Metal Injection Molding Companies offer a cost-effective manufacturing solution for complex metal components, combining the versatility of plastic injection molding with the material strength of traditional metalworking techniques.

Metal Injection Molding (MIM) has revolutionized the manufacturing industry by offering a cost-effective and efficient solution for producing complex metal parts. As the demand for precision engineering continues to surge, MIM companies have emerged as the go-to experts in transforming intricate designs into tangible products.

With their cutting-edge technology, expertise in material selection, and unwavering commitment to quality control, these trailblazers have proven time and again why they are at the forefront of innovation. In this blog post, we will delve deeper into the fascinating world of Metal Injection Molding Companies, uncovering their secrets behind unparalleled success and exploring how they are shaping industries around the globe.

Get ready to embark on an exciting journey where science meets artistry and creativity merges with precision in ways you never thought possible!

OptiMIM

Contact phone: (503) 404-1200

Facebook page: Facebook

Services and products:

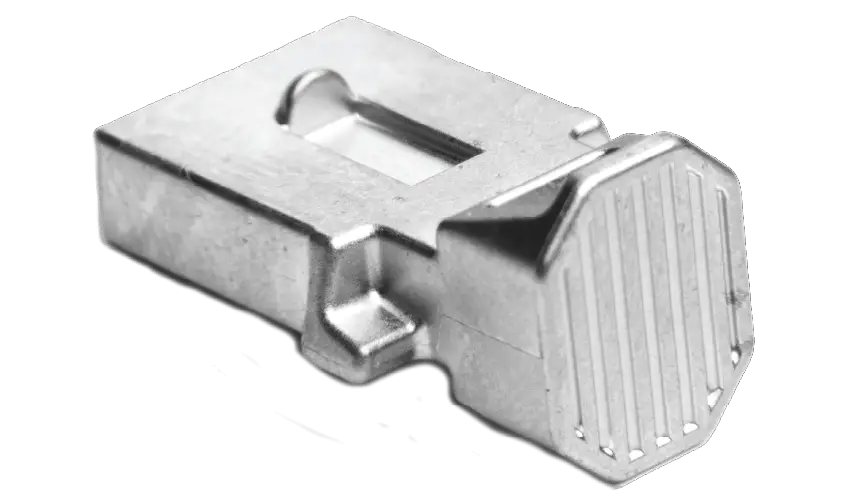

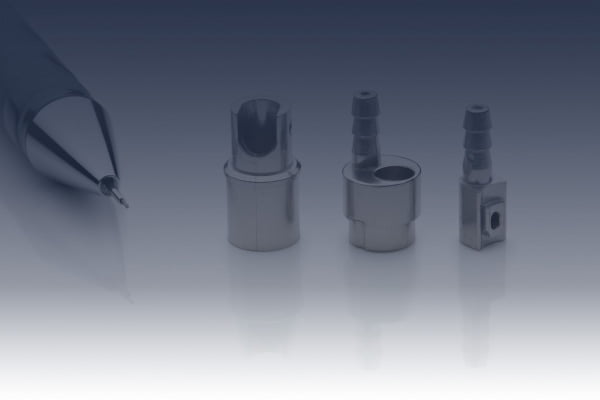

- High performing small precision metal components

- Metal injection molding technology

- Components with almost any level of complexity

- Components at virtually any volume

- Precision where it matters most

OptiMIM, a leading Metal Injection Molding (MIM) company and a part of Form Technologies, utilizes cutting-edge technology to produce small precision metal components with exceptional performance. With the ability to manufacture complex parts at various volumes, OptiMIM delivers precision where it is needed the most.

Smith Metal Products

Services and products:

- Titanium MIM

- Metal Injection Molding

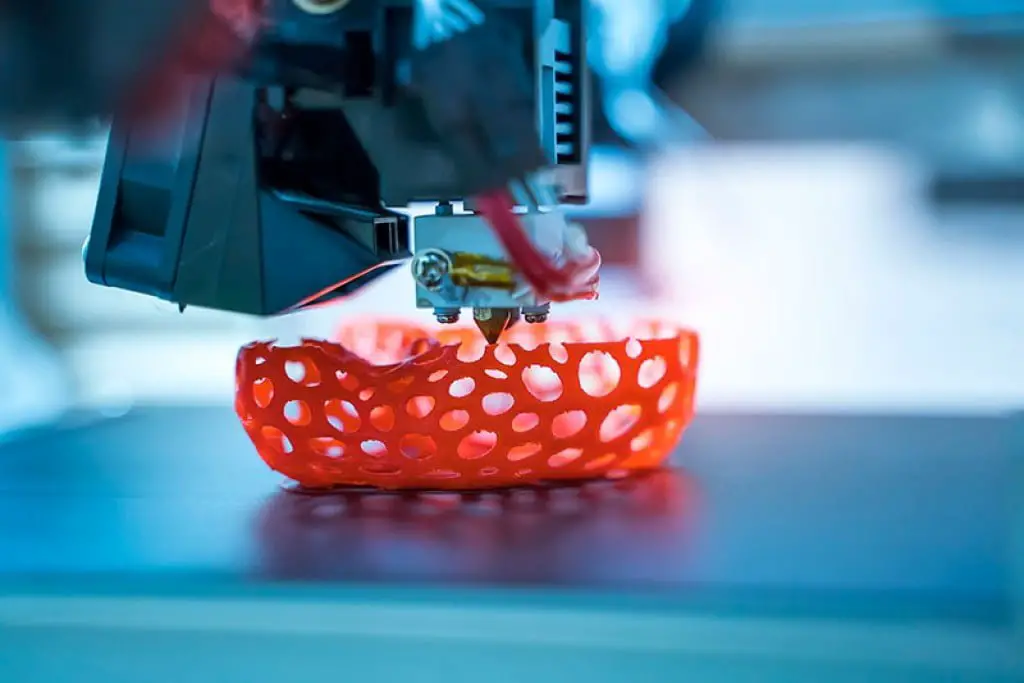

- 3D Binder-Jet Metal Printing

- In-House Metallurgy Lab

- CNC Machined Part VS MIM Part

This Metal Injection Molding (MIM) company specializes in producing high-quality parts for various industries including firearms, medical, aerospace, automotive, and more. With their advanced capabilities in 3D binder-jet metal printing and in-house metallurgy lab, they offer a wide range of advantages over other manufacturing technologies.

Their expertise in MIM process essentials, unique aspects of MIM, and tooling for MIM ensures superior quality and precision in the production of components with excellent surface finish and dimensional tolerances.

The Federal Group USA

Facebook page: Facebook

Services and products:

- Custom metal parts manufacturing in complex shapes

- Production of small, intricate components

- Design freedom for creating complex shapes

- Utilization of a wide range of metal powder and plastic binders

- Mass production capabilities for small, tailored metal parts

The metal injection molding (MIM) process involves four key steps: feedstock preparation, injection molding, debinding, and sintering. In the first step, metal powder is combined with a binder to create a feedstock that can be easily injected into molds.

The next step is injection molding, where the feedstock is injected into the mold cavity to create the desired shape. Once the part has been molded, it goes through debinding to remove the binder material.

Sintering is done to fuse the metal particles together and achieve final density and strength.

Advantages of Metal Injection Molding: Metal injection molding offers numerous advantages over traditional metal fabrication methods. It allows for high productivity and cost-effectiveness in mass production due to its ability to produce complex shapes in large quantities with minimal labor costs.

MIM also provides excellent dimensional accuracy and surface finish compared to other manufacturing processes. It enables engineers to design parts with intricate features that cannot be achieved through conventional machining methods.

