Plastic injection molding companies in Alabama offer a range of services for various industries, providing efficient and high-quality plastic parts manufacturing.

Plastic injection molding companies play a critical role in bringing innovative products to life, and Alabama is home to some of the best in the business. From automotive components to medical devices, these companies possess the expertise and technology needed to deliver high-quality plastic parts with precision and efficiency.

In this blog post, we will explore the top plastic injection molding companies in Alabama, highlighting their capabilities, certifications, and commitment to excellence. Whether you are a product designer or manufacturer searching for reliable partners or simply curious about the industry in this region, get ready to discover how Alabama is shaping the future of plastic injection molding.

Xometry

Contact phone: (833) 333-3333

Facebook page: Facebook

Services:

- Highly customized injection molding service

- On-demand prototype and production molding

- Expert consultation on each injection mold quote

- Project managers on every order

- Quality assurance with ISO 9001:2015 and AS9100D certified quality management system, ITAR registration, and options for inspections, hardware traceability, material certifications, and CoCs

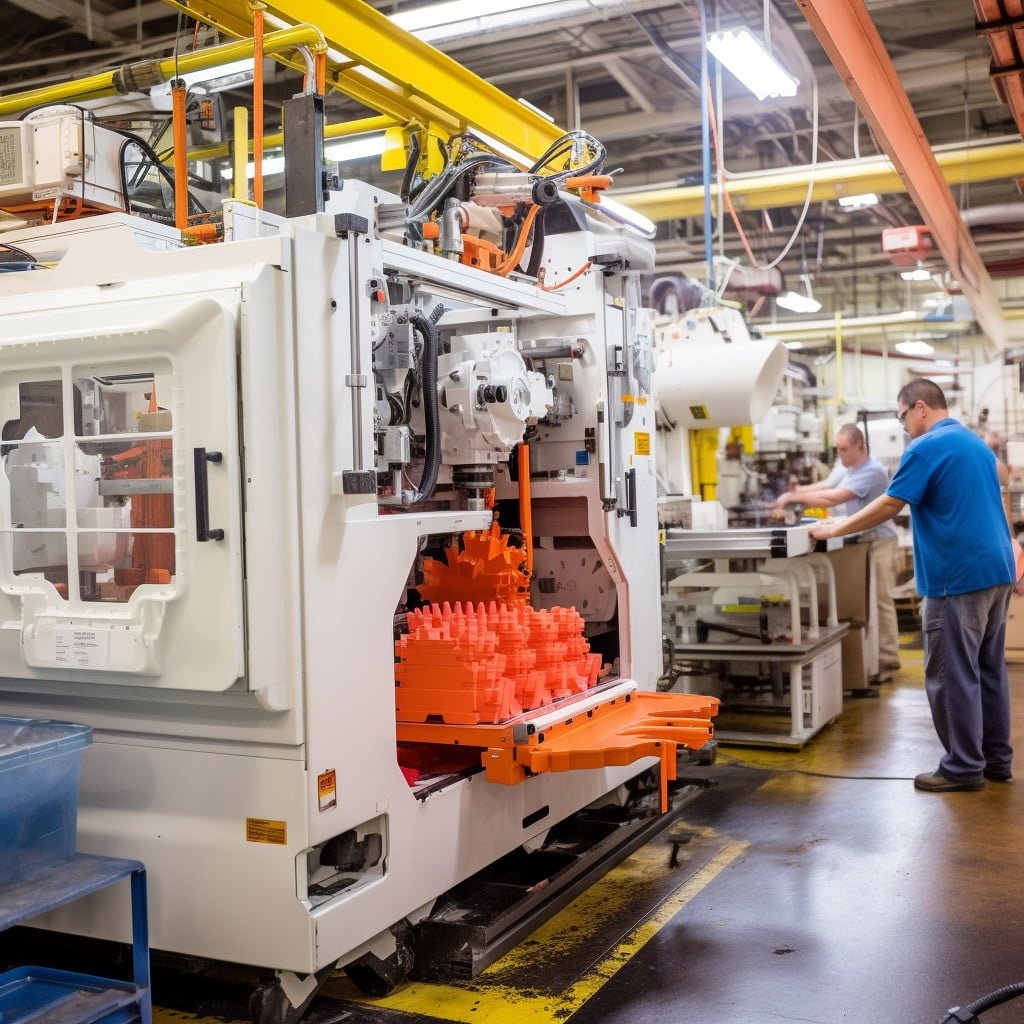

Xometry injection molding is a leading provider of custom, on-demand prototype and production molding services in Birmingham, Alabama.

Innovative Plastics

Company: innovativeplasticsinc.com

Facebook page: Facebook

Services:

- Injection molding

- Mold design and mold making

- Plastic part design and engineering

- 3D rapid prototyping

- Value-added manufacturing

Innovative Plastics is an injection molding company that offers a wide range of services, including mold design and making, plastic part design and engineering, 3D rapid prototyping, and value-added manufacturing. With their ISO 9001:2015 certification, they prioritize delivering high-quality tooling and custom molding at a competitive price in the shortest possible time.

Recognized for their excellence, Innovative Plastics has been awarded the Alabama Manufacturer of the Year Award by the Business Council of Alabama.

Amdek Inc

Contact phone: (256) 778-8141

Services:

- Plastic Injection Molding Manufacturing

- Custom Injection Molding

- Thermo-plastic expertise

- Quality Assurance and process controls

- Pad printing and custom plastic injection molding services

Amdek is a trusted Plastic Injection Molding Manufacturer that has been delivering precise molded products with efficiency since 1991. With their industry knowledge and experience, they are able to handle all types of thermo-plastics and continuously improve their processes to ensure optimized results.

Their expertise extends to customized pad printing and custom plastic injection molding services, as well as robust engineering and brilliant design.

Cumberland Plastic Solutions

Facebook page: Facebook

Services:

- Plastic Injection Molding for a wide variety of industries

- Precision Tooling with in-house mold shop for repairs, engineering changes, and new tool builds

- Automated Assembly using the latest technologies

- Expertise in serving the Lawn & Garden industry with resin performance and UV requirements

- Comprehensive capabilities in the Automotive industry, including interior/exterior trim and HVAC assemblies

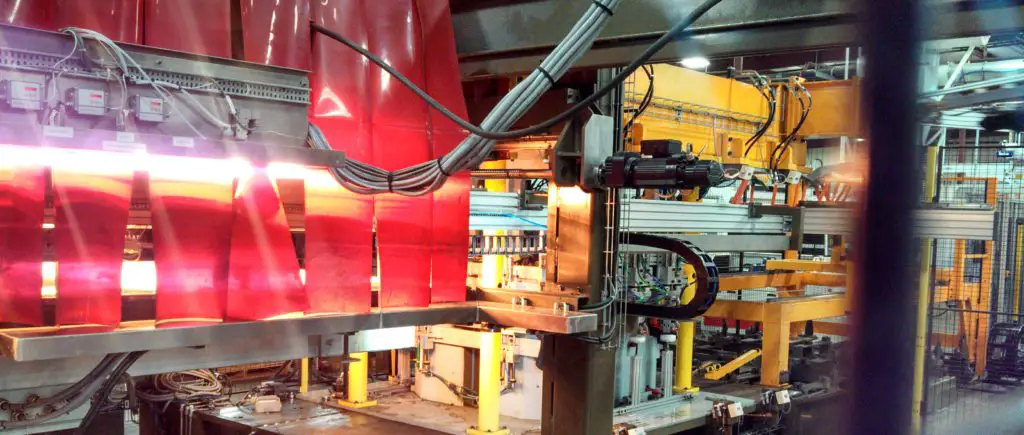

This injection molding company offers a wide range of services to various industries. Their world-class injection molding operation provides value-added solutions for your product.

They also have an in-house mold shop for emergency repairs, engineering changes, and new tool builds. Their automated assembly capabilities ensure the highest quality products at competitive prices.

With expertise in industries such as Lawn & Garden, Building & Construction, Automotive, and Standby Generators, they are able to meet specific requirements and deliver top-notch solutions.

Baytech Plastics

Company: baytechplastics.com

Facebook page: Facebook

Services:

- Quick and seamless transfers of molds

- Expertise in executing complex tooling transfers in a short amount of time

- Ability to support tight production schedules

- Skilled team of engineers and tool makers for mold retrofitting and repair

- Capability to mold acceptable parts and complete level 3 PPAP

Baytech, an injection molding company, showcased their expertise in rapid tooling transfer when a major Automotive customer needed to move molds quickly due to a supplier’s financial troubles. Despite the poor condition of the molds upon arrival, Baytech’s skilled team successfully retrofitted and repaired them to seamlessly integrate into their machines for immediate production of acceptable parts and completion of a level 3 PPAP.

RJG, Inc

Company: rjginc.com

Facebook page: Facebook

Services:

- Part Design

- Mold Design Checklist

- Simulation

- Process Consulting

- TZERO Consulting

This injection molding company, located in Opelika, Alabama and certified ISO 9001:2015, offers training courses covering various aspects of the injection molding process. Their course highlights include part design, material selection, machine operation, mold design, and troubleshooting techniques.

They also provide additional services such as process consulting and technology solutions to aid in quality control and improving speed to market.

Custom Molding

Services:

- Custom plastic injection molding with machines ranging from 88 ton to 1500 ton

- High pressure and low pressure structural foam molding capabilities

- Daily capacities ranging from several hundred large parts to over 500,000 smaller parts

- In-house services including design and engineering, fully equipped tool rooms, and warehousing

- Integrated ISO 9001 quality control with additional services like press side packaging, hot stamping, and sonic welding available if needed

Plastic Industries, located in Tennessee, is a reliable injection molding company that ships products to Alabama with same-day delivery. Their range of plastic injection molding machines allows them to produce large and small parts efficiently, with daily capacities ranging from several hundred to over 500,000 pieces.

Additional services include design and engineering support, fully equipped tool rooms, warehousing facilities, integrated ISO 9001 quality control system as well as press side packaging, hot stamping and sonic welding capabilities.

Plastic Injection Molding

Services:

- Custom plastic molding services

- Tooling services

- Material selection guidance

- Design and creation of custom molds

- Production of high-quality plastic parts according to client specifications

This injection molding company is a premier provider of custom plastic molding services, offering the best molding and tooling services to a wide range of industries. With years of experience and skilled workers, they stay precise in producing custom molded plastic parts.

Their vast knowledge in the field and high level of flexibility allows them to excel in custom plastic molding. They are also available to guide clients in choosing the perfect material for their custom molded parts.

As a leading Plastic Injection Molding manufacturer, they specialize in creating high-quality plastic components using the injection molding process. Their expertise lies in designing and producing custom molds to meet client specifications across various industries such as automotive, medical, and electronics.

The result is lightweight, durable, and cost-effective components that meet the needs of their clients efficiently.

Calhoun Community College

Contact phone: (256) 306-2938

Facebook page: Facebook

Services:

- Injection molding production

- Custom mold design and manufacturing

- Prototyping and product development

- Secondary operations and assembly

- Quality control and inspection

The injection molding company is a highly reputable and experienced player in the industry. They offer a wide range of services, including concept design, prototyping, tooling, and production.

With a focus on precision and quality, they consistently deliver high-performance molded products to their clients.

Shelton State

Facebook page: Facebook

Services:

- Injection molding courses for qualified workers in the field

- Training opportunities for mold setters and process technicians

- Safety training and use of personal protective equipment

- Instruction on machine parts and functions, mold setup, and alignment

- Education on nozzle tips, crane safety and controls, and material handling systems

This injection molding company provides training courses for qualified workers in the injection molding industry, offering a clear path to employment. Their courses cover a range of essential topics, including safety protocols, machine parts and functions, mold setup and alignment, nozzle tips, and more.

They also offer specialized training programs for mold setters and process technicians.

Star Automation, Inc

Company: starautomation.com

Contact phone: (262) 253-3550

Services:

- Custom-designed robotic solutions for fully automating plastics operations

- Injection molding machine tending robots for maximizing efficiency and capacity

- Servo motor-driven robots, sprue pickers, and pallet changers available

- User-friendly interfaces and precise technology in all products

- Expert engineers to help find the best solution for each operation

Star Automation is a trusted supplier of automated solutions for injection molding companies. With their custom IMM robots and sprue pickers, they provide fully automated options for plastics operations, regardless of the product being manufactured.

Their state-of-the-art robotic solutions are designed specifically for each factory’s needs, maximizing efficiency and capacity with user-friendly interfaces and precise technology.

Koller Craft South

Services:

- Strategic location in the Southeast with easy access to the Interstate Highway System

- Supplying high-quality and competitively priced parts and assemblies to customers

- Experience in supplying parts to major automotive manufacturers such as Mercedes, Honda, Nissan, Ford, and Hyundai/KIA

- Expertise in producing non-automotive commercial parts, assemblies, and complete Box Build products for major North American retailers and online platforms such as Wal-Mart, Target, Amazon, and Bed Bath & Beyond

- Commitment to world-class quality with ISO 9001:2015 certification and recipient of the 2017 Kasai Supplier Quality Assurance Excellence Award

Koller Craft South is an injection molding company strategically located in the Southeast, offering easy access to the Interstate Highway System. With a strong reputation for supplying high-quality and competitively priced parts and assemblies, Koller Craft South’s products can be found in major automobile brands such as Mercedes, Honda, Nissan, Ford, and Hyundai/KIA.

Their expertise extends to non-automotive commercial parts and complete Box Build products that are featured in renowned North American retailers like Wal-Mart, Target, Amazon, and Bed Bath & Beyond. With a dedication to understanding customer needs and prioritizing satisfaction as their number one goal, Koller Craft South aims to create value for shareholders, customers, owners, employees through exceptional manufacturing solutions.

Available Plastics, Inc

Company: apiplastics.com

Contact phone: (800) 633-7212

Services:

- Production of plastic fittings and custom parts using an interchangeable family mold base system

- Ability to produce parts in varying combinations to meet specific needs

- Greater part flexibility for customers

- More competitive mold costs

- Quicker turnaround times and lower production costs

This injection molding company offers a flexible and cost-effective solution for producing plastic fittings and custom parts. With their interchangeable mold base system, they can meet varying specifications, leading to increased part flexibility, competitive mold costs, faster turnaround times, and reduced production expenses.

They specialize in custom injection molded PVC parts and provide convenient ways to request quotes or get in touch with them.

Kumi Manufacturing of Alabama

Services:

- Full service provider of high quality plastic injection molding parts

- Focus on growth in the automotive sector

- Commitment to respect for all associates and a safe, clean environment

- Implementation of 5s and Kaizen programs for continuous improvement

- Business planning, ISO 14000, and ISO 9001 programs to bring increased value to customers and associates

Kumi Manufacturing of Alabama, a subsidiary of Kamco Industries, Inc., is a leading provider of high quality plastic injection molding parts. With locations in Clanton, Alabama as well as Bradford, Ontario and West Unity, Ohio, they specialize in serving the automotive sector.

Committed to delivering value and maintaining a safe environment for their associates through programs like 5s and Kaizen, Kumi Manufacturing consistently aims to exceed customer expectations with their comprehensive capabilities. Browse their site for more information and discover how they can meet your company’s needs.

Alabama Germany

Facebook page: Facebook

Services:

- Oversight of day-to-day production activities within the injection molding function

- Development and optimization of processes to maximize product output and ensure safe, efficient operations

- Troubleshooting of molding issues to identify and resolve problems

- Technical development of injection molding employees

- Provision of technical support within an automotive production facility

This injection molding company is responsible for overseeing day-to-day production activities in the injection molding function. They offer a challenging work environment that promotes personal and professional growth.

Their main objectives include ensuring high product yield, performing proactive maintenance tasks, optimizing processes for maximum output and safety, troubleshooting molding issues, assisting in the technical development of employees, and achieving production/quality targets. They are looking for individuals with excellent work ethic who exceed expectations and have a minimum Bachelor’s Degree in Plastics Technology or related engineering discipline.

Strong verifiable injection molding/tooling experience is required along with 3-5 years of experience providing technical support within an automotive production facility and 2-3 years of supervisory experience.

Royal Technologies

Facebook page: Facebook

Services:

- Urethane foam and thermoplastic injection molding solutions

- Two-shot and multi-shot injection molding processes

- Precision plastic lens manufacturing

- IATF 16949 (ISO 9001) and ISO 14001 certified systems

- Advanced engineering and manufacturing for diverse industries

Royal Technologies is an advanced engineering and manufacturing company specializing in urethane foam and thermoplastic injection molding.

Engineered Plastic Components, Inc

Contact phone: (641) 236-3100

Services:

- Injection molding with press sizes ranging from 25 ton to 4000 ton

- Two shot injection molding with presses ranging from 100 ton to 880 ton

- Urethane foaming for manufacturing automotive front dash

- Vacuum forming for producing the outer skin of front dashes in the automotive division

- CAD design software expertise including Pro/ENGINEER, Catia, and SolidWorks

This injection molding company, EPC, operates multiple facilities across the United States and Mexico. They offer a wide range of services including injection molding with press sizes ranging from 25 ton to 4000 ton, two shot injection molding with presses ranging from 100 ton to 880 ton, urethane foaming specializing in automotive front dash manufacturing, and vacuum forming for producing outer skins of front dashes.

Their engineering department utilizes industry-leading CAD design software such as Pro/ENGINEER, Catia, and SolidWorks.

Mira Plastics

Company: miraplastics.com

Services:

- Injection molding of plastic products for various industries

- Operation of semi and automatic two-plate, three-plate, runner-less, and hydraulic core pull molds

- Utilization of cutting-edge robotics for parts removal

- Expertise in a wide range of injection molding materials, including thermoplastic polymers and resins, colorants, and additives

- Selection of optimum components for any project based on extensive knowledge of material properties and processing parameters

Mira Plastics is a premier plastic injection molding company based in Fredon Township, New Jersey. With over 65 years of experience, they specialize in producing high-quality injection molded plastic products for various industries.

Their state-of-the-art facility and expertise in mold operation, robotics, and material selection make them one of the top choices for customers seeking reliable and efficient solutions.

The Rodon Group®

Company: rodongroup.com

Facebook page: Facebook

Services:

- Plastic Injection Molding

- Custom Plastic Injection Molding

- Standard Parts

- Parts Gallery

- Varying materials and surface finishes for custom injection molding

The injection molding company specializes in custom plastic injection molding, offering a wide range of materials to suit various applications. Some of these materials include Acrylonitrile Butadiene Styrene (ABS), which is flexible and lightweight; Low-Density and High-Density Polyethylene (LDPE and HDPE), known for their high tensile strength and impact resistance; Polycarbonate (PC), a transparent and durable alternative to glass; Polyamide (Nylon), offering excellent electrical properties and resistance to heat and chemicals; High Impact Polystyrene (HIPS), a versatile and economical plastic ideal for food-grade components; and Polypropylene (PP), known for its excellent chemical resistance and high melting point.

Recap