Learn how fire-resistant polymer additives enhance the performance and safety of construction materials in this informative article.

Fire-resistant polymer additives innovative materials can slow down or even stop the spread of fire, giving people more time to escape and firefighters more time to put out the flames.

In this article, we’ll dive deeper into what these additives are and how they work. We’ll also look at some examples of how they are being used in real-world construction projects today.

So let’s get started!

Fire-Resistant Polymers: An Overview

Fire-resistant polymers are a type of material that has been specifically designed to withstand high temperatures and prevent the spread of fire. They are made by adding special additives to traditional polymer materials, such as plastics or rubbers.

These additives work by creating a barrier between the heat source and the rest of the material, slowing down or even stopping combustion.

Many building codes now require certain structures – particularly those with high occupancy rates like hospitals and schools – be constructed using fire-resistant polymers.

The use of these materials can make all the difference in an emergency situation where every second counts. By slowing down or preventing fires from spreading throughout a building’s structure, they give occupants more time to evacuate safely while also making it easier for firefighters to contain any flames that do occur.

It’s exciting news for anyone who cares about safety in construction projects!

Types of Polymer Additives

There are several types of polymer additives that can be used to make construction materials more fire-resistant. One common type is intumescent additives, which expand when exposed to heat and form a protective layer over the material.

Another type is halogenated flame retardants, which release chemicals that extinguish flames.

But why stop at just one type of additive? By combining different types of polymer additives, manufacturers can create materials with even greater fire resistance and performance capabilities.

Going back to our earlier scenario: imagine if the building had been constructed using a combination of intumescent and halogenated flame retardant additives. The result would have been an even stronger defense against fires, potentially saving more lives in the process.

It’s clear that these innovative polymer additives have immense potential for boosting safety in construction projects. But how exactly do they work? Let’s take a closer look at their mechanisms next.

Enhancing Performance in Construction Materials

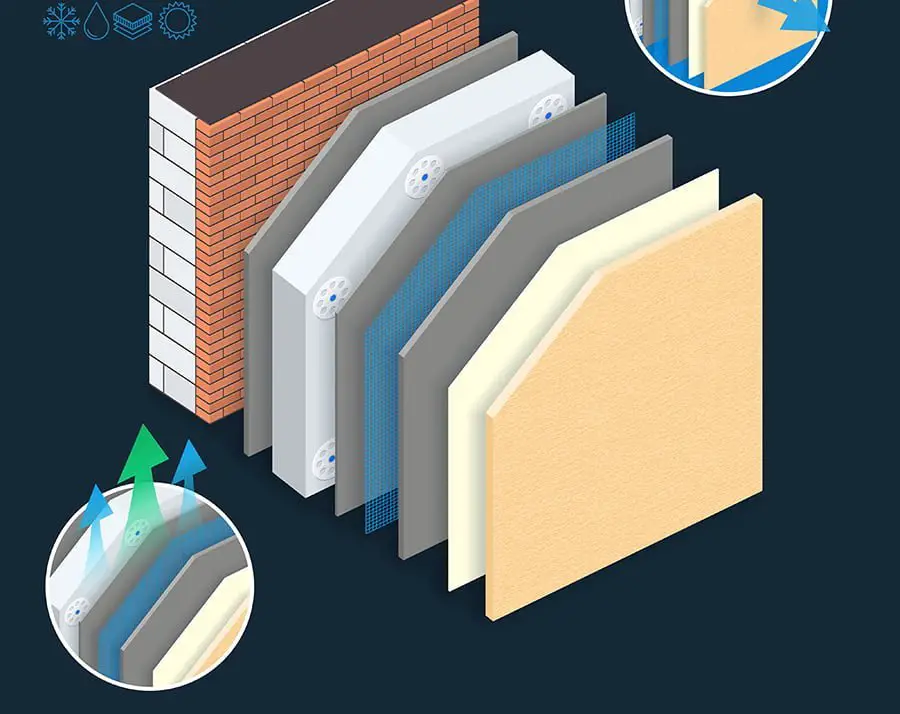

In addition to improving safety, fire-resistant polymer additives can also enhance the performance of construction materials. These additives are designed to be mixed into various building materials such as concrete, drywall, and insulation.

They work by creating a barrier that prevents flames from spreading and reduces smoke production.

This is achieved through a combination of chemical reactions that occur when the material is exposed to heat or flame. The polymer additive releases water vapor which cools down the surface temperature of the material and creates an insulating layer between it and any potential source of ignition.

By enhancing performance in this way, these innovative additives can help extend the lifespan of buildings while reducing maintenance costs over time.

Going back to our earlier scenario – imagine if firefighters had been able to contain that office building fire more quickly because its walls were made with fire-resistant polymers? Not only would lives have been saved but there would have been less damage done overall thanks in part due to enhanced performance capabilities provided by these advanced construction materials.

Fire-resistant polymer additives not only improve safety but also enhance overall performance for construction projects big or small!

Improving Safety With Fire Resistance

When it comes to building safety, fire resistance is a critical factor that cannot be overlooked. Fires can start for many reasons, and once they do, they can spread quickly through a building’s structure.

This is where fire-resistant polymer additives come in. These innovative materials are designed to improve the performance and safety of construction materials by making them more resistant to flames and heat.

By adding these additives into various construction products such as insulation foam or roofing membranes, we can significantly reduce the risk of fires spreading throughout buildings. In our earlier scenario where an office building caught on fire with people trapped inside.

If this same building had been constructed using these polymer additives in its insulation foam or other components like roofing membranes then there would have been less damage caused by the flames which could have saved lives too.

The use of these advanced technologies not only improves overall safety but also helps builders meet increasingly stringent regulations around fire protection standards set forth by local authorities.

Applications in the Building Industry

Fire-resistant polymer additives are becoming increasingly popular in the building industry due to their ability to enhance safety and performance. These additives can be incorporated into a wide range of construction materials, including insulation, roofing, flooring, and even structural components like beams and columns.

In fact, many architects and builders are now specifying fire-resistant polymer additives as a standard requirement for new construction projects. This is because they understand that investing in these materials not only helps protect people’s lives but also reduces property damage caused by fires.

Going back to our earlier scenario where you witnessed an office building on fire – imagine if that same building had been constructed with these innovative materials. The chances of the fire spreading would have been significantly reduced or even prevented altogether.

This means fewer injuries or fatalities among occupants inside while firefighters could focus on extinguishing flames without worrying about it spreading elsewhere.

Incorporating fire-resistant polymer additives into construction materials is an effective way to boost safety standards across various industries while improving overall performance levels at minimal additional cost compared with traditional non-fire resistant alternatives.

Testing and Certification Standards

Before we dive into the benefits of fire-resistant polymer additives, it’s important to understand how these materials are tested and certified. In order for a construction material to be considered “fire-resistant,” it must undergo rigorous testing by independent third-party organizations such as Underwriters Laboratories (UL) or Intertek.

These tests evaluate the material’s ability to withstand exposure to heat and flames without igniting or spreading fire. The results are then used to assign a rating based on specific criteria, such as flame spread index (FSI) and smoke developed index (SDI).

But even with certification standards in place, not all fire-resistant materials are created equal. It’s crucial for builders and architects alike to do their due diligence when selecting construction materials that meet safety requirements.

By incorporating fire-resistant polymer additives into building products like insulation foam or roofing membranes, we can significantly reduce the risk of fires spreading throughout buildings – ultimately saving lives in emergency situations like the one described earlier.

Recap