Yes, polymer can replace plastic as it is a type of plastic that has unique properties such as being biodegradable and compostable.

As a child, I remember playing with plastic toys and using plastic bags to carry my lunch to school. It was the norm back then, and we didn’t think twice about it.

But as I grew older and learned more about the negative impact of plastic on our environment, I began to question whether there was a better alternative.

That’s when I stumbled upon the world of polymers – a material that has been around for decades but is only now gaining attention as a potential replacement for traditional plastics. As an expert in the construction industry, I’ve seen firsthand how polymers are being used in innovative ways to create sustainable building materials.

But can polymer really replace plastic? In this article, we’ll explore what polymers are, how they differ from traditional plastics, and their potential applications in various industries. So sit tight and let’s dive into this fascinating topic together!

Polymer Vs Plastic: Key Differences

Polymer and plastic are often used interchangeably, but they are not the same thing. While both materials share some similarities, there are key differences that set them apart.

Polymer is a broad term that refers to any material made up of long chains of repeating units called monomers. These chains can be natural or synthetic and have a wide range of properties depending on their composition.

Plastic, on the other hand, is a specific type of polymer made from petrochemicals such as crude oil or natural gas. It’s widely used in packaging materials like bags and bottles because it’s cheap to produce and lightweight.

But here’s where things get interesting: not all polymers are plastics! In fact, many sustainable alternatives to traditional plastics fall under the umbrella term “biopolymers”. These include materials like starch-based bioplastics derived from corn or potato starches which break down more easily than traditional petroleum-based plastics.

So while polymer may seem similar to plastic at first glance, it actually encompasses a much broader range of materials with varying properties – including those that could potentially replace plastic altogether!

As we continue our exploration into whether polymer can replace plastic entirely let us delve deeper into how these two differ in terms of sustainability.

Advantages of Polymer Materials

While plastic has been a go-to material for decades due to its durability and versatility, it’s no secret that it comes with significant environmental drawbacks. Polymer materials, on the other hand, offer several advantages over traditional plastics.

Firstly, polymers are more sustainable than plastic as they can be made from renewable resources such as corn starch or sugarcane. This means that they have a lower carbon footprint compared to petroleum-based plastics.

Secondly, polymers are biodegradable and compostable. Unlike traditional plastics which take hundreds of years to decompose in landfills or oceans causing harm to wildlife and ecosystems; polymer materials break down into natural elements within months under the right conditions.

Lastly but not least important is their strength properties: Polymers can be engineered with specific mechanical properties making them stronger than some types of conventional plastic while still being lightweight enough for easy handling during manufacturing processes.

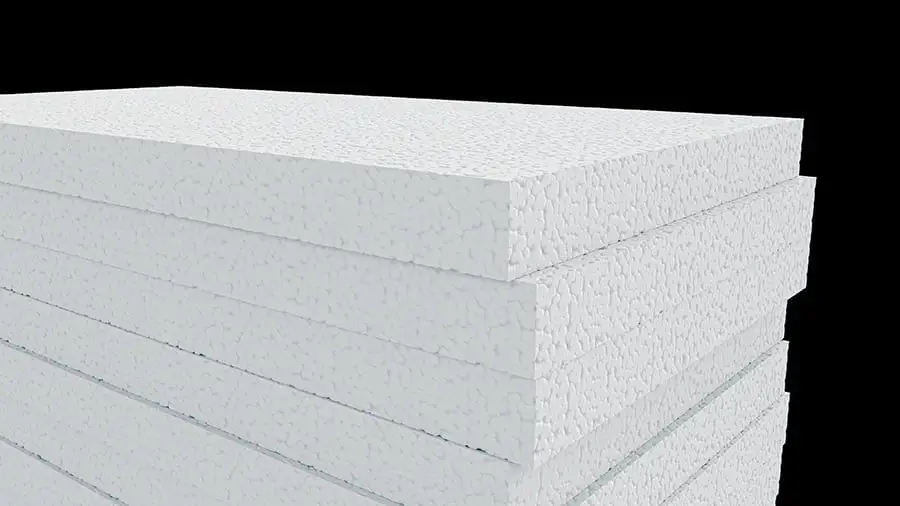

As an expert in construction industry I’ve seen how these advantages make polymer materials ideal candidates for use in building products like insulation panels or roofing tiles where durability is essential but sustainability also matters. But before we get too excited about this new wonder material replacing all our old-fashioned plastics let’s explore further whether there any limitations we should consider when using polymers instead of conventional petrochemical-based ones?

