Discover the fascinating world of biodegradable plastics as we delve into their various types and the significant role they play in reducing environmental pollution.

Have you ever wondered what happens to the plastic products we use every day once they are disposed of? Sadly, most of them end up in landfills or oceans, where they take hundreds of years to decompose and harm the environment.

But what if there was a way to create plastics that could break down naturally and not contribute to pollution? That’s where biodegradable plastics come in! In this article, we’ll explore the different types of biodegradable plastics available today and how they can help reduce our impact on the planet.

So let’s dive in!

Key takeaways:

- Starch-based plastics: Made from renewable resources and break down naturally when exposed to moisture and microorganisms.

- Polylactic Acid (PLA): Decomposes into natural compounds and can be used for packaging, disposable tableware, and medical implants.

- Polyhydroxyalkanoates (PHA): Made from vegetable oils and starches and quickly break down in the environment without leaving harmful residues.

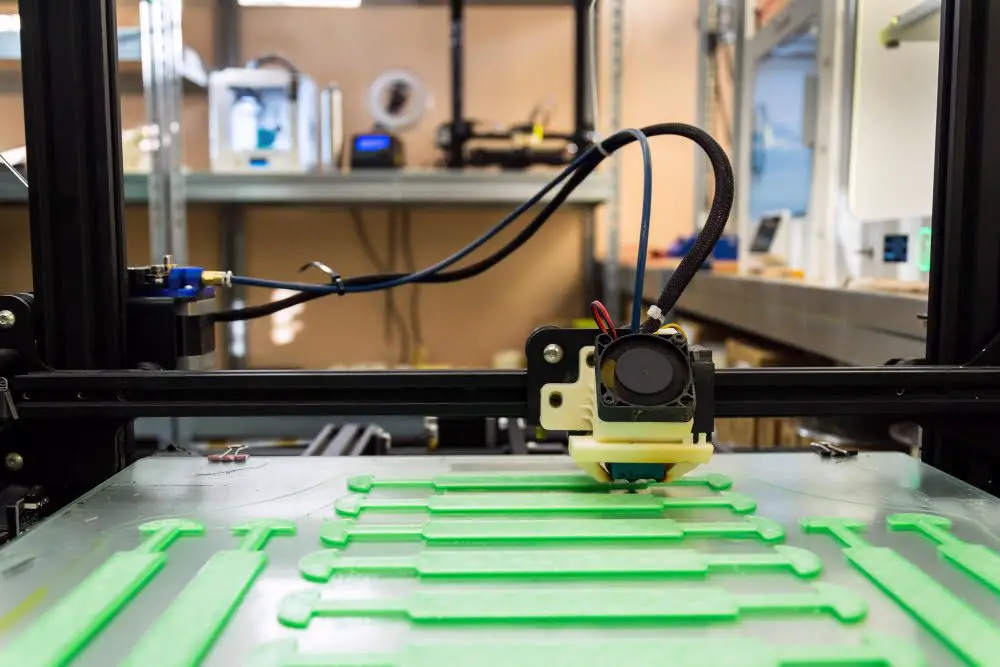

- Polycaprolactone (PCL): Degrades slowly over time and is versatile, making it suitable for 3D printing and drug delivery systems.

- Cellulose-based plastics: Made from the most abundant organic polymer on earth and have excellent mechanical properties.

Starch-based Plastics

They are made from renewable resources such as corn, potatoes, and tapioca. These materials contain starch, which is extracted and processed to create a polymer that can be used in various applications.

One significant advantage of starch-based plastics is their ability to break down naturally when exposed to moisture and microorganisms. This makes them an excellent alternative for single-use plastic products like bags or cutlery that would otherwise end up in landfills or oceans.

However, there are also some limitations to consider when using starch-based plastics. For instance, they tend to have lower mechanical strength than traditional petroleum-based plastic products; hence they may not be suitable for heavy-duty applications.

Polylactic Acid (PLA)

It has gained popularity in recent years due to its eco-friendliness and versatility. PLA can be used for various applications such as packaging materials, disposable tableware, 3D printing filaments, textiles and even medical implants.

