Carbon fiber polymer composites are revolutionizing the construction industry. This article explains just why.

As a kid, I loved watching superhero movies and reading comic books. I was always fascinated by the incredible powers and abilities of these characters.

But as I grew older, I realized that real-life superheroes exist too – in the form of engineers and construction workers who build the structures we rely on every day.

One such game-changing technology that has revolutionized modern engineering and construction is carbon fiber polymer composites. These materials are like the Iron Man suit for buildings – they are incredibly strong, lightweight, and flexible, making them ideal for use in a wide range of applications.

In this blog post, we’ll explore how carbon fiber polymer composites work, what makes them so special, and why they’re quickly becoming an essential tool in the construction industry’s arsenal. So buckle up your seatbelts because we’re about to take a deep dive into this amazing technology!

Introduction to Carbon Fiber Composites

Carbon fiber polymer composites are a type of material that has been around for decades but has only recently gained popularity in the construction industry. These materials consist of carbon fibers embedded in a polymer matrix, which gives them their unique properties.

Carbon fibers are incredibly strong and lightweight, making them ideal for use in applications where weight is a concern. The polymer matrix provides flexibility and durability to the composite material, allowing it to withstand stress and strain without breaking or deforming.

Just like Iron Man’s suit allows him to fly through the air effortlessly while protecting him from harm, carbon fiber composites can be used to create structures that are both strong and lightweight. This makes them an excellent choice for building bridges, skyscrapers, airplanes – even spacecraft!

In recent years there has been an increasing demand for sustainable construction practices with reduced environmental impact; this is where carbon fiber polymers come into play as they have low embodied energy compared with traditional materials such as steel or concrete.

So why exactly are these materials considered game-changers? Let’s take a closer look at some of their key benefits!

Properties of Carbon Fiber Polymers

Carbon fiber polymer composites are made up of two main components: carbon fibers and a polymer matrix. The carbon fibers provide the strength, while the polymer matrix acts as a binding agent to hold everything together.

One of the most remarkable properties of these materials is their incredible strength-to-weight ratio. Carbon fiber polymers are up to five times stronger than steel but weigh only about one-third as much.

This makes them ideal for use in applications where weight is a critical factor, such as aerospace engineering or high-performance sports equipment.

But it’s not just their strength that makes carbon fiber polymers so special – they’re also incredibly flexible and resistant to fatigue. Unlike traditional materials like steel or concrete, which can crack under stress over time, carbon fiber polymers can bend and flex without losing their structural integrity.

All these properties make them an excellent choice for modern engineering and construction projects where durability, flexibility, lightweight design matter most. Carbon Fiber Polymer Composites have become game-changers in modern construction technology because they offer unique advantages over traditional building materials like wood or concrete; They’re lighter yet stronger with greater resistance against wear-and-tear from weather elements such as windstorms and earthquakes!