Environmental Impact: Polymers Vs Plastics

While plastic has been a convenient material for many years, its environmental impact cannot be ignored. Plastic waste takes hundreds of years to decompose and often ends up in our oceans, harming marine life and polluting the water.

This is where polymers come in as a potential solution.

Polymers are made from long chains of molecules that can be broken down into their individual components through chemical processes. Unlike traditional plastics, which take centuries to degrade, polymers can break down much faster and with less harm to the environment.

As someone who cares deeply about sustainability and reducing our carbon footprint on this planet, I believe that exploring alternatives like polymers is crucial for creating a more sustainable future. In fact, some companies have already started using biodegradable polymer materials instead of traditional plastics in their products.

While it may take time for polymer technology to catch up with the convenience factor that plastic currently offers us (think grocery bags or food packaging), I am optimistic about what we will see from this innovative material moving forward.

Biodegradable Polymers: A Sustainable Alternative?

One of the biggest concerns with traditional plastics is their inability to biodegrade. It can take hundreds or even thousands of years for plastic to break down, and in the meantime, it pollutes our oceans and harms wildlife.

This is where biodegradable polymers come in as a potential sustainable alternative.

Biodegradable polymers are designed to break down naturally over time through microbial activity or exposure to certain environmental conditions such as heat or moisture. They offer all the benefits of traditional plastics without leaving behind harmful waste that takes centuries to decompose.

In recent years, there has been an increase in research and development focused on creating biodegradable polymer alternatives for single-use items like straws, utensils, and packaging materials. These products have gained popularity among consumers who want more eco-friendly options but still need convenience.

While there are some challenges associated with using biodegradable polymers – such as cost-effectiveness compared to traditional plastics – they represent a promising step towards reducing our reliance on non-biodegradable materials that harm our planet’s ecosystems.

As we continue exploring new ways of utilizing this versatile material called polymer while keeping sustainability at its core – one thing remains clear: The future looks bright!

Applications of Polymer Replacing Plastic

Polymers have a wide range of applications, and they are being used in various industries to replace traditional plastics. In the construction industry, for example, polymers are being used to create sustainable building materials such as insulation foam and roofing tiles.

These materials not only reduce waste but also provide better insulation properties than their plastic counterparts.

In the packaging industry, polymers are being used to create biodegradable bags that can decompose naturally without harming the environment. This is a significant improvement over traditional plastic bags that take hundreds of years to break down.

The medical industry is also exploring the use of polymers in creating biocompatible implants and devices that can be safely implanted into patients’ bodies without causing adverse reactions or rejection by their immune systems.

As we continue our journey towards sustainability, it’s clear that polymer has enormous potential as an alternative material for replacing plastic across various industries. While there may still be some challenges ahead regarding cost-effectiveness and scalability on an industrial level – it’s exciting to see how this innovative material could help us move towards a more sustainable future!

Challenges in Adopting Polymer Solutions

While polymers offer a promising alternative to traditional plastics, there are still several challenges that need to be addressed before they can become widely adopted. One of the main obstacles is cost – currently, producing polymers on a large scale is more expensive than manufacturing plastic.

Another challenge is the lack of infrastructure for recycling and disposing of polymer products. Unlike plastic, which has an established recycling system in many countries, there are limited facilities available for processing and reusing polymer materials.

Furthermore, some industries may be resistant to adopting new materials due to concerns about performance and durability. For example, in construction projects where strength and longevity are critical factors, it may take time for builders and architects to trust that polymer-based solutions can meet their requirements.

Despite these challenges though I believe we should not give up on exploring this option as it could lead us towards finding sustainable alternatives that will help preserve our planet’s resources while also meeting our needs as consumers.

Future Prospects for a Plastic-Free World

As I delved deeper into the world of polymers, I began to see a glimmer of hope for a plastic-free future. The versatility and durability of polymers make them an attractive alternative to traditional plastics in various industries such as construction, packaging, and textiles.

In the construction industry specifically, polymer-based materials are being used to create sustainable building products that are not only eco-friendly but also cost-effective. For instance, recycled polymer composites can be used as an alternative to wood in decking or fencing applications.

Similarly, in the packaging industry where plastic waste is rampant due to single-use items like straws and bags; biodegradable polymers offer a promising solution. These materials break down naturally over time without harming our environment.

While it may take some time before we completely eliminate plastic from our lives; with continued research and development on innovative alternatives like polymers – we can move towards creating a more sustainable future for generations ahead!

Recap