In this article, we’ll uncover what a polymer lower is and its intriguing applications in various fields.

Key takeaways:

- Polymer lowers are lightweight and resistant to corrosion

- Polymer lowers are cost-effective and allow for design flexibility

- Metal lowers are more durable but polymer lowers offer customization options and shoulder-saver benefits

- Legal considerations require serialization and compliance with local regulations

- Future trends include lighter yet more robust polymers, 3D printing customization, eco-friendly materials, and improved tracking and serialization methods.

Definition of Polymer Lower

A polymer lower, widely known as a lower receiver, refers to the part of a firearm made from polymer plastics instead of traditional metal. Think of it as the chassis of a car, but for guns. This core component houses the firing mechanism and provides a framework for other parts like the stock and the barrel to attach.

The use of polymers in this context isn’t just a trendy choice; it plays a crucial role due to its lightweight nature. Imagine carrying less weight during a long hunt or day at the range—your shoulders would thank you! Moreover, polymers are not only light but also resistant to corrosion. Unlike metal, which might throw tantrums in different weather conditions, polymers remain unbothered by humidity and rain.

In essence, polymer lowers make firearms easier to handle and maintain, granting them a modern edge over their heavier, metal ancestors.

Advantages of Using Polymer Lowers in Firearms

Polymer lowers in firearms truly shine when it comes to their lightweight nature. This makes weapons easier to handle, especially during extended periods of use—think less fatigue and more fun at the range! They’re also resistant to corrosion, a superhero trait that allows them to withstand harsh weather conditions without rusting faster than a speeding bullet.

On the economic side, polymer is generally cheaper to manufacture than metals. This cost-effectiveness does not only lighten the load on your wallet but also makes shooting sports more accessible to a broader audience.

Furthermore, these materials offer excellent design flexibility. Manufacturers can mold them into complex shapes that might be difficult or more expensive with metals. This ability allows for ergonomic enhancements that ensure a more comfortable grip, boosting the shooter’s accuracy—because who doesn’t want to hit the bullseye? These characteristics make polymer lowers an attractive choice for both novice and seasoned shooters.

Comparing Polymer Lowers With Traditional Metal Lowers

Metal lowers, typically crafted from materials like aluminum or steel, have long ruled the roost in firearm construction, prized for their robustness and hefty feel. Enter polymer lowers, the new kids on the block, who shake things up with their lightweight and corrosion-resistant properties, giving traditional metals a run for their money.

Unlike their metal counterparts, polymers aren’t prone to rust and can handle rough weather without a batting a rust-induced eyelid. They also offer a foray into customization, easily colored and molded into intricate designs that might be more labor-intensive with metals. Plus, if you’re not planning on bench-pressing with your firearm, the lighter weight of polymers can be quite a shoulder-saver during long hikes or extended training sessions.

However, hold your horses before you ditch all metals. While polymer lowers are indeed sturdy, metal still takes the crown for ultimate durability under extreme conditions. Metals can withstand greater heat and mechanical stress, factors crucial in high-performance or heavy-duty shooting scenarios. Moreover, there’s an undeniable trust in the heft and solid feel of metal that many firearm enthusiasts still prefer, sometimes it’s hard to teach an old dog new tricks.

So, considering what suits your specific needs and scenarios is key. Are you all about trekking through the wild or do you fancy the heat of heavy-duty action? Choose wisely!

Legal Considerations and Regulations for Polymer Lowers

Before diving into the world of polymer lowers, it’s crucial to understand that these components, like all parts of firearms, are subject to specific legal considerations. Depending on where you live, the rules can vary significantly, so it’s a good idea to become chummy with local regulations.

Firstly, because polymer lowers are integral to the operation of a firearm, they are considered a firearm by most legal definitions when they reach a certain stage of manufacture. This means you’ll need to ensure your polymer lower is serialized if it’s to be legally recognized.

In some places, making your own firearm from a polymer lower—affectionately known in the biz as a ‘ghost gun’ due to its initially untraceable nature—can bring additional legal responsibilities. This typically involves applying for a serial number through appropriate legal channels—yes, even for that nifty DIY project.

Recent laws and proposals in several states aim to directly tackle the regulation of these ‘ghost guns’, pushing for more stringent requirements like background checks even for private assembly.

Remember, staying updated on current and changing laws where you reside or plan to use your polymer lower is the key to staying in the good graces of the law. It’s less hassle than sorting through a tangle of legal jargon after the fact!

Future Trends in Polymer Lower Development and Use

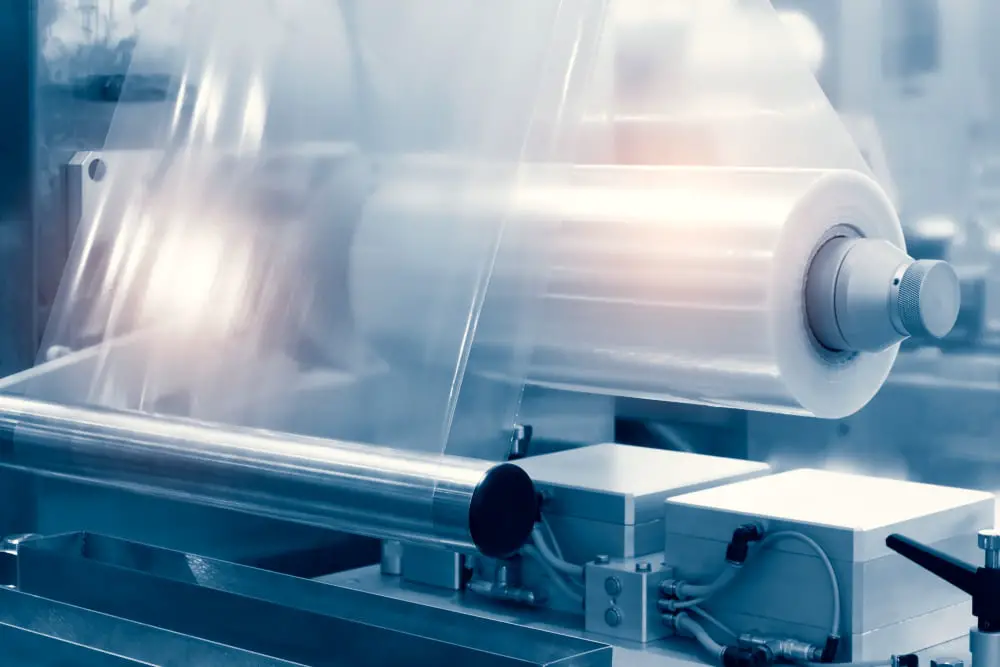

With the relentless march of technology, the future of polymer lowers looks as bright as a chemist’s neon-tinted lab coat. Innovations in materials science could lead to even lighter yet more robust polymers. Imagine something as light as a feather but tough as your old gym teacher! These advancements may significantly reduce the overall weight of firearms, making them easier to handle without sacrificing durability.

Additionally, 3D printing technology holds the promise of custom-made firearm parts. Soon, individuals could download designs and print their own customized lowers right from the comfort of their homes, tailoring the grip, size, and aesthetics to their personal needs.

Environmental sustainability is also becoming a hot topic. Future polymers might be crafted from bio-based materials, leading to firearms that Mother Nature might nod approvingly at. This shift would help reduce the environmental footprint of firearm manufacturing and appeal to the eco-conscious shooter.

As regulations evolve, so too will the methods for tracking and managing these materials. We might see embedded tracking features or new forms of serialization that ensure compliance without compromising privacy.

In short, the realm of polymer lowers is set for some exciting developments, each promising to make your shooting experience a bit more space-age!

Recap