Discover the basics of polymer chains and their pivotal role in modern construction materials.

Key takeaways:

- Polymer chains are made up of repeating units called monomers.

- Polymerization can occur through addition or condensation reactions.

- Polymer chain structure can be linear, branched, or cross-linked.

- Polymer properties include strength, flexibility, thermal resistance, chemical resistance, and insulation.

- Polymers have various construction applications such as concrete reinforcement, insulation, waterproofing, adhesives, coatings, flooring, roofing, and piping.

What You Will Learn

Etymology

The term “polymer” originates from two Greek words: “poly,” meaning “many,” and “meros,” which translates to “parts” or “units.” Each polymer is made up of many repeating units known as monomers, which are the building blocks that join together to form these long and intricate chains.

Picture it like a train, where each car is a monomer and the entire train represents a polymer chain. This provides a clue as to how polymers can have such diverse properties – the nature of the monomers and the way they link together determines the characteristics of the resulting polymer.

Synthesis

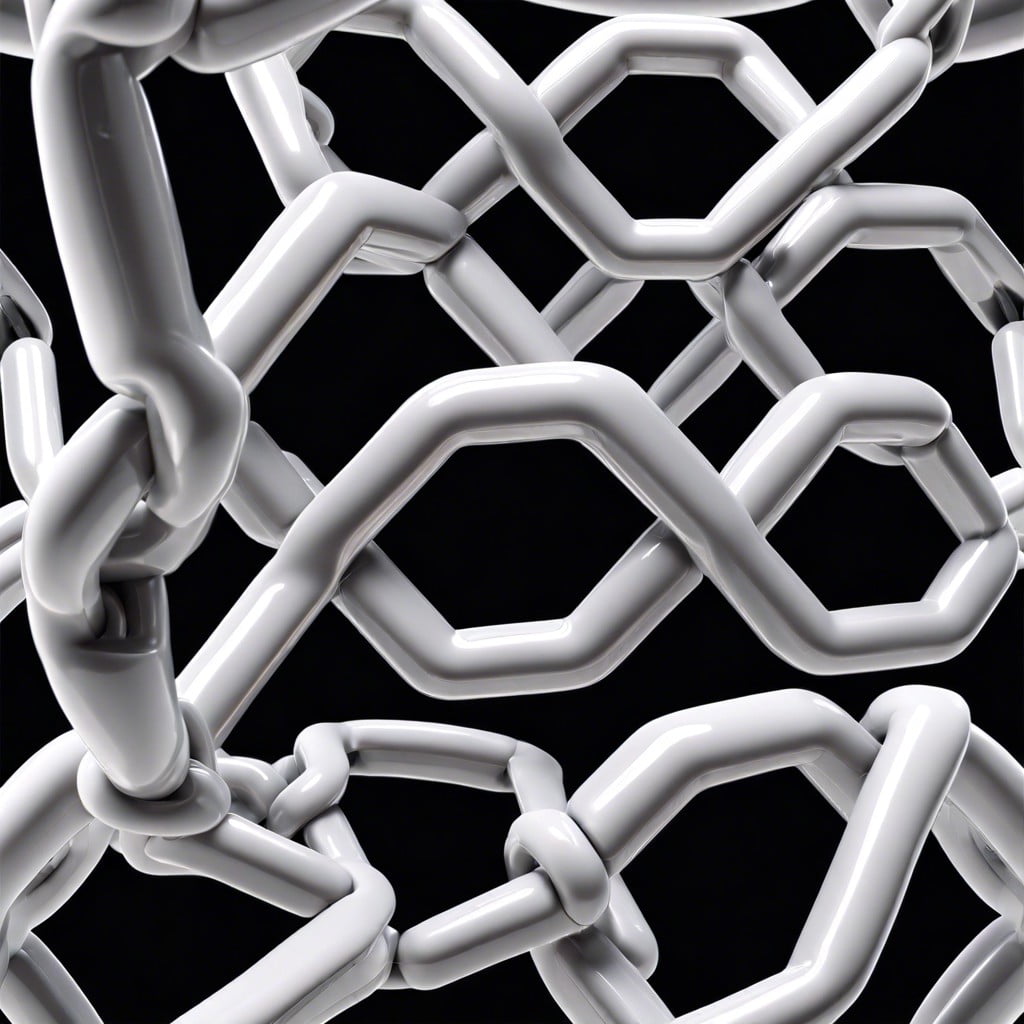

Polymers are born from a process called polymerization, where small molecules named monomers link together like chain links to form long chains. Two main types of polymerization exist: addition polymerization and condensation polymerization.

– Addition polymerization occurs when monomers add to each other without losing any atoms. Imagine a line of people holding hands, each person representing a monomer; as more people join hands, the chain gets longer.

– Condensation polymerization involves the loss of small molecules such as water when monomers bond together. Think of this like building a structure with toy blocks, but with each connection, a piece falls off, signifying the loss of water or another molecule.

These reactions can be controlled to tailor the polymer’s properties, such as strength or flexibility, making polymers incredibly versatile for construction and other industries. Initiators and catalysts often help kick-start and guide these polymerization processes, ensuring consistency and quality in the resulting polymer chains.

