In this article, we’ll explore how expanded polymer insulation can enhance thermal performance while being lightweight.

Expanded polymer insulation is not only easy to install but also incredibly effective at keeping homes warm in the winter and cool in the summer.

In this blog post, we’ll explore how this innovative technology works and why it’s quickly becoming one of the go-to solutions for homeowners looking to improve their energy efficiency.

So sit back, grab a cup of cocoa, and let’s dive into the world of expanded polymer insulation!

Key takeaways:

- Expanded polymer insulation is lightweight and effective for thermal performance.

- It is made from EPS beads and provides excellent insulation properties.

- Expanded polymer insulation has high R-values and energy savings.

- It is commonly used in construction for walls, roofs, and floors.

- Expanded polymer insulation is environmentally friendly and sustainable.

Expanded Polymer Insulation Basics

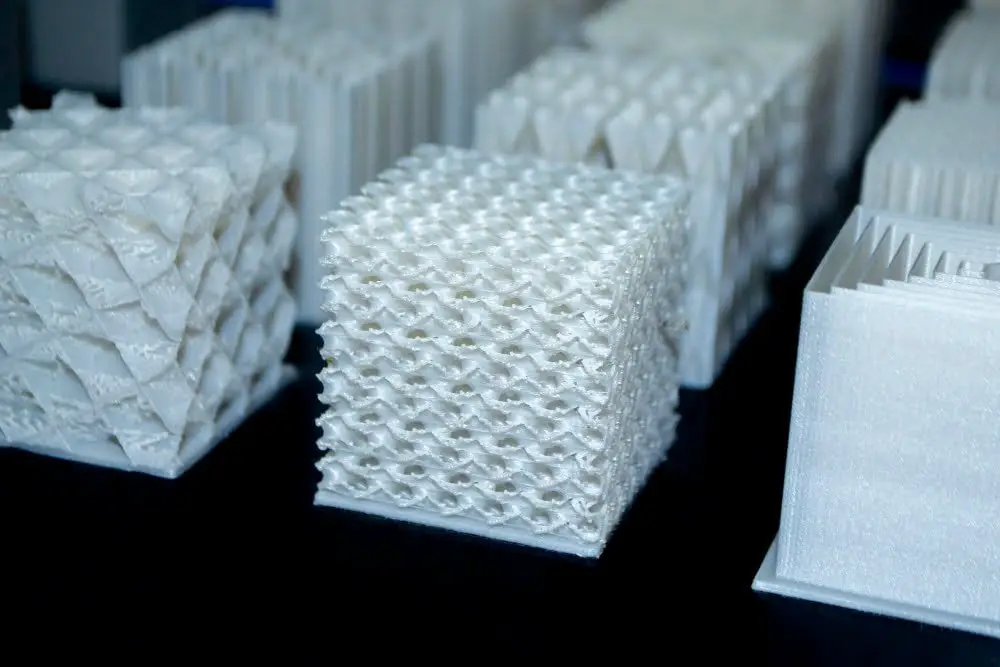

Expanded polymer insulation is a type of foam insulation that is made from expanded polystyrene (EPS) beads. These beads are heated and then fused together to create a lightweight, durable material that can be used in a variety of applications.

One of the key benefits of expanded polymer insulation is its ability to provide excellent thermal resistance while still being incredibly light. This means that it won’t add unnecessary weight or bulk to your walls or ceilings but will still help keep your home comfortable year-round.

Because it’s made from EPS beads – which are 98% air – it has excellent insulating properties without requiring thick layers like other types of foam insulation do. This makes installation easier and more cost-effective than traditional methods.

Lightweight Insulation Materials

How could something so lightweight be effective at keeping my home warm? The key to its effectiveness lies in its unique composition.

Expanded polymer insulation is made up of tiny beads of polystyrene foam that are fused together to create a solid panel. These panels are incredibly lightweight and easy to handle, making them an ideal choice for homeowners looking for a DIY solution.

But don’t let their weight fool you – these panels pack a powerful punch when it comes to thermal performance. The tiny air pockets within the foam act as insulators, trapping heat inside your home during the winter months and keeping it out during summer.

In fact, expanded polymer insulation has been shown to have one of the highest R-values (a measure of thermal resistance) per inch compared with other types of insulation materials like fiberglass or cellulose. This means that even though it’s lightweight and easy to install yourself; you can still expect significant energy savings on your heating bills throughout winter!

So if you’re tired of feeling chilly in your own home or just want an eco-friendly way to reduce energy consumption while staying comfortable all year round- consider giving expanded polymer insulation a try!

Improved Thermal Performance

Improved thermal performance is the ultimate goal for any homeowner looking to reduce their energy bills and increase comfort levels. Expanded polymer insulation was a lightweight solution that could significantly improve my home’s thermal performance.

Expanded polymer insulation works by trapping air pockets within its structure, creating an effective barrier against heat transfer. This means that during the winter months, it keeps warm air inside your home while preventing cold air from seeping in.

Conversely, during summer months it prevents hot outdoor temperatures from penetrating your living space.