One of the significant advantages of PLA is that it decomposes into natural compounds like carbon dioxide and water when exposed to heat or moisture. This makes it an excellent alternative to traditional plastics that take hundreds of years to break down.

However, there are some limitations with using PLA in certain applications due to its low-temperature resistance compared with other plastics like polyethylene terephthalate (PET). The production process for PLA requires a lot of energy which could offset some environmental benefits if not sourced sustainably.

Polyhydroxyalkanoates (PHA)

PHA plastics are made from renewable resources such as vegetable oils and starches, making them an eco-friendly alternative to traditional petroleum-based plastics. These materials have gained popularity in recent years due to their ability to break down quickly in the environment without leaving harmful residues.

One of the most significant advantages of PHA is its versatility. It can be used for various applications, including packaging materials, disposable cutlery and plates, medical implants and sutures, agricultural films and coatings for textiles.

However, there are still some challenges associated with using PHAs on a large scale. The production process can be expensive compared to other types of biodegradable plastics like PLA or PCL because it requires specific conditions such as temperature control during fermentation processes.

Despite these challenges though research continues into finding more cost-effective ways to produce this material at scale while maintaining its unique properties that make it so attractive environmentally speaking.

Polycaprolactone (PCL)

It is a thermoplastic polyester that can be easily molded and shaped into various forms, making it ideal for use in 3D printing applications. PCL degrades slowly over time, taking anywhere from six months to two years depending on the environmental conditions.

One of the significant advantages of PCL is its versatility as it can blend with other polymers such as PLA or PHA to create materials with improved mechanical strength and durability. PCL’s low melting point makes it an excellent candidate for drug delivery systems where controlled release rates are essential.

However, despite its many benefits, there are still concerns about the widespread adoption of PCL due to energy costs associated with production and disposal methods required for end-of-life management.

Cellulose-based Plastics

These plastics are made from cellulose, which is the most abundant organic polymer on earth and can be found in plants’ cell walls. Cellulose-based plastics have excellent mechanical properties and can be used for a wide range of applications, including packaging materials, disposable cutlery, and textiles.

One significant advantage of cellulose-based plastics over other types of biodegradable plastic is their low cost. Since cellulose is readily available from plant sources such as wood pulp or cotton linters, it makes these types of bioplastics more affordable to produce than some other alternatives.

However, there are also some challenges associated with using cellulose as a raw material for producing bioplastics. One issue is that the production process requires large amounts of energy to break down the complex structure into usable components called “cellulosic sugars.” since many plants contain lignin (a compound that gives them rigidity), removing this substance during processing can also pose environmental concerns.

Aliphatic Polyesters

They have gained popularity in recent years due to their excellent mechanical properties and ability to degrade naturally without releasing harmful toxins into the environment.

One of the most commonly used aliphatic polyesters is polycaprolactone (PCL), which has a low melting point and can be easily molded into various shapes. PCL degrades slowly over time, making it ideal for applications such as drug delivery systems or surgical implants.

Another popular aliphatic polyester is polybutylene succinate (PBS), which has similar properties to traditional petroleum-based plastics but can be broken down by microorganisms in soil or water within months rather than centuries.

Aliphatic polyesters offer an eco-friendly alternative to traditional plastics while still maintaining high performance standards.

Bio-based Polyethylene (Bio-PE)

It has the same properties as traditional polyethylene but with one significant difference: it’s environmentally friendly. Bio-PE can be recycled and reused, making it an excellent alternative to petroleum-based plastics.

The production process for Bio-PE involves converting sugarcane into ethanol, which is then used to create ethylene through dehydration. The resulting ethylene monomer undergoes polymerization to form Bio-PE resin pellets that can be molded into various shapes and sizes.

One of the benefits of using bio-based polyethylene is its reduced carbon footprint compared to traditional plastics. Sugarcane plants absorb carbon dioxide during their growth cycle, making them a renewable source for producing bioethanol used in creating this type of plastic.

