Discover how 3D-printed polymer composites are revolutionizing the construction industry and shaping a more sustainable future.

The use of 3D printing in construction has been gaining traction over the past few years, with many companies exploring its potential in creating everything from houses to bridges. But what about using 3D-printed materials for composite structures? This is where things get really interesting.

In this blog post, we’ll explore how 3D-printed polymer composites are shaping the future of construction and revolutionizing the way we build things.

From their unique properties to their potential applications in various industries, let’s dive into this exciting new technology and discover what it has to offer.

Advantages of Polymer Composites in Construction

One of the most significant advantages of using polymer composites in construction is their strength-to-weight ratio. Traditional building materials such as concrete and steel are heavy, making them difficult to transport and maneuver on a construction site.

However, 3D-printed polymer composites are lightweight yet incredibly strong, making them an ideal choice for creating complex structures that require both durability and flexibility.

Moreover, these materials can be customized to meet specific project requirements by adjusting the composition or printing process parameters. This means that architects and engineers have more design freedom than ever before when it comes to creating unique shapes or intricate details.

Another advantage of using 3D-printed polymer composites is their resistance to corrosion and weathering. Unlike traditional building materials like steel or wood which can rust or rot over time due to exposure to moisture, these composite structures remain intact even in harsh environments.

Materials and Technologies for 3D Printing

To understand the potential of 3D-printed polymer composites in construction, it’s important to first explore the materials and technologies used in this process.

There are several types of polymers that can be used for 3D printing, including thermoplastics like ABS and PLA, as well as more advanced materials such as nylon and polycarbonate. These polymers can be reinforced with various fillers like carbon fiber or glass fibers to enhance their strength.

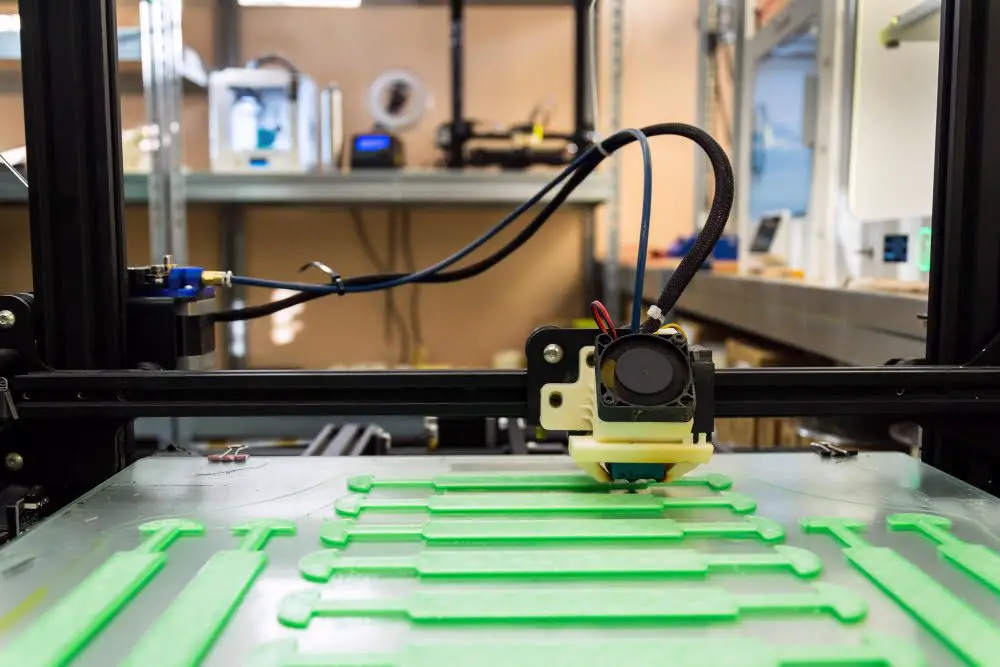

In addition to the choice of material, there are also different technologies available for 3D printing. Fused Deposition Modeling (FDM) is one popular method where a heated nozzle extrudes melted plastic layer by layer until an object is formed.

Another technique called Stereolithography (SLA) uses a laser beam to cure liquid resin into solid layers.

The combination of these materials and technologies allows for endless possibilities when it comes to creating complex structures with unique properties that traditional construction methods cannot achieve.

Applications in Modern Architecture

One of the most exciting aspects of 3D-printed polymer composites is their potential applications in modern architecture. Imagine being able to create complex, curved structures that were previously impossible with traditional building materials.

With 3D printing technology, architects can now design and construct buildings with intricate shapes and patterns that not only look stunning but also offer superior strength and durability.

For example, a company called Branch Technology has developed a unique method for constructing walls using 3D-printed polymer composites. Their patented Cellular Fabrication (C-Fab) technology allows them to print large-scale panels that are lightweight yet incredibly strong.

These panels can be used as load-bearing walls or as decorative elements in architectural designs.

Another company called Winsun has taken things even further by using 3D printing technology to construct entire houses! They have successfully printed multiple homes using a mixture of recycled construction waste and cement-based materials.

The possibilities for incorporating this innovative material into modern architecture are endless – from creating sustainable housing solutions to designing awe-inspiring skyscrapers unlike anything we’ve seen before.

It’s clear that the future of construction is being shaped by these cutting-edge technologies, paving the way for more efficient, cost-effective building methods while pushing creative boundaries like never before.

Environmental Impact and Sustainability

As we continue to explore the potential of 3D-printed polymer composites in construction, it’s important to consider their environmental impact and sustainability. Traditional building materials such as concrete and steel have a significant carbon footprint due to their production processes, transportation, and disposal.

In contrast, 3D printing offers a more sustainable alternative by reducing waste material during the manufacturing process.

Moreover, some companies are experimenting with using recycled plastics for 3D printing structures. This approach not only reduces plastic waste but also provides an affordable solution for constructing buildings in areas where traditional building materials may be scarce or expensive.

In addition to being eco-friendly during production, these composite structures can also offer energy-efficient benefits once they’re built. For example, some designs incorporate insulation properties that help regulate indoor temperatures without relying on heating or cooling systems powered by fossil fuels.

Incorporating sustainable practices into construction is crucial for mitigating climate change impacts while meeting our growing infrastructure needs. By utilizing innovative technologies like 3D-printed polymer composites that prioritize sustainability throughout the entire lifecycle of a structure – from design through demolition – we can build smarter cities that benefit both people and planet alike.

Challenges and Limitations

While 3D-printed polymer composites have the potential to revolutionize the construction industry, there are still some challenges and limitations that need to be addressed. One of the main challenges is ensuring that these materials meet safety standards and regulations.

As with any new technology, it’s important to thoroughly test and validate its performance before implementing it on a large scale.

Another limitation is the size of objects that can be printed using current 3D printing technology. While we’ve seen impressive examples of entire houses being printed in just a few days, these structures are typically small-scale models or prototypes rather than full-sized buildings.

Despite these challenges and limitations, researchers continue to push forward in developing new techniques for 3D printing polymer composites at larger scales while maintaining their structural integrity. With continued innovation in this field, we may soon see even more exciting applications for this groundbreaking technology beyond what we can currently imagine.

As with any emerging technology or technique within an industry as established as construction – there will always be hurdles along the way but by addressing them head-on through research & development – they become opportunities for growth instead!

Future Developments in the Industry

As 3D printing technology continues to evolve, we can expect even more exciting developments in the construction industry. One area of focus is on creating larger and more complex structures using 3D-printed polymer composites.

This could include everything from entire buildings to bridges and other infrastructure projects.

Another potential development is the use of sustainable materials for 3D printing. As concerns about climate change continue to grow, there’s a growing demand for eco-friendly building materials that are both durable and cost-effective.

Researchers are already exploring ways to create biodegradable polymers that can be used in construction applications.

We may see an increase in customization options as this technology becomes more widely adopted by architects and builders alike. With the ability to print unique shapes and designs quickly and easily, it’s possible that we’ll see a shift away from traditional rectangular buildings towards more organic forms.

It’s clear that 3D-printed polymer composites have enormous potential when it comes to shaping the future of construction. Whether through increased efficiency or new design possibilities, this innovative technology is sure to play a major role in how we build things moving forward – just like my childhood Legos did so many years ago!

Recap