Learn how to achieve success in polymer composite manufacturing by mastering construction techniques and technologies with our informative yet easy-to-understand guide.

As a kid, I used to love playing with Legos. Building towering structures and intricate designs was my favorite pastime.

And now, as an expert in the construction industry, I realize that my love for building and creating has only grown stronger over time.

One of the most exciting advancements in construction technology is the use of polymer composites. These materials are incredibly versatile and can be used to create everything from durable bridges to sleek architectural designs.

But mastering polymer composite manufacturing techniques is no easy feat. It requires a deep understanding of complex technologies and processes that can seem overwhelming at first glance.

That’s why I’m excited to share my knowledge with you today. In this blog post, we’ll explore everything you need to know about polymer composite manufacturing in the construction industry.

From understanding the benefits of these materials to mastering key techniques for success, we’ll cover it all.

So sit back, grab your hard hat (metaphorically speaking), and let’s dive into the world of polymer composite manufacturing together!

Polymer Composite Basics

Before we dive into the nitty-gritty of polymer composite manufacturing, let’s start with the basics. Polymer composites are materials made up of two or more constituent parts that work together to create a stronger and more durable material than each individual part could on its own.

In construction, these materials are often used as an alternative to traditional building materials like concrete and steel. They offer several benefits such as being lightweight yet strong, corrosion-resistant, and easy to mold into complex shapes.

But mastering polymer composite manufacturing techniques requires a deep understanding of both the constituent parts that make up these materials and how they interact during production. It can be overwhelming at first glance but fear not! With some guidance from experts in this field (like myself), you’ll soon be able to master these techniques for success in your construction projects.

So whether you’re looking to build bridges or architectural designs that stand out from the crowd – stay tuned because we’ve got everything you need right here!

Construction Techniques

When it comes to polymer composite manufacturing, understanding the construction techniques is crucial for success. These materials are incredibly versatile and can be used in a variety of applications, from building bridges to creating architectural designs.

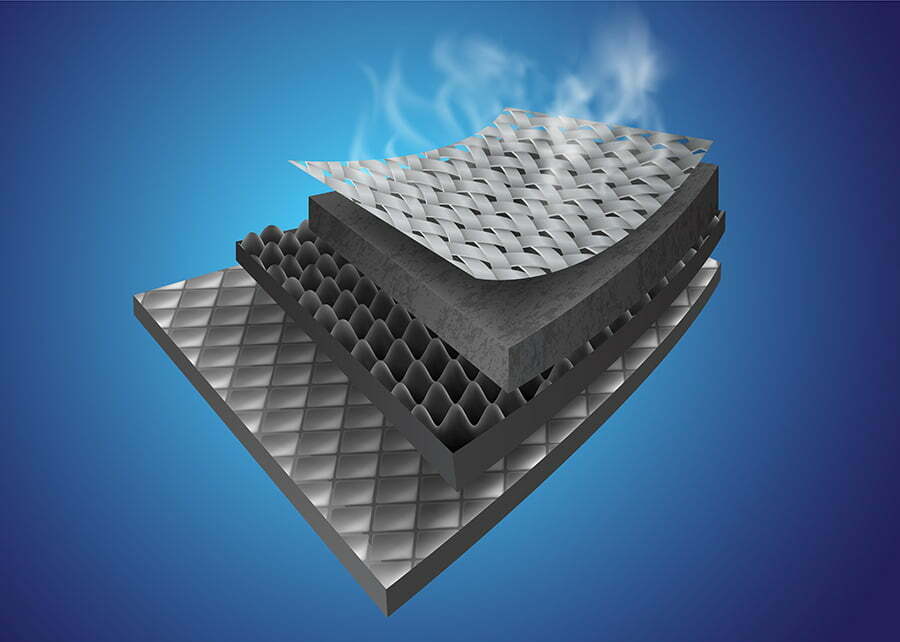

One of the most important techniques in polymer composite manufacturing is layering. This involves stacking layers of material on top of each other until you achieve the desired thickness or strength.

The layers are typically made up of a combination of fibers and resin that work together to create a strong, durable structure.

Another key technique is molding. This involves shaping the material into specific forms using molds or templates.

Molding allows for precise control over shape and size, making it ideal for creating complex structures like curved panels or intricate designs.

But mastering these construction techniques requires more than just technical knowledge – it also takes creativity and innovation. As with any form of artistry, there’s always room for experimentation when working with polymer composites.