Unlike petroleum-derived plastics that take hundreds or even thousands of years to decompose in landfills or oceans after disposal, bio-based polyethylene breaks down naturally within months under certain conditions such as exposure to sunlight and oxygen.

Bio-based Polypropylene (Bio-PP)

It has similar properties to traditional polypropylene but with the added benefit of being environmentally friendly. Bio-PP can be used in various applications such as packaging materials, automotive parts, and consumer goods.

One significant advantage of Bio-PP over traditional plastics is its reduced carbon footprint during production. The manufacturing process for Bio-PP emits fewer greenhouse gases compared to petroleum-based plastics since it uses plant-derived feedstocks instead of fossil fuels.

Moreover, unlike conventional polypropylene which takes hundreds or even thousands of years to decompose in landfills or oceans after disposal; bio-based polypropylene breaks down naturally within a few months under certain conditions like high temperature and humidity levels.

The development and use of bio-based polypropylene are essential steps towards reducing our dependence on non-renewable resources while also minimizing environmental pollution caused by plastic waste.

Bio-polyamides (Bio-PA)

They have excellent mechanical properties and can be used in various applications such as automotive parts, electrical components, and packaging materials. Bio-PA has high thermal stability which makes it suitable for use in high-temperature environments.

One significant advantage of bio-polyamides over traditional petroleum-based plastics is their ability to break down naturally without causing harm to the environment. When disposed of properly through composting or other natural processes like soil burial or marine degradation, they decompose into harmless substances like water and carbon dioxide.

However, it’s important to note that not all bio-polyamides are created equal when it comes to biodegradability. Some may require specific conditions for decomposition while others may take longer than expected depending on the environment they’re exposed to.

Biodegradable Polyurethanes (Bio-PU)

They have similar properties to traditional polyurethane but can break down naturally in the environment without causing harm. Bio-PU has many applications in construction, automotive manufacturing, and medical devices.

In construction, Bio-PU can be used for insulation foam or coatings on walls and roofs. It provides excellent thermal insulation while reducing energy consumption by up to 50%.

In the automotive industry, it is used for car seats or interior parts because of its durability and resistance to wear-and-tear.

Moreover,Bio-PUs also have potential use in biomedical engineering due to their biocompatibility with human tissues which makes them suitable for implantable medical devices like artificial heart valves or pacemakers.

However,it’s important not to confuse bio-based polyurethanes with conventional ones that contain toxic chemicals like diisocyanates which pose health risks during production processes.Bio-based alternatives offer a safer option while still providing high-performance materials needed across various industries.

Prodegradant Additives

These additives work by breaking down the plastic into smaller pieces, which then become more susceptible to biodegradation by microorganisms in the environment. Prodegradant additives are often used in applications where it is not feasible or practical to use fully biodegradable plastics, such as packaging materials.

However, there has been some controversy surrounding prodegradant additives and their impact on the environment. Some studies have suggested that these types of plastics may actually contribute more harm than good due to their potential for fragmenting into microplastics and releasing harmful chemicals during degradation.

As with any technology or product designed for environmental sustainability, it is important for consumers and manufacturers alike to carefully consider all aspects of its production and disposal before implementing it on a large scale.

Oxo-Degradable Plastics

These plastics contain additives that help them break down into smaller pieces when exposed to oxygen and sunlight. However, unlike other biodegradable plastics, oxo-degradable plastics do not fully decompose into natural elements like water and carbon dioxide but instead leave behind microplastics.

The use of oxo-degradable plastic has been a subject of controversy due to concerns about the environmental impact caused by the accumulation of microplastics in soil and water bodies. Some countries have even banned their use altogether.

Despite these concerns, some argue that oxo-degradables can still be useful for certain applications where full degradation is not necessary or feasible, such as packaging materials with short lifespans or single-use items like straws.

Photo-Biodegradable Plastics

These plastics contain additives that make them sensitive to ultraviolet (UV) light, which triggers the degradation process. The UV light causes the polymer chains in the plastic to break down into smaller fragments, making it easier for microorganisms like bacteria and fungi to consume them.

While photo-biodegradable plastics may seem like an ideal solution for reducing environmental pollution caused by traditional non-degradable plastics, they have been met with some controversy. Some experts argue that these types of biodegradables do not fully degrade but instead fragment into small pieces known as microplastics, which can still harm marine life and ecosystems.

Despite this concern, photo-biodegradables remain a promising alternative in certain applications where exposure to sunlight is guaranteed or easily controlled such as agricultural films or packaging materials used outdoors.

Hydro-Biodegradable Plastics

These plastics contain additives that help them degrade into smaller pieces when exposed to moisture, which then allows microorganisms to consume and decompose them further. Hydro-biodegradable plastics are commonly used for products such as shopping bags, food packaging, and agricultural films.

While hydro-biodegradable plastics offer an environmentally friendly alternative to traditional non-degradable plastic products, there is still some debate over their effectiveness in reducing pollution. Some critics argue that these types of biodegradables may not fully break down under certain conditions or may release harmful chemicals during degradation.

Despite this controversy surrounding hydro-biodegradables’ efficacy as a sustainable solution for waste management issues globally; they remain one of the most promising options available today due to their ability to reduce environmental pollution significantly.

Compostable Plastics

Unlike traditional plastics, which require hundreds of years to decompose and release harmful chemicals into the soil, compostable plastics can be turned into nutrient-rich soil within weeks or months.

To be considered compostable, these materials must meet specific standards set by organizations such as the Biodegradable Products Institute (BPI) and European Norms (EN). These standards ensure that the material will fully break down under controlled conditions without leaving any toxic residue behind.

Compostable plastics are made from various sources such as corn starch, sugarcane bagasse or cellulose. They have many applications including food packaging products like cups and utensils.

However it is important to note that not all “biodegradable” products are created equal – some may only degrade in industrial facilities while others may take longer than expected to decompose if they end up in landfills instead of being properly disposed through commercial composting programs.

Factors Affecting Biodegradation

These can be intrinsic or extrinsic to the plastic material itself. Intrinsic factors include molecular weight, crystallinity, and chemical composition of the polymer.

For example, polymers with high molecular weights take longer to break down than those with lower molecular weights.

Extrinsic factors refer to environmental conditions such as temperature, humidity levels, oxygen availability and microbial activity in soil or water where plastics are disposed of. The presence of microorganisms is crucial for biodegradation since they produce enzymes that break down complex molecules into simpler ones that can be absorbed by other organisms.

The rate at which a plastic degrades depends on these various intrinsic and extrinsic factors working together in a complex way; therefore it’s difficult to predict how long it will take for any given type of biodegradable plastic product to decompose completely under different environmental conditions.

Intrinsic Factors

These factors include molecular weight, crystallinity, chemical structure, and thermal stability. The higher the molecular weight of a plastic material, the slower its degradation rate due to reduced surface area for microbial attack.

Crystalline structures in polymers also hinder biodegradation since they form barriers that prevent microorganisms from accessing polymer chains.

Chemical structure plays a significant role in determining how easily microbes can break down plastics into simpler compounds. For instance, polyesters with ester linkages are more susceptible to hydrolysis by enzymes than those with amide or ether bonds.

Thermal stability is another intrinsic factor affecting biodegradability since high temperatures can cause irreversible changes in polymer chains’ structures leading to decreased susceptibility to microbial attack.

Extrinsic Factors

These include temperature, humidity, oxygen availability, microbial activity in soil or water bodies where they are disposed of. For instance, higher temperatures and moisture levels accelerate the breakdown process by increasing microbial activity that breaks down the polymer chains into smaller fragments.

On the other hand, low-temperature environments such as those found in landfills may slow down biodegradation rates significantly. Similarly, lack of oxygen can also impede degradation since most microorganisms require it to break down organic matter effectively.

Biodegradable Vs. Compostable Plastics

Biodegradable plastics break down into natural elements over time through a biological process, while compostable plastics break down into organic matter that can be used as fertilizer for plants. Compostable plastic requires specific conditions to decompose properly, such as high temperatures and moisture levels found in industrial composting facilities.

On the other hand, biodegradable plastic can decompose under various environmental conditions but may leave behind harmful residues or take longer to degrade than expected. It’s important to note that not all biodegradable or compostable products are created equal; some require special disposal methods or only partially degrade.

When choosing between these two types of eco-friendly alternatives, it’s essential to consider their intended use and end-of-life options carefully.

Environmental Benefits of Biodegradable Plastics

Firstly, they reduce the amount of plastic waste that ends up in landfills and oceans, which can take hundreds of years to decompose. Biodegradable plastics break down naturally into non-toxic substances such as water, carbon dioxide and biomass within a few months or years depending on the type.

Secondly, biodegradable plastics are made from renewable resources such as corn starch or sugarcane instead of fossil fuels like oil and gas used for conventional plastic production. This reduces our dependence on non-renewable resources while also reducing greenhouse gas emissions associated with their extraction.

Thirdly, biodegradable plastics have lower toxicity levels compared to traditional petroleum-based ones since they do not contain harmful chemicals like phthalates or bisphenol A (BPA). These chemicals can leach out into food products stored in plastic containers leading to health risks when ingested.

Lastly but not least important is that biodegradable materials contribute positively towards sustainable development goals by promoting circular economy principles where waste is minimized through recycling/reuse/composting/biodegradation processes rather than being disposed off irresponsibly causing harm to ecosystems and human health alike.

Environmental Concerns and Issues

One major concern is that some types of biodegradable plastics require specific conditions to break down properly, such as high temperatures or exposure to UV light. If these conditions are not met, the plastic may still persist in the environment for years.

Another issue is that some manufacturers use prodegradant additives in traditional plastics to make them “biodegradable.” However, these additives only cause fragmentation of the plastic into smaller pieces rather than true biodegradation. These microplastics can be just as harmful as regular-sized ones and can even enter our food chain through marine life.

Furthermore, there is also a risk of greenwashing – companies claiming their products are environmentally friendly when they’re actually not. It’s important for consumers to do their research and look out for certifications like ASTM D6400 or EN 13432 before purchasing any supposed “biodegradable” product.

Energy Costs for Production

However, the amount of energy required varies depending on the type of biodegradable plastic and its manufacturing process. For instance, some types require high temperatures during production or use large amounts of water and other resources.

Despite this fact, many experts believe that producing biodegradable plastics is more sustainable in the long run than traditional petroleum-based plastics because they have a lower carbon footprint. This is because they are made from renewable resources such as corn starch or sugarcane instead of non-renewable fossil fuels.

Moreover, advancements in technology have led to more efficient methods for producing these materials with less waste and fewer emissions. As a result, manufacturers can reduce their overall environmental impact while still meeting consumer demand for eco-friendly products.

Consumer Labelling and Greenwashing

Biodegradable plastics have gained popularity in recent years as a sustainable alternative to traditional plastics. However, not all biodegradable plastic products are created equal, and some companies may use misleading labels or marketing tactics to make their products appear more eco-friendly than they actually are.

This practice is known as greenwashing and can be harmful to both the environment and consumer trust. To avoid falling victim to greenwashing when purchasing biodegradable plastic products, it’s essential for consumers to look beyond the label claims and do their research on the specific type of material used in production.

Some certifications such as “OK Compost” or “Seedling” indicate that a product has undergone testing by an independent third-party organization for compostability according to international standards. Other certifications like ASTM D6400 certify that a product will break down within 180 days under industrial composting conditions.

It’s important for manufacturers of biodegradable plastics also ensure transparency about what happens after disposal since many materials require specific conditions (such as high temperatures) before breaking down completely.

Global Regulations and Standards

The United States, European Union, and British Standards have all established guidelines for biodegradable plastics. In the US, ASTM International has developed a set of standards for testing the biodegradability of plastic materials under controlled composting conditions.

