In this article, you’ll learn about the properties, uses, and benefits of PVC polymer in the construction industry.

Key takeaways:

- PVC is a synthetic plastic polymer used in construction.

- PVC can be rigid or flexible, depending on the application.

- PVC is made through a chemical process using ethylene and chlorine.

- PVC has key properties such as durability, non-conductivity, versatility, chemical stability, and low flammability.

- PVC can be recycled and is used in various industries such as construction, healthcare, electronics, and everyday items.

What Is PVC (Polyvinyl Chloride)?

Polyvinyl chloride, commonly known as PVC, is a popular synthetic plastic polymer. It is unique because it comes in two basic forms: rigid and flexible. The rigid form is often used in construction for pipes, doors, and windows. On the other hand, when plasticizers are added, PVC becomes flexible and is then used in applications such as electrical cable insulation and clothing.

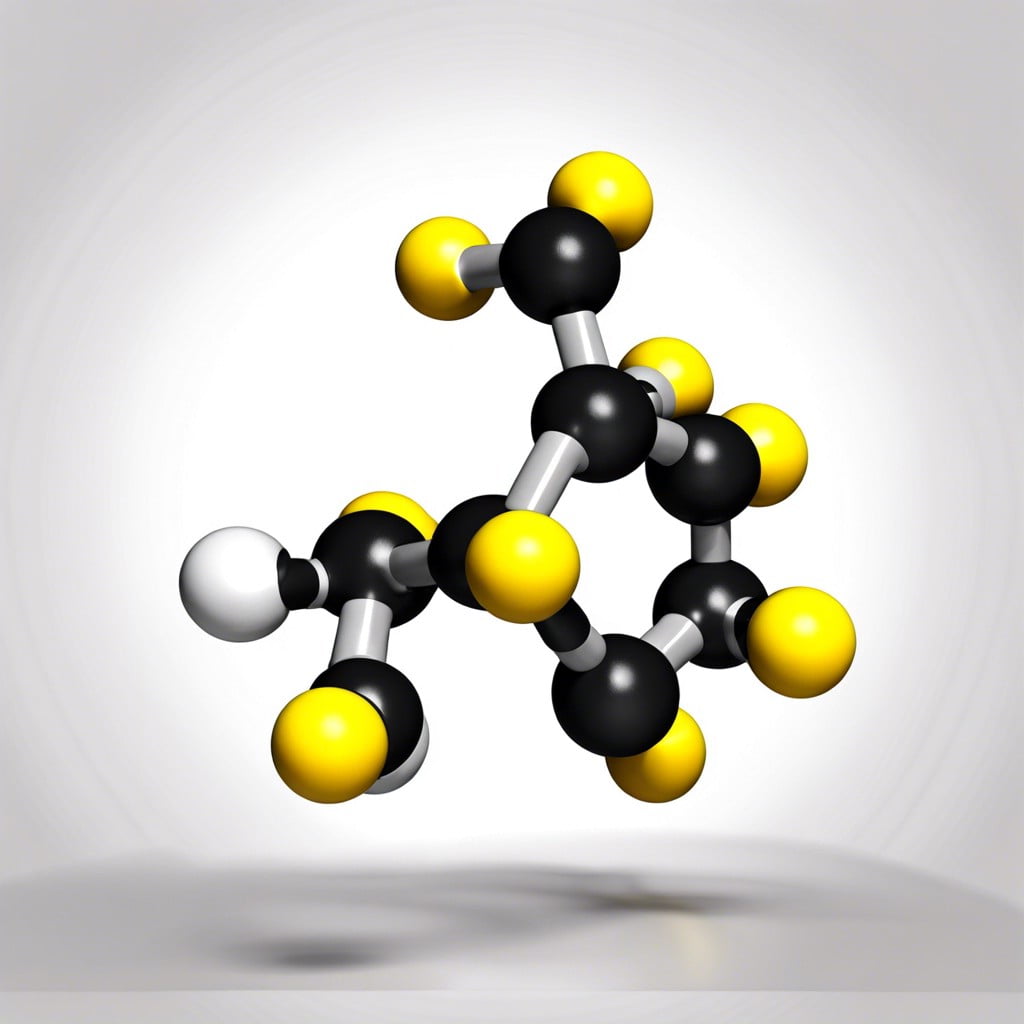

PVC is made from the polymerization of vinyl chloride monomers, which provides its distinctive properties such as high strength, durability, and resistance to moisture and chemicals. This is why it’s a favorite in sectors that require sturdy and long-lasting materials.

Environmentally, one should note that PVC is a type of plastic that can release hazardous compounds if not disposed of correctly. However, advancements in production and waste management techniques are continuously improving its environmental footprint, making PVC a material that balances practicality with sustainability.

How Is PVC Manufactured?

Polyvinyl Chloride, commonly known as PVC, is produced through a series of chemical reactions. Starting with ethylene, derived from crude oil or natural gas, and chlorine, obtained from salt, the two substances undergo a process called “ethylene dichloride (EDC) cracking” to produce vinyl chloride monomer (VCM).

VCM molecules then undergo polymerization, a chemical reaction that bonds them together to form long chains, yielding the PVC resin. This typically occurs in a reactor vessel, with initiators to kickstart the reaction and other additives to control the process.

Once the polymerization reaction is complete, the result is a white powder known as PVC resin, which is the basis for a wide variety of PVC products.

This PVC resin is then combined with other ingredients, such as impact modifiers, stabilizers, pigments, and plasticizers, to further enhance its properties for specific applications.

After mixing, the compound is melted and formed into its final shape through various methods, such as extrusion, molding, or calendering, depending on the desired end product.

Key Properties of PVC

PVC is known for its durability, which makes it a favorite for indoor and outdoor use. It resists weathering, chemical rotting, corrosion, shock, and abrasion. These properties translate into products that last a long time with minimal maintenance.

The material is also non-conductive to electricity, making it an ideal component for electronics and industrial applications where insulation is essential. This characteristic enhances safety in environments that deal with electrical equipment.

Another significant feature of PVC is its versatility. It can be manufactured in varying degrees of flexibility by adding plasticizers, resulting in a wide range of products from rigid pipes and window frames to flexible cables and inflatable products.

Chemical stability is yet another key attribute. PVC stands up to water, acids, bases, fats, salts, and alcohol. This robustness allows it to be used in applications like sewage pipes or medical tubing where resistance to a variety of substances is crucial.

Lastly, PVC’s low flammability is noteworthy. It is self-extinguishing, which means that if the source of fire is removed, the material stops burning. This makes it a safe choice in applications where the risk of fire needs to be minimized.

PVC Recyclability

Recycling PVC plays a crucial role in reducing its environmental impact. This sturdy plastic can be reprocessed and repurposed multiple times without significant quality loss. Several points illustrate PVC’s recyclability:

- Mechanical recycling is one common method. Here, PVC waste is ground into smaller pieces, cleaned, and melted to form new material.

- Chemical recycling involves breaking down PVC into its chemical components, which are then used to create new PVC, effectively closing the loop.

- Despite its chlorine content, which poses recycling challenges, technology has advanced to safely recycle PVC, turning potential waste into valuable resources.

- PVC recycling requires the separation of different types of plastics due to its unique composition. Thanks to modern sorting technology, this process is becoming increasingly efficient.

- Recycled PVC finds its way into a variety of products, including pipes, flooring, and traffic cones, illustrating the material’s versatility post-recycling.

Market Applications of PVC

PVC’s versatility and cost efficiency make it a popular choice across various industries.

In construction, it’s utilized for piping, window frames, and siding because of its strength and resistance to moisture and corrosion. Its durability ensures long-lasting infrastructure with minimal maintenance requirements.

In healthcare, PVC is integral for medical devices like blood bags and tubing. It’s preferred for being easily sterilized and flexible, which is crucial for patient safety and comfort.

The material’s water resistance and easy shaping also contribute to its use in clothing and upholstery, providing waterproof covers and faux leather goods that blend style with functionality.

In electronics, PVC’s electrical insulation properties protect wires and cables, keeping our devices running safely and efficiently.

For everyday items, it’s used in containers and bottles due to its clarity and chemical stability, making it safe for containing consumables and household chemicals.

The ease of molding PVC also lends itself to children’s toys and a wide range of home decor products, combining safety with aesthetic appeal.

Lastly, its contribution to modern transport can’t be overlooked, as PVC is often incorporated in vehicle interiors, offering longevity and ease of cleaning.

Each application takes advantage of PVC’s unique traits to deliver products that are as practical as they are innovative.

Recap