Plastic medical devices play a crucial role in modern healthcare, and understanding the manufacturers behind them is essential for ensuring safe and effective use.

Plastic medical devices have revolutionized the healthcare industry in ways that were once unimaginable. These innovative instruments have made medical treatment more cost-effective and efficient than ever before, providing not only physicians but also patients with better outcomes.

From simple syringes to complex heart pacemakers, plastic medical devices have become an integral part of modern medicine. But have you ever wondered how these miraculous machines are manufactured? In this blog post, we will delve into the world of plastic medical device manufacturers – their challenges and opportunities, technological advancements they’ve been leveraging, trends driving their growth and some interesting facts about these lifesaving instruments.

So buckle up and let’s explore this fascinating Industry together!

BMP Medical

Services and products:

- Custom OEM injection molded medical devices

- Design consultation and engineering

- Drawing, R&D, tooling, and mold development

- Process automation and statistical process control

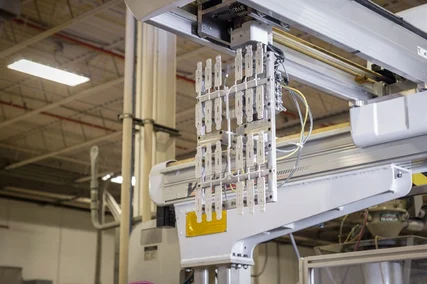

- Manufacturing, assembly, and packaging in a Class 8 cleanroom

BMP Medical is a trusted and experienced medical contract manufacturer offering design, assembly, and packaging services for custom OEM injection molded medical devices. With over 40 years of experience, state-of-the-art molding techniques, and a Class 8 cleanroom facility, they provide varying-sized components with very tight specifications while ensuring utmost regulatory compliance.

Based in North America and headquartered in Sterling, Massachusetts, BMP Medical caters to various markets with quality service that guarantees enduring product life-cycles.

EVCO Plastics

Company: evcoplastics.com

Services and products:

- Medical disposables

- Medical devices

- Medical packaging

- Medical instruments

- Medical plastic components

EVCO is a leading medical device manufacturer that specializes in medical injection molding. With two Class 100,000/ISO Class 8 clean rooms and rigorous controls around machinery and processes validation, they ensure supreme precision and repeatability for customer projects.

Their facilities are FDA registered, cGMP compliant and ISO certified to 13485 and 9001, making them a trusted partner for medical disposables, devices, packaging, instruments and plastic components.

Spectrum Plastics Group

Contact phone: (325) 925-2195

Services and products:

- Full partnership from idea to final product

- Extruded medical tubing

- Catheter technologies

- Medical balloons

- Injection molding

This company is a leading manufacturer of plastic medical devices and offers a full range of services from ideation to final product. Their extensive experience in medical device manufacturing allows them to provide specialized solutions for every need, including extruded tubing, catheter technologies, medical balloons, and injection molding.

Have you considered using their expertise for your next project?

SEA-LECT Plastics

Contact phone: (425) 339-0288

Facebook page: Facebook

Services and products:

- Rapid prototyping

- Mold creation

- Engineering design

- Quality control

- Production of molded products for distribution to finished device manufacturers or end consumers.

SEA-LECT Plastics is a leading manufacturer in the medical device manufacturing industry that supports the creation of innovative new products through their top-tier facility and robust quality initiative. As a reliable partner, they offer rapid prototyping, mold creation, and engineering design to enable advancements in technology and plastic injection molding for medical devices.

Their commitment to excellence is evident through their ISO 9001:2015 certification and strict management system that ensures the highest quality products reach manufacturers and consumers alike.

Thogus

Contact phone: (866) 933-8850

Facebook page: Facebook

Services and products:

- Precision, custom injection molded parts for medical device manufacturers

- Regulatory requirement and validation process advice

- Material selection for medical plastic injection molding projects

- Manufacturing by design process

- Cleanroom assembly services

Thogus is a premier plastic medical device manufacturer that specializes in providing precision, custom injection molded parts to medical device manufacturers. They offer medical-grade plastic injection molding solutions that are durable, reliable, and meet regulatory requirements.

With their experience and expertise in material selection and cleanroom assembly, Thogus is committed to helping its clients succeed through each phase of a project’s life cycle.

Ensinger

Company: ensingerplastics.com

Services and products:

- One-stop-shop for medical device manufacturing needs

- Development of new and innovative medical products

- Emphasis on product safety and patient benefits

- Cost control solutions for medical product manufacturers

- Compliance with regulatory requirements and patient safety standards

Ensinger is a plastic medical device manufacturer that offers a comprehensive range of solutions for the complex challenges faced by the healthcare industry, including aging patients, tightening regulations and cost pressures. From unannounced audits to new treatment options, Ensinger emphasizes product safety, patient benefits and cost control in order to develop innovative solutions for tomorrow’s medical needs.

Putnam Plastics

Contact phone: (860) 774-1559

Facebook page: Facebook

Services and products:

- Partnering with 500+ medical device companies across 36 countries in all stages of the product life cycle

- Unparalleled engineering expertise serving global clientele

- Technical skills, knowledge, and facilities to take on projects others cannot

- Single-source solution from start to finish for thousands of medical plastics solutions

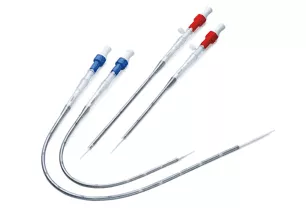

- Innovative solutions to medical device challenges, including variable durometer continuous extrusion technology and design and development of first-ever catheters.

Putnam Plastics, a prominent plastic medical device manufacturer established in 1984, has been providing unprecedented engineering expertise to over 500 medical device companies across 36 countries. The company’s state-of-the-art facilities, ISO certification and technical skills enable them to take on projects that others can’t.

From start to finish, Putnam Plastics offers single-solution services for thousands of medical plastics solutions.

Emco Industrial Plastics

Company: emcoplastics.com

Contact phone: (800) 292-9906

Facebook page: Facebook

Services and products:

- Medical grade plastic for sensitive medical equipment, devices, and supplies

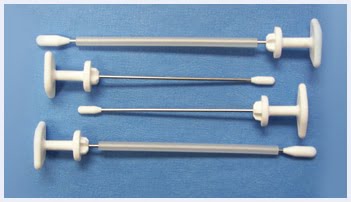

- Manufacturing of medical devices and equipment such as MRI machines, diagnostic wands, and surgical instruments

- Production of dental instruments and sterilization trays

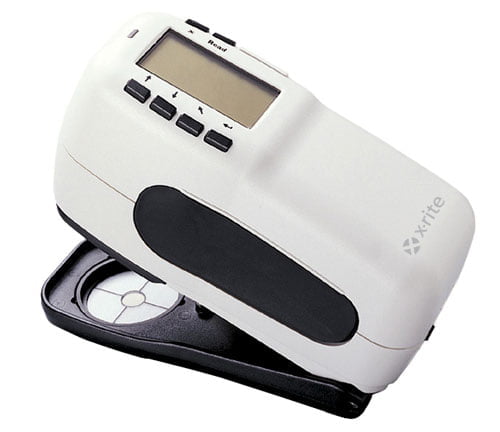

- Anesthetic, diagnostic, and imaging equipment

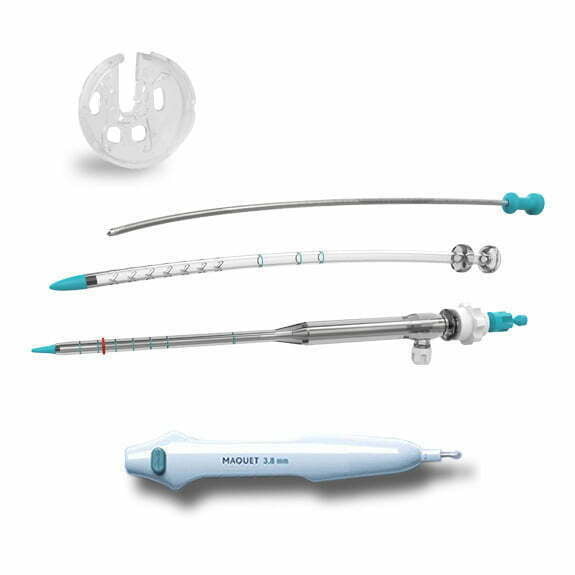

- Customized medical plastic product solutions for companies such as Maquet Cardiovascular, St. Jude Medical, Stryker, Merck, and Pfizer.