Similarly in Europe, EN 13432 is a standard that specifies requirements for packaging recoverable through composting or anaerobic digestion.

However, there are concerns about greenwashing – companies making false claims about their products being “biodegradable” or “compostable.” This can lead to confusion among consumers who may not understand what these terms mean or how they differ from traditional plastics.

It’s important to note that while some countries have strict regulations on biodegradable plastics’ production and labeling practices; others do not yet regulate them at all. As such it is essential always to check if your country has any specific rules regarding these types of products before purchasing them.

United States Standards

The FTC has issued guidelines for companies that claim their products are biodegradable. According to these guidelines, a product can only be labeled as “biodegradable” if it can completely break down into natural elements within five years of disposal.

Manufacturers must provide scientific evidence to support their claims.

The state of California also has its own regulations on biodegradability labeling. In 2008, California passed a law requiring all plastic bags sold in the state to be either compostable or meet certain standards for recycled content.

While there is no federal standard for compostable plastics in the US yet, several states have enacted laws regulating them. For example, Minnesota requires that all food waste generated by large producers must be composted using certified compostable bags and containers.

European Union Standards

The EU has established strict standards for biodegradable plastics to ensure that they meet specific criteria before being labeled as such. These standards include testing for disintegration, ecotoxicity, and heavy metal content.

To be considered a compostable plastic in the EU, it must break down into carbon dioxide within six months under industrial composting conditions. It should not contain any harmful substances or leave behind any toxic residues after decomposition.

The EU’s regulations on biodegradable plastics have helped promote their use in various industries while ensuring that they do not harm the environment further. As consumers become more aware of environmental issues and demand eco-friendly products from manufacturers worldwide, these regulations will continue to play an essential role in shaping how we produce and consume goods sustainably.

British Standards

The BS EN 13432 standard specifies requirements for packaging recoverable through composting and biodegradation. It sets out criteria for the disintegration of materials in a composting environment and requires that at least 90% of the material must be converted into CO2 within six months.

It mandates that no more than 10% residue should remain after three months.

The BS PAS 9017 is another standard developed to assess plastic products’ environmental impact throughout their lifecycle. This includes evaluating raw material sourcing, manufacturing processes, product use phase and disposal methods.

Adhering to these standards ensures that consumers can trust claims made about a product’s environmental credentials while also providing manufacturers with clear guidelines on how they can produce environmentally friendly products.

Role of Genetic Engineering and Synthetic Biology

Scientists are now able to modify microorganisms such as bacteria, yeast, and algae to produce bioplastics with specific properties. For instance, researchers have engineered E.coli bacteria to produce PHA bioplastics that can be used for packaging materials.

Synthetic biology has also enabled scientists to create new enzymes that can break down plastics more efficiently.

Moreover, genetic engineering has allowed for the production of bio-based monomers from renewable resources like corn starch or sugarcane instead of petroleum-based sources. These monomers are then polymerized into various types of biodegradable plastics.

While genetic engineering and synthetic biology offer promising solutions for creating sustainable alternatives to traditional plastic products, there is still much research needed before these technologies become widely adopted in commercial applications.

Biodegradable Plastics in the Medical Field

Medical devices such as sutures, implants, and drug delivery systems require materials that can safely degrade within the body without causing harm or toxicity. Biodegradable polymers like polylactic acid (PLA) and polyglycolic acid (PGA) are commonly used for surgical sutures because they gradually break down into lactic and glycolic acids which are naturally occurring compounds in the body.

Moreover, biodegradable plastics have also been used to create implantable devices such as screws, pins, plates for bone fixation after surgery. These implants provide temporary support until new tissue growth replaces them over time.

Another exciting development is using biodegradable polymers to create drug delivery systems that release medication at a controlled rate over an extended period of time. This technology has shown promise in treating chronic diseases like cancer by delivering drugs directly to affected areas while minimizing side effects on healthy tissues.

Future Developments in Biodegradable Plastics

Biodegradable plastics have already made significant strides in reducing pollution and waste, but what does the future hold for this innovative technology?.

One exciting development is the use of nanotechnology to create biodegradable materials with enhanced properties. For example, researchers are exploring ways to incorporate nanoparticles into bioplastics that could make them stronger and more durable.

Another area of focus is developing new types of feedstocks for producing bioplastics. Currently, most bioplastics are made from crops like corn or sugarcane which can compete with food production and lead to deforestation.

However, scientists are investigating alternative sources such as algae or bacteria that could be grown sustainably without impacting food supplies.

Advances in genetic engineering may allow us to create entirely new types of polymers that break down even faster than current options while still maintaining their strength and durability.

Overall it’s clear that there’s no shortage of innovation happening in the field of biodegradable plastics – we can expect many exciting developments over the coming years as we work towards a greener future!.

FAQ

What are the 5 types of biodegradable plastics?

The 5 types of biodegradable plastics are Starch, Cellulose, Protein, Organic, and Aliphatic Polyesters.

What are the most biodegradable plastics?

The most biodegradable plastics include Polybutylene succinate (PBS), Polycaprolactone (PCL), Polybutyrate adipate terephthalate (PBAT), and Polyvinyl alcohol (PVOH/PVA).

What are the 2 types of biodegradable plastics describe?

Answer: The 2 types of biodegradable plastics are oxo-biodegradable, which undergoes chemical degradation by oxidation, and hydro-biodegradable, which undergoes chemical degradation by hydrolysis, both leading to physical disintegration and reduced molecular weights.

What is the process of biodegradation in different types of biodegradable plastics?

Answer: The process of biodegradation in different types of biodegradable plastics involves the breakdown of these materials by microorganisms, such as bacteria or fungi, into smaller molecules, eventually releasing carbon dioxide, water, and biomass.

How do the environmental impacts of biodegradable plastics compare to traditional plastics?

Answer: Biodegradable plastics have lesser environmental impact compared to traditional plastics, as they break down more easily and quickly, reducing pollution and negative effects on ecosystems.

What are the potential applications and limitations of using biodegradable plastics in various industries?

Potential applications of biodegradable plastics include packaging, agriculture, and automotive industries; however, limitations involve higher costs, reduced mechanical strength, and longer degradation times.

Biodegradable Plastics and the Food Packaging Industry

Biodegradable plastics have gained significant attention in the food packaging industry due to their potential to reduce environmental impact. These types of plastics are designed to break down naturally over time, minimizing waste and pollution.

In the food packaging sector, biodegradable plastics offer a more sustainable alternative to traditional petroleum-based materials.

One key advantage of using biodegradable plastics in food packaging is that they can help extend the shelf life of perishable products. By creating a protective barrier against moisture and oxygen, these materials can help preserve freshness and prevent spoilage.

This not only reduces food waste but also enhances product quality for consumers.

Furthermore, biodegradable plastic films or containers used for wrapping or storing foods are often compostable as well. This means that after use, they can be collected along with organic waste and processed into nutrient-rich compost through industrial composting facilities.

The resulting compost can then be used as fertilizer for agricultural purposes.

However, it’s important to note that not all bioplastics are suitable for direct contact with certain types of foods due to potential chemical interactions or migration risks between the plastic material and the packaged product itself. Therefore, careful consideration must be given when selecting appropriate grades of biodegradable plastics specifically formulated for safe use in contact with different types of foods.

End-of-Life Options for Biodegradable Plastics

One option is composting, where the plastic is broken down into organic matter through microbial activity. This process requires specific conditions such as temperature and moisture levels to ensure proper decomposition.

Another option is anaerobic digestion, which involves breaking down the biodegradable plastic in an oxygen-free environment. This process produces methane gas that can be used as a renewable energy source.

In addition to composting and anaerobic digestion, some biodegradable plastics can also be recycled alongside traditional plastics if they meet certain criteria. However, it’s important to note that not all types of biodegradable plastics are suitable for recycling due to differences in their chemical composition.

Ultimately, choosing the right end-of-life option for biodegradable plastics depends on various factors such as local infrastructure capabilities and environmental considerations.

Biodegradable Plastics and Marine Pollution

Traditional plastics can take hundreds of years to decompose, leading to significant environmental damage when they end up in our oceans. However, biodegradable plastics offer a more sustainable alternative.

When biodegradable plastics enter marine environments, they undergo degradation processes that break them down into smaller pieces over time. These smaller fragments are then consumed by microorganisms and other organisms present in the water.

As a result, biodegradable plastics have the potential to reduce the long-term impact on marine ecosystems compared to traditional non-biodegradable counterparts.

It is important to note that not all biodegradable plastic materials are suitable for use in marine environments or will degrade at similar rates under different conditions. Factors such as temperature, salinity levels, and exposure time can influence their breakdown process.

To ensure effective reduction of marine pollution caused by plastic waste, it is crucial for manufacturers and consumers alike to choose certified compostable or specifically designed bioplastics that meet recognized standards for aquatic environment degradation.

Advancements in Chemical Processes to Enhance Biodegradability

These innovations are crucial for reducing the environmental impact of plastic waste and promoting a more sustainable future.

One such advancement is the development of additives that can be incorporated into traditional plastics to accelerate their breakdown when exposed to specific conditions. These additives help break down the polymer chains, making it easier for microorganisms to consume and decompose them.

Another promising approach involves creating new polymers from renewable resources such as plant-based materials or agricultural waste. These bio-based polymers have properties similar to conventional plastics but are designed with built-in mechanisms for faster degradation once they enter natural environments.

Furthermore, researchers are exploring ways to modify existing plastic manufacturing processes by introducing catalysts or enzymes that facilitate biodegradation without compromising product performance. By fine-tuning these chemical reactions, scientists aim to create plastics that retain their functionality during use but degrade rapidly after disposal.

It’s important not only for manufacturers but also consumers and policymakers alike, as these advancements offer viable solutions towards reducing plastic pollution while still meeting our everyday needs.

Case Studies of Successful Biodegradable Plastic Usage

In the Food Service Industry: One notable case study in the food service industry involves a popular fast-food chain that switched from traditional plastic packaging to biodegradable alternatives. By using biodegradable plastics for their takeout containers, cups, and utensils, they were able to significantly reduce their environmental impact.

These biodegradable materials broke down naturally over time without leaving behind harmful microplastics or contributing to landfill waste.

2. Agricultural Applications: Another successful case study focuses on the use of biodegradable plastics in agriculture.

Farmers have started adopting mulch films made from bio-based polymers instead of conventional plastic films for crop cultivation purposes such as weed control and moisture retention. These mulch films degrade into organic matter after use, eliminating the need for manual removal or disposal.

3. Environmentally Friendly Packaging Solutions: Several companies have successfully implemented innovative packaging solutions using compostable and bioplastic materials derived from renewable resources like cornstarch or sugarcane fibers instead of petroleum-based plastics. These eco-friendly packages are designed to break down naturally when exposed to specific conditions such as heat or moisture while still providing adequate protection during transportation and storage.

4. Construction Sector Initiatives: In construction projects where temporary structures are required (e.g., scaffolding), some companies have adopted reusable formwork systems made with bio-composite materials that can be easily disassembled after use without generating excessive waste. These sustainable alternatives not only reduce environmental impact but also offer cost savings by minimizing material consumption over multiple construction cycles.

5. Textile Industry Innovations: The textile industry has witnessed successful implementation of plant-based fibers like polylactic acid (PLA) derived from corn starches as an alternative to synthetic polyester fabrics which contribute significantly towards microplastic pollution. By utilizing these environmentally friendly textiles in clothing production processes, manufacturers can create garments that decompose more rapidly once discarded compared to traditional synthetic fibers.

These case studies demonstrate the successful adoption of biodegradable plastics in various industries, highlighting their potential to reduce pollution and waste while promoting sustainability.

Recap