Networks

Online business-to-business (B2B) networks are a vital tool for sourcing and connecting with potential plastic extrusion clients. The platforms facilitate interactions between manufacturers, suppliers, wholesalers, and purchasers from various industries.

Leverage potential clients’ online presence on networks like Alibaba, TradeKey, and GlobalSpec. These sites host profiles of companies and provide precise filtering options. Custom filters can be set depending on parameters such as geographical location, type of company, and nature of required extrusion plastic product.

Draw on the capabilities of LinkedIn and its advanced search features. Numerous businesses maintain company profiles, making it an ideal platform for identifying potential clients. Moreover, LinkedIn’s groups and communities can be advantageous for networking purposes.

Exploit the benefits of attending webinars, online industry gatherings, and digital exhibitions offered by these B2B platforms. These e-gatherings can bring invaluable exposure to your plastic extrusion products and services.

Lastly, contribute regularly on industry-specific online forums. Sharing expert knowledge and offering helpful insights can create credibility, promoting your services to potential clients passively. Your participation in these forums can help your company stand out as an authority, hence gaining the attention of potential clients who frequent such forums to gather information.

Leveraging Digital Marketing to Attract Plastic Extrusion Clients

Harnessing the power of search engines can provide a significant boost to finding potential clients. Optimization of websites, using Search Engine Optimization (SEO) strategies, can allow businesses to appear at the top of search results related to plastic extrusion.

Social media platforms such as Linkedin, Facebook, or Instagram, can also be effective tools. Regular posts about company news, industry trends, and exciting new projects can generate interest and attract potential clients.

Paid advertising, particularly on Google AdWords and social media platforms, is an effective way to target potential clients in specific industries and regions.

Email campaigns, despite being considered somewhat traditional, are still potent tools in digital marketing and can be engaging with appealing content and design.

Crafting informative and engaging content, such as blog posts or eBooks, can provide value to potential and existing customers. Not only will this boost SEO but also position your company as a thought-leader in the field.

Webinars and virtual trade shows have surged in popularity, providing an opportunity to attract and interact with potential clients worldwide. Producing these kinds of events can be an excellent way to demonstrate expertise and product offering.

Incorporating these digital marketing strategies can help to attract a broad range of potential clients, connect with them more effectively and eventually convert them to loyal customers.

Effective Networking Techniques for Plastic Extrusion Businesses

Crafting a strong network is a pivotal step towards finding clients in the plastic extrusion sector. Each interaction is an opportunity to cultivate relationships and possibly secure new clients. Key strategies might include:

- Regular Participation in Industry Events: Trade shows, conferences or seminars related to the plastics industry offer a fertile ground for networking with potential clients. Participating actively can boost your professional presence and provide valuable contacts.

- Using Social Media: LinkedIn, a professional networking platform, and industry-specific online forums allow constructive interaction with industry peers and potential clients. Creating and sharing relevant content helps establish your business as an expert in the field.

- Joining Professional Associations: Membership in organizations such as the Plastic Extruders Association provides access to a database of professionals and a variety of resources that can assist in meeting prospective clients.

- Facilitating Employee Networking: Arrange for employees to attend relevant meetings and events, ensuring increased reach and a broader network.

- Building Relationships through Existing Clients: Current clients often can be an effective reference point for more clients. A satisfied client can introduce your services to others, enhancing your network.

- Offering Knowledge Sharing Events: Hosting webinars, workshops, or offering to be a speaker at events can enhance business visibility and fortify credibility.

Remember, successful networking is not solely about gaining new contacts, but also nurturing existing relationships. Be proactive, visible, and reliable within your network for optimal outcomes.

Important Plastic Extrusion Tradeshows and Industry Events

Attending plastic extrusion trade shows and industry events provide significant opportunities to connect with potential clients. These events typically showcase the latest advancements in plastic extrusion technology, materials, and applications.

Considering events such as the International Plastic Fair (IPF) Japan, it showcases the modern innovations in the field, and it is an excellent platform for companies to showcase their capabilities.

A tradeshow such as NPE: The Plastics Show in Orlando, held every three years by the Plastics Industry Association, also brings together plastic extrusion businesses and potential clients from around the world.

Aside from these, United Kingdom’s Interplas is another trade show where companies dealing with plastic extrusion can expose their product range and connect with potential clients.

Similar, China’s CHINAPLAS, the largest plastics and rubber trade fair in Asia, can offer businesses an excellent opportunity to make connections with potential clients from various industries, including automotive, packaging, and construction.

Remember to make the most of these industry events by preparing in advance: identify key attendees you’d like to connect with, ensure your team clearly articulates your company’s value proposition, and follow up promptly with contacts after the event.

Regular participation in such events can significantly help in increasing your business network and potentially finding the right clients.

Joining Professional Associations for Plastic Extrusion to Gain Prospective Clients

Joining a professional association in the field of plastic extrusion can provide valuable networking opportunities and business leads.

Associations often host events and workshops which offer the chance to meet industry peers, professionals, and potential clients. At such gatherings, businesses can showcase their capabilities and initiate profitable collaborations.

Member directories can be excellent resources, often containing hundreds or even thousands of potential clients. Most associations offer online directories which can be accessed by all members, allowing direct connection to businesses in need of plastic extrusion services.

An affiliation with a credible industry association adds credibility to a company. Potential customers looking for trustworthy vendors are reassured by the association membership, potentially making the acquisition process smoother.

Hosting webinars and presentations through the association is another practical step to be taken. Demonstrating expertise and thought leadership on industry-specific topics can generate interest and organically grow a client base.

The sharing of industry-related knowledge, news, and updates by associations can facilitate businesses in aligning their offerings to market demands, allowing them to attract more clients.

While each business strategy will differ, these are key methods to utilize professional associations for client acquisition in the field of plastic extrusion.

Optimizing Sales Strategy to Draw in Plastic Extrusion Clients

Presenting a strategic sales approach entails detailed awareness of the client’s needs and business objectives.

Invest time in understanding the potential client’s operations. Familiarize yourself with their industry, track their product development cycle, and identify the role of plastic extrusion in their processes.

Craft a personalized pitch that highlights how your services could boost their performance or solve a problem. Include concrete examples of past success stories to induce trust and confidence.

Take advantage of digital platforms to reach potential clients. Employ email marketing, focused online advertising, and compelling website content to engage and attract prospective customers.

Develop a strong after-sales support system to ensure your clients are satisfied with your services. A satisfied client is more likely to refer your services to other potential clients.

Stay open to feedback from clients and adjust your strategy as needed. Offer innovative solutions, and don’t be afraid to adapt your services and support to better meet the specific requirements of each client.

Finally, consider strategic partnerships or collaborations within the industry. Solid alliances can broaden your reach, open new doors, and add to your client base.

Remember, consistency is key. Implement these strategies as a systematic routine, not just one-off efforts.

Take a proactive approach and keep learning about the changing needs of the industry. Market trends shift, clients evolve, and businesses that stay agile enjoy long-term success.

Building Collaborative Partnerships Within Construction and Packaging Industries

Creating strategic alliances with construction and packaging groups can significantly help in broadening your customer base. These partnerships can be cultivated by providing unique solutions catering to their specific needs. Here are some crucial concepts to consider:

Understand their needs: Thoroughly grasp what these industries require in terms of plastic extruded components. Whether it’s adding durability in construction or creating efficient packaging, offer solutions tailored to their necessities.

Identify potential connections: Think about how your services can complement theirs. Perhaps your plastic profiles are perfect for their new line of window frames or your unique packaging tubes can increase product safety.

Reach out with a distinctive offer: Highlight your unique value proposition. Convey how your services can add value to their operations and create a beneficial synergy.

Continuous communication and support: After establishing the relationship, ensure to maintain regular communication. Offer ongoing technical support and quality assurance, strengthening the bond over time.

Diversify and adapt your offerings: As the needs of these industries evolve, be ready to innovate with new designs, materials and techniques. This will showcase your dedication to growth and add value to your partnerships.

By following these steps, you may enhance your business relationships within the construction and packaging industries, subsequently expanding your client base.

Strategies for Plastic Extrusion Companies to Expand Client Base

First off, understanding the client’s needs is vital. Tailoring products and services to meet specific industry needs can set a company apart in the competitive landscape.

Next is ensuring quality and consistency. Clients in sectors such as construction and packaging value consistent quality in plastic extrusion products, as their operations largely depend on it. Having rigorous quality control measures in place can significantly enhance the reputation of a company, encouraging more clients to come on board.

Creating a strong online presence is another strategy. A well-designed website that effectively showcases the company’s offerings can attract a wider audience. This is beneficial not only in terms of visibility but also for credibility in this digital age.

It’s also important to exploit social media platforms. These platforms offer an opportunity to reach out to potential clients, start conversations, and build relationships. Particularly, LinkedIn can be used to connect with professionals and businesses in related industries.

Additionally, attending industry-specific tradeshows and events not only provides learning opportunities, but also enables companies to showcase their products and interact with potential clients.

Moreover, offering unique value propositions such as sustainable or eco-friendly plastic extrusion processes can be another strategy to attract clients who prioritize sustainability.

Lastly, cultivating a reputation for exceptional customer service can go a long way. Ensuring prompt response to inquiries, offering excellent after-sale service, and stepping up to quickly resolve any issues can make a profound level of difference for clients.

All these strategies can have a substantial impact on expanding a company’s client base in the plastic extrusion market.

Spotting Emerging Market Trends in the Plastic Extrusion Industry

Staying on top of emerging trends is integral to finding new plastic extrusion clients. Businesses must analyze market shifts, technological advancements, and evolving customer needs to stay ahead of the competition. Here are some strategies you can follow:

Keep an eye on green and sustainable manufacturing trends. With growing concerns about environmental impacts, many clients are seeking plastic extrusion solutions that adhere to sustainable practices.

Take note of advancements in plastic materials technology. Higher performance materials such as biopolymers are gaining popularity. Offering innovative material options can attract clients looking for improved product characteristics.

Pay attention to global market movements. Plastic extrusion is a global industry. Events such as new trade agreements, tariffs, or environmental regulations can influence client needs and opportunities.

Monitor industry publications and reports. These are excellent sources for tracking trends and developments in plastic extrusion technology and market dynamics.

Engage with online communities and forums where industry professionals gather. These platforms often host discussions about experiences, challenges, and predictions related to the plastic extrusion market.

Remember, knowledge of industry trends can be beneficial for reaching out to prospective clients with services that align with their current and future needs.

Addressing Challenges and Solutions in Acquiring Plastic Extrusion Clients

Effective sales strategies in today’s competitive plastic extrusion market often encounter hiccups. There are some common challenges businesses typically face:

- It can be difficult to stand out from competitors who offer similar services at competitive prices.

- Clients might not be aware of the benefits and full potential of your plastic extrusion services.

- Technological advancements in the industry could render certain methods obsolete, making it harder to acquire clients who are on the lookout for the latest developments.

- Diversification of application industries might cause potential clients to overlook your services in favor of more specialized providers.

Even though these challenges seem daunting, they are navigable with the right approach:

- Differentiate your services: Highlight unique selling points to make your services standout. Showcase real-world applications and proof of efficacy.

- Educate potential clients: Informative brochures, thought leadership articles and informative website content can help elucidate the benefits of your offerings. A well-informed client can make a well-informed decision.

- Stay updated: Keep a pulse on the industry’s technological advancements. Regularly update your methods and production techniques to meet evolving market demands.

- Expand your footprint: Diversify your scope to serve various industries. Customize your approach and services according to each industry’s unique demands. Tailor your sales and marketing strategies accordingly.

By addressing these challenges and putting in place these solutions, you open opportunities to acquire new clients in the plastic extrusion industry.

Maintaining and Enhancing Relationships With Existing Plastic Extrusion Clients

Building a strong connection with your existing clientele can greatly benefit your plastic extrusion business. Consider these strategies:

- Regular Communication: Stay in touch with your clients. Provide them updates on new products, industry trends, or matters that affect their orders. It shows you value their partnership and are proactive.

- Quality Assurance: Always strive to offer superior quality. Your clients are relying on your materials for their product efficiency. Make sure your plastic extrusion output is consistent and matches your clients’ exact specifications.

- Issue Resolution: Incase of problems or concerns, ensure they’re resolved quickly and effectively. Demonstrating concern for your customers’ issues and acting promptly can enhance loyalty.

- Client Feedback: Actively seek feedback from your clients. It helps you understand their needs better and reassures them that their opinions matter.

- Customized Offerings: Customize your services according to client needs. Show them you understand their unique requirement and can provide tailored solutions.

- Continued Education: Keep your clients informed of new developments in polymer science and plastic extrusion technology. It emphasizes your expertise and positions you as a trusted advisor.

Remember that in the plastic extrusion business, maintaining relationship with existing clients not only encourages repeat business, but can also lead to referrals, thus expanding your client base.

Working With Key Decision-makers in Companies Needing Plastic Extrusion

Understanding the company hierarchy is crucial toward making an impact. Establishing relationships with those in positions to make or influence decisions can speed up the negotiation process.

Get a grasp on the company’s needs: Understand what type of plastic extrusion solutions the company may require. Thorough research can help you cater to their specific needs and goals.

Presenting a tailored solution: Tailoring your pitch to match the needs of the decision-makers can prove beneficial. Show how your plastic extrusion services can drive efficiency and cost effectiveness for their business.

Offering flexible terms: Remaining flexible in your negotiations can win over clients. Provide options in terms of pricing, delivery timelines, and customization capabilities.

Leveraging testimonials: Share experiences of current or past clients who have benefited from your plastic extrusion services. Testimonials can reinforce the value of your solution and set apart your company from competitors.

Continuous engagement: Keep decision-makers updated with industry trends, improvements in your services and technology advancements. This helps in reinforcing your position as a trusted partner for their plastic extrusion needs.

Adopting an Agile Approach in the Rapidly Evolving Plastic Extrusion Market

The agility in business is measured by its quick response to changes in industry trends, customer needs and market forces. Undoubtedly, the plastic extrusion market is a dynamic one, with trends rapidly shifting due to advancements in technology, changes in regulations, and evolving client needs.

Here are a few actionable steps to adopt an agile approach in this industry:

Understand the key trends: Keep abreast of industry trends through continuous learning, attending industry-specific conferences and seminars. This allows businesses to stay ahead of competition by adapting to changes promptly.

Embrace technology: Incorporate latest technologies and machinery into your production process. This can augment your output, reduce wastage and, ultimately, increase profit margins.

Expand product range: Offer a wider array of plastic extrusion products to suit various construction needs. Diverse offerings can attract a broader range of clients and ensure retention of existing ones.

Develop a flexible strategy: Create a business strategy that can be adjusted swiftly as per changing market conditions, rather than a rigid plan. This includes being open to diversification, partnerships, mergers, and possible acquisitions.

Cultivate customer centricity: Place your clients at the heart of your business. This means understanding their needs, providing superior service, and fostering long-term relationships.

Innovation is key: Encourage a culture of creativity and innovation in your company. This can lead to the development of unique, high-quality plastic extrusion products which can set you apart from competitors.

By adopting these steps, businesses can ensure their agility amidst the rapid evolution of the plastic extrusion market.

FAQ

What are extrusion companies?

Extrusion companies are businesses that produce extruded plastic products, such as pipes, rods, and different shapes, which can be stock or custom-ordered based on the requirements of the customer.

Where is plastic extrusion used?

Plastic extrusion is used in the production of items such as pipe/tubing, weatherstripping, fencing, deck railings, window frames, plastic films and sheeting, thermoplastic coatings, and wire insulation.

What is the world’s largest extruder?

The world’s largest extruder is the KE 800, which is the largest single-screw extruder and has a total weight of 220 tonnes excluding the underwater pelletizer.

Is plastic extrusion expensive?

Plastic extrusion is less expensive upfront due to significantly lower tooling costs compared to injection molding, but it becomes slightly more costly over time due to medium cost per part production.

How is the process of plastic extrusion beneficial to the construction industry?

Plastic extrusion in the construction industry is beneficial as it allows for mass production of complex, durable plastic components used in various construction applications, including piping, cladding, insulating materials, and glazing.

What are the environmental impacts of using plastic extrusion in construction projects?

The environmental impacts of using plastic extrusion in construction projects include the generation of considerable waste and greenhouse gases due to the high energy requirements, as well as potential pollution from improper disposal.

What advancements in plastic extrusion technology have been made in recent years?

Recent advancements in plastic extrusion technology include the development of computer-controlled systems for precision manufacturing, the improvement of materials for durability and environmental friendliness, and the invention of multi-layer extrusion techniques for diverse functionality.

Recap