This company specializes in manufacturing medical grade plastic products that are resistant to wear, high temperatures, and corrosion. The products range from surgical instruments to diagnostic equipment and are used in hospitals worldwide.

They have worked with leading medical companies such as Maquet Cardiovascular, St. Jude Medical, Stryker, Merck, and Pfizer.

Seaway Plastics Engineering

Services and products:

- Complete solutions to complex challenges in the medical industry

- High-quality products for Class 1, 2 & 3 medical devices

- Injection molding and assembly with medical-grade plastics and silicone

- Design-for-manufacturing services for ease of manufacturing and long-term sustainability

- Prototyping to full-scale production and assembly

Seaway Plastics is a leading medical device manufacturer that specializes in producing high-quality products for Class 1, 2, and 3 medical devices. With years of expertise in injection molding and assembly using the latest and most advanced technology, they provide complete solutions to complex challenges with a focus on precision, quality, and innovation.

Their ISO 13485 Class 7 and 8 certified cleanrooms ensure that their products meet the most stringent industry standards while their FDA registration guarantees that projects are completed under one roof without compromising product integrity or safety.

The Rodon Group®

Company: rodongroup.com

Facebook page: Facebook

Services and products:

- Full-service, turnkey plastic component injection molding solutions

- Comprehensive part manufacturing capabilities

- ISO certification

- Use of FDA/medical-grade materials

- Complete part traceability from start to finish

Sterling Healthcare Manufacturing is an experienced and reliable medical/pharmaceutical component manufacturer that offers full-service, turnkey plastic component injection molding solutions. They prioritize quality and complete part traceability throughout the manufacturing process, while maintaining ISO certification and using FDA/medical-grade materials to meet strict industry standards.

Customers can expect transparency and accountability with Sterling’s comprehensive part manufacturing capabilities.

Microdyne Plastics

Facebook page: Facebook

Services and products:

- Syringes

- Tubes

- Fluid bags

- Endoscopic instruments

- Intravenous products

This plastic medical device manufacturer is an important player in a growing and thriving industry with a sizable output of $38 billion. Plastic is an essential material in modern medicine, used for many devices and equipment that are critical to delivering effective care.

With excellent salaries and job opportunities, the future looks bright for this company and the industry as a whole.

Natech Plastics

Contact phone: (631) 580-3506

Services and products:

- Engineering services

- Custom injection molding

- Contract manufacturing services

- High-volume production using reliable materials

- Servo-driven robotics for high-speed automation

Natech Plastics is a top-rated medical plastic injection molding company that specializes in engineering, custom injection molding, and contract manufacturing services. They use reliable materials and have expert engineers and manufacturers to meet demanding applications.

With their production parts made in the USA, they can produce high-volume production while maintaining quality.

Kaysun

Company: kaysun.com

Facebook page: Facebook

Services and products:

- Full-service complex injection molding for medical devices

- MedAccred accreditation for quality assurance

- Expertise in part and tooling design

- Material selection guidance

- Process control optimization

Kaysun is a leading medical injection molding company that partners with manufacturers to provide increased design freedom and process efficiencies. With MedAccred accreditation, Kaysun offers expertise from part and tooling design through material selection and process control to help medical OEMs address issues before they impact production or the bottom line.

Their experienced team helps overcome the unique challenges of medical injection molding while keeping pace with technological advancements in the industry.

Baytech Plastics Inc

Company: baytechplastics.com

Facebook page: Facebook

Services and products:

- Manufacturing of medical plastic devices

- Design flexibility for parts and components

- Injection molding for precision parts

- Production of a wide range of medical devices, from small components to larger items like wheelchair or bed parts

- Use of plastics with antimicrobial benefits

This medical plastic device manufacturing company uses injection molding to create precision parts for a wide range of medical devices. Plastics offer affordability, design flexibility and antimicrobial benefits making it an ideal option for mass production of parts and components.

With their expertise in medical plastic device manufacturing, they are the trusted choice for developers looking to produce safe and effective medical devices.

Molded Devices, Inc

Facebook page: Facebook

Services and products:

- Customized plastic injection molding

- Innovative design for custom plastic parts

- Expertise in solving supply chain and contract manufacturing challenges

- Wide range of innovative techniques

- Medical product design services

MDI is a leading plastic medical device manufacturer with over 50 years of experience in providing customized plastic injection molding solutions. They offer expertise in industrial, energy, aerospace and defense sectors, and apply innovative engineering techniques to ensure your custom parts consistently meet rigorous quality standards.

MDI is dedicated to helping clients solve supply chain and contract manufacturing challenges for OEMs in every industry.

Modern Plastics

Facebook page: Facebook

Services and products:

- Plastics for medical devices

- Medical grade polymer/plastics stock shapes

- Biocompatible, FDA-approved medical grade plastics

- Expert assistance for questions about medical plastics

- Wide range of medical markets served with medical plastics

Modern Plastics is a trusted medical plastics manufacturer and distributor in the United States. They provide high-quality medical grade polymer/plastics stock shapes to various industries, including medical devices, defense & aerospace, food processing, and more.

With their expertise and FDA-approved materials, they can serve a wide range of medical markets with biocompatible plastics for all kinds of applications.

PTI – Plastic Technologies, Inc

Facebook page: Facebook

Services and products:

- Full-service advanced product development for medical device manufacturers

- Design for manufacturability

- Medical device molding

- Cleanroom molding and assembly (Class 8)

- ISO 13485 and FDA registered and compliant

PTI Engineered Plastics is a trusted plastic medical device manufacturer backed by 30 years of experience in the industry. They provide advanced product development services with reliable design, tooling, and molding capabilities delivered on time.

The company is ISO 13485 certified and FDA registered for quality assurance and offers medical device design support, cleanroom molding, cavity pressure sensing, among other services.

Viant Medical

Company: viantmedical.com

Contact phone: (480) 553-6400

Services and products:

- End-to-End Solutions: All the services needed from design and development to finished device manufacturing and assembly

- Quality-first culture for consistent, reliable quality

- Deep knowledge of a wide range of materials, from thermoplastics to elastomers to metals

- Focused on medical devices for specialized markets such as surgical technologies, orthopedics, cardiac & interventional, bioelectronics, drug delivery, and diagnostics & patient care markets

- Medical device components and systems development

This plastic medical device manufacturer is a global leader with many resources, yet still provides individualized attention. With expertise in various markets and materials, they offer end-to-end services from design to finished product.

They specialize in producing medical devices for a variety of industries and prioritize quality above all else.

Crescent Industries, Inc

Facebook page: Facebook

Services and products:

- Superior medical injection molding solutions for medical, pharmaceutical, and dental industries

- Manufacturing of Class I, II, and III components and devices using medical grade resin materials

- Injection molding operations in general molding facility or certified ISO 8 (100K) cleanroom

- Cleanroom assembly and packaging services adhering to critical medical quality standards

- Complete quality control and inspection including IQ, OQ, and PQ validations, and lot traceability.

Crescent Industries is a leading plastic medical device manufacturer that has been producing high-quality injection molding solutions for over 50 years. With extensive experience in manufacturing Class I, II, and III components and devices using medical-grade resin materials, they offer their services both in general molding facilities and certified ISO 8 cleanrooms.

They provide customers with complete quality control and inspection services using state-of-the-art automated work cells while adhering to critical medical quality standards.