Structure

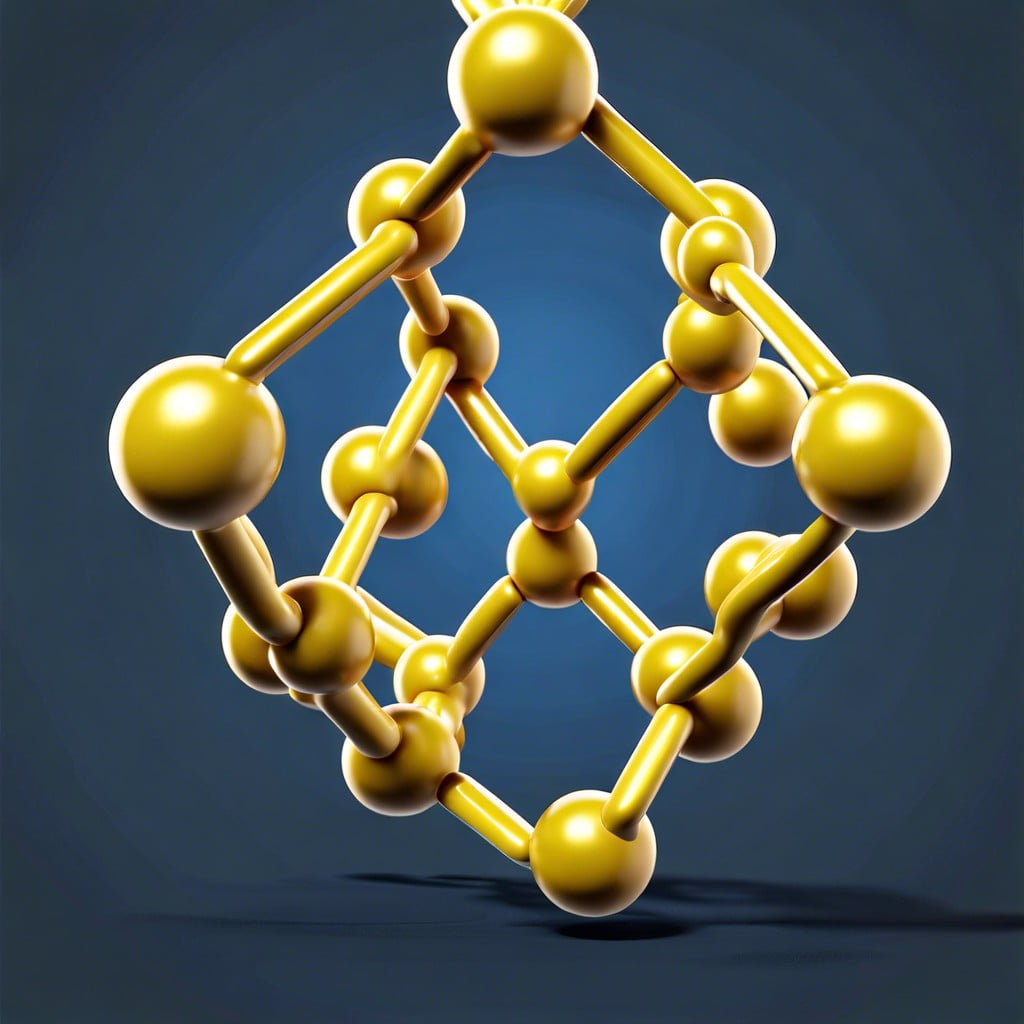

Polymer chains are composed of repeating units called monomers, which link together like a chain of train carriages. The structure can be linear, with a straight sequence, branched, where side-chains are attached to the main chain, or cross-linked, where chains are interconnected forming a three-dimensional network. The arrangement of these monomers can be random, alternating, block, or graft, leading to different material characteristics. Molecular weight, the total mass of the monomers within a chain, also influences properties like strength and melting point. Understanding this intricate architecture helps engineers tailor polymers for specific construction tasks.

Properties

Polymers exhibit a diverse array of characteristics due to the variations in their molecular makeup. Imagine a polymer chain as a train with many cars — the properties of the train change depending on the type of cars and their arrangement.

1. Strength and Durability: Longer polymer chains often result in materials with greater strength and durability. Strong intermolecular forces, such as those in nylon, lead to a sturdy and resistant material.

2. Flexibility: The flexibility of polymers like rubber is due to the long chains that can move around and adjust without breaking. This is likened to a series of interconnected springs that can stretch and rebound.

3. Thermal Properties: Polymers can be engineered to withstand high temperatures, as seen in heat-resistant plastics, or to melt at low temperatures, facilitating their molding and shaping.

4. Chemical Resistance: Some polymers are resistant to chemicals, making them ideal for containers and coatings. The specific arrangement of atoms in the chain provides defense against corrosive substances.

5. Insulation: Electrical insulation is a key trait for polymers used in electronics. Polymer chains don’t conduct electricity, which makes them perfect for safeguarding electrical components.

6. Optical Properties: Certain polymers can be made transparent or tailored to filter specific wavelengths of light, much like a pair of sunglasses that filters out UV rays.

Understanding these properties is vital to selecting the appropriate polymer for a specific application in construction, ensuring materials perform as expected in different environments and uses.

Applications

Polymers have revolutionized the construction industry by bringing in materials with unique characteristics that benefit various applications:

- Concrete Reinforcement: Synthetic fibers, such as polypropylene, are used to reinforce concrete, reducing cracking and increasing its tensile strength.

- Insulation: Foam polymers, such as expanded polystyrene (EPS) and polyurethane foam, offer exceptional thermal insulation in buildings, improving energy efficiency.

- Waterproofing: Liquid polymer membranes provide a seamless barrier against moisture penetration, protecting structures from water damage.

- Adhesives and Sealants: Polymer-based adhesives and sealants, such as epoxy and silicone, bond materials together and seal joints, enhancing the structural integrity and air-tightness of buildings.

- Paints and Coatings: Polymers like acrylic and vinyl serve as bases for paints and coatings, delivering durable and aesthetically pleasing finishes that withstand environmental factors.

- Flooring Systems: Durable polymer composites are used in flooring, providing resistance to wear and chemical spills while being easy to maintain.

- Roofing Materials: Thermoplastic polyolefin (TPO) and polyvinyl chloride (PVC) are used in roofing membranes for their longevity and resistance to UV light and harsh weather conditions.

- Piping and Plumbing: Polyvinyl chloride (PVC) and polyethylene pipes are lightweight, corrosion-resistant, and easy to install, making them ideal for plumbing applications.

Through these applications, polymers play an indispensable role in enhancing the functionality, durability, and sustainability of construction projects.

Related reading: