Polymers offer superior performance to traditional insulation materials at a comparable cost.

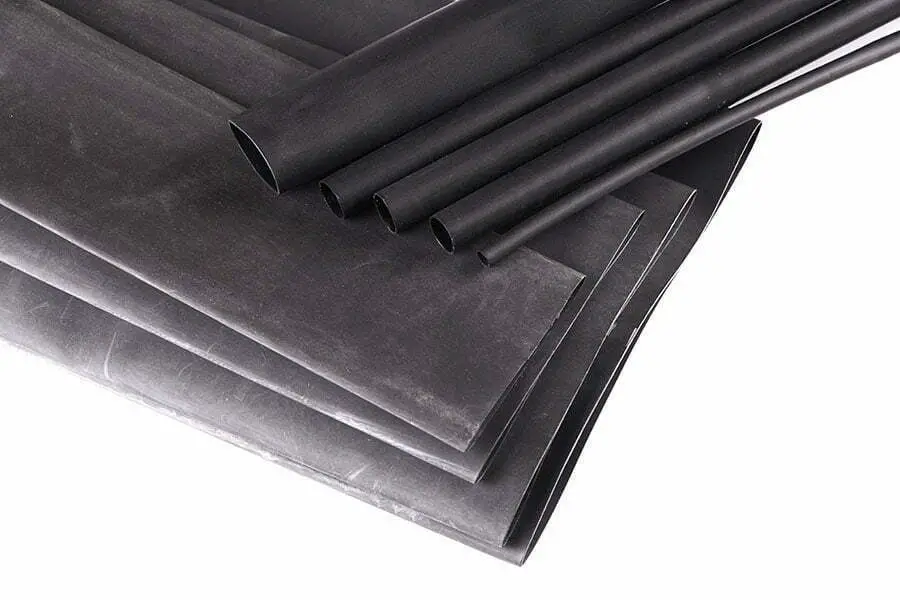

Polymers are alternatives to traditional insulation materials in various applications. They offer several advantages over conventional insulation materials, from residential and commercial buildings to industrial processes.

In this blog post, we’ll look at how polymers compare to traditional insulation materials in terms of performance and cost. We’ll also discuss the potential benefits of using polymer-based insulation products.

Polymers tend to be more expensive than traditional insulation materials, but they provide superior performance in terms of energy efficiency and durability.

Key takeaways:

- Polymers offer superior performance to traditional insulation materials.

- Polymers tend to be more expensive than traditional insulation materials.

- Polymers are more energy-efficient and durable than traditional materials.

- Conducting a life cycle analysis is crucial when comparing polymers and traditional insulation materials.

- Polymers have advantages in terms of maintenance, durability, and fire resistance.

Traditional Insulation Materials

Traditional insulation materials have been used for many years to insulate buildings and other structures. These materials include fiberglass, cellulose, rock wool, and foam board.

They are typically made from natural or synthetic fibers that trap air in small pockets to create a barrier between the inside and outside of a structure. Traditional insulation materials can be effective at reducing energy costs by keeping warm air during the winter months and cool air during the summer months.

However, they can also be expensive to install due to their bulky nature and labor-intensive installation process. Traditional insulation materials may not provide as much protection against moisture or sound as newer types of insulation, such as polymers.

Cost

The cost of polymers and traditional insulation materials can vary greatly depending on the type of material used, the size and complexity of the project, and other factors. Generally speaking, polymers tend to be more expensive than traditional insulation materials due to their higher performance capabilities.

However, when considering long-term costs, such as energy savings from improved insulation efficiency or reduced maintenance costs over time, polymer insulation may be a more cost-effective option in some cases.

Certain polymer insulations may have lower upfront costs than traditional materials while still providing superior performance. For instance, Jyoti Prakash Dhal and S. C. Mishra, in their article Processing and Properties of Natural Fiber-Reinforced

Polymer Composite, provide examples of low-cost polymer composites and their use in construction.

Ultimately, it is essential to consider all factors when comparing the cost of different insulation materials for any project.

Performance

Performance is an essential factor to consider when comparing polymers and traditional insulation materials. Polymers are generally more efficient at insulating than conventional materials, meaning they can provide better protection against heat transfer.

This means that polymers can help keep a building or home cooler in the summer and warmer in the winter, leading to lower energy costs over time. Polymers are more durable than traditional insulation materials, making them less likely to need repairs or replacements due to wear and tear.

However, this increased performance comes with a higher upfront cost than traditional insulation materials.

Life Cycle Analysis: Polymers Vs Traditional Insulation Materials

When comparing polymers to traditional insulation materials in terms of performance and cost, conducting a life cycle analysis is crucial. Life cycle analysis takes into account the environmental impact of a product from its production to its disposal.

Polymers have shown promising results in this regard. They often require less energy during manufacturing compared to traditional insulation materials like fiberglass or mineral wool.

Polymers can be recycled and reused, reducing waste generation.

On the other hand, traditional insulation materials may have higher energy consumption during production due to their extraction processes or high-temperature requirements for manufacturing.

Considering the entire life cycle of both options allows us to make informed decisions about which material is more sustainable and environmentally friendly in construction projects.

Environmental Impact: Polymers and Traditional Insulation

On one hand, polymers can be more energy-efficient during production due to their lightweight nature and lower transportation costs. Some polymer insulations are made from recycled materials or renewable resources, reducing their carbon footprint.

However, it is important to consider the end-of-life stage of these materials. Traditional insulation materials like fiberglass or mineral wool can be recycled at the end of their lifespan.

In contrast, certain types of polymer insulations may not be easily recyclable or biodegradable.

To mitigate this issue and improve sustainability in construction practices using polymers as insulation material alternatives such as bio-based polyurethane foams are being developed which offer better environmental performance by utilizing renewable resources instead of fossil fuels for production.

Maintenance and Durability: Polymer Insulation Vs Traditional Materials

One key advantage is its resistance to moisture and mold growth. Unlike some traditional insulation materials that can absorb water, polymers are inherently waterproof.

This means they won’t degrade or lose their insulating properties when exposed to moisture.

Polymer insulation is highly durable and long-lasting. It has excellent resistance against wear and tear, making it less prone to damage during installation or over time due to environmental factors such as temperature fluctuations or vibrations.

Furthermore, polymers have a high thermal stability which allows them to maintain their performance for extended periods without significant degradation. Traditional materials like fiberglass may deteriorate over time due to settling or compression which can reduce their effectiveness in providing consistent thermal protection.

In terms of maintenance requirements, polymer insulation typically requires minimal upkeep compared with traditional options. Once installed correctly by professionals following manufacturer guidelines, there’s usually no need for regular inspections or replacements unless there are specific issues identified during routine building assessments.

Fire Resistance Properties of Polymer Insulation in Construction

Traditional insulation materials like fiberglass and cellulose can be highly flammable, posing a risk in the event of a fire. However, polymers offer improved fire resistance due to their inherent chemical structure.

Polymer-based insulations are often designed with additives that enhance their flame retardant properties. These additives work by reducing the material’s ability to ignite or spread flames when exposed to heat or an open flame source.

Some polymer insulations undergo special treatments during manufacturing that further enhance their fire-resistant characteristics.

The use of polymers in construction has led to the development of insulation materials with excellent thermal performance while also meeting stringent safety standards for fire protection. This is particularly important as building codes and regulations continue to prioritize occupant safety.

It is worth noting that not all polymer-based insulations possess equal levels of fire resistance; therefore, it is crucial for builders and architects to select products specifically designed for this purpose. Consulting industry experts and adhering strictly to local building codes will ensure proper selection and installation practices are followed.

Future Prospects and Advances in Polymer Insulation Technology

Researchers and engineers are constantly exploring new ways to enhance the performance of polymers in construction applications.

One area of focus is increasing the thermal resistance or R-value of polymer insulation materials. By incorporating innovative additives or modifying their molecular structure, scientists aim to develop polymers with even higher insulating properties.

This would allow for better energy efficiency and reduced heating and cooling costs in buildings.

Another promising avenue is improving fire resistance properties. While many polymer insulations already have good fire-retardant characteristics, ongoing research aims to make them even more resistant to flames and heat exposure.

This would provide an added layer of safety in case of a fire incident.

Efforts are being made towards developing sustainable and eco-friendly alternatives within the realm of polymer insulation materials. Scientists are exploring bio-based polymers derived from renewable sources such as plant oils or agricultural waste products instead of relying solely on fossil fuel-derived plastics.

Furthermore, advancements in manufacturing techniques may lead to cost reductions associated with producing high-quality polymer insulation materials at scale without compromising performance standards.

Future prospects for polymer insulation technology look promising as researchers continue pushing boundaries through innovation and collaboration across various scientific disciplines.

FAQ

What compares the effectiveness of different materials as insulators of heat?

The effectiveness of different materials as insulators of heat is compared by their R-values, with higher values indicating greater thermal resistance and insulation effectiveness.

What term is used for comparing the insulation materials?

The term used for comparing insulation materials is "thermal conductivity".

Why are polymers good thermal insulators?

Polymers are beneficial as thermal insulators due to their inherently low thermal conductivity.

What polymer provides insulation?

The polymer that provides insulation is polyurethane.

How does the structural design of polymers affect their insulating properties?

The structural design of polymers affects their insulating properties as alterations in their molecular arrangements, like branching and cross-linking, can modify the level of heat transfer resistance they offer.

Which construction sectors primarily use polymer-based insulators?

The construction sectors that primarily use polymer-based insulators are the utilities sector, including electrical and telecommunications networks, and the building and civil engineering sector, where they are used for insulation in walls, roofs, and floors.

What advancements have been made in recent years in polymer thermo-insulating technology?

Recent advancements in polymer thermo-insulating technology include the development of high-performance polyurethane foams and aerogel-based insulators that offer superior heat resistance and reduced environmental impact.

Recap