Discover how scientific polymer products revolutionize construction by providing stronger, more durable, and versatile building materials.

Key takeaways:

- Custom synthesis creates unique polymers tailored for projects.

- Monomers are the building blocks; plasticizers enhance flexibility.

- Analytical services ensure polymers are reliable and safe.

- Polymerization explains how monomers form long, strong chains.

- Chemical manufacturing transforms raw materials into construction stars.

Custom Synthesis

Imagine you need a polymer that’s as unique as a snowflake, but without the cold feet. That’s where the magic happens!

Custom synthesis is like giving a bespoke tailor scientific tools. You define what you need, and chemists start their alchemical work. Here’s how it works:

First, you specify the desired properties. Do you want it flexible, robust, or both?

Second, chemists whip out their secret recipes—those complex formulas involving specific monomers and catalysts.

They then blend and brew, often using equipment that looks straight out of a sci-fi movie. The polymer undergoes a series of tests to ensure it meets your exact specifications—no more, no less.

Voila! Your one-of-a-kind, made-to-order polymer, tailored for your project! Don’t worry, there’s no fashion show, but your construction project will be strutting its stuff.

Monomers & Plasticizers

Monomers are the building blocks of polymers. Think of them as the Lego bricks of the polymer world. When monomers link together, they form long chains called polymers, which can be molded into various shapes.

Then we have plasticizers. These are the secret sauce that makes polymers more flexible and less brittle. Ever wondered why PVC pipes are rugged, but a PVC shower curtain is soft and bendy? That’s the magic of plasticizers at work.

Here are some points to explain this better:

- Monomers can be natural or synthetic. Natural ones include proteins and cellulose, while synthetic ones involve things like styrene and vinyl chloride.

- Plasticizers are often added to make polymers usable in different conditions. Think of them as tiny fitness trainers, stretching out the polymer chains to make them more flexible.

- Without plasticizers, many everyday items—from soft rubber hoses to pliable plastic bags—would snap or crack easily.

In summary, monomers are the basic units, while plasticizers make sure those units can flex their muscles when needed.

Analytical Services

Analytical services are the Sherlock Holmes of the polymer world, minus the deerstalker hat. They play a pivotal role in understanding what makes a polymer tick. Here’s a quick look at what they involve:

First up, there’s chemical composition analysis. Think of it as a DNA test but for polymers, identifying what elements and compounds form the tiny building blocks.

Next, we have molecular weight determination. Picture polymers strutting down a runway; this service measures their mass and length, giving insight into their strength and flexibility.

Thermal analysis burns polymers—but in a good way! It checks how polymers behave at different temperatures. Will they melt, burn, or stay cool under pressure?

Last but not least, there’s mechanical testing. This subject involves bending, stretching, and squeezing polymers to understand their durability. It’s like taking polymers to a mini gym workout.

These services ensure that polymers used in construction are safe, reliable, and up to the job. They uncover the mysteries behind every synthetic strand, making sure your polymer product is the real deal.

Polymerizations

Imagine making a giant Lego castle. That’s somewhat like polymerization but instead of colorful bricks, we have monomers. These monomers join forces to create long, sturdy polymer chains.

There are two main types to know about: addition polymerization and condensation polymerization. Think of addition as a conga line where each dancer (monomer) holds onto the next without letting go. It’s all about adding and adding, no loss.

On the flip side, condensation polymerization is more like a potluck where everyone brings a dish but leaves some leftovers behind. When monomers join, they kick out small molecules (like water) as a side effect. Neat, right?

Different techniques include bulk, solution, suspension, and emulsion polymerizations. Each has its own quirks and perks, like choosing between baking, frying, steaming, or microwaving your favorite snack. Some methods give you more control, others are quicker. Pick your polymerization recipe based on the desired traits of your final polymer product.

Understanding these processes helps in making everything from strong plastic chairs to stretchy rubber bands. Trust the polymers; they’ve got our backs – or rather, our Lego castles.

