In this blog post, we explore how biocomposites with polymers are revolutionizing the construction industry by combining natural and synthetic materials for enhanced performance.

These advanced construction materials are made by combining natural fibers like wood or bamboo with synthetic polymers like plastic.

At first glance, it may seem strange to mix these two seemingly opposite materials together. But when you think about it, it makes perfect sense.

Nature has already provided us with strong and durable fibers that have been used for centuries in construction projects. And science has given us polymers that can be molded into any shape we need.

By combining these two materials together, we can create something truly remarkable: a material that is both sustainable and high-performing. Biocomposites with polymers are not only stronger than traditional building materials but also more environmentally friendly.

In this blog post, we’ll explore how biocomposites are made and why they’re such an exciting development in the world of construction.

Biocomposite Basics

Biocomposites with polymers are a relatively new development in the construction industry, but they’re quickly gaining popularity due to their unique properties. These materials are made by combining natural fibers like wood or bamboo with synthetic polymers like plastic.

The result is a material that has the best of both worlds: the strength and durability of natural fibers and the versatility of synthetic polymers.

The process for making biocomposites involves mixing together these two materials using specialized equipment. The natural fibers provide reinforcement while the polymer matrix holds everything together.

This combination results in a material that is lightweight, strong, and resistant to moisture.

One major advantage of biocomposites over traditional building materials is their sustainability factor. Natural fibers can be grown sustainably without depleting resources or harming ecosystems, making them an eco-friendly alternative to other building materials such as concrete or steel.

In addition to being sustainable, biocomposite construction also offers improved insulation properties compared to traditional methods which can lead to lower energy costs over time for homeowners and businesses alike.

As we continue our exploration into this exciting field at the intersection between nature and science it’s clear that there’s much more potential yet untapped when it comes down creating advanced construction solutions through biomimicry – taking inspiration from nature itself!

Polymer Types in Biocomposites

Biocomposites with polymers are a combination of natural fibers and synthetic polymers. But what exactly are these synthetic polymers? There are several types of polymer that can be used in biocomposites, each with its own unique properties.

One common type is polypropylene (PP), which is known for its strength and durability. It’s often used in automotive parts or packaging materials but has also found a place in construction due to its resistance to moisture and chemicals.

Another popular choice is polyethylene (PE), which comes in both high-density (HDPE) and low-density (LDPE) forms. HDPE is commonly used for pipes or containers while LDPE can be found as plastic wrap or bags.

In construction, PE can provide flexibility while still maintaining strength.

Polystyrene (PS) may also be utilized as it’s lightweight yet rigid nature makes it ideal for insulation applications such as foam boards or panels.

These different types of polymer allow manufacturers to tailor their biocomposite material based on the specific needs of their project – whether that means prioritizing strength over flexibility, durability over weight reduction etc. By combining natural fibers with various types of synthetic polymers like PP, PE & PS; we get advanced composite materials that offer superior performance compared to traditional building materials alone.

Biocomposites not only reduce our reliance on non-renewable resources but also help us build more sustainable structures without compromising quality!

Natural Fibers and Fillers

Natural fibers and fillers are the backbone of biocomposites with polymers. These materials come from a variety of sources, including wood, bamboo, hemp, and even coconut husks.

They’re chosen for their strength and durability as well as their sustainability. When I first learned about biocomposites with polymers, I was skeptical about how well natural fibers would hold up in construction projects.

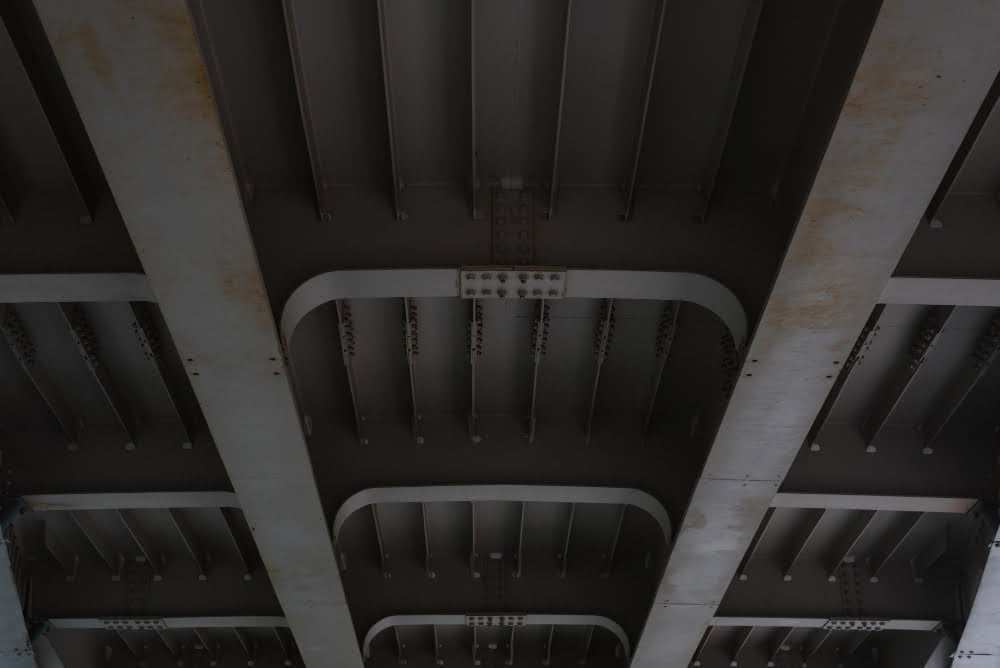

But after seeing them in action firsthand, I was blown away by their performance. One project that stands out to me is a bridge made entirely out of biocomposite materials.

The bridge spans over 100 feet long and can support the weight of multiple cars at once! It’s an incredible feat that wouldn’t have been possible without the use of natural fibers like wood pulp mixed with synthetic resins. But it’s not just bridges where these materials shine; they’re also being used in everything from furniture to flooring to insulation.

And because they’re made from renewable resources instead of non-renewable ones like oil or gas-based plastics – using them helps reduce our carbon footprint while still providing high-quality building materials.

Natural fibers may seem old-fashioned compared to modern synthetic alternatives but when combined with advanced polymer technology – we get something truly remarkable: A sustainable material that performs better than traditional building products while reducing environmental impact!

Processing Techniques

Now that we understand the basics of biocomposites with polymers, let’s dive into the processing techniques used to create these advanced construction materials. There are two main methods: compression molding and extrusion.

Compression molding involves heating a mixture of natural fibers and synthetic polymers until they become pliable. The material is then placed in a mold where it is compressed under high pressure until it takes on the desired shape.

This method is ideal for creating complex shapes or parts with varying thicknesses.

Extrusion, on the other hand, involves melting a mixture of natural fibers and synthetic polymers together before forcing them through an extruder die to create long continuous shapes like pipes or tubes. This method allows for precise control over dimensions and can produce large quantities quickly.

Both methods have their advantages depending on what type of product you’re trying to make. But regardless of which technique you choose, one thing remains constant: biocomposites with polymers are changing the game when it comes to sustainable construction materials.

By using renewable resources like wood or bamboo instead of traditional non-renewable resources like steel or concrete, we can reduce our impact on the environment while still producing strong and durable building materials. It’s exciting to think about how far this technology will go in advancing sustainable architecture – from eco-friendly homes made entirely out of biocomposite panels down to small details such as door handles made from recycled plastic mixed with bamboo fiber!

Mechanical Properties

When it comes to construction materials, strength and durability are key. And biocomposites with polymers deliver on both fronts.

In fact, these advanced materials have been shown to be stronger than traditional building materials like concrete or steel.

The natural fibers used in biocomposites provide a strong foundation for the material, while the synthetic polymers add flexibility and resilience. This combination results in a material that can withstand extreme weather conditions and heavy loads without cracking or breaking.

But it’s not just about strength – biocomposites with polymers also offer other mechanical advantages over traditional building materials. For example, they’re lighter weight than concrete or steel which makes them easier to transport and install on job sites.

Because they’re made from renewable resources like wood or bamboo instead of non-renewable resources like oil (which is used to make plastic), they have a lower carbon footprint overall.

As we continue our exploration of this exciting new development in construction technology, we’ll dive deeper into how these unique properties make biocomposites with polymers an attractive option for builders looking for sustainable yet high-performing solutions.

Environmental Benefits

As we discussed earlier, biocomposites with polymers are a sustainable alternative to traditional building materials. But what exactly makes them so environmentally friendly? Let’s take a closer look.

Firstly, the natural fibers used in biocomposites come from renewable sources like wood or bamboo. This means that they can be replenished over time and won’t deplete our natural resources as quickly as non-renewable materials like steel or concrete.

Secondly, because these materials are made by combining natural fibers with synthetic polymers, they require less energy to produce than traditional building materials. This results in lower greenhouse gas emissions and less pollution overall.

When it comes time to dispose of biocomposite products at the end of their lifespan (which is typically longer than that of traditional building materials), they can often be recycled or even composted instead of ending up in landfills where they would contribute to environmental degradation.

By using biocomposites with polymers for construction projects instead of more conventional options like steel or concrete, we’re not only creating stronger and more durable structures but also doing our part for the environment. It’s truly amazing how nature and science can work together towards a common goal!

Applications in Construction

Biocomposites with polymers have a wide range of applications in the construction industry. They can be used to create everything from building facades and roofing materials to flooring and furniture.

One of the most significant advantages of biocomposites is their strength-to-weight ratio, which makes them ideal for use in high-stress areas like bridges or wind turbines.

But it’s not just their durability that makes biocomposites so appealing; they’re also incredibly versatile when it comes to design. Because they can be molded into any shape, architects and designers have more freedom than ever before when creating structures using these materials.

One example where biocomposite technology has been applied is at The Bullitt Center in Seattle, Washington – a six-story office building designed as one of the greenest commercial buildings on earth. The center features an innovative façade made entirely out of cross-laminated timber (CLT) panels reinforced with fiberglass polymer composite strips that provide additional structural support while maintaining its natural look.

Biocomposite technology has come a long way since its inception, but there’s still much room for growth and innovation within this field. As we continue exploring new ways to combine nature with science through advanced construction materials like these composites, we’ll undoubtedly see even more exciting developments emerge over time!

Recap