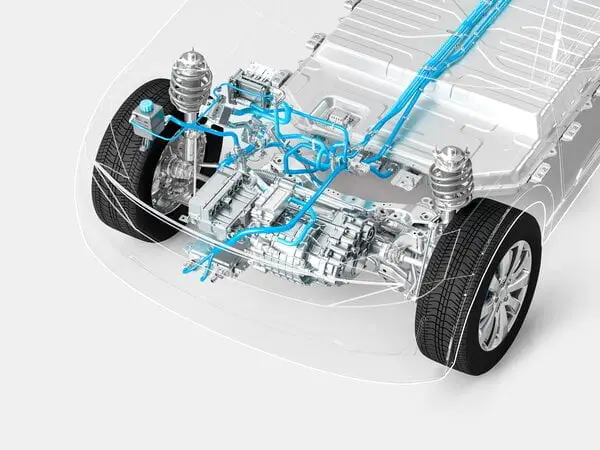

Applications of Metal Injection Molding: MIM finds application in various industries including automotive, aerospace, medical devices, electronics, consumer products, firearms manufacturing and many more. It excels at producing small components such as gears,pins,screws,bushings,valves,micro connectors etc

ASH Industries

Company: ashindustries.com

Contact phone: (973) 580-5205

Facebook page: Facebook

Services and products:

- Metal injection molding (MIM) production

- Short and long-run production of metal parts

- Manufacturing of smaller-sized and detailed metal parts

- Injection molding of powdered metal combined with a binding material

- Creation of metal parts through the MIM process

ASH™ is a leading metal injection molding company that specializes in the production of high-quality metal parts. Their MIM process involves combining powdered metal with a binding material and injecting it into a mold, resulting in precise and detailed metal parts.

This method is ideal for both short and long-run production, particularly for smaller-sized components requiring intricate properties. ASH™ offers reliable solutions for customers seeking efficient and cost-effective manufacturing of metal parts.

Advanced Powder Products

Facebook page: Facebook

Services and products:

- Metal Injection Molding (MIM) technology for small and complex parts

- Rapid engineering and production of quality MIM components

- Manufacturing of small, complex-shaped metal components with outstanding mechanical properties

- Production of medium to high volume components by increasing the number of mold cavities

- Ideal for components weighing less than 100 grams, with complex geometries and tight tolerances, and can fit in the palm of your hand

APP is a Metal Injection Molding (MIM) company that specializes in producing small and complex metal components. With extensive expertise in the MIM process and alloys, APP’s proprietary technology ensures high-performance designs and efficient production of quality MIM components.

They serve various industries looking for medium to high volume manufacturing of components weighing less than 100 grams, with complex geometries, tight tolerances, and dimensions ranging from 2.0 mm (0.08 in) to 150 mm (6 in).

MICRO

Services and products:

- Metal injection molding (MIM) for mass manufacturing of small, intricate geometric components

- Material selection and preparation for MIM

- Production of injection moldable feedstock

- Binder removal process for MIM parts

- Sintering process to ensure correct material composition and physical properties of MIM parts

This Metal Injection Molding (MIM) company specializes in the mass manufacturing of small, intricate geometric components using a hybrid technology that combines plastic injection molding and powder metallurgy. By achieving 95% to 98% of wrought materials properties at a lower cost, MIM is an excellent choice for customers looking for high-quality parts for their products.

Xometry

Contact phone: (833) 333-3333

Facebook page: Facebook

Services and products:

- Complex small-sized metal parts in high volume

- Metal injection molding (MIM) process

- Expertise in MIM process

- High-quality parts delivered to customers

- Other high-volume metal manufacturing processes such as die casting and extrusion

At Xometry, we specialize in the production of complex small-sized metal parts through Metal Injection Molding (MIM). Our industry experts have extensive knowledge and experience in the MIM process, which enables us to deliver high-quality parts in large quantities.

In addition to MIM, we also offer other high-volume metal manufacturing processes such as die casting and extrusion. Learn more about the differences between metal injection molding and die casting on our website.

Schunk Mobility

Facebook page: Facebook

Services and products:

- Production of metal-powder alloys with various alloying elements

- Manufacturing of rust and acid resistant steels

- Production of nickel-based alloys and other high-temperature materials

- Manufacturing of highly wear-resistant and highly heat-resistant soft-magnetic materials

- Shaping through injection molding using metal-powder mixtures with thermoplastic binding agents

The MIM company specializes in producing metal components using the innovative MIM production method. With a wide range of materials available, including rust and acid-resistant steels, nickel-based alloys, and high-temperature materials, they can create highly wear-resistant and heat-resistant soft-magnetic components.

