Learn more about polymer and its unique structural properties in this post. Read about how they degrade over time due to several factors.

Polymers have unique structural properties due to their long chains of repeating units. They are typically lightweight, flexible, and have high strength-to-weight ratios.

Additionally, polymers can be engineered to have specific properties such as thermal stability or impact resistance by adjusting the chemical composition and processing conditions during production. However, polymers can also degrade over time due to exposure to heat, light, and chemicals.

As a kid, I loved playing with Legos. I could spend hours building different structures, from towering skyscrapers to intricate castles.

But as I grew older and learned more about the materials used in construction, my fascination shifted towards the properties of polymers.

Polymers are a type of material that can be found in everything from plastic water bottles to car parts. They have unique structural properties that make them ideal for a range of applications.

In this article, we’ll dive into what makes polymers so special and explore their role in the construction industry. So sit back, grab your hard hat, and let’s get started!

Introduction to Polymers

Polymers are a type of material that consists of long chains of repeating units. These chains can be made up of various types of molecules, including plastics, rubber, and even DNA.

The unique structure and properties make polymers incredibly versatile materials with applications in many industries.

As I continued to explore the world around me as an adult, I found myself drawn to the construction industry. It was fascinating to see how different materials were used together to create structures that could withstand extreme weather conditions or support massive amounts of weight.

But what about polymers? How do they fit into this picture? As it turns out, polymers have become increasingly important in construction due to their unique structural properties. In this article, we’ll take a closer look at these properties and explore some examples where they’re being used today.

Polymer Classification

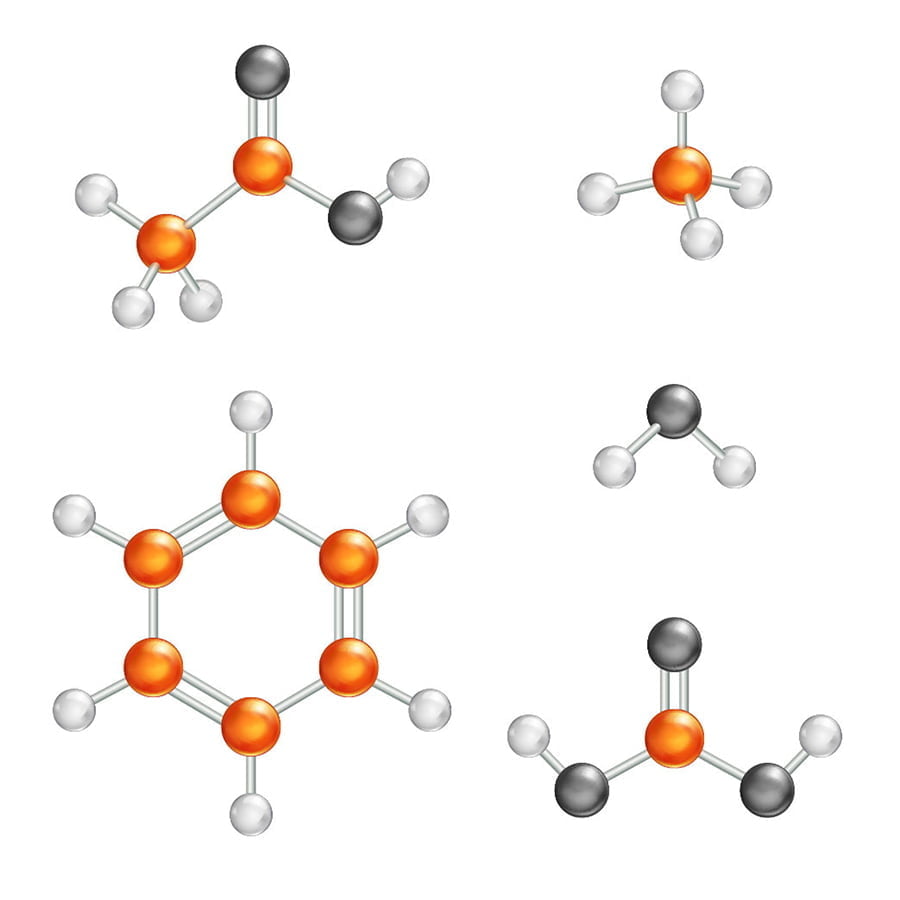

Before we dive into the structural properties of polymers, let’s first understand what they are. Polymers are large molecules made up of repeating units called monomers.

These monomers can be natural or synthetic and can vary in size and shape.

Polymers can be classified based on their structure, which affects their physical and chemical properties. For example, some polymers have a linear structure with straight chains of monomers while others have a branched or cross-linked structure that gives them more rigidity.

As I continued to learn about polymer classification, I couldn’t help but think back to my childhood love for Legos. Just as each Lego piece has its unique shape and function in building structures, each type of polymer has its own set of characteristics that make it suitable for different applications.

In the construction industry specifically, understanding these classifications is crucial when selecting materials for various projects such as roofing systems or insulation materials. By choosing the right type of polymer with specific structural properties suited to your needs you ensure durability over time while also reducing costs associated with maintenance down the line.

Molecular Structure of Polymers

To understand the structural properties of polymers, we first need to take a closer look at their molecular structure. Polymers are made up of long chains of repeating units called monomers.

These chains can be linear or branched, and the way they are arranged affects the material’s overall properties.

As I continued my exploration into polymers, I learned that their unique molecular structure gives them some impressive characteristics. For example, some types of polymers have high tensile strength and can withstand significant amounts of stress without breaking or deforming.

But it’s not just about strength – different arrangements in polymer structures also affect other important factors like flexibility and durability. By understanding these structural properties on a molecular level, engineers can design materials with specific qualities tailored to meet various needs in construction projects.

In fact, many modern building materials rely heavily on polymer technology for everything from insulation to roofing membranes. As our understanding continues to grow alongside advancements in manufacturing techniques for these versatile materials – who knows what kind of innovative applications we’ll see next!

Mechanical Properties

When it comes to construction, one of the most important aspects is ensuring that materials have the necessary mechanical properties to withstand various loads and stresses. Polymers are no exception.

One of the key mechanical properties of polymers is their strength. This refers to a material’s ability to resist deformation or failure under stress.

In general, polymers tend to be less strong than metals or ceramics but can still exhibit impressive strength when designed correctly.

Another important property is stiffness, which describes how much a material will deform under load. Polymers can range from very flexible (like rubber) to extremely stiff (like some types of plastic).

The stiffness required for a particular application depends on factors such as load requirements and environmental conditions.

Toughness refers not only to how much energy it takes for a polymer sample to break but also its ability to absorb energy before breaking completely apart; this makes them ideal in applications where impact resistance matters like car bumpers or helmets.

Understanding these mechanical properties helps engineers design structures that are safe and reliable while taking advantage of all the benefits that polymers offer over other materials in terms of cost-effectiveness and versatility – just like building with Legos!

Thermal Behavior

As I continued to explore the world of polymers, one property that caught my attention was their thermal behavior. Polymers have a unique ability to withstand extreme temperatures without losing their structural integrity.

This makes them ideal for use in applications where temperature fluctuations are common, such as automotive parts or electronic devices.

One factor that contributes to this thermal stability is the molecular structure of polymers. Unlike metals and other materials, which have a crystalline structure at the atomic level, polymers have long chains of repeating units called monomers.

These chains can be arranged in different ways depending on the type of polymer and its intended application.

Another important factor is cross-linking – when two or more polymer chains are chemically bonded together – which can increase a material’s resistance to heat deformation even further.

Understanding how polymers behave under different temperature conditions is crucial for selecting appropriate materials for specific applications in construction and engineering industries.

With their unique properties like thermal stability combined with versatility and durability make them an increasingly popular choice among engineers today!

Chemical Resistance

One of the most impressive properties of polymers is their chemical resistance. As a kid, I remember accidentally spilling nail polish remover on my plastic toy car and watching in horror as it melted before my eyes.

But not all polymers are created equal, and some have an incredible ability to withstand exposure to harsh chemicals.

In construction, this property is particularly important when considering materials for pipes or tanks that will be used to transport or store corrosive substances. Polymers such as polyethylene (PE) and polypropylene (PP) are commonly used due to their excellent chemical resistance.

But how do these materials resist degradation from chemicals? It all comes down to the molecular structure of the polymer chains. The long chains that make up a polymer can either be linear or branched, with different types offering varying degrees of chemical resistance.

Linear polymers have fewer side branches than branched ones, making them more tightly packed together and less likely for molecules from other substances like solvents or acids penetrate between them causing damage over time.

Understanding the structural properties of polymers can help us choose better materials for construction projects based on specific needs such as durability against certain environmental factors like heat exposure or corrosion caused by contact with acidic solutions – just like choosing which Lego pieces would work best for building your dream castle!

Electrical Properties

As I continued to explore the world of polymers, one property that particularly caught my attention was their electrical properties. Polymers can be either conductive or insulating, depending on their molecular structure and composition.

Conductive polymers have a unique ability to conduct electricity while still maintaining flexibility and durability. This makes them ideal for use in electronic devices such as sensors, solar cells, and batteries.

On the other hand, insulating polymers are used to protect electrical components from damage caused by exposure to moisture or other environmental factors. They also play a crucial role in preventing electric shocks by acting as an insulator between live wires and human contact.

Understanding the electrical properties of different types of polymers is essential for selecting materials that will perform optimally in specific applications within construction projects. From wiring systems to lighting fixtures – these versatile materials continue proving themselves useful across various industries!

Optical Characteristics

In addition to their mechanical properties, polymers also have unique optical characteristics. Some polymers are transparent, while others can be made opaque or translucent through the addition of pigments or other additives.

As I continued my exploration of polymer properties, I was fascinated by how these materials could be used in construction to create visually stunning structures. For example, some architects use transparent polymer panels as a way to let natural light into buildings while still maintaining energy efficiency.

Polymers can also be molded into intricate shapes and designs that would not be possible with traditional building materials like wood or metal. This allows for greater creativity and flexibility in design.

However, it’s important to note that the optical characteristics of polymers can change over time due to exposure to UV radiation and other environmental factors. As such, proper maintenance is crucial for ensuring the longevity and aesthetic appeal of polymer-based structures.

Understanding the optical properties of polymers is just one piece of the puzzle when it comes to utilizing these versatile materials in construction projects.

By combining their unique structural and visual qualities with careful planning and maintenance practices we can create truly remarkable buildings that stand out both functionally as well as aesthetically from those built using more traditional methods!

Recap