MRPC

Contact phone: (262) 781-7122

Facebook page: Facebook

Services and products:

- Full contract manufacturing of medical devices, instruments, and disposables

- Design for Manufacturability process to improve quality and reduce costs

- Silicone molding, plastic molding, and extrusions in clean room environments

- Multi-material molding of dissimilar materials onto each other

- Full range product lifecycle capabilities including design assistance, development, and manufacturing

MRPC is a premier contract manufacturer of medical devices with FDA registration and ISO 13485 certification. They offer full product lifecycle capabilities and specialize in design for manufacturability, silicone molding, plastic molding, extrusions, and multi-material molding.

Their unique processes ensure both product integrity and improved form, fit, and function for the end user.

Chemtech Plastics

Facebook page: Facebook

Services and products:

- Leading-edge medical injection molding capabilities

- Design for Manufacturing (DFM) and Design for Assembly (DFA) principles

- High-volume automated assembly lines with in-line inspection

- Technical authority for manufacturing medical device components

- Extensive knowledge of medical-grade and FDA-approved materials

Chemtech Plastics is a leading manufacturer of plastic medical devices with expertise in medical injection molding. They specialize in surgical and diagnostic applications and have a strong background in medical manufacturing.

Their engineers use Design for Manufacturing (DFM) and Design for Assembly (DFA) principles to optimize parts for cost-effective manufacturing while ensuring government compliance requirements are met. With high-volume automated assembly lines that produce millions of parts per year, they offer consistent quality assurance through machine validation processes, defect prevention programs, and production traceability measures.

Chemtech guarantees durable, reliable, cost-efficient, and reproducible molded components meeting the highest industry standards from start to finish for all their clients’ needs.

All-Plastics

Services and products:

- Cost-saving injection molding solutions for the Medical Device industry

- Expertise in medical injection molding for tight tolerance micro-sized components and complete medical devices

- Project Management solutions from Concept to Operational Excellence

- Full program documentation and component traceability

- High-quality plastic products of various shapes and sizes through medical injection molding process

All-Plastics is a reputable Plastic Medical Device Manufacturer that specializes in providing high-quality injection molding solutions for the Medical Device industry. They offer project management services from concept to operational excellence, ensuring efficient and professional services.

Their expertise in medical injection molding and strict compliance with regulations make them a reliable partner for anyone seeking superior medical device manufacturing.

RSP (Renaissance Specialties and Plastics)

Facebook page: Facebook

Services and products:

- Medical product production

- Manufacturing of orthopedics, surgical instruments, diagnostic apparatus, dental technology, and more

- ISO 13485 certification

- FDA approved PPE equipment production

- Full-turnkey diagnostic devices production

RSP is a trusted Plastic Medical Device Manufacturer, with over 50 years of experience in the medical industry. They specialize in producing high-quality products such as orthopedics, surgical instruments, diagnostic apparatus and dental technology that meets specific ISO certifications and FDA requirements.

As an ISO 13485 certified company which can produce approved PPE equipment too, RSP guarantees to provide top-notch manufacturing services for any project needing medical-grade products.

WayKen Rapid Manufacturing Ltd

Contact phone: (580) 872-5518

Facebook page: Facebook

Services and products:

- Medical injection molding services

- Production of medical supplies and equipment

- Fabrication of medical injection devices

- Use of medical-grade plastics that comply with FDA requirements

- Cost-effective manufacturing of medical devices without compromising quality

This Plastic Medical Device Manufacturer specializes in using medical-grade plastics to produce high-quality medical injection devices. They offer a cost-effective alternative to metals and alloys while meeting all FDA requirements for medical supplies.

Their expertise in additive manufacturing ensures strong, durable parts with high dimensional accuracy, making them a reliable choice for large-scale production of single-use medical equipment.

Kingland Industrial Co., Ltd

Company: kingmedtec.com

Services and products:

- Mold design

- Mold manufacturing

- Plastic injection molding

- Quality control

- Production of precision medical plastics

Kingland Industrial, a plastic medical device manufacturer approved by ISO and GMP certifications, boasts an injection molding department equipped with high-precision automatic molding and feeding equipment. With their mold design capabilities and strict quality control measures, they produce high-quality medical plastics for suppliers in the industry.

Cameron-Price

Company: cameron-price.co.uk

Services and products:

- Plastic injection moulded manufacture for medical devices

- Manufacturing of dental instruments

- Manufacturing of diagnostic apparatus

- Production of high-quality plastic moulded parts and products

- Decades of experience in plastic medical device manufacture

Cameron-Price is a top plastic medical device manufacturer based in Birmingham, UK with decades of experience. They offer cost-effective and efficient injection moulding services for a wide range of medical and pharmaceutical products, delivering high-quality components to meet their clients’ needs for precision healthcare solutions.

Solvay

Company: solvay.com

Facebook page: Facebook

Services and products:

- Polymer and material selection for medical devices

- Custom medical device design and development

- Medical device manufacturing

- Quality control and testing services

- Regulatory compliance consulting for medical devices

This plastic medical device manufacturer provides guidance and insight on the important distinctions between “medical devices” and “medical equipment” in the healthcare industry. They emphasize the importance of understanding these differences to properly evaluate materials for their end-use requirements.

AdvanTech Plastics, LLC

Company: advantechplastics.com

Facebook page: Facebook

Services and products:

- Zero-defect quality plastic-injection molded products

- Turnkey plastic medical device manufacturing service

- Complete part traceability from beginning to final delivery

- Partnership with customers for maximum transparency and accountability

- Use of only FDA/medical-grade materials and maintenance of ISO certification

AdvanTech Plastics is a plastic medical device manufacturer that prioritizes zero-defect quality for every plastic-injection molded product they deliver to their customers. With complete part traceability and collaborative partnership with clients, they offer comprehensive manufacturing capabilities that meet the exacting specifications and standards of both customers and FDA regulations.

Their obsession with quality throughout the manufacturing process ensures maximum transparency and accountability.

Elos Medtech

Facebook page: Facebook

Services and products:

- Injection molding of small medical plastic parts with narrow tolerances

- Insert molding, combining high-performance polymer with metal into a single product

- Four decades of expertise in manufacturing instruments and apparatuses for drug production, and laboratory, diagnostic, analytic, and intensive care products

- Precision and thoroughness throughout the process, focusing on control and measurement

- Flexibility in design and manufacturing to meet different project requirements and explore options before launching into the design

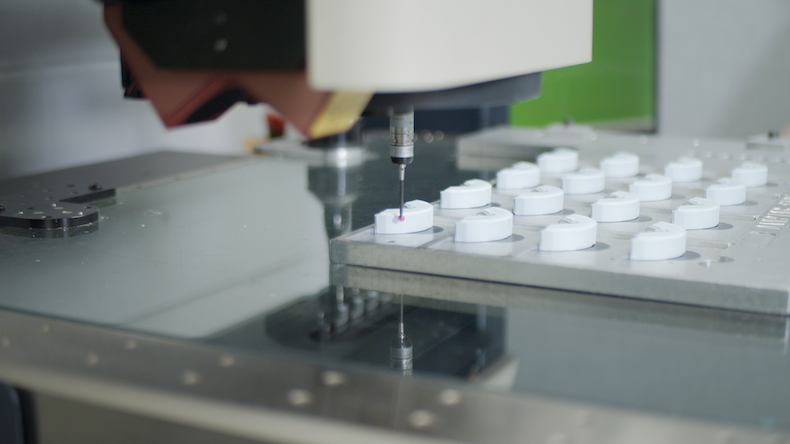

Elos Medtech is a reliable and experienced plastic medical device manufacturer that specializes in the injection molding of small, complex medical parts with narrow tolerances. With over four decades of expertise, Elos Medtech provides precision and thoroughness at every stage of the process, ensuring optimal outcomes for their clients.

They also offer insert molding services by combining high-performance polymer with metal into a single product through their engineering know-how.

Schmit Prototypes

Contact phone: (715) 235-8474

Services and products:

- Custom injection molding for medical devices

- Rapid prototyping of medical devices

- New product development for innovative physicians and inventors

- Production of prototypes for plastic medical device manufacturing

- Mass production of medical devices as part of a medical injection manufacturing process

Schmit Prototypes is a leading manufacturer of custom medical devices with extensive experience in rapid prototyping and injection molding. They work with some of the largest medical companies and device manufacturers in the country, as well as innovative physicians and inventors to bring ideas to life.