Not only does this technology keep you comfortable year-round but also reduces energy consumption and costs associated with heating or cooling your home. With expanded polymer insulation installed in my house walls and attic spaces, I no longer have to worry about high utility bills or feeling chilly on those frosty winter nights.

If you’re looking for a lightweight solution to improve your home’s thermal performance without breaking the bank – look no further than expanded polymer insulation!

EPS and XPS: Key Differences

Expanded polymer insulation is a type of foam insulation that comes in two main forms: expanded polystyrene (EPS) and extruded polystyrene (XPS). While both types are made from the same base material, they differ in their manufacturing process and properties.

EPS is created by expanding small beads of polystyrene with steam, which then fuse together to form large blocks or sheets. EPS has a lower density than XPS, making it more lightweight and easier to handle during installation.

It also has better thermal resistance at low temperatures compared to XPS.

On the other hand, XPS is made by melting down polystyrene pellets under high pressure and temperature before extruding them into rigid boards or panels. This results in a denser product that can withstand higher compressive loads without deforming over time.

XPS offers superior moisture resistance compared to EPS due to its closed-cell structure.

When choosing between EPS and XPS for your home’s insulation needs, it’s important to consider factors such as cost-effectiveness, environmental impact, durability requirements as well as specific application requirements like load-bearing capacity or water-resistance.

Applications in Construction Industry

Expanded polymer insulation has become a popular choice in the construction industry due to its lightweight and versatile nature. It can be used in various applications, including walls, roofs, floors, and foundations.

This type of insulation is particularly useful for retrofitting existing buildings as it can be easily installed without adding significant weight or altering the building’s structure.

Many construction companies are also turning to this technology to improve their projects’ thermal performance. The material’s lightweight properties make it an ideal solution for high-rise buildings where reducing overall weight is crucial.

Moreover, expanded polymer insulation offers excellent soundproofing capabilities that make it perfect for commercial spaces such as offices or hospitals where noise reduction is essential. Its versatility makes it a go-to option across different industries – from residential homes to large-scale commercial projects.

Expanded Polymer Insulation has proven itself as an effective solution not only in residential but also industrial settings by providing improved thermal performance while being easy-to-install and cost-effective compared with other traditional insulations available today!

Energy Efficiency Benefits

Not only did expanded polymer insulation keep you warm and cozy on a chilly winter evening, but it also helps save on your energy bills. This innovative technology is designed to improve the thermal performance of homes by reducing heat transfer through walls, ceilings, and floors.

Homeowners can significantly reduce their heating and cooling costs by minimizing heat loss in the winter and preventing unwanted heat gain in the summer months.

In fact, according to a study conducted by EPA, adding insulation to your home can result in an average savings of 15% on heating and cooling costs. With expanded polymer insulation’s superior insulating properties compared to traditional materials like fiberglass or cellulose – which tend to settle over time – you could potentially see even greater savings.

But energy efficiency isn’t just about saving money; it’s also about reducing our carbon footprint. By using less energy for heating or cooling our homes with expanded polymer insulation installed we are contributing towards a more sustainable future for ourselves as well as generations yet unborn!

Environmental Impact & Sustainability

Thankfully, expanded polymer insulation is an eco-friendly solution that aligns with sustainability goals. It’s made from recycled materials and doesn’t contain any harmful chemicals or substances that could harm the environment.

Moreover, this type of insulation has a long lifespan – up to 50 years – which means it won’t need frequent replacements or contribute significantly to landfill waste. Since it helps reduce energy consumption in buildings by improving thermal performance and reducing heat loss through walls and roofs; it can lead to lower carbon emissions over time.

Choosing expanded polymer insulation for your home not only benefits you but also contributes positively towards creating a more sustainable future for generations ahead!

Installation Guidelines for Expanded Polymer Insuation

When it comes to installing expanded polymer insulation, there are a few guidelines that can help ensure optimal performance. First and foremost, it is important to properly prepare the surface where the insulation will be applied.

This includes removing any debris or loose materials that could affect adhesion.

Next, make sure to carefully measure and cut the insulation panels to fit snugly against walls, floors, or ceilings. It’s crucial to leave no gaps or spaces between panels as this can compromise thermal efficiency.

During installation, pay attention to sealing joints and edges with compatible adhesive tapes or sealants specifically designed for expanded polymer insulation. This helps create an airtight barrier which further enhances energy efficiency.

Consider using mechanical fasteners such as screws or nails in conjunction with adhesive for added stability in areas prone to movement or high wind loads.

Lastly but importantly – always follow manufacturer instructions regarding temperature conditions during installation as extreme temperatures may impact the performance of expanded polymer insulation.

Potential Drawbacks and Limitations of EPS & XPS

It is important to be aware of their potential drawbacks and limitations.

One limitation of EPS and XPS is their susceptibility to damage from prolonged exposure to sunlight or certain chemicals. UV radiation can cause the material’s surface to degrade over time, leading to a reduction in its insulating properties.

Some solvents or petroleum-based products may dissolve or soften EPS and XPS.

Another consideration is the environmental impact of these materials. Both EPS and XPS are derived from non-renewable fossil fuels, making them less sustainable compared to other insulation options such as natural fibers or recycled materials.

Furthermore, during production, these polymers release greenhouse gases that contribute significantly towards climate change.

Fire safety is another concern when using EPS and XPS insulation. While they have flame-retardant additives incorporated into their composition for improved fire resistance, they can still melt under high heat conditions which could potentially spread flames further if not properly protected with additional fire-resistant barriers.

Lastly but importantly for construction projects requiring load-bearing capabilities; both EPS & XPS have limited compressive strength compared with other rigid foam insulations like polyisocyanurate (ISO). This means that caution must be exercised when considering applications where heavy loads will be placed on top of the insulation layer.

How Expanded Polymer Insulation Complements Other Building Materials

Its lightweight nature makes it an ideal choice for integration with various construction components. When used in combination with traditional building materials such as concrete, wood, or steel, expanded polymer insulation enhances the overall thermal performance of the structure.

One way expanded polymer insulation complements other building materials is by providing excellent thermal resistance. By reducing heat transfer through walls and roofs, it helps maintain a comfortable indoor temperature while minimizing energy consumption for heating or cooling systems.

This not only improves occupant comfort but also reduces utility costs and environmental impact.

Expanded polymer insulation can enhance structural integrity when combined with load-bearing elements like concrete or steel frames. It acts as a protective layer against moisture infiltration and condensation buildup within walls and ceilings – common issues that can compromise the durability of these structures over time.

Moreover, its compatibility with different cladding systems allows architects to achieve both aesthetic appeal and energy efficiency goals simultaneously. Whether using brickwork, metal panels, stucco finishes or any other exterior cladding material; incorporating expanded polymer insulation ensures enhanced thermal performance without compromising on design choices.

Expanded polymer insulation offers numerous benefits when integrated into construction projects alongside traditional building materials.

Case Studies: Examples of Successful Applications

Let’s take a look at some real-life case studies that demonstrate the successful application of this lightweight solution.

In a commercial building project located in a hot climate region, expanded polymer insulation was chosen to improve the overall energy efficiency. By installing it on the roof and walls, the building achieved significant reductions in heat transfer through conduction and convection.

This resulted in lower cooling costs during summer months while maintaining comfortable indoor temperatures for occupants.

Another example is a residential development where expanded polymer insulation was utilized to enhance thermal comfort throughout all seasons. The material was applied within wall cavities and under floors, effectively reducing heat loss during winter months while preventing excessive heat gain during summer months.

As a result, residents enjoyed consistent indoor temperatures year-round without relying heavily on heating or cooling systems.

Furthermore, an industrial facility implemented expanded polymer insulation as part of their sustainability efforts to reduce carbon emissions and decrease energy consumption. By insulating pipes carrying hot fluids with this lightweight material, they minimized heat loss along distribution lines significantly.

This not only improved operational efficiency but also reduced fuel usage required for reheating processes.

Fire Safety Considerations for Expanded Polymer Insulation

Expanded polymer insulation, such as EPS (expanded polystyrene) and XPS (extruded polystyrene), can be combustible if exposed directly to flames or high temperatures for an extended period.

To mitigate the risk of fire, building codes often require additional measures when using expanded polymer insulation. These may include installing thermal barriers or protective coverings that act as a shield against direct flame exposure.

These barriers help delay ignition and slow down the spread of flames in case of a fire.

It’s crucial to follow proper installation guidelines provided by manufacturers and adhere strictly to local building codes when using expanded polymer insulation in construction projects. This ensures that appropriate fire safety measures are implemented during installation.

Regular maintenance inspections should be conducted on buildings with this type of insulation installed. Any damage or deterioration should be promptly addressed since compromised areas could increase the risk of flammability.

By understanding these fire safety considerations associated with expanded polymer insulations like EPS and XPS, builders can ensure safer construction practices while still benefiting from their excellent thermal performance characteristics.

FAQ

What is better XPS or EPS?

XPS is better than EPS for insulating spaces prone to humidity, such as floors, cellars, and foundation walls, due to its superior resistance to water vapour.

Is EPS the same as Styrofoam?

Yes, EPS (Expanded Polystyrene) is indeed the same as what is commonly referred to as Styrofoam.

Is XPS more expensive than EPS?

Yes, Extruded Polystyrene (XPS) is more expensive than Expanded Polystyrene (EPS) when comparing cost efficiency in the context of R-value and compressive strength.

Should I use EPS or XPS for basement walls?

For basement walls, XPS is the preferable choice due to its superior moisture resistance compared to EPS.

How does the insulation value of XPS compare to EPS?

The insulation value of Extruded Polystyrene (XPS) is slightly higher than that of Expanded Polystyrene (EPS) due its denser structure and lower moisture absorption rates.

What are the environmental impacts of using XPS versus EPS?

XPS (Extruded Polystyrene) has a greater environmental impact than EPS (Expanded Polystyrene) because its manufacturing process involves more energy consumption and releases more carbon dioxide.

Can EPS and XPS be recycled or decomposed?

Yes, both Expanded Polystyrene (EPS) and Extruded Polystyrene (XPS) can be recycled, but they are not biodegradable and do not decompose naturally in the environment.

Recap