Flexible polymer insulation offers a versatile solution for architects seeking to accommodate unique designs with its adaptable properties.

As a construction expert, I’ve seen my fair share of architectural designs that push the boundaries of what’s possible. From towering skyscrapers to whimsical treehouses, architects are constantly pushing the limits of creativity and innovation.

But with these unique designs come unique challenges, especially when it comes to insulation. Traditional insulation materials can be inflexible and difficult to work with in unconventional spaces.

That’s where flexible polymer insulation comes in. This versatile material is changing the game for architects and builders alike by adapting to even the most unconventional designs.

Let me tell you about some of the amazing ways this material is being used in real-world projects, and how it can benefit your next build.

Polymer Insulation Overview

Polymer insulation is a type of insulation material that is made from synthetic polymers. It’s known for its flexibility and adaptability, making it an ideal choice for unique architectural designs.

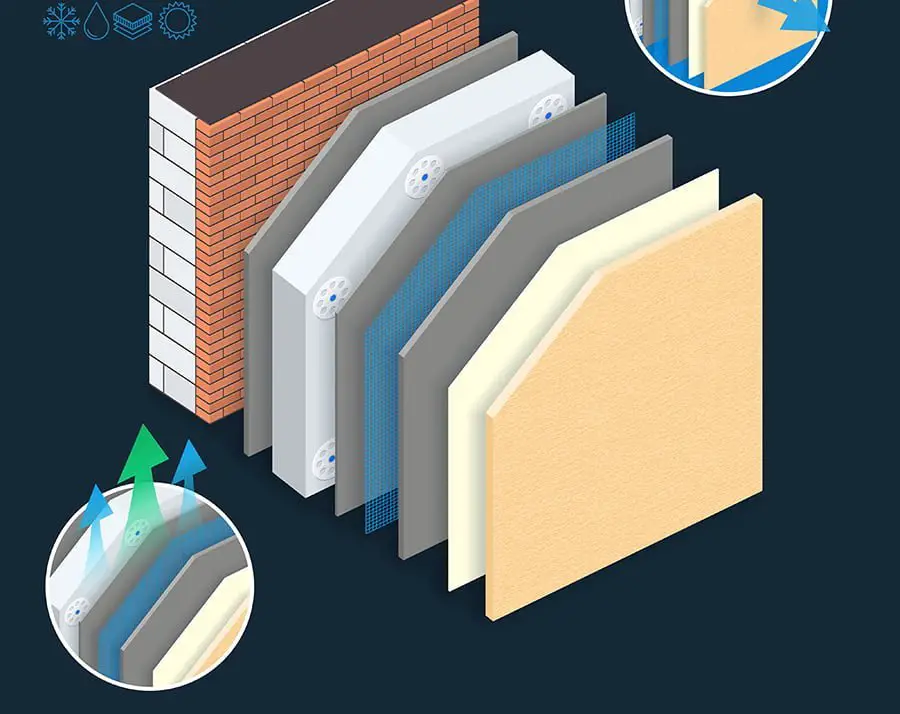

Unlike traditional insulation materials like fiberglass or foam board, polymer insulation can be easily molded to fit any shape or size.

One example of this versatility can be seen in the construction of curved walls and ceilings. These features are becoming increasingly popular in modern architecture but pose a challenge when it comes to insulating them effectively.

Traditional materials would require cutting and piecing together small sections which could lead to gaps where air could escape through.

Flexible polymer insulation solves this problem by being able to conform seamlessly around curves without leaving any gaps behind. This not only ensures better energy efficiency but also provides greater comfort levels inside the building.

Flexible polymer insulation has excellent thermal performance properties that help maintain consistent temperatures throughout the building while reducing noise transmission between rooms – perfect for those who want both privacy and comfort!

If you’re looking for an innovative solution that adapts well with unconventional designs while providing superior performance benefits than traditional options- flexible polymer Insulation should definitely be on your list!

Unique Architectural Designs

Architects are constantly pushing the boundaries of what’s possible with their designs. They’re creating buildings that twist, turn, and curve in ways that were once thought impossible.

But these unique designs come with unique challenges when it comes to insulation.

Traditional insulation materials like fiberglass or foam board can be difficult to work with in unconventional spaces. They often require cutting and shaping to fit properly, which can be time-consuming and expensive.

That’s where flexible polymer insulation comes in. This material is designed specifically for use in unconventional spaces where traditional insulation materials may not work as well.

Flexible polymer insulation is made from a blend of polymers that allow it to bend and flex without losing its insulating properties. It can conform easily to irregular shapes, making it ideal for use in curved walls or other non-standard architectural features.

In the next section of this article, we’ll take a closer look at how flexible polymer insulation works and why it’s becoming increasingly popular among architects and builders alike.

Flexibility in Polymers

One of the key benefits of flexible polymer insulation is, as the name suggests, its flexibility. Unlike traditional insulation materials like fiberglass or foam board, which can be rigid and difficult to work with in unconventional spaces, flexible polymer insulation can bend and conform to fit any shape or size.

This makes it an ideal choice for architects who want to create unique designs without sacrificing energy efficiency.

For example, I recently worked on a project where the architect wanted to incorporate curved walls into their design. Traditional insulation materials would have been nearly impossible to install in these areas without compromising their effectiveness.

But by using flexible polymer insulation instead, we were able to easily mold it around every curve and contour of the wall while still maintaining optimal thermal performance.

The versatility of this material doesn’t stop there either – it’s also great for insulating irregularly shaped spaces like attics or crawlspaces that may not have standard dimensions. By being able to adapt so easily and effectively in these situations means that builders no longer need worry about losing valuable space due bulky traditional insulations taking up too much room.

In short: if you’re looking for an innovative solution that will allow you more freedom when designing your next building project while still ensuring top-notch energy efficiency standards are met – look no further than flexible polymer insulation!

Material Adaptability

One of the biggest advantages of flexible polymer insulation is its adaptability. Unlike traditional insulation materials, which can be rigid and difficult to work with in unconventional spaces, flexible polymer insulation can conform to any shape or size.

This makes it an ideal choice for architects and builders who are looking to push the boundaries of design.

For example, I recently worked on a project where we were tasked with insulating a curved wall in a modern art museum. The wall was made up of irregularly shaped panels that jutted out at odd angles – not exactly an easy task for traditional insulation materials! But by using flexible polymer insulation, we were able to easily mold the material around each panel and create a seamless layer of protection against heat loss.

This kind of adaptability is what sets flexible polymer insulation apart from other options on the market today. It allows architects and builders to think outside the box when it comes to design without sacrificing energy efficiency or comfort within their buildings.

Thermal Performance

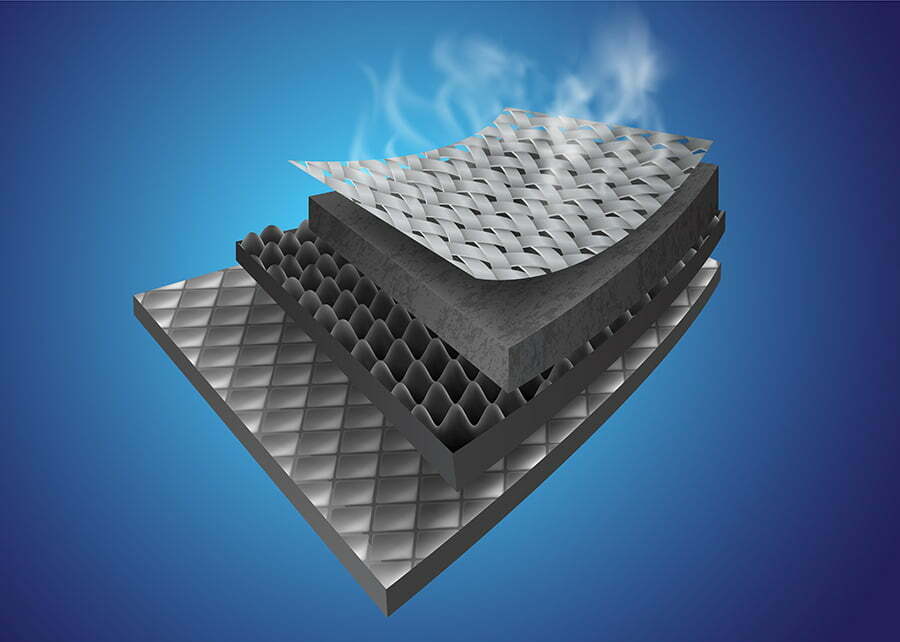

When it comes to insulation, thermal performance is key. It’s not enough for a material to be flexible and adaptable if it can’t also provide the necessary level of insulation.

Fortunately, flexible polymer insulation excels in this area as well.

In fact, some types of flexible polymer insulation have been shown to outperform traditional materials like fiberglass and cellulose in terms of thermal resistance. This means that even in unconventional spaces with unique shapes or sizes, you can still achieve optimal energy efficiency without sacrificing design.

One example where this has been put into practice is the construction of curved walls using insulated metal panels (IMPs). These panels are made up of two layers: an outer layer for structural support and an inner layer filled with polyurethane foam – a type of flexible polymer insulation known for its excellent thermal performance.

By using IMPs with polyurethane foam as the insulating material, architects were able to create curved walls that not only looked stunning but also provided superior energy efficiency compared to traditional flat wall designs.

Flexible polymer insulation truly offers endless possibilities when it comes to adapting your building’s design while maintaining optimal thermal performance.

Installation Techniques

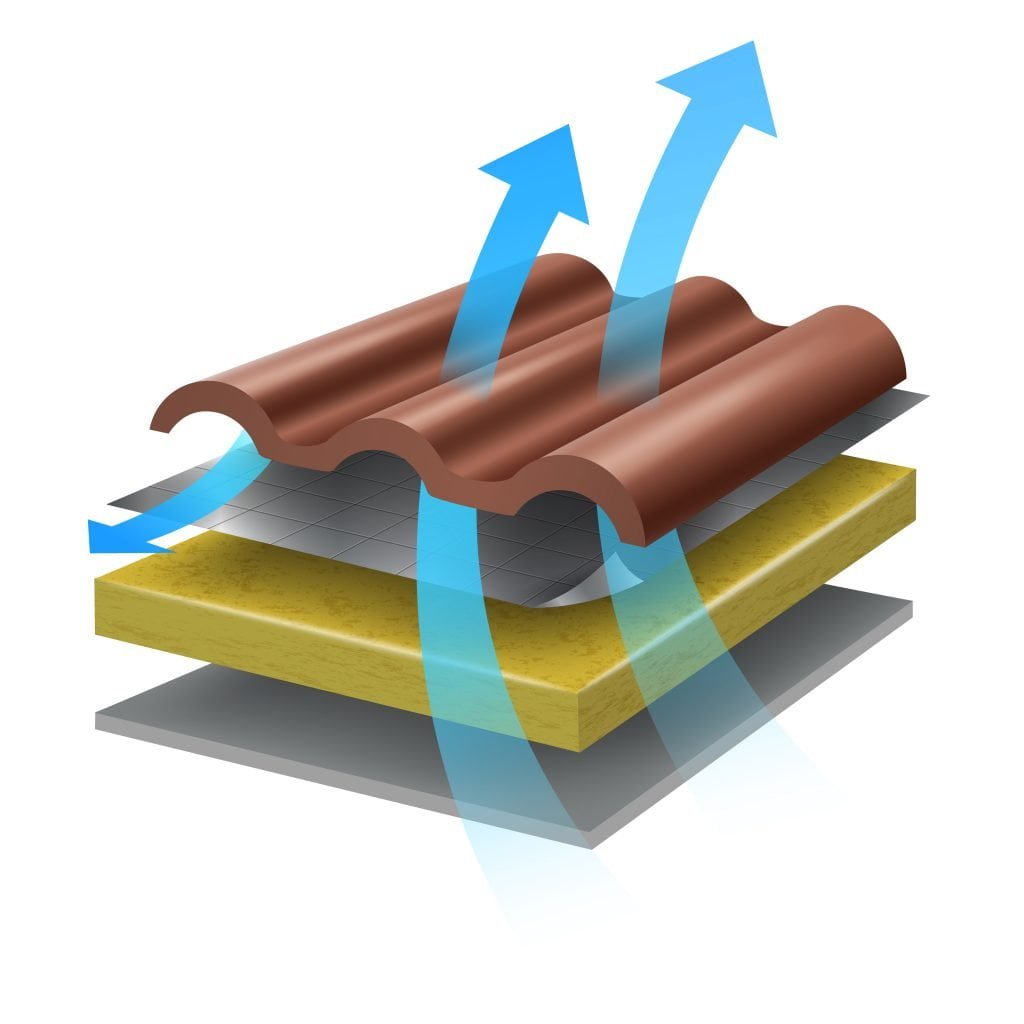

When it comes to insulation, installation can be a tricky process. Traditional materials like fiberglass or foam board require precise measurements and cutting to fit into tight spaces.

But with flexible polymer insulation, the installation process is much more forgiving.

In fact, one of the biggest advantages of this material is its ability to adapt to unique architectural designs without sacrificing performance. Its flexibility allows it to conform easily around curves and corners, making it ideal for irregularly shaped buildings or structures.

I recently worked on a project where we used flexible polymer insulation in an unconventional space: a treehouse! The curved walls and sloping roof made traditional insulation methods nearly impossible. But with this innovative material, we were able to create a seamless layer of protection against heat loss and gain.

Whether you’re working on an ambitious skyscraper or designing your dream home with unusual angles and shapes – don’t let traditional insulations hold you back from achieving your vision! Flexible polymer insulation offers endless possibilities for adapting even the most unique architectural designs while providing superior thermal performance that will keep occupants comfortable year-round.

Durability and Lifespan

One of the most important factors to consider when choosing insulation materials is durability and lifespan. After all, no one wants to invest in a product that will break down or deteriorate over time.

Fortunately, flexible polymer insulation has proven itself to be incredibly durable and long-lasting.

In fact, many manufacturers offer warranties of up to 25 years for their flexible polymer insulation products. This means that you can have peace of mind knowing that your building’s insulation will remain effective for decades.

But what makes this material so durable? For starters, it’s resistant to moisture and mold growth – two common issues with traditional fiberglass or cellulose insulations. Its flexibility allows it to withstand movement without cracking or breaking apart.

This durability is especially important in unique architectural designs where access may be limited for maintenance purposes. With flexible polymer insulation installed properly from the start, you won’t have worry about replacing it anytime soon – even if your building design requires unconventional shapes or angles.

When considering which type of insulation material best suits your project needs- think beyond just R-value (thermal resistance) ratings; take into account other factors such as adaptability and longevity too!

Recap