Their cutting-edge equipment and processes allow them to produce high-quality prototypes for plastic medical device manufacturing across various applications in the industry.

PTA Plastics

Contact phone: (203) 888-0585

Services and products:

- Upfront Design for Manufacturability (DFM)

- Customized molds for absolute precision

- Educated material suggestions to avoid project difficulties

- Quality T-1 parts that save time and money

- Manufacturing with quality and precision

PTA Plastics is a trusted plastic medical device manufacturer that offers start-to-finish solutions, from upfront design for manufacturability to customized molds and expert material recommendations. They are committed to producing quality T-1 parts with precision and efficiency, ensuring a smoother and more reliable manufacturing process for their clients.

With years of industry experience and ISO certifications, PTA Plastics is the go-to choice for medical device manufacturers large and small.

Donatelle Medical

Services and products:

- Contract manufacturing services for medical devices

- Design concepting and development

- Prototyping through process validation

- Manufacturing and assembly

- Sterilization management

This is a medical device contract manufacturing company with a strong focus on providing rigorous processes to drive predictability, absolute quality, and cost-effectiveness. Their vertically integrated facility includes design concepting, development, prototyping, manufacturing and assembly, packaging and labeling as well as sterilization management.

The company offers expertise in intricate applications where precision, tolerances, validation and timelines are critical.

Genesis Medical Plastics

Company: genesismedicalplastics.com

Services and products:

- Converting implantable PEEK and other medical polymers into stock shapes, film, prototypes, and injection molded or machined components

- Medical prototypes

- Toll and contract manufacturing

- Extruded machinable stock shapes

- Precision machining and injection molding

Genesis Medical Plastics is a leading manufacturer of medical devices and equipment, providing precision machining, injection molding, and polymer conversion services. With deep expertise in polymer processing and materials testing, we help customers energize medical product development and move from prototype to full-scale production quickly and efficiently.

Our comprehensive approach to quality ensures that all products meet the highest standards for safety, reliability, and performance.

Jaycon Systems

Facebook page: Facebook

Services and products:

- High-precision and accurate medical and pharmaceutical products

- Full part traceability from beginning to end

- Plastic injection molding for lab tools, testing equipment, and medical monitoring tools and devices

- Prototyping and full-production units of medical devices and equipment components

- Utilization of newer plastic materials and component designs for reduced incidence of infectious diseases, improved pain management, and decreased healthcare expenses.

This Plastic Medical Device Manufacturer specializes in creating high-quality medical and pharmaceutical products through plastic injection molding. They prioritize the strict standards necessary to guarantee product quality, with full part traceability from design to final inspection.

By utilizing advancements in material manufacturing processes and technological improvements, they contribute to reducing infectious diseases, improving pain management and lessening healthcare expenses within the medical industry.

RevPart

Facebook page: Facebook

Services and products:

- Medical-grade plastics injection molding for medical devices

- Injection molding for components of laboratory and facility equipment

- Injection molding for housings and casings of medical and laboratory equipment

- Injection molding for surgical equipment and components

- Injection molding for drug delivery equipment and components

This Plastic Medical Device Manufacturer specializes in injection molding for medical devices, components, laboratory and facility equipment. With their ability to meet exacting specifications and regulatory needs of the medical industry, they offer cost-effective solutions for applications such as implantable components, surgical equipment and drug delivery equipment.

Upland Fab Inc

Contact phone: (909) 986-6565

Services and products:

- High-performance thermoplastics for medical devices

- Manufacturing complex plastic medical device parts to close tolerances

- Medical grade plastic surgical caddies

- Low volume highly customized caddies and other medical equipment and supplies

- Internal processes such as Digital Product Definition/Model Based Definition (DPD/MBD) controls and cryogenic deburring

Upland Fab is a highly experienced plastic medical device manufacturer that specializes in creating complex parts to close tolerances. With extensive knowledge of unique cutting techniques and expertise in high-performance thermoplastics, Upland Fab supplies leaders in the medical device industry with top-quality surgical caddies and other custom equipment and supplies optimized for repeated sterilization cycles.