Using injection molding techniques, they shape their feedstock mixture of metal powders blended with thermoplastic binding agents to deliver precise and complex metal components with almost limitless design possibilities.

INDO-MIM

Facebook page: Facebook

Services and products:

- Metal Injection Molding (MIM) parts manufacturing

- Ceramic Injection Molding

- Precision Investment Casting

- Precision Machining

- Additive Manufacturing

INDO-MIM is a world-leading Metal Injection Molding (MIM) parts manufacturer with extensive expertise in design, tooling, materials, and finishing. With locations in India and the United States, INDO-MIM offers a comprehensive range of services including Metal Injection Molding, Ceramic Injection Molding, Precision Investment Casting, Precision Machining, Additive Manufacturing, and Special Processes.

This one-stop solution provider has established itself as a trusted supplier of high-precision products to customers in over fifty countries across the globe.

Sintex a/s

Company: sintex.com

Contact phone: (229) 468-0989

Services and products:

- Metal Injection Molding process

- Excellent and complex design solutions

- Labor-intensive technologies for finishing components

- 3D printing for post-finishing avoidance

- Automated and optimized high-volume production

Sintex is a leading Metal Injection Molding company that offers an innovative solution to the challenges faced in traditional component production. By utilizing their automated and optimized process, Sintex is able to achieve high volume production with strict quality control.

Their four-step MIM process ensures precise and efficient manufacturing of components, resulting in cost-effective solutions for complex design requirements.

Höganäs

Facebook page: Facebook

Services and products:

- High-performance metal injection moulding (MIM) applications

- Cost-effective production of high-volume parts with complex design

- Net-shape capability minimizing material waste

- Enhanced mechanical properties reflecting fine particle size used and high sintered density achieved

- High level of surface finish minimizing post-treatment operations, such as mechanical finishing

Höganäs is a leading metal injection molding company that specializes in the production of high-performance MIM applications for various industries, including automotive, medical, and aerospace. Their range of MIM products is engineered to deliver optimal performance with cost-effective production of high-volume parts featuring complex designs.

With fine particle size and high sintered density, their products also exhibit enhanced mechanical properties comparable to wrought alloys. Höganäs’ MIM process ensures a high level of surface finish, minimizing the need for post-treatment operations.

For more information or requests, contact their sales representative who can provide further assistance while ensuring the privacy and confidentiality of personal data.

FacFox

Services and products:

- Sheet metal prototypes and low-volume production parts shipped in as fast as 2 days

- Metal Injection Molding (MIM) for producing complex and precision-shaped parts

- MIM process offers cost savings of 50% compared to CNC machining or casting

- Greater design freedom with MIM for shaping stainless steel, copper, titanium, and other metals

- Integration and consolidation of multiple components into a single molded piece, reducing costs and assembly time

FacFox is a leading Metal Injection Molding (MIM) company that specializes in producing complex and precision-shaped parts from a variety of materials. With the ability to integrate and consolidate multiple components into a single molded piece, FacFox offers greater design freedom and reduced manufacturing costs.

Their fast prototyping service also allows for quick validation of metal product designs before investing in molds.

MIM International

Company: mimindiacompany.com

Contact phone: (858) 907-7120

Services and products:

- Metal Injection Molding (MIM) parts for Medical

- Metal Injection Molding (MIM) parts for Dental

- Metal Injection Molding (MIM) parts for Automotive

- Metal Injection Molding (MIM) parts for Sports

- Metal Injection Molding (MIM) parts for Mobile phone components

MIM INTERNATIONAL is a leading metal injection molding (MIM) company based in Kerala, India. They specialize in manufacturing small and intricate MIM components for industries such as medical, dental, automotive, sports, and mobile phone components.

With their state-of-the-art R&D facilities and a focus on high volume production, they are emerging as a global supplier of top-quality MIM parts.

Redstone Manufacturing

Company: redstonemanufacturing.com

Services and products:

- Metal injection molding services in China

- Guaranteed delivery backed by a US-based company

- US-based sales force for assistance with the buying process

- Global supply chain management

- Tariff consulting services to optimize costs

Redstone Manufacturing simplifies the metal injection molding buying process by offering a trusted US-based company with manufacturing facilities in China. With over 800 manufacturers to choose from in China, Redstone’s global supply chain and experienced sales force ensure guaranteed delivery, cost savings, and reduced risk throughout the entire metal injection molding process.

Optimize tariff costs and experience a hassle-free buying experience with Redstone Manufacturing.

PSM Industries

Contact phone: (310) 715-9800

Facebook page: Facebook

Services and products:

- Custom metal injection molding parts and components

- Shape complexity and component performance enhancement

- Production of complex shapes beyond conventional powdered metallurgy

- Ability to create parts with features such as OD/ID threads and undercuts without secondary machining

- Manufacturing of metal injection molded parts/components for various industries including automotive, aerospace, medical, business machine, computer components, hardware, sporting, and consumer goods.

PolyAlloys Injected Metals, a division of PSM Industries, Inc., is a leading provider of custom metal injection molding parts and components for various industries. With their expertise in Metal Injection Molding (MIM), they are able to produce complex shapes and high-performance components economically, surpassing the capabilities of conventional powdered metallurgy.

Their comprehensive range of markets served includes automotive, aerospace, medical, business machine, computer components, hardware, sporting goods, and consumer goods.

Norwood Medical

Contact phone: (937) 228-4101

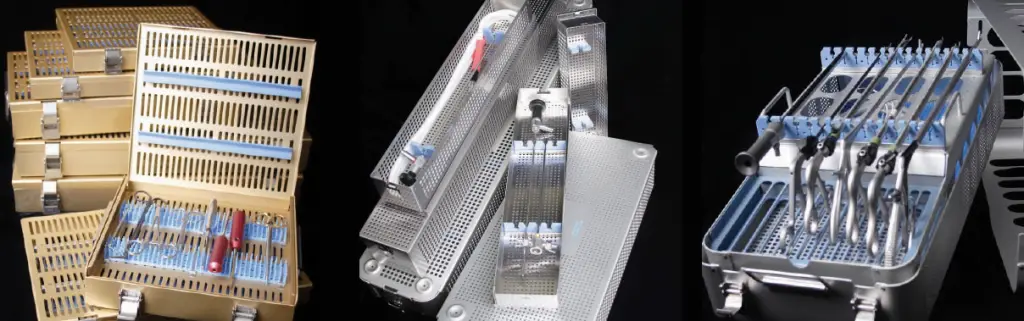

Services and products:

- Full-service contract manufacturing for medical devices

- Plastic injection molding capabilities

- Metal injection molding (MIM) capabilities

- Design, engineering, and production of medical devices using thermoplastics, liquid silicone, or MIM

- Process engineering to reduce production costs, increase quality, and ensure tight tolerances

Norwood Medical is a leading provider of full-service contract manufacturing for medical devices. With an extensive range of capabilities including plastic injection molding and metal injection molding, the company demonstrates their commitment to vertical integration.

Their experienced team offers design recommendations that lower production costs, enhance quality, and produce medical devices with the utmost precision.

REINER®

Contact phone: (772) 365-7294

Services and products:

- Production of cost-efficient precision parts with complex geometries

- Capability to work with dimensions up to 400x700mm tool opening area

- Ability to produce parts weighing up to 75g

- Expertise in working with different materials, including low-alloyed steels and non-corrosive and heat-resistant steels

- Utilization of the MIM procedure for high-volume production with little material waste and post-processing requirements

REINER® is a leading Metal Injection Molding (MIM) company that specializes in producing cost-efficient precision parts with complex geometries. With their state-of-the-art Arburg 270-MIM 50T closing force machine and wide range of materials, including low-alloyed steels and heat-resistant steels, they have been providing high-quality parts to various industries since 2000.

Their advantages include their own tool design and construction expertise, as well as advanced CNC processing centers for complete end processing, making them the go-to choice for customers in need of reliable and high-volume production.

