Discover how biodegradable polymers are revolutionizing the construction industry toward a more sustainable future.

As a kid, I loved playing with Legos. I could spend hours building and creating new structures with those colorful plastic bