How polymer building and polymer processing are used in construction today?

Polymer building materials are becoming increasingly popular in the construction industry due to their versatility, durability, and cost-effectiveness.

Polymers are synthetic materials made from long chains of molecules that can be manipulated to create various shapes and sizes. They can be used for many applications, including insulation, waterproofing, structural reinforcement, and decorative elements.

Polymer processing is manipulating polymers to create a desired shape or size. This can be done through various methods, including extrusion, injection molding, and thermoforming. Each method has advantages and disadvantages, so choosing the right one for your project is essential.

Key takeaways:

- Polymer building materials are versatile, durable, and cost-effective.

- Polymers can be used for insulation, waterproofing, reinforcement, and decorative elements.

- Polymer processing methods include extrusion, injection molding, and thermoforming.

- Polymers offer benefits like energy efficiency, structural strength, and moisture resistance in construction.

- Polymer materials have a positive environmental impact and are recyclable.

The Quick History of Polymer Materials

The history of polymer materials in construction dates back to 1850 when Alexander Parkes invented the first thermoplastic, Parkesine. This plastic quickly became popular and was used for various products, such as combs and umbrella handles.

Then, in 1907, Leo Baekeland developed Bakelite – the world’s first fully synthetic plastic – which enabled manufacturers to create an even more comprehensive range of products from plastics. These two inventions paved the way for modern plastics.

The Use of Plastic in Construction in the Past

Plastic has been used in construction since its invention and was an essential part of the building process. Plastic was used to coat bricks before insulation became available.

This helped protect the bricks from weathering and gave them a much more attractive look than traditional techniques, such as painting or stucco.

Coating the brick with plastic allowed for more decorative elements to be added to buildings, such as groves, curves, ridges, and other architectural features that were difficult or impossible with traditional techniques.

Uses of Polymer Materials in Construction Today

Polymers are advantageous due to their low cost and easy fabrication, making them an excellent choice for large and small projects.

Polymers have become increasingly popular in recent years due to technological advances, allowing them to be used on a larger scale while still being eco-friendly.

These materials can be incorporated into various construction projects such as window frames, shingles, light fixtures, pipes, insulation, and EIPs (expanded polystyrene insulation).

Polymers offer various benefits, including improved energy efficiency by reducing heat loss through the walls or roof; increased structural strength; reduction in weight for lightweight structures; moisture resistance; fire retardancy; chemical resistance, and corrosion protection.

In addition to these uses on building sites, such as plumbing or household appliances like dishwashers or cookers, they also often use polymer components due to their durability compared with traditional materials such as wood or metal.

Future Trends of Polymer Materials in Construction

The use of polymers in the construction and building sectors has grown exponentially in recent years. Polymers are being developed to provide various structural, non-structural, and decorative applications.

Advances in plastic technology have allowed for complex designs such as bridges and stadiums to be made out of plastic material. Additionally, new materials are allowing for faster construction times than ever before.

One future trend is self-healing and intelligent/reactive polymers, which can repair themselves if damaged or respond to changing conditions, making them invaluable for long-term projects that need flexibility.

Furthermore, polymer additives can be incorporated into traditional building materials like mortar and concrete to improve their strength or durability without compromising aesthetics or cost efficiency.

Overall, with the continuing development of plastic technology, the scope of what is possible with polymer application will continue expanding significantly over time.

This could revolutionize how we build structures by simultaneously making them lighter yet more robust – all while utilizing recycled materials that would create a more sustainable environment moving forward!

The Properties of Polymer Materials

Polymer materials are lightweight and low-density compared to other materials, such as steel.

They can be natural or synthetic and have many uses in everyday life – from clothing to medical supplies. The low density of polymer materials is due mainly to their light elements composition.

For example, polymethyl pentane has a density of 830 kg per cubic meter; polypropylene (PP) has a density of 905 kg per cubic meter; and polytetrafluoroethylene (PTFE) has a

The Types of Polymers and How They Are Used in Construction

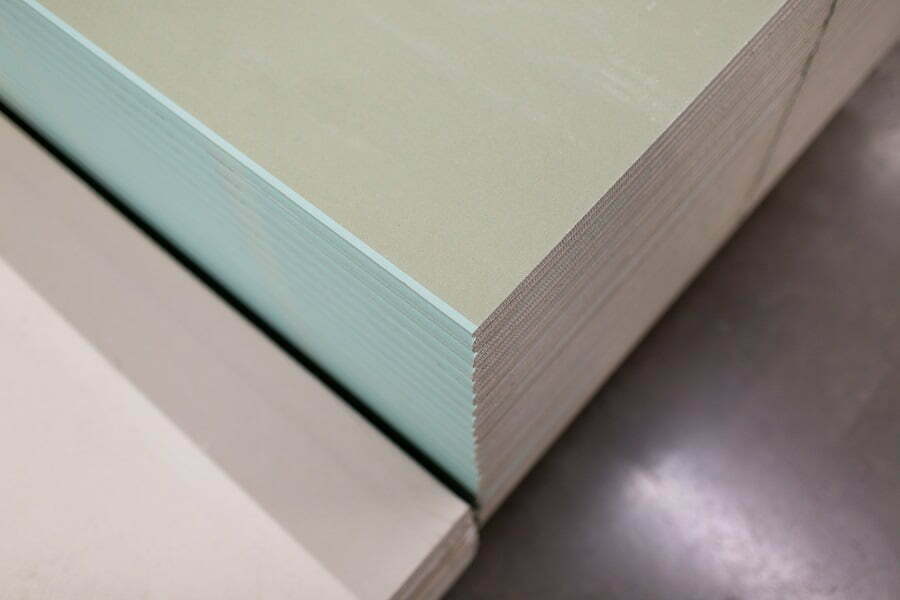

Polymers are versatile materials used in construction to create a variety of products. They can be made from various substances, including plastics, rubbers, thermoplastic elastomers, adhesives, sealants, and paints.

Polymers are easy to fabricate and cost-effective for producing finished products for their wide range of applications in construction. One popular type of polymer is epoxy resin which has many desirable properties when cured, such as heat resistance, corrosion resistance, and electrical insulation.

This makes it an incredibly versatile substance used in many construction projects, such as bonding stone, glass, metal concrete, most plastics, and wood. It is also helpful for waterproofing or filling gaps between surfaces due to its adhesive qualities.

Ethyl Vinyl Acetate

Ethyl Vinyl Acetate (EVA) is a copolymer of ethylene and vinyl acetate used in various construction applications. It has excellent elasticity, toughness, and adhesion to many different surfaces.

This makes it an ideal choice for various building materials, such as hot-melt adhesives, hot glue sticks, and top-notch soccer cleats. EVA also offers excellent flex-crack and puncture resistance when applied to construction projects.

Polyethylene (PE)

Polyethylene (PE) is a versatile and widely used thermoplastic found in many construction projects. PE is lightweight, easy to work with, and has excellent resistance to chemicals, heat, and UV light.

This makes it ideal for various applications, including roofing membranes, window films, vapor retarders, flooring materials, countertop protection products, and more. PE also has superior flexibility compared to other plastics, allowing it to be heated or cooled without degrading its properties.

Its durability makes it an ideal material for many construction projects, as it can withstand harsh weather conditions such as strong winds or heavy rain.

Polycarbonate

Polycarbonate is a type of plastic that is becoming increasingly popular in the construction industry. It has many valuable properties, such as being lightweight yet strong, temperature resistant up to 140°C (with some grades able to go even lower), and shatter-resistant.

This makes it ideal for building applications such as windows and walls, roofs, and other protective barriers like safety shields. It also has excellent optical clarity, allowing light to pass through it quickly.

Polycarbonate is also flame retardant, making it safer in specific areas like kitchens or laboratories. With all these benefits plus its low cost compared to other materials like glass or metal, polycarbonate is quickly becoming the material of choice for many construction projects worldwide.

Polymer Substrates

Polymer substrates are materials composed of synthetic resins, fillers, plasticizers, curing agents, and other components increasingly used in the construction industry. Polymer concrete is a polymer substrate with many applications, such as prefabricated walls, hydraulic structures, road surfaces and decks, and underground constructions.

The use of polymer substrates in construction has been found to possess several unique advantages over traditional materials.

For instance, they have a higher strength-to-weight ratio than conventional concrete, which makes them ideal for lightweight building constructions.

Additionally, they have superior resistance to harsh environmental conditions such as extreme temperatures or chemical exposure due to their strong bond between the resin molecules.

Furthermore, fiber-reinforced polymers (FRPs) can be used for prefabrication purposes, thus providing affordable housing options for the growing population.

Research has also been conducted on various aspects regarding the properties of polymer substrates, including flexural behavior tests on polymer concrete; mechanical properties testing on nano-MMT reinforced polymer composite; durability assessments on waste products used in obtaining a composite material; crack propagation studies on unsaturated polyester PC; etc.

Thus, there is an increasing interest in studying the various features and uses of this relatively new material to maximize its potential benefits within construction projects worldwide.

Polymer Binders

Polymer binders modify cement pastes and mortars to improve their physical properties. These polymers are added to the cement mixture, which helps reduce its stiffness and provide flexibility.

These polymers’ performance depends on the glass transition temperature (Tg) and the emulsifier used for commercial production. The microstructure, polymer-cement matrix interaction, hydration evolution, film-forming process, and mechanical performance of polymer-modified mortars have been extensively studied.

Furthermore, renewable resources derived materials (RRDM), such as biochar, rice husk ash, palm fruit ash, or soybean flour, have also been explored successfully as polymer binders. Tarar et al., for instance, studied the effects of RRDM on asphalt binder performance in terms of rheological properties and anti-aging performance.

Polymer binders are essential components in construction projects that help improve specific physical properties of cement mixtures while also being made from renewable sources when available.

Environmental Impact of Using Polymer Materials in Construction

Polymer materials have gained significant attention in the construction industry due to their positive environmental impact. Unlike traditional building materials such as concrete and steel, polymers are lightweight and require less energy during production.

This results in reduced carbon emissions and a smaller ecological footprint.

Polymer-based products can be recycled or reused at the end of their lifespan, further minimizing waste generation. The versatility of polymers also allows for the development of eco-friendly alternatives to conventional construction methods.

Furthermore, using polymer materials can contribute to improved energy efficiency in buildings. Polymers possess excellent insulation properties that help regulate temperature fluctuations within structures, reducing reliance on heating or cooling systems.

By adopting polymer building materials, we not only reduce our dependence on non-renewable resources but also promote sustainability throughout the entire lifecycle of a structure – from manufacturing to disposal.

Innovations in Polymer Manufacturing for Construction Purposes

These advancements have revolutionized the industry by offering new possibilities and improved performance in building materials.

One notable innovation is the development of high-performance polymers that possess exceptional strength and durability. These polymers are engineered to withstand extreme weather conditions, resist corrosion, and provide long-lasting structural integrity.

They offer a viable alternative to traditional construction materials like steel or concrete.

Another breakthrough is the introduction of lightweight polymer composites that combine strength with reduced weight. This allows for easier transportation and installation while maintaining structural stability.

These composites can be molded into various shapes and sizes, providing architects with greater design flexibility.

Polymer manufacturers have also focused on enhancing fire resistance properties in their products through advanced formulations. Fire-retardant additives are incorporated into polymers during production to improve their ability to withstand high temperatures without compromising safety standards.

Furthermore, advancements in polymer manufacturing techniques have led to more sustainable options for construction projects. Recycled plastics can now be transformed into durable building materials such as roofing tiles or insulation boards through innovative processes like extrusion molding or injection molding.

Case Studies of Polymer Use in Modern Construction

Let’s take a look at some fascinating case studies that highlight the successful use of polymers in modern construction projects.

One notable example is the Burj Khalifa, the tallest building in the world located in Dubai, United Arab Emirates. The exterior cladding of this iconic structure incorporates polymer-based composite panels.

These panels not only provide excellent insulation but also offer exceptional resistance to extreme weather conditions such as high temperatures and strong winds.

Another remarkable case study is found in Japan’s Kansai International Airport Terminal 2. The roof of this airport terminal features a translucent polymer material called ETFE (ethylene tetrafluoroethylene).

This lightweight yet durable material allows natural light to penetrate through, reducing energy consumption for lighting while creating an aesthetically pleasing environment for travelers.

Polymers have revolutionized bridge construction with examples like Scotland’s Queensferry Crossing over River Forth. Polymer-modified concrete was used extensively during its construction due to its enhanced durability and resistance against harsh environmental factors such as freeze-thaw cycles and chloride ingress from de-icing salts.

These case studies demonstrate how polymer materials are transforming modern construction practices by offering improved performance characteristics compared to traditional building materials.

Cost-Effectiveness of Polymer Materials in Construction

Compared to traditional building materials like concrete or steel, polymers offer several advantages that contribute to overall project savings.

Firstly, polymer-based materials are lightweight, which reduces transportation and installation costs. Their lighter weight makes them easier and faster to handle during construction processes, resulting in reduced labor expenses.

Polymers have excellent durability and resistance properties. They can withstand harsh weather conditions such as extreme temperatures or high humidity without deteriorating quickly.

This longevity translates into lower maintenance costs over time since repairs or replacements are less frequent compared to other materials.

Moreover, the versatility of polymer composites allows for customization according to specific project requirements. Manufacturers can tailor the composition of polymers based on desired characteristics such as strength, flexibility, fire resistance or thermal insulation properties.

This adaptability eliminates waste by ensuring that only necessary amounts of material are used while still meeting performance standards.

Furthermore, polymer-based products often require minimal additional treatments for protection against corrosion or decay compared with traditional alternatives like wood or metal structures. This not only saves money but also reduces environmental impact by minimizing chemical usage during construction processes.

Lastly, the production process for polymer building materials is generally more energy-efficient than manufacturing conventional counterparts. The lower energy consumption contributes positively towards reducing greenhouse gas emissions associated with construction activities while simultaneously lowering production costs.

The cost-effectiveness of using polymer materials in construction is evident through reduced transportation expenses due to their lightweight nature, lower maintenance requirements thanks to their durability and resistance properties, customization options leading to optimized material usage,.

Minimal additional treatments needed for protection against corrosion,.

And a more energy-efficient production process. By choosing these innovative solutions over traditional alternatives when appropriate projects arise,.

Maintenance and Durability of Polymer-Based Structures

Unlike traditional building materials such as wood or concrete, polymers are resistant to rotting, corrosion, and weathering. This means that polymer-based structures require minimal upkeep over their lifespan.

One key advantage of polymer materials is their resistance to moisture damage. Unlike wood that can warp or rot when exposed to water for extended periods, polymers do not absorb moisture and are impervious to mold growth.

This makes them an excellent choice for areas with high humidity levels or frequent rainfall.

Polymers have excellent resistance against UV radiation from the sun’s rays. Traditional building materials like wood can fade and deteriorate under prolonged exposure to sunlight; however, polymer-based structures retain their color vibrancy and structural integrity even after years of exposure.

Furthermore, due to their inherent strength properties combined with advanced manufacturing techniques like reinforced fibers or additives for increased toughness (such as carbon fiber reinforcement), polymer-based structures exhibit impressive durability against impacts and heavy loads compared to other conventional construction materials.

The low-maintenance nature of these structures also translates into cost savings over time since there is no need for regular painting or sealing treatments typically required by other building materials like metal or timber.

Polymer-based buildings provide long-lasting performance without requiring extensive maintenance efforts commonly associated with traditional construction methods.This combination of durability,ease-of-care,and cost-effectiveness has made them increasingly popular in modern architecture.

FAQ

What are polymers as building materials?

Polymers in construction are versatile materials that include varieties like plastics, rubbers, thermoplastic elastomers, adhesives, foams, paints, and sealants, used extensively for their unique mechanical, aesthetic, and thermal properties.

What are 5 examples of polymer materials?

Five examples of polymer materials include synthetic fibers used in clothing, polyethylene cups, nylon bearings, epoxy glue, and Teflon-coated cookware.

What are the advantages of polymer construction?

The advantages of polymer construction include its durability, long-term aging properties, and reduced need for additional resources over its life cycle, with certain polymer-based materials such as PVC pipes showcasing a life cycle substantially longer than general building materials’ 30 to 50 years.

What are polymer materials examples?

Examples of polymer materials include synthetic polymers like nylon, polyethylene, polyester, Teflon, and epoxy, as well as naturally occurring polymers such as silk, wool, DNA, cellulose, and proteins.

How have polymers revolutionized the construction industry?

Polymers have revolutionized the construction industry by offering increased durability and flexibility, aiding in energy efficiency, reducing construction time, and enabling innovation in design aesthetics.

Which properties make polymers suitable for construction purposes?

Polymers are suitable for construction purposes due to their durability, resistance to environmental conditions, light weight, and versatility in molding and design.

How does the application of polymers impact the sustainability of a building project?

The application of polymers enhances the sustainability of a building project by offering improved durability, energy efficiency, and reduced material usage due to their lightweight yet strong properties.

Recap