Chemical Manufacturing

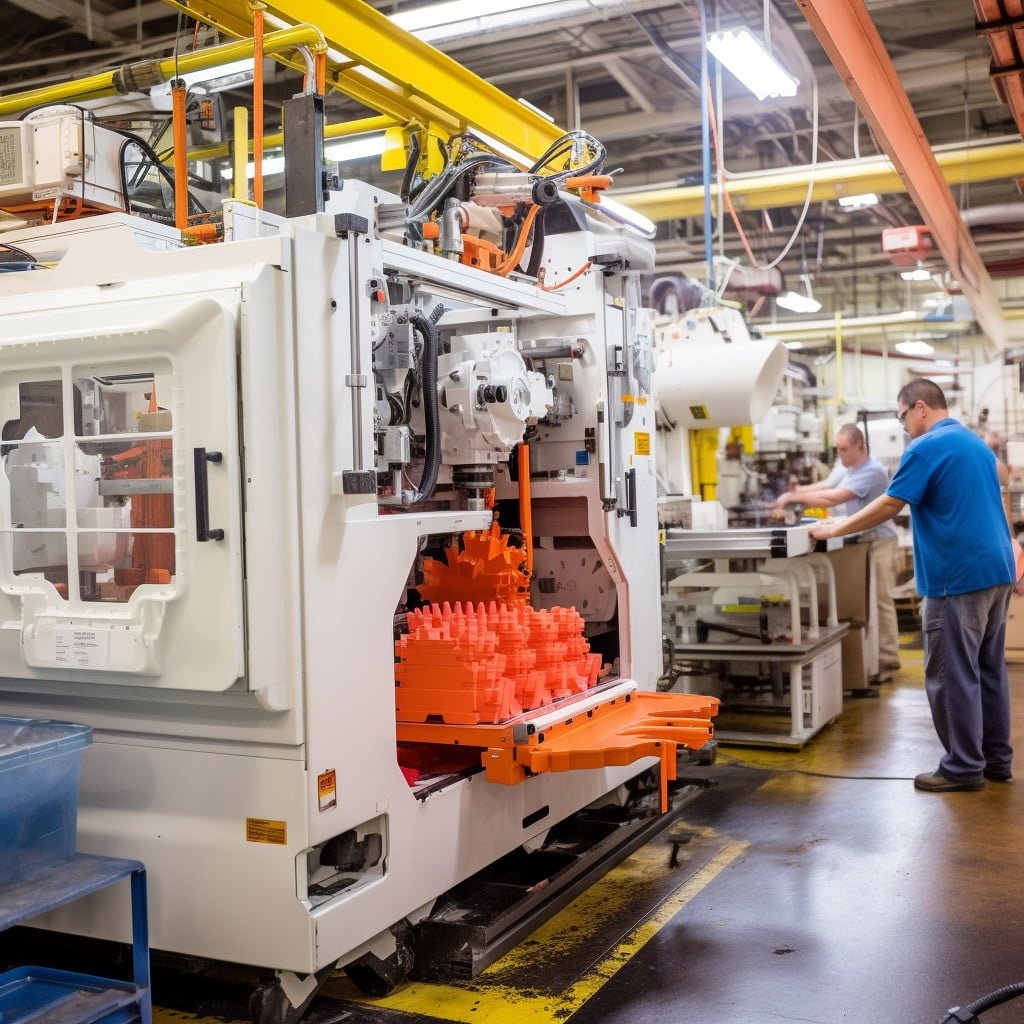

Imagine a factory where polymers get to dress up for a chemistry party. This is where raw materials transform into the superstars of the construction world. Let’s dive straight into the fun bits of this process.

Picture giant mixers; these are reactors, where liquid monomers (the party guests) meet catalysts (the DJs) to form polymers. It’s like the ultimate matchmaking event for chemicals.

Temperature control is crucial, think of it as the thermostat at a house party. Too hot, and the components might start a rebellion. Too cold, and they’ll be too sluggish to mingle.

Quality checks here are as rigorous as a bouncer at an exclusive club. Each batch gets tested for consistency, ensuring only the A-listers make it to the construction site.

Safety is paramount. Protective gear, containment measures, and regular monitoring keep the environment and workers safe. No one likes a party pooper, especially when it’s a hazardous chemical leak.

In short, chemical manufacturing is a blend of meticulous science and a bit of event planning.

Recap