Discover how composite polymer materials are revolutionizing the construction industry with their lightweight and durable properties in this informative blog post.

Picture this: You’re walking down the street, admiring the towering skyscrapers that surround you. You can’t help but wonder how these massive structures were built and what materials were used to construct them.

As you continue your stroll, you come across a construction site where workers are busy assembling what looks like a futuristic building made of sleek and shiny material.

You approach one of the workers and ask about the material they’re using to build this impressive structure. The worker grins at you and says, “Composite polymer materials.”

You nod as if you know exactly what that means, but in reality, your mind is racing with questions. What are composite polymer materials? How are they different from traditional building materials? And why do they seem to be taking over the construction industry?

Well my friend, let me tell you all about it! In this blog post, we’ll dive into everything there is to know about composite polymer materials – from their properties and benefits to their applications in various industries. So buckle up and get ready for an informative ride!

Polymer Composites Overview

Polymer composites are materials that consist of two or more components, where one component is a polymer matrix and the other is a reinforcing material. The reinforcing material can be in the form of fibers, particles, or flakes.

When combined with polymers, these materials create composite polymer structures that have unique properties such as high strength-to-weight ratio and excellent durability.

Going back to our construction site scenario from earlier – imagine if we could build structures using lightweight yet strong materials like composite polymers? It would revolutionize the way we construct buildings and infrastructure! And guess what? That’s exactly what’s happening in today’s world.

Composite polymer materials are becoming increasingly popular in various industries due to their exceptional mechanical properties. They offer superior strength while being significantly lighter than traditional building materials like concrete and steel.

This makes them an ideal choice for constructing large-scale structures such as bridges, wind turbines, aircraft parts – you name it!

But why stop there? Composite polymers also have applications beyond just structural use cases; they’re used extensively in manufacturing consumer goods too! From sports equipment to automotive parts – these versatile composites can be found everywhere around us.

Polymer composites are here to stay! Their unique combination of lightweight design coupled with impressive durability make them an attractive option for many industries looking for innovative solutions when it comes to designing new products or constructing new infrastructure projects alike.

Lightweight Structures Advancements

As we saw in the intro, composite polymer materials are being used to construct futuristic buildings that look like they belong in a science fiction movie. But what makes these materials so special? One of their key advantages is their ability to create lightweight structures without sacrificing durability.

Traditionally, building structures have been made from heavy and dense materials such as concrete and steel. While these materials are strong and durable, they also come with significant drawbacks – namely weight.

Heavy buildings require more resources for transportation during construction which can increase costs significantly.

Composite polymer materials offer a solution to this problem by providing an alternative that is both lightweight and strong. These advanced composites consist of two or more different types of material combined together at the molecular level resulting in unique properties not found in traditional building components.

The use of composite polymers has already revolutionized industries such as aerospace where reducing weight while maintaining strength is critical for fuel efficiency and safety reasons. Now it’s time for the construction industry to follow suit!

With advancements being made every day on new formulations, manufacturing processes, design techniques etc., it’s clear that composite polymer technology will play an increasingly important role when designing future infrastructure projects around the world!

Durability in Composite Polymers

As the worker explained to you earlier, composite polymer materials are becoming increasingly popular in the construction industry. One of their most significant advantages is their durability.

Unlike traditional building materials like concrete and steel, composite polymers have a much longer lifespan due to their resistance to corrosion and weathering.

Composite polymers consist of two or more different types of materials that work together to create a stronger material than either one could on its own. This combination results in a material that can withstand harsh environmental conditions such as extreme temperatures, moisture, and UV radiation without deteriorating over time.

In addition to being highly durable against external factors, composite polymer structures also have excellent impact resistance properties. They can absorb shock from heavy loads or sudden impacts without cracking or breaking apart – making them ideal for use in high-traffic areas such as bridges and walkways.

It’s clear that durability is one of the key benefits offered by composite polymer materials when compared with traditional building methods. As we continue our exploration into this exciting new field within construction technology let’s take a closer look at some other advantages these innovative composites offer!

Aerospace & Automotive Applications

As the worker at the construction site mentioned, composite polymer materials are becoming increasingly popular in various industries. One of these industries is aerospace and automotive engineering.

In fact, many modern aircraft and automobiles are already using composite polymer materials for their structures. The reason behind this shift towards composites is simple: they offer a perfect balance between strength and weight reduction.

For example, Boeing’s 787 Dreamliner uses carbon fiber reinforced plastic (CFRP) composites extensively in its airframe structure. This has resulted in a lighter aircraft that consumes less fuel while still maintaining structural integrity.

Similarly, high-performance sports cars like Lamborghini Aventador also use CFRP composites to reduce weight without compromising on safety or performance.

The benefits of using composite polymers extend beyond just reducing weight; they also provide better resistance to corrosion and fatigue compared to traditional metals used in aerospace & automotive applications.

It’s clear that as technology advances further, we can expect more innovative uses of composite polymers across different sectors – from transportation to infrastructure development – making them an essential material for building lightweight yet durable structures that will shape our future world!

Nanocomposites Technology

As we learned in the intro, composite polymer materials are becoming increasingly popular in the construction industry due to their lightweight and durable properties. But did you know that there’s a specific type of composite material that takes these benefits to a whole new level? Enter nanocomposites technology.

Nanocomposites are essentially composites with nanoparticles dispersed throughout them. These nanoparticles can be made from various materials such as carbon, silica, or clay and can significantly enhance the mechanical properties of traditional composites.

In fact, studies have shown that adding just 1% of nanoparticles to a composite material can increase its strength by up to 30%. This means structures built using nanocomposite technology could potentially be lighter yet stronger than those constructed using traditional building materials.

But it’s not just about strength – nanocomposite technology also offers other advantages such as improved thermal stability and flame retardancy. It’s no wonder why this innovative approach is being hailed as the future of lightweight and durable structures!

So next time you come across a futuristic-looking building made out of sleek shiny material like we did in our intro story, remember that it might just be constructed using cutting-edge nanocomposite technology!

Environmental Impact & Recycling

As the worker continues to explain the benefits of composite polymer materials, you can’t help but wonder about their environmental impact. After all, with climate change becoming an increasingly pressing issue, it’s important to consider how our construction practices affect the planet.

Fortunately, composite polymer materials are not only lightweight and durable but also eco-friendly. Unlike traditional building materials like concrete and steel that require a lot of energy to produce and transport, composite polymers have a lower carbon footprint due to their lighter weight.

Moreover, these materials are recyclable which means they can be repurposed at the end of their lifespan instead of ending up in landfills. This is particularly important as we strive towards more sustainable construction practices.

In fact, some companies have already started using recycled composites in new structures or products such as decking boards or outdoor furniture. As technology advances further in this field we may see even more innovative ways for recycling composites being developed making them even more environmentally friendly than before!

Future Trends in Polymer Materials

As we saw in the previous section, composite polymer materials are already making waves in the construction industry. But what does the future hold for these innovative materials? Let’s take a look at some of the trends that are shaping up.

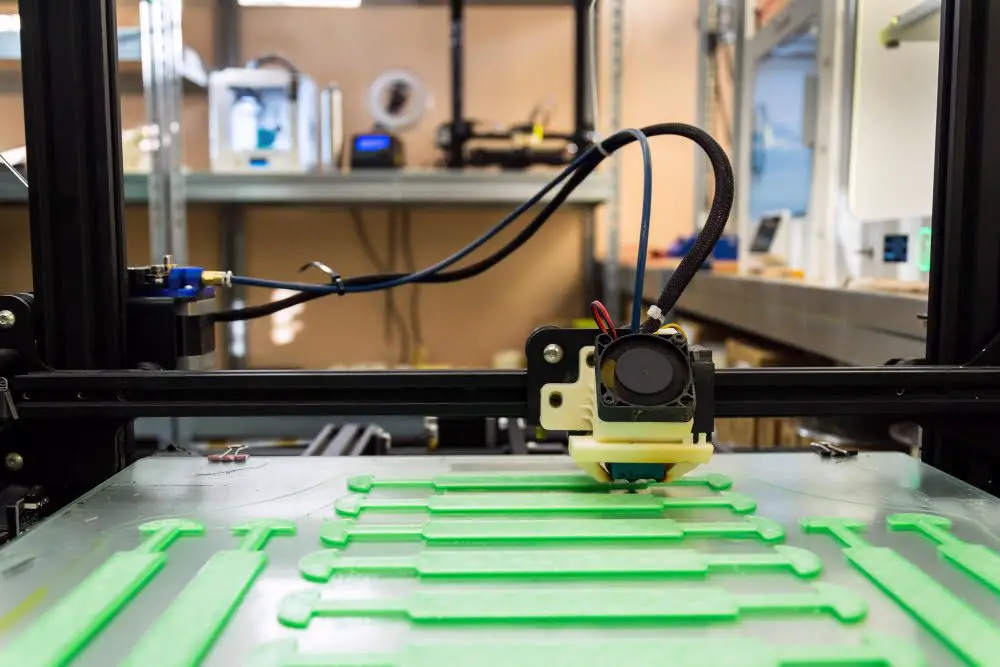

One trend that is gaining momentum is 3D printing of composite polymers. This technology allows for complex shapes and designs to be created with ease, which can lead to more efficient use of material and reduced waste.

3D printing enables customization on a large scale – imagine buildings tailored to specific needs or environments!

Another exciting development is self-healing polymers. These materials have been designed with an ability to repair themselves when damaged by using heat or light stimuli.

Self-healing polymers could revolutionize maintenance practices by reducing downtime and costs associated with repairs.

Researchers are exploring ways to make polymer composites even stronger while maintaining their lightweight properties through nanotechnology advancements such as carbon nanotubes and graphene oxide.

As you can see, there’s no shortage of innovation happening in this field! With continued research into new applications and technologies like those mentioned above, it’s clear that composite polymer materials will play an increasingly important role in building structures both now and well into the future!

Recap