If you’re in search of reliable plastic injection molding companies in Arizona, look no further.

Plastic injection molding has become a vital process in the manufacturing industry, and companies across the globe are constantly seeking reputable partners to meet their production needs. When it comes to plastic injection molding companies, Arizona stands out as a hub of innovation and expertise.

In this blog post, we will explore some of the top plastic injection molding companies in Arizona, highlighting their capabilities, services, and commitment to delivering exceptional results. Whether you are an entrepreneur looking for a trustworthy partner or an industry enthusiast wanting to stay informed about cutting-edge techniques, this post will provide valuable insights into Arizona’s thriving injection molding landscape.

So let’s dive right in!

ICON Injection Molding

Facebook page: Facebook

Services:

- Engineering-based design and manufacturing processes

- ISO 9001:2015 certified quality expertise

- Custom solutions tailored to meet customer needs

- In-house capabilities and strategic partnerships

- Responsive and flexible supply chain partnership

ICON is an engineering-based injection molding company that takes a scientific approach to design, qualification, and manufacturing processes. With ISO 9001:2015 certification and a commitment to customer satisfaction, ICON creates custom solutions that deliver excellence from art to part.

With complete in-house capabilities and strategic partnerships both domestically and offshore, they offer global experience in this competitive market.

Arizona Applied Engineering

Company: arizonaapplied.com

Contact phone: (928) 772-9887

Services:

- Engineering and Plastic Injection Molding

- Prototypes made in-house from ABS material

- CNC Machining with ten machining centers

- In-house mold building by skilled machinists and mold makers

- Injection molding for diverse customer base with varying order volumes and tolerances

This injection molding company specializes in engineering and plastic injection molding, taking customers’ product concepts from design to functional reality. They have in-house capabilities for fast and functional plastic injection molding prototypes made from ABS material, as well as CNC machining services.

Molds are built by skilled machinists and plastic injection mold makers on-site, while specialized projects can be handled through partnerships. With a diverse customer base, they are capable of serving orders ranging from simple low volume to high tolerance multi-million part orders.

To meet customers’ expectations, they offer quality assurance at all levels and provide post-molding operations such as pad printing, screen printing, laser engraving, sonic welding, and machining.

Moldworx

Company: moldworx.com

Contact phone: (480) 668-8400

Facebook page: Facebook

Services:

- Plastic Injection Molding

- Mold Building

- Automation Design

- Precision Automation and Assembly Solutions

- Injection Mold Repair and Component Manufacturing

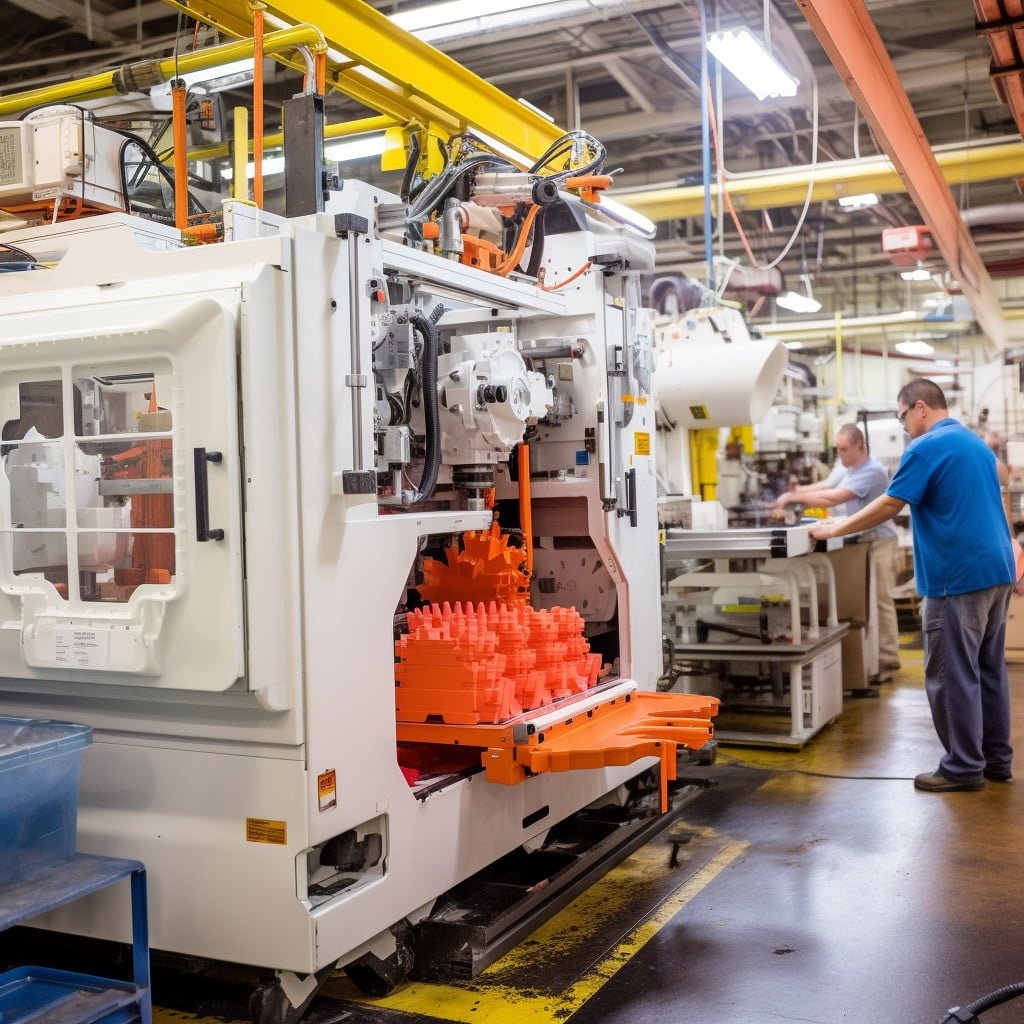

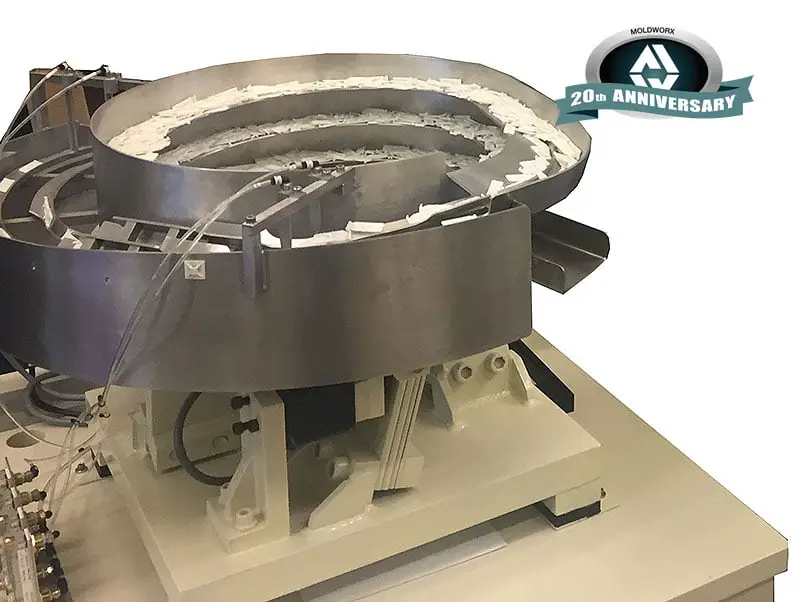

Moldworx is a reputable injection molding company based in Chandler, Arizona. Established in 1995, they specialize in plastic injection molding and automation design services.

With state-of-the-art facilities and a highly skilled staff, Moldworx offers precision automation and assembly solutions to meet the demands of their clients in the manufacturing industry.

Plastic Products Co

Contact phone: (480) 966-1088

Services:

- Design services

- Multiple process choices

- Wide range of presses

- Order fulfillment services

- A la carte menu of services

Plastic Products Co. Inc.

Is a well-established injection molding company with plants across multiple states. They offer a wide range of plastic manufacturing services, including design, production, and order fulfillment.

With their extensive capabilities and commitment to meeting customer requirements, Plastic Products Co. Inc.

Is the go-to choice for high-quality plastic products.

Molded Devices Inc

Contact phone: (361) 851-2252

Facebook page: Facebook

Services:

- Custom injection molding

- Mold making

- Dedicated Program Managers

- Quality Engineers

- Fast and comprehensive quotes

MDI’s Tempe, Arizona facility is an established injection molding operation that specializes in custom injection molding and mold making. Since its acquisition by MDI in 2006, the facility has undergone significant upgrades to enhance infrastructure, equipment, personnel, and technology.

With dedicated Program Managers and Quality Engineers, MDI’s Tempe facility ensures the highest standard of quality through advanced inspection systems and real-time statistical process control software. For a fast and competitive quote on injection molding services, customers can submit their 3D solid models and 2D part drawings along with relevant specifications through the contact page or by calling 480-785-9100.

Legacy Molding

Company: legacy-molding.com

Services:

- Product development: Collaborate with a qualified designer to create a 3D model for prototyping and proof of concept.

- Mass production: Accommodate small or large runs of injection molded parts with a line of injection molding machines.

- Secondary processes: Offer additional services such as printing, laser engraving, and assembly alongside molding.

- Precision mold making: Ensure high-quality molds for injection molding production.

- Post-production services: Provide assembly, packaging, printing, and cutting to complete the manufacturing process.

Legacy Molding is an injection molding company that offers comprehensive solutions for all types of projects. From product development and 3D modeling, to mass production and secondary processes such as printing and assembly, they provide a range of services to bring your ideas to life.

Based in Phoenix, AZ, Legacy Molding is equipped with state-of-the-art equipment and a team of experts to ensure precision and quality throughout the entire manufacturing process.

Plastic Injection Molding

Services:

- Scientific method injection molding

- Excellent mold designing service

- Offering custom-engineered solutions for customers

- Engineered solutions for customized assemblies

- Mold making and design

This injection molding company is known for its wide global customer base, catering to the needs of both start-ups and larger establishments. Starting as a small-sized business, they have gradually emerged as one of the leading plastic injection molding companies in Tucson, AZ.

Their expertise lies in scientific method injection molding, mold designing services, custom-engineered solutions, customized assemblies, mold making and design, product designing, and post-molding procedures. With their extensive experience in injection molding and manufacturing, they offer excellent services to their customers.

Flambeau, Inc

Services:

- Injection molding capabilities

- Secondary operations capabilities

- Mold quotation form

- Consulting/product design

- Prototype capabilities

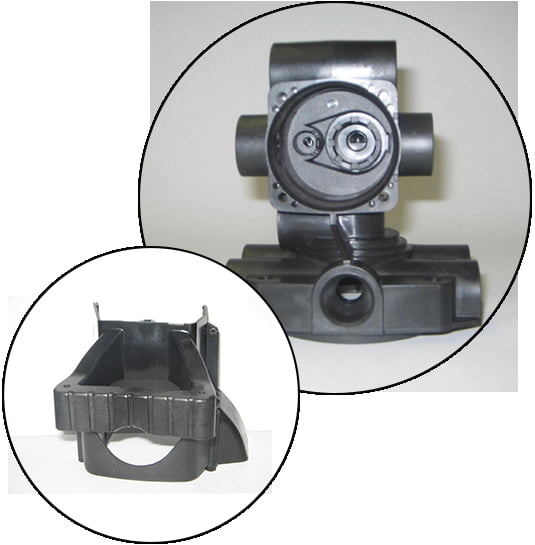

This injection molding company specializes in a range of industries including agriculture, appliances, automotive, business electronics, communications, defense, fluid systems, industrial, lawn & garden, medical/healthcare, recreational/outdoors and transportation. They offer blow molding capabilities as well as injection molding capabilities.

The company provides secondary operations capabilities and services such as consulting/product design and tool fabrication.

Harris Precision Mold

Company: hpmold.com

Contact phone: (480) 731-3135

Services:

- Design and Engineering: The company has a team of mold designers, manufacturing engineers, and CNC/Wire EDM programmers who utilize SolidWorks, SurfCam, and Esprit software for design and engineering purposes.

- Mold Manufacturing: They specialize in building Class 101 plastic injection molds, including 2-shot, unscrewing, and shuttle molds, catering to the medical, pharmaceutical, and packaging markets.

- Two Locations: The company operates from two locations, Tempe, Arizona, and West Jordan, Utah. The Tempe facility provides engineering and inspection services and builds production molds, while the Utah division supports the Tempe facility and serves the repair and tooling needs of companies in the western US.

- Engineering and Inspection Services: The main facility in Tempe offers engineering and inspection services to ensure the quality and functionality of the molds.

- Repair and Tooling: The Utah division specializes in providing repair and tooling services to companies in the western US, supporting their ongoing mold maintenance and repair needs.

Harris Precision Mold is an injection molding company with two locations in Tempe, Arizona and West Jordan, Utah. Their team of experienced engineers and mold designers utilize state-of-the-art software to provide design and engineering services.

They specialize in building Class 101 plastic injection molds for the medical, pharmaceutical, and packaging industries. Their Utah division offers repair and tooling support to companies throughout the western US.

Contact details provided are (480) 731-3135 or [email protected] for the Tempe facility, and (801) 561-1866 or [email protected] for the Utah division.

Fiesta Plastics Inc

Services:

- Plastic Injection Molding

- Quality Tooling and Machining

- Product Design using SolidWorks 2020

- Rapid Prototyping through 3D Printing and RTV Tooling

- Full-service capabilities including designing, manufacturing, and delivering complete and finished products

Fiesta Plastics Inc. Is a full-service injection molding company with 18 molding machines and a complete tooling and machining facility.

Specializing in designing, manufacturing, and delivering finished products, Fiesta Plastics has been in the industry for over 30 years and continues to grow. Their commitment to meeting customer needs has allowed them to adapt in today’s competitive market.

Stratasys Direct

Facebook page: Facebook

Services:

- Injection molding manufacturing service

- Production of plastic parts in higher volumes

- Mold and die construction using various materials

- Secondary operations such as removal of excess material

- Expertise in working with thermoplastic and thermoset plastic materials

This injection molding company specializes in manufacturing plastic parts using the commonly used method of injection molding. Injection molding involves heating plastic or rubber materials, injecting them into a mold to form the desired shape, and then cooling and ejecting the part.

They use molds made from various materials such as steel, aluminum, and beryllium-copper alloy with hardened steel being the most durable option but also more expensive.

PDC – Plastic Design Company

Services:

- Precision injection molding and value-added assembly for medical device and life science customers

- Expertise in producing complex materials such as PEEK, PEBA, and PEI

- Knowledge and experience with a wide range of complex materials including COP, COC, Polycarbonate, PMMA, and Polystyrene

- Quicker decision-making and flexibility for customers

- In-house tooling and design capabilities for better control over iterations and scheduling

- Exclusive cleanroom production in an ISO 8 Cleanroom with state-of-the-art automated equipment

PDC is a specialty manufacturing company founded in 1991 that specializes in precision injection molding and value-added assembly for the medical device and life science industry. They have expertise in producing complex materials such as PEEK, PEBA, and PEI within an ISO 13485:2016 quality system.

Their strengths lie in their knowledge of complex materials, ability to make quick decisions, in-house tooling and design capabilities, and exclusive production in an ISO 8 Cleanroom with advanced automated equipment.

Quickparts

Company: quickparts.com

Facebook page: Facebook

Services:

- Design review and support

- Prototyping

- Low-volume production

- Scale up capabilities

- Fast lead times for tooling delivery

Quickparts is an injection molding company that specializes in providing fast and reliable services to its customers. With their multiple U.S.

Manufacturing facilities, they have the capability to begin tooling projects on the same day they receive files, ensuring quicker turnaround times for their clients. Their comprehensive range of services includes design review, prototyping, low-volume production, and scaling up for a seamless injection molding experience.

Service Rubber Group

Services:

- Design assistance and adjustment for custom rubber products

- Material selection and compound creation for optimal performance

- Prototyping services for product development

- Performance testing and evaluation

- Consultation with engineers and free quotes

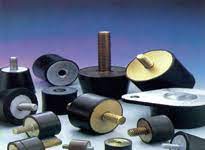

Service Rubber Group is a leading provider of custom rubber injection molding services in Phoenix, AZ. With a team of experts and state-of-the-art technology, they offer design and technical support to ensure the highest quality industrial rubber products for their clients.

From creating prototypes to administering performance testing, their goal is to deliver durable and effective solutions that will greatly benefit various applications. Consult with their engineers today for a free quote and experience the exceptional service of Service Rubber Group’s custom rubber injection molding in Phoenix, AZ.

The Rodon Group®

Company: rodongroup.com

Facebook page: Facebook

Services:

- Plastic Injection Molding

- Custom Plastic Injection Molding

- Standard Parts

- Parts Gallery

- Varying materials and surface finishes for custom injection molding

This injection molding company specializes in custom plastic injection molding for a wide range of applications. Using materials such as ABS, LDPE, HDPE, PC, nylon, HIPS, and PP, they are able to produce high-quality parts with varying properties and finishes.

These materials offer characteristics such as flexibility, impact resistance, durability, transparency, electrical properties, heat resistance, chemical resistance, and non-toxicity.

Ramtecco

Contact phone: (586) 752-9270

Services:

- High precision aluminum and steel molds with tolerances of +/- .0001

- Fast turnaround time for prototype molds

- Specialization in Master Unit Die (MUD) molds and standalone molds

- Mold sizes ranging from 5″ X 8″ to 24″ X 24″

- Complete package for prototype mold projects, including simultaneous operations and 30 years of mold manufacturing expertise

Ramtec is an injection molding company specializing in high-precision aluminum and steel molds. Their prototype molds offer exceptional accuracy and quality, with a focus on establishing essential production tooling requirements.

They are experts in Master Unit Die (MUD) molds, which provide cost savings and quick turnaround for prototype revisions. With their state-of-the-art equipment and extensive mold manufacturing experience, Ramtec delivers precise and cost-effective services for any prototype mold project.

Quality Mold, Inc

Services:

- Plastic injection mold manufacturing

- Product designing and engineering

- 3D programming for plastic injection molds

- Full-scale manufacturing

- Turn-key quality outcomes for complex solutions

Quality Mold, Inc. Is a reputable plastic injection mold manufacturer located in Chandler, Arizona.

With over 50 years of combined expertise, their team of highly skilled Journeymen Machinists and Mold Makers is committed to delivering top-notch solutions for all customers’ tooling needs. From product designing and engineering to full-scale manufacturing, Quality Mold, Inc.

Excels in providing complex solutions and ensures turn-key quality outcomes every time.

Mira Plastics

Company: miraplastics.com

Services:

- Injection molding of plastic products for various industries

- Operation of semi and automatic two-plate, three-plate, runner-less, and hydraulic core pull molds

- Utilization of cutting-edge robotics for parts removal

- Expertise in a wide range of injection molding materials, including thermoplastic polymers and resins, colorants, and additives

- Selection of optimum components based on extensive knowledge of material properties and processing parameters

Mira Plastics is a premier plastic injection molding company based in Fredon Township, New Jersey. With over 65 years of experience, they specialize in producing high-quality injection molded plastic products for various industries.

Their state-of-the-art facility is equipped with advanced machinery and robotics, allowing them to efficiently handle a wide range of molds and materials.

Recap