Manufacturing Techniques

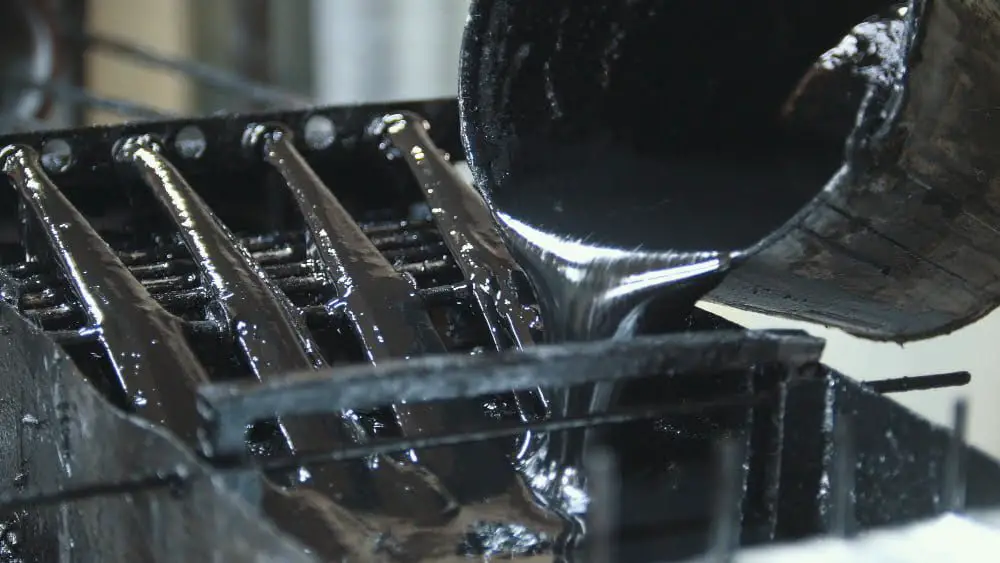

To create carbon fiber polymer composites, manufacturers use a variety of techniques. One common method is called filament winding, where continuous strands of carbon fibers are wound around a mandrel in a specific pattern.

The mandrel is then coated with resin and cured to form the final composite structure.

Another technique used in manufacturing these composites is called pultrusion. In this process, continuous fibers are pulled through a bath of liquid resin and then passed through heated dies that shape the material into its final form.

These manufacturing techniques require precision and expertise to ensure that the resulting composite materials meet strict quality standards for strength, durability, and flexibility.

As we can see from these examples alone – creating carbon fiber polymer composites requires advanced technology coupled with skilled craftsmanship. It’s no wonder why engineers have been so excited about this game-changing material!

Aerospace Applications

While carbon fiber polymer composites have become increasingly popular in the construction industry, their use is not limited to buildings and infrastructure. In fact, one of the earliest adopters of this technology was the aerospace industry.

Just like how Iron Man’s suit allows him to fly through the air with ease, carbon fiber polymer composites have enabled aircraft manufacturers to create planes that are lighter and more fuel-efficient than ever before. By replacing traditional metal components with these advanced materials, engineers can reduce an airplane’s weight by up to 20%, resulting in significant cost savings over its lifetime.

But it’s not just about saving money – using carbon fiber polymer composites also improves safety. These materials are incredibly strong and durable, making them ideal for use in critical parts such as wings or fuselage sections.

Plus, they’re resistant to corrosion and fatigue damage caused by repeated stress cycles – a common problem faced by metal components.

In short: just like how superheroes need their suits made from special materials that enhance their abilities while keeping them safe from harm; airplanes too require advanced technologies such as carbon fiber polymer composites for better performance while ensuring passenger safety at all times!

Automotive Industry Advancements

Carbon fiber polymer composites have been a game-changer in many industries, including the automotive industry. In recent years, car manufacturers have started using carbon fiber reinforced polymers (CFRPs) to make their vehicles lighter and more fuel-efficient.

One example of this is BMW’s i3 electric car. The i3 features a passenger cell made entirely out of CFRP, making it one of the lightest cars on the market.

This not only improves its energy efficiency but also makes it more agile and easier to handle.

Similarly, McLaren Automotive has used carbon fiber extensively in its supercars for over 30 years now. Their latest model – McLaren Artura – uses an all-new lightweight architecture that combines aluminum with high-strength carbon fiber composites to achieve exceptional performance while reducing weight by up to 110 pounds compared with previous models.

The use of CFRPs has allowed automakers like BMW and McLaren Automotive to push boundaries when designing their vehicles without compromising safety or performance standards. As we continue exploring how these materials are transforming modern engineering and construction across various industries let’s take a closer look at some other exciting applications!

Civil Engineering Innovations

Civil engineering has come a long way since the days of building structures with stone and mortar. Today, engineers are using cutting-edge materials like carbon fiber polymer composites to create buildings that are stronger, more durable, and more efficient than ever before.

One of the most exciting innovations in civil engineering is the use of these composites in bridge construction. Bridges have always been a challenging feat for engineers due to their size and weight requirements.

However, carbon fiber polymer composites offer an excellent solution as they can be molded into any shape or size while still maintaining their strength.

In fact, one such example is Japan’s Kurushima-Kaikyo Bridge – one of the longest suspension bridges globally – which was constructed using carbon fiber-reinforced plastic cables instead of traditional steel cables. This innovative approach reduced both cost and weight by 80%, making it possible to build longer spans without sacrificing structural integrity.

As we continue exploring this game-changing technology throughout this article series on Carbon Fiber Polymer Composites: The Game Changer in Modern Engineering and Construction”, you’ll discover how these materials are transforming various aspects within civil engineering from skyscrapers’ design to earthquake-resistant buildings!

Sports Equipment Revolution

Carbon fiber polymer composites have been a game-changer in many industries, including sports equipment. Just like how Iron Man’s suit gives him an edge over his enemies, carbon fiber has given athletes an advantage over their competitors.

In the early 1990s, tennis players started using rackets made of carbon fiber instead of wood or aluminum. The new material allowed for larger racket heads and lighter weights without sacrificing strength or stiffness.

This resulted in faster swings and more powerful shots.

Similarly, golfers began using clubs with carbon-fiber shafts that were stronger than steel but weighed less than half as much. This allowed them to swing faster and hit the ball farther with greater accuracy.

Carbon-fiber helmets are also becoming increasingly popular among professional cyclists due to their lightweight yet durable construction that provides superior protection against head injuries during crashes.

The use of these materials is not limited to just tennis rackets or cycling helmets; they can be found in everything from hockey sticks to skis and snowboards too! Carbon Fiber Polymer Composites have revolutionized sports equipment by making it lighter yet stronger – giving athletes a competitive edge on the field while reducing fatigue caused by heavy gear off-field!

Environmental Impact and Sustainability

While carbon fiber polymer composites are undoubtedly a game-changer in modern engineering and construction, it’s essential to consider their environmental impact and sustainability. As we become more aware of the need to reduce our carbon footprint, it’s crucial that we choose materials that are eco-friendly.

Fortunately, carbon fiber polymer composites have several sustainable advantages over traditional building materials. For one thing, they’re incredibly lightweight compared to steel or concrete.

This means less energy is required for transportation and installation – reducing fuel consumption during transport.

Moreover, these composite materials can be recycled at the end of their lifespan instead of ending up in landfills like other non-recyclable products such as plastics or metals. Recycling them reduces waste production while also conserving resources by reusing existing material rather than extracting new ones from nature.

Carbon Fiber Polymer Composites not only provide strength but also offer an environmentally friendly solution for modern engineering and construction needs- making them a win-win choice!

Challenges and Limitations

While carbon fiber polymer composites are undoubtedly a game-changer in modern engineering and construction, they do come with their fair share of challenges and limitations. One significant challenge is the high cost associated with producing these materials.

Carbon fibers themselves are expensive to manufacture, and the process of weaving them into a composite material can be time-consuming and labor-intensive.

Another limitation is that carbon fiber polymer composites have limited resistance to impact damage compared to traditional building materials like concrete or steel. This means that structures made entirely out of these materials may not be suitable for certain applications where impact resistance is critical.

Despite these challenges, engineers continue to push the boundaries of what’s possible with carbon fiber polymer composites by developing new manufacturing techniques that reduce costs while improving performance characteristics such as impact resistance.

While there are still some hurdles to overcome when it comes to using carbon fiber polymer composites in construction projects fully, it’s clear that this technology has enormous potential for revolutionizing how we build our world.

As engineers continue refining their methods for working with this incredible material, we can expect even more exciting breakthroughs on the horizon – just like Tony Stark continually upgraded his Iron Man suit!

Future Prospects

Looking ahead, the future prospects for carbon fiber polymer composites in engineering and construction are incredibly promising. As research continues to advance, we can expect to see even more innovative uses of these materials.

For example, scientists are currently exploring ways to incorporate self-healing properties into carbon fiber polymer composites. This would allow structures made from these materials to repair themselves when damaged – just like how Wolverine’s healing factor allows him to recover from injuries quickly.

Researchers are investigating how carbon fiber polymer composites could be used in 3D printing technology. By combining the strength and flexibility of these materials with the precision of 3D printing techniques, engineers could create complex structures that were previously impossible or impractical using traditional building methods.

It’s clear that carbon fiber polymer composites have already had a significant impact on modern engineering and construction – but their potential is far from fully realized. As new applications continue to emerge and existing technologies improve further still; we can look forward with excitement at what this game-changing material will bring next!

Recap