FineMIM

Facebook page: Facebook

Services and products:

- Metal injection molded components for consumer electronics

- Metal injection molded components for automotive parts

- Metal injection molded components for medical applications

- Metal injection molded components for aerospace industry

- Metal injection molded components for industrial sectors

FineMIM is a leading Metal Injection Molding (MIM) manufacturer in China, specializing in the production of metal components for various industries such as consumer electronics, automotive, medical, aerospace, and industrial sectors. With over 15 years of experience, our company utilizes the latest technology to design and manufacture MIM parts made of stainless steel and alloys like titanium.

We offer cost-effective solutions with reduced lead times and significant savings compared to traditional machining methods. Our dedication to precision allows us to deliver high-quality components that meet your requirements while providing excellent service throughout your project development process.

ZCMIM

Facebook page: Facebook

Services and products:

- Metal injection molding for stainless steel parts

- MIM design and mold design

- Tool making for MIM parts

- Debinding and sintering processes

- Surface finishing of MIM parts

ZCMIM is a leading metal injection molding company based in China. With our 8,000 square meter facility and expertise in stainless steel injection molding, we are capable of handling low, medium, and high volume production of MIM parts.

Our comprehensive services include everything from design and tool making to sintering and surface finishing. With over a decade of experience, ZCMIM has gained a strong reputation for manufacturing precision MIM parts that are both cost-effective and of exceptional quality.

We take pride in our ability to produce MIM parts with complex geometries and excellent mechanical properties, making us your trusted partner for all your MIM manufacturing needs.

Matrix Tool

Facebook page: Facebook

Services and products:

- Metal Injection Molding (MIM) process

- Net shape production without flash and surface imperfections

- Creation of complex geometries in volume

- Elimination of the need for secondary operations

- High-quality MIM tooling production with deep experience and expertise

Matrix Tool is a highly experienced Metal Injection Molding (MIM) company that specializes in creating complex metal parts with net shape and without flash or surface imperfections. With over 25 years of experience, they are known for their precision, tight tolerance, and expertise in producing high-quality MIM tooling for some of the biggest names in the industry.

The partnership between Matrix Tool and its customers has consistently yielded exceptional results.

Control Plastics Inc

Company: controlplastics.com

Services and products:

- High-volume metal injection molding (MIM) for finished or almost finished parts

- Wide range of metals available for MIM, including exotics, stainless steels, ferrous and non-ferrous alloys, and magnetic materials

- Ceramic injection molding (CIM) with materials such as zirconia, alumina, and silicon nitride

- High wear resistance, dimensional stability, and high strength in ceramic injection molded parts

- Additional services to minimize marks and improve part quality, such as machining, tumbling, magnetic polishing, electropolishing, or a combination of these.

This Metal Injection Molding (MIM) company specializes in producing high-volume, complex parts in a wide variety of metals and ceramic materials. They offer a range of options including exotic materials with low CTE, stainless steels, ferrous and non-ferrous alloys, magnetic materials, as well as Zirconia, Alumina & Silicon Nitride for Ceramic Injection Molded (CIM) parts.

With expert engineers conducting detailed Design For Manufacturability (DFM) reviews and utilizing various finishing techniques such as machining, tumbling, magnetic polishing, electropolishing or their combination, they ensure the production of high-quality parts with minimal warp and distortion.

Avalign Technologies

Contact phone: (855) 282-5446

Services and products:

- Metal Injection Molding (MIM) process

- Cost savings and weight reduction

- Creation of larger parts

- Titanium components

- Compliance with ASTM standards

Avalign Thortex is a leading Metal Injection Molding (MIM) company that specializes in creating larger titanium components to meet the highest standards set by the American Society for Testing and Materials (ASTM). Their patented MIM process not only provides cost savings and weight reduction but also guarantees exceptional quality.

NNF Tech

Services and products:

- Metal Injection Molded (MIM) components

- End-to-end manufacturing solutions

- Design, engineering, and manufacturing under one roof

- Solutions based on customer specific requirements

- De-binding process for removing thermoplastic binders from molded components

NNF TECH PVT. LTD. is a trusted global supplier of Metal Injection Molded (MIM) components. With a state-of-the-art manufacturing facility in Bangalore, India, we offer comprehensive solutions tailored to customer specifications.

With over a decade of experience in MIM technology, our team ensures the highest quality standards and provides end-to-end manufacturing solutions for industries including defense, consumer goods, industrial applications, medical devices, and automotive sectors. We serve customers worldwide and have expertise in various materials and component varieties.

Our de-binding process efficiently removes thermoplastic binders from molded components using controlled heat and flow-ability techniques.

3ERP

Facebook page: Facebook

Services and products:

- Metal injection molding for low-volume and mass production

- Creation of precise and repeatable metal parts in large quantities

- Capability to work with a variety of metals including alloy steel, carbon steel, stainless steel, iron, copper, nickel, and titanium

- Expertise in using common binder materials such as wax and polypropylene

- Trusted by worldwide engineers for producing high-quality metal parts

3ERP is an experienced provider of metal injection molding services that offers low-volume and mass production capabilities. With their expertise in the process, they can create precise and repeatable metal parts in large quantities using a combination of metal powder and binder.

The company has gained trust from worldwide engineers, as evidenced by the successful implementation of their molded metal parts in various applications.

Get It Made

Contact phone: (847) 962-6539

Services and products:

- Metal Injection Molding (MIM) for high volume production

- No Minimum Order Quantity (MOQ) requirement

- Secondary processes including CNC Machining

- Capability and flexibility to deliver bespoke molded parts

- On-time delivery, specification adherence, and competitive pricing

Get It Made is a trusted manufacturing partner specializing in Metal Injection Moulding (MIM) for high volume production. With no minimum order quantity, they offer flexibility and capability to deliver bespoke moulded parts with additional secondary processes like CNC Machining.

Over 3000 projects have been successfully delivered to leading companies worldwide, ensuring on-time delivery of final metal parts at a competitive price.

CMG Technologies

Contact phone: (619) 710-6707

Facebook page: Facebook

Services and products:

- Injection molded components for medical, aerospace, automotive, and industrial sectors

- In-house MIM process facilitation, including tool design and build, compounding feedstock, and final sintering stage

- Consistency and dimensional repeatability management for unrivaled quality

- Full accreditation to ISO9001-2008

- Reduced lead times and costs for intricate and complex components compared to traditional manufacturing methods

Welcome to CMG Technologies, the UK’s leading Metal Injection Molding (MIM) producer. With over 14 years of experience, we provide injection molded components to various sectors including medical, aerospace, automotive, and industrial.

Our in-house production process allows us to maintain consistent quality and achieve unrivaled dimensional repeatability, while also reducing lead times and costs compared to traditional manufacturing methods.

Custiv

Contact phone: (340) 825-5706

Services and products:

- Multiple metal injection molding facilities

- One-stop metal injection molding solution

- Unlimited capacity

- Certified production

- Tolerances up to 5 microns

This Metal Injection Molding company boasts multiple facilities and offers a comprehensive one-stop solution for metal injection molding needs. With unlimited capacity and certified production, the company guarantees competitive prices while maintaining tolerances up to 5 microns.

They also provide a proprietary software platform and multiple finishing options for their customers. This company offers various materials options including steel alloys, stainless steel, titanium, and titanium alloys.

They excel in post processing services such as sintering, anodizing (Type 2 & 3), chem coating (chromate conversion coating), passivation, and electro-plating. Furthermore, they have a wide supplier presence in countries like Indonesia, India (Ludhiana,Gurgaon ,Jaipur,Noida,Kharagpur,Mphal(Jammu And Kashmir),Jamshedpur,Lucknow(VARANASI) Visakhapatnam(Andhra Pradesh.) Hyderabad,Telangana.,Chennai,Kochi(Kerala.),Bangalore(Capital State-Karnataka,)Coimbatore(PAPER MILLS),Pune(Marathi People from india should be proud of this place.)Mumbai,Vadodara(Ayurveda is really flourish..Area Ahemdabad- Gandhinagar,)Ahmedabad(the

Recap