Learn about common polymers used in everyday items and their applications in various industries.

Key takeaways:

- Polymers have many repeating units connected in long chains.

- Common examples of polymers include polyethylene, nylon, PVC, silicone, and polystyrene.

- Polymers are synthesized through addition or condensation polymerization.

- Polymers exhibit diverse properties like elasticity, rigidity, thermal resistance, chemical resistance, and optical clarity.

- Polymers are used in construction, electronics, medical applications, and apparel industry.

Etymology

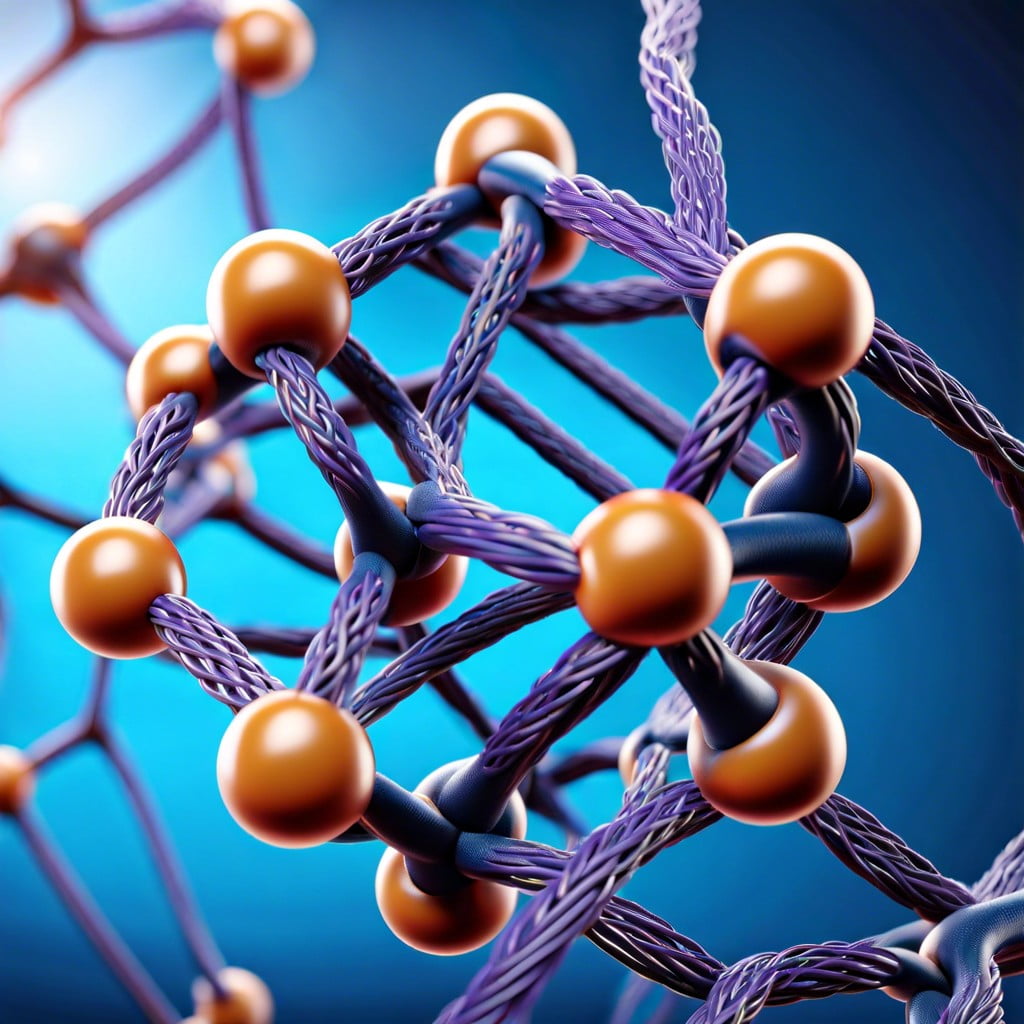

The term “polymer” stems from the Greek words “poly,” meaning many, and “meros,” meaning parts or units. This reflects the molecular structure of polymers, which consists of numerous repeating units connected in long chains. This fundamental configuration is what gives polymers their wide array of characteristics and functionality in various applications. Essentially, the name polymer itself gives a quick peek into how these substances are structured on a molecular level.

Common Examples

Polyethylene, often found in shopping bags and food packaging, is a familiar household polymer thanks to its flexibility and durability. Nylon, another popular example, revolutionized the textile industry with its strength and resistance to wear; it is extensively used in everything from clothing to carpeting. PVC, or polyvinyl chloride, is widely recognized in the construction sector for its role in pipes and vinyl siding due to its robustness and resistance to environmental degradation. Silicone stands out in both the medical field and in cookware, appreciated for its heat resistance and pliability. Lastly, polystyrene is commonly seen in disposable coffee cups and packing materials, chosen for its lightweight and insulating properties. Each of these examples showcases the versatility and essential roles polymers play in modern materials.

Synthesis

Polymers are crafted through a process that links small molecules, known as monomers, into long, repeating chains. This process is called polymerization and occurs in two primary forms: addition polymerization and condensation polymerization.

In addition polymerization, monomers add to each other without losing any small molecules. This type is used to make polymers like polyethylene and PVC, common in plastic bags and pipes.

Condensation polymerization, on the other hand, involves the loss of small molecules as byproducts, often water, when monomers bond. This method is essential for creating nylon and polyester, which have numerous applications in clothing and fabrics.

Temperature and catalysts play crucial roles in determining the speed and efficiency of these reactions, significantly impacting the final polymer’s properties. This variability allows chemists to tweak the process to suit specific needs, from elasticity to tensile strength, making it a cornerstone of polymer science.

Properties

Polymers exhibit a diverse array of properties determined by their specific chemical structures. They can be either elastic or rigid, making them highly adaptable for different applications. For instance, rubber bands stretch due to their elastic properties, whereas plastic containers are hard due to their rigidity.

Thermal resistance is another key characteristic. Some polymers can withstand high temperatures without degrading, which is crucial for use in environments like kitchens and industrial processes.

Their resistance to chemicals also plays a vital role. This makes them suitable for storage containers and protective coatings, as they can prevent reactions with stored materials or external elements.

Optical clarity is a property utilized in items like eyeglasses and car headlights. This quality depends on the polymer’s ability to allow light to pass through without scattering.

Understanding these properties helps manufacturers choose the right polymer for a given application, maximizing both performance and durability.

Applications

Polymers are remarkably versatile, finding uses in every corner of our daily lives and industrial processes. In the construction industry, for example, synthetic polymers like polyvinyl chloride (PVC) are used extensively for pipes and fittings due to their strength and resistance to corrosion. Polyurethane foam serves as an excellent insulator, helping to keep buildings warm in the winter and cool in the summer, which cuts down on energy costs.

In the world of electronics, polymers like polystyrene are used to make casings and components light yet durable. For medical applications, silicone rubbers are trusted for their flexibility and bio-compatibility—essential for medical implants and devices.

Moreover, polymers are critical in the apparel industry; polyester fabrics are favored for their durability and resistance to shrinking and stretching. Thus, from protective clothing to fashionable outfits, the role of polymers is both foundational and transformative.

Recap