Their streamlined process allows for quick design adjustments and efficient production through advanced control processes like Digital Product Definition/Model Based Definition (DPD / MBD) controls and cryogenic deburring.

JG Plastics

Contact phone: (714) 751-4266

Services and products:

- Precision injection molded parts

- High-tolerance tooling

- Experience with FDA approved engineered resin

- Custom parts manufacturing

- High volume disposable products manufacturing

JG Plastics is a leading plastic medical device manufacturer with over four decades of experience in supplying precision injection molded parts and tooling. With their expertise and modern scientific molding principles, they are able to meet the most difficult molding challenges for medical devices.

They provide quality mold making services by ensuring that all aspects of tooling design and construction support the ultimate goal of producing superior injection molded parts, which include complex precise medical molded part, medical device enclosure, ultra-precise dual lumen overmold that can be used in various types of FDA approved engineered resin.

Productive Plastics

Contact phone: (210) 205-1813

Facebook page: Facebook

Services and products:

- Thermoforming of medical device enclosures and structural coverings

- Thermoforming of components for CT scanners, MRI diagnostics, PET scanners, X-ray imaging, and ultrasound imaging

- Thermoforming of laboratory equipment, patient bed components, and monitoring equipment enclosures

- Thermoforming of lavatory components and medical cart paneling and surrounds

- Thermoforming of large parts at low cost, with Class A finishes and industry compliant materials

This Medical Device Manufacturer utilizes plastic thermoforming to produce a variety of medical and diagnostic components such as enclosures, imaging components, laboratory equipment, monitoring equipment enclosures, and patient bed components. With numerous benefits including easy cleaning, aesthetic designs with customizable colors and branding options, lower cost than other materials like fiberglass or metals, the company stands out for their ability to produce industry-compliant high-quality parts at a moderate volume and low upfront investment cost.

Mack Molding – Medical Division

Facebook page: Facebook

Services and products:

- Product development and engineering support

- Medium- to large-part molding and manufacturing

- Assembly services up to and including Class III PMA medical device manufacturing

- Quality and regulatory compliance

- Skilled and experienced medical manufacturing team

MackMedical is a highly specialized plastic medical device manufacturer. Their team of experts includes product development, program management, quality, regulatory, and production staff who work diligently to create products that are biocompatible, autoclavable, chemically resistant and designed for flexibility.

With a culture focused on the medical industry and state-of-the-art technology for manufacturing in Arlington Vermont, MackMedical is uniquely positioned to meet the demands of clients worldwide with unparalleled service.

AIP Precision Machining

Company: aipprecision.com

Facebook page: Facebook

Services and products:

- Precision medical device machining for inside the operating room or inside the body

- High-performance precision minimal plastics for medical industry

- Machining complex plastic medical devices and components

- Close tolerances and extraordinary precision plastic machining expertise

- Machining applications for medical and life science

This plastic medical device manufacturer specializes in precision machining for the medical industry, using high-performance minimal plastics like PEEK that offer the benefits of metal with added advantages such as low coefficient of friction and ability to withstand repeated autoclave sterilization. With a keen focus on exceptional cleanliness and close tolerances, they are able to create complex components required for advanced and minimally invasive procedures.

Blackwell Plastics

Company: blackwellplastics.com

Contact phone: (713) 643-6577

Services and products:

- Manufacturing products for the life science industry

- Developing and manufacturing medical devices

- Manufacturing surgical tools and dentistry products

- Manufacturing diagnostics devices

- Manufacturing products for research laboratories

Blackwell Plastics is an experienced medical device manufacturer with a strong track record of producing quality products for the life science industry. With a history of collaborating with prestigious medical professionals, they specialize in manufacturing plastic tools and devices for various healthcare fields, using GMP protocols to ensure high standards of manufacturing.

They also provide guidance on regulatory compliance and access to industry contacts as part of their commitment to helping clients bring innovative ideas to market.

Recap