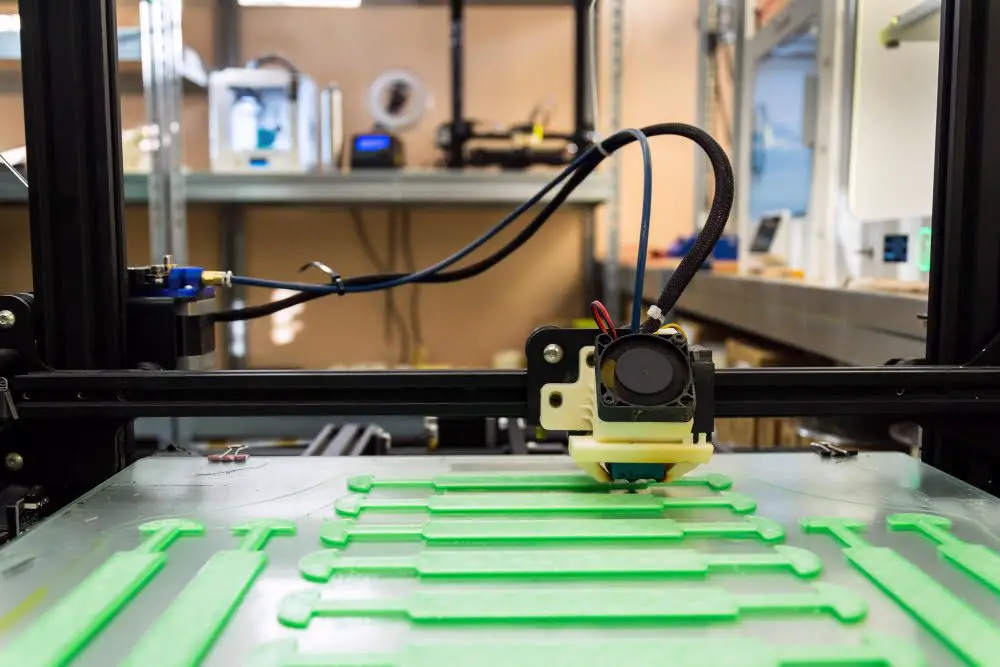

By combining different materials or trying out new methods like 3D printing technology we can push boundaries even further. Innovation coupled with expertise will lead us towards achieving greater heights in this field!

Advanced Technologies

As I mentioned earlier, polymer composites are incredibly versatile materials that have revolutionized the construction industry. But what makes them so special? The answer lies in their advanced technologies.

Polymer composite manufacturing involves combining two or more materials to create a new material with enhanced properties. These materials can be tailored to meet specific needs, such as increased strength or durability.

One of the most exciting advancements in polymer composite technology is 3D printing. This process allows for complex shapes and designs to be created quickly and efficiently, reducing waste and increasing precision.

Another key technology is nanotechnology, which involves manipulating particles at the molecular level. By incorporating nanoparticles into polymer composites, manufacturers can enhance their mechanical properties even further.

But mastering these advanced technologies requires expertise and experience. That’s why it’s important for construction professionals to work with experienced manufacturers who understand how these techniques can benefit their projects.

Understanding advanced technologies like 3D printing and nanotechnology is crucial for success in modern-day construction using polymer composites. With this knowledge under your belt (and a little bit of creativity), you’ll be able to take on any project with confidence!

Material Selection

When it comes to polymer composite manufacturing, material selection is a critical factor in achieving success. With so many different types of composites available on the market, choosing the right one for your project can be overwhelming.

As I mentioned earlier, polymer composites are incredibly versatile and can be used for a wide range of applications. However, not all composites are created equal.

Some may offer better strength or durability than others depending on their composition and intended use.

That’s why it’s important to work with an experienced team that understands how to select the right materials for each project. By taking into account factors such as load capacity requirements, environmental conditions and budget constraints – we can help ensure that you get the best possible results from your investment in polymer composite technology.

Process Optimization

As we discussed earlier, polymer composite manufacturing is a complex process that requires a deep understanding of various technologies and techniques. One key aspect of this process is optimization.

Process optimization involves identifying areas where improvements can be made to increase efficiency, reduce costs, and improve the overall quality of the final product. This can involve everything from streamlining production processes to implementing new technologies or materials.

In the construction industry, optimizing polymer composite manufacturing processes is essential for success. By improving efficiency and reducing waste during production, companies can save time and money while also delivering high-quality products that meet customer demands.

But achieving optimal results in polymer composite manufacturing isn’t always easy. It requires careful planning and execution at every stage of the process – from material selection to final finishing touches.

Fortunately, there are many tools available today that make it easier than ever before to optimize these processes effectively. From advanced software programs designed specifically for construction professionals to cutting-edge equipment like 3D printers capable of producing highly detailed prototypes quickly – there’s no shortage of options when it comes to optimizing your workflow in this field.

By mastering these techniques for success in polymer composite manufacturing through effective process optimization strategies you will be able not only deliver better products but also stay ahead in an increasingly competitive market!

Quality Control

As we discussed earlier, polymer composite manufacturing is a complex process that requires careful attention to detail. One of the most critical aspects of this process is quality control.

In the construction industry, quality control ensures that every product meets or exceeds specific standards and requirements. This includes everything from ensuring proper mixing ratios to verifying structural integrity.

When it comes to polymer composites, there are several key factors that must be considered during the quality control process. For example, manufacturers must ensure that each batch has consistent properties such as strength and durability.

As an expert in the construction industry with years of experience under my belt, I know firsthand how important it is for companies to prioritize quality control measures when working with these materials. By doing so, they can guarantee their products meet high standards while also minimizing waste and reducing costs over time.

So if you’re looking to master polymer composite manufacturing techniques for success in your business or project endeavors – don’t overlook this crucial aspect! Quality should always come first when striving towards excellence in any field – especially one as intricate as construction technology!

Structural Analysis

As we discussed in the introduction, polymer composites are a game-changer in the construction industry. But to truly master their use, it’s essential to understand how they behave under different loads and stresses.

This is where structural analysis comes into play.

Structural analysis involves using mathematical models and simulations to predict how a structure will perform under various conditions. In the case of polymer composites, this can help engineers determine which materials and techniques will be most effective for a given project.

For example, let’s say you’re designing a pedestrian bridge made from polymer composite materials. By conducting structural analysis on your design, you can identify potential weak points or areas that may require additional reinforcement before construction begins.

This type of analysis not only helps ensure safety but also saves time and money by identifying issues early on in the design process rather than during construction or after completion when changes are much more difficult (and expensive) to make.

In short: mastering structural analysis is crucial for success when working with polymer composites in construction projects. It allows us as engineers and builders to create structures that are both safe and efficient while taking full advantage of all that these innovative materials have to offer!

Recap