Here are the top types of polymers that are used in construction as building materials.

Polymers are widely used in the construction industry for a variety of purposes. The most common polymers used include Polyvinyl Chloride (PVC), Polyethylene (PE), Acrylic, and Polypropylene (PP).

PVC is a versatile and cost-effective polymer highly resistant to corrosion and chemical damage, making it an ideal choice for outdoor applications.

PE is a lightweight and durable polymer used for roofing membranes and waterproofing.

Acrylic is a transparent thermoplastic often used to create skylights and windows.

PP is a strong and lightweight polymer used to produce carpets, flooring, and other interior components.

But there’s more.

Key takeaways:

- PVC: Versatile and corrosion-resistant, used for outdoor applications.

- PE: Lightweight and durable, used for roofing and waterproofing.

- Acrylic: Transparent thermoplastic used for skylights and windows.

- PP: Strong and lightweight, used for carpets and interior components.

- EVA: Low-cost and flexible, used for encapsulating solar panels and other applications.

Ethyl Vinyl Acetate

Ethyl Vinyl Acetate (EVA) is a type of plastic polymer with a wide range of uses in construction. It comprises two monomers, vinyl acetate, and ethylene, which gives it excellent adhesion to many non-porous and polar surfaces.

EVA is widely used in construction because it is relatively low-cost, flexible, crack-resistant, puncture-resistant, and heat-sealed. One example where EVA is helpful in construction projects is encapsulating solar panels.

This process involves wrapping the panel with a thin layer of EVA material to protect it from weathering and other external factors while allowing light to pass through the material.

Other common uses for EVA include various plastic sheeting applications such as:

- Roof underlayment or vapor barriers around windows.

- Metal surface protection.

- Coated paper lamination.

- Hot melt adhesive film.

Polyethylene (PE)

Polyethylene (PE) is a type of plastic that has become increasingly popular in the construction industry due to its durability and lightweight properties. It can be molded easily and recycled multiple times, making it an ideal material for many applications.

In construction, PE is used in a variety of ways. As a vapor retarder, it prevents moisture from seeping into a structure’s walls or ceiling.

It can also be used as flooring, window films, countertop protection, and roofing material – all with excellent results! For example, PE roofing protects against extreme weather conditions such as heavy rainfall or hail storms.

Polycarbonate

Polycarbonate is a versatile material with many applications in construction. It can be used for roofing, siding, and glazing.

Its high impact resistance makes it ideal for safety and security glazings, such as bulletproof windows or barrier walls to protect against sound or wind. Its transparency also makes it an attractive option for skylights and conservatories.

Moreover, its durability allows it to withstand extreme climates, making it suitable for indoor and outdoor construction projects.

As a thermoplastic material, polycarbonate can be melted down and reused multiple times, increasing its sustainability compared to other materials.

Polypropylene

Polypropylene is a type of plastic that is used in many construction projects. It has several benefits because of its durability and affordability.

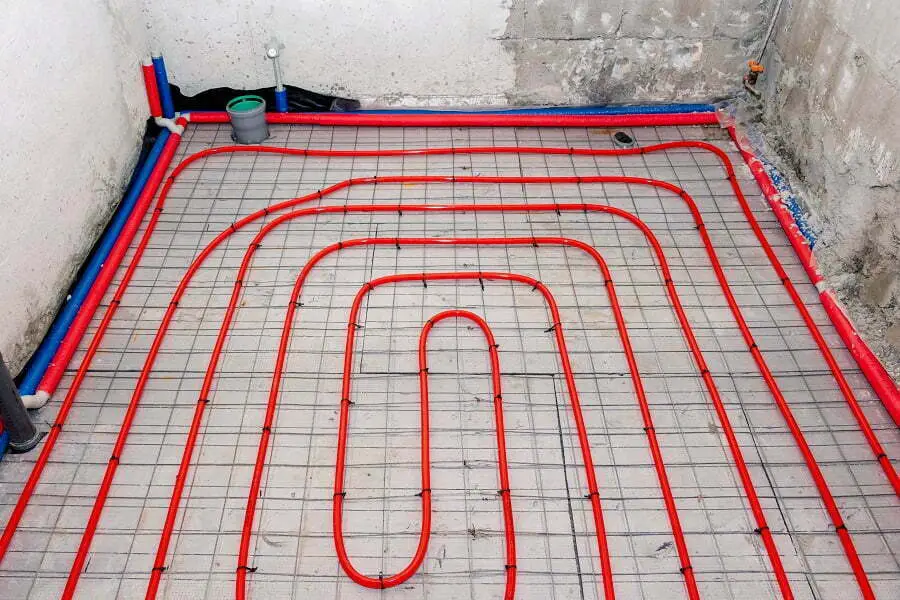

This versatile material can be used for carpets, electrical insulation, piping systems, and machine parts. Polypropylene is well known for its heat and fatigue resistance, making it an ideal choice for many construction materials.

It also has excellent shatter resistance, making it ideal for use in high-traffic areas or areas exposed to extreme temperatures.

Polyvinyl Chloride

Polyvinyl Chloride (PVC) is a plastic material used in construction for various applications. It is an economical and durable choice for many building projects.

PVC is typically used to make pipes, fittings, flooring, window and door frames, and roof membranes. PVC has many benefits as a building material.

It’s inexpensive compared to other options like metal or wood, making it more cost-effective over the long run. Its durability also makes it ideal for use in areas exposed to harsh weather conditions.

Acrylic

Acrylic is a plastic material with many uses in construction projects. It is highly versatile and lightweight yet firm and durable.

Acrylic is known for its optical clarity, scratch resistance, and rigidity, making it an ideal choice for use in many different building materials and applications.

One example is light fixtures — acrylic can create transparent sheeting applications such as windows or LCD screens. Its high transparency makes it perfect when creating walls with glass or other see-through building blocks.

Composites

Composites are materials made up of two or more constituent parts. They are often used in construction to provide strength, durability, and other benefits, such as lightweight construction and corrosion resistance.

One type of composite material that is commonly used in construction is a fiber-reinforced polymer (FRP). This material combines plastic with fiberglass strands to create a strong yet flexible material that can be used instead of heavier metals for load-bearing applications.

Due to their weight savings and durability, FRP composites have been successfully used for bridges, buildings, boat hulls, and even spacecraft components.

Other composite materials include:

- Reinforced concrete, which combines steel bars with concrete to provide additional strength.

- Composite wood, which uses glue and particles of wood to form a stronger board.

- Reinforced plastics, which combine plastic resins with fibers like glass or carbon.

- Ceramic matrix composites, which use ceramic particles embedded in a resin matrix.

- Metal matrix composites, which incorporate metal fibers into a metallic alloy.

And many other advanced composite materials that are developed specifically for specific applications.

Overall, the use of composites provides many advantages when it comes to constructing structures: they offer enhanced load-bearing capabilities while also being lightweight enough for aircraft applications, plus they can help reduce costs associated with building structures due to their relatively low cost compared to traditional materials like steel or aluminum alloys.

Epoxy Resins

Epoxy resins are widely used in construction due to their durability and strength. One common use is as a coating for floors, such as terrazzo flooring.

The resin forms a strong bond with the floor’s surface, protecting it from scratches, chips, and other damage while providing an attractive finish.

Epoxy resins can also anchor fixings in structures such as walls and ceilings, allowing them to be securely held in place without damaging the substrate.

Expanded Polystyrene

Expanded polystyrene (EPS) is a versatile material that can be used for many different construction applications. One of the most common uses for EPS in construction is as a form material for concrete molds and castings.

EPS is lightweight and rigid, which makes it an ideal choice for forming shapes in concrete projects such as footers, walls, pillars, and even entire buildings. Another popular use of EPS in construction is insulation.

Polyisobutylene (PIB)

Polyisobutylene (PIB) is a synthetic rubber material that is used in a variety of construction applications. It has excellent resistance to weathering, aging, and chemical exposure, making it an ideal choice for outdoor construction projects.

One of the most common uses of PIB in construction is as a glazing sealant. It can be applied around window frames and other openings to ensure airtight seals resist water, dust, and wind penetration.

Polyurethane (PU)

Polyurethane, or PU for short, is a versatile material used in many construction aspects. It can be formed into various shapes and sizes, making it an ideal choice for use in various applications.

One common use of PU in construction is as a sealant. This can be used around windows and door frames to provide an airtight seal against the elements and help keep energy bills down by preventing heat from escaping.

Rubber

Rubber is a versatile material with many applications in the construction industry. It can provide insulation, reduce vibration and noise, create waterproofing seals, and more.

One of the most common uses of rubber in construction is bridge bearings. This type of bearing uses a layer of rubber between two metal plates to allow for movement within the structure while still providing support.

The Practical Uses and Applications of Polymers in Construction

Polymers have become an integral part of the construction industry due to their versatile properties and wide range of applications. These materials are used in various aspects of building construction, from structural components to insulation and finishes.

One practical use of polymers is in the production of polymer composites, which are lightweight yet strong materials that can be used for constructing bridges, buildings, and other infrastructure projects.

Another application is in waterproofing systems where polymers such as polyurethane or acrylic-based coatings are applied on roofs or concrete surfaces to prevent water infiltration. These coatings provide a protective barrier against moisture while also offering excellent durability.

Polymers also play a crucial role in insulation materials used for thermal and acoustic purposes. Expanded polystyrene (EPS) foam boards or spray polyurethane foam (SPF) offer superior insulating properties compared to traditional options like fiberglass batts.

They help maintain comfortable indoor temperatures by reducing heat transfer through walls, floors, and roofs.

In addition to these uses, polymers find their way into adhesives and sealants utilized during construction projects. Polymer-based adhesives provide strong bonding capabilities between different substrates like wood panels or tiles while sealants ensure air-tightness around windows/doors preventing energy loss due to drafts.

Moreover, polymer-modified mortars have gained popularity as they enhance the performance characteristics of conventional cementitious products such as increased flexibility/strength/toughness/resistance against cracking etc., making them suitable for demanding applications like tile installation on uneven surfaces or repairing damaged concrete structures.

Polymers offer numerous practical benefits when it comes to construction.

Environmental Impact of Polymers in the Construction Industry

It is important to consider the environmental impact of using polymers in construction projects.

One significant concern is the production process of polymers, which often involves the use of fossil fuels and releases greenhouse gases into the atmosphere. These emissions contribute to climate change and air pollution.

Some polymer manufacturing processes generate hazardous waste that can harm ecosystems if not properly managed.

Another aspect to consider is disposal at end-of-life. Many traditional building materials such as concrete or steel can be recycled or repurposed after demolition, reducing waste sent to landfills.

In contrast, certain types of polymers may not be easily recyclable or biodegradable.

To mitigate these environmental concerns, researchers are actively working on developing more sustainable alternatives for polymer production by exploring bio-based sources instead of relying solely on fossil fuels. Efforts are being made towards improving recycling technologies for post-consumer polymer waste.

It’s worth noting that despite these challenges, there are also positive aspects regarding polymers’ environmental impact in construction when compared with other materials like wood or metal: they tend to require less energy during transportation due their lightweight nature; they offer better insulation properties leading potentially lower energy consumption over a building’s lifetime; and they can contribute towards reducing overall carbon footprint through innovative design approaches such as modular constructions that minimize material wastage during assembly.

Advancements in Polymer Technology for Construction

High-performance polymers: The development of high-performance polymers has revolutionized the construction industry. These advanced materials possess exceptional strength, durability, and resistance to various environmental factors such as extreme temperatures, chemicals, and UV radiation.

They are being used in applications like roofing membranes, structural components, and protective coatings.

2. Self-healing polymers: Researchers have made significant progress in creating self-healing polymer systems that can repair cracks or damages automatically without human intervention.

These innovative materials have the potential to extend the lifespan of structures by minimizing maintenance needs and reducing repair costs.

3. Smart polymers: Smart or responsive polymers are designed to undergo reversible changes when exposed to external stimuli such as temperature variations or moisture levels.

In construction applications, these intelligent materials can be utilized for adaptive insulation systems that adjust their thermal properties based on ambient conditions.

4.Nanocomposite-based polymers: Incorporating nanoparticles into polymer matrices has led to the development of nanocomposite-based polymeric materials with enhanced mechanical properties like increased tensile strength and improved fire resistance compared to traditional counterparts.

5. Recyclable and sustainable options: With a growing focus on sustainability within the construction industry, research is underway towards developing recyclable polymer alternatives derived from renewable sources. These eco-friendly options aim at reducing carbon footprint while maintaining performance standards required for building projects.

6. Bio-inspired designs using biopolymers: Taking inspiration from nature’s design principles, biopolymers derived from natural sources (such as cellulose) are being explored for their potential use in constructing environmentally friendly buildings. Their unique combination of lightweight yet strong characteristics makes them an attractive choice for sustainable architecture.

7. Additive manufacturing with 3D printing: The integration of 3D printing technology with specialized polymeric filaments allows architects and engineers greater freedom in designing complex shapes while optimizing material usage. This additive manufacturing technique has the potential to revolutionize construction processes, making them more efficient and cost-effective.

8. Enhanced insulation materials: Polymeric foams with improved thermal insulation properties are being developed to enhance energy efficiency in buildings.

These advanced insulating materials help reduce heat transfer through walls, roofs, and floors, resulting in reduced energy consumption for heating or cooling purposes.

9. Fire-resistant polymers: In response to fire safety concerns, researchers have been working on developing flame-retardant polymers that can withstand high temperatures and prevent the spread of flames.

These innovative materials are crucial for enhancing building safety standards.

10. Self-cleaning coatings: Polymer-based self-cleaning coatings have gained attention due to their ability to repel dirt particles and maintain a clean appearance over time. By reducing maintenance requirements, these coatings offer practical benefits for building exteriors while also contributing towards sustainability efforts.

Safety Precautions in Utilizing Polymers for Building

Here are some key measures to consider:

1. Proper Ventilation: Ensure that the construction area has adequate ventilation to prevent the accumulation of harmful fumes or vapors released during polymer application.

2. Personal Protective Equipment (PPE): Workers should wear appropriate PPE such as gloves, goggles, and respiratory masks when handling polymers or working in close proximity to them.

3. Training and Education: It is essential for workers involved in polymer-based construction projects to receive proper training on handling and using these materials safely.

This includes understanding potential hazards, emergency procedures, and safe disposal practices.

4. Storage and Handling: Store polymers according to manufacturer guidelines in a well-ventilated area away from heat sources or open flames that could cause ignition or degradation of the material.

5. Fire Safety Measures: Implement fire safety protocols by having fire extinguishers readily available at construction sites where polymers are being used extensively.

6.Waste Management: Dispose of waste materials properly by following local regulations for recycling or disposing of unused polymer products responsibly without causing harm to the environment.

Overview of Market Growth and Economy Related to Polymers in Construction

This can be attributed to the numerous advantages that polymers offer over traditional building materials. Polymers are lightweight, durable, and resistant to corrosion and weathering.

They also have excellent thermal insulation properties and can be easily molded into various shapes.

In terms of the economy, the increased use of polymers in construction has created new opportunities for manufacturers and suppliers. The demand for polymer-based building materials has led to a rise in production capacities, resulting in job creation within the industry.

Furthermore, as more builders recognize the benefits of using polymers, there is a growing trend towards incorporating them into sustainable construction practices. Polymers can contribute to energy efficiency by reducing heat loss or gain through walls or roofs due to their insulating properties.

With advancements in polymer technology and increasing awareness about their benefits among architects and contractors alike, it is expected that the market growth related to polymers will continue its upward trajectory while positively impacting both local economies and environmental sustainability efforts within the construction sector.

FAQ

What are the polymer materials used in building?

The polymer materials used in construction include plastics, rubbers, thermoplastic elastomers, adhesives, foams, paints, and sealants.

What are the 4 types of polymers?

The four types of polymers are linear polymers, branched polymers, crosslinked polymers, and networked polymers.

What are 5 examples of polymer materials?

Five examples of polymer materials include synthetic fibers used in clothing, polyethylene cups, nylon bearings, polyurethane foam cushions, and Teflon-coated cookware.

What are the 7 building materials?

The seven most common building materials used in construction are wood, cement, aggregates, metals, bricks, concrete, and clay.

How are polymers integrated into the process of concrete production?

Polymers are integrated into the concrete production process through techniques like polymer impregnation and polymer modification, which enhance properties like tensile strength, durability, and resilience to environmental influences.

What key benefits would a building gain from incorporating polymer materials?

Incorporating polymer materials in building construction can lead to increased durability, thermal and acoustic insulation, flexibility in design, and resistance to corrosive elements, making them exceptionally suited to modern architectural applications.

Can you share notable examples of buildings globally that have effectively used polymers in their construction?

The Centre Pompidou in Paris is an iconic example of a building using polymers, specifically in its translucent, colorful, high-performance ETFE polymer panels that envelop the structure, and the Taipei Water Park in Taiwan, which utilized advanced polyvinyl chloride (PVC) in constructing water tubes and pools, demonstrating resilience, water resistance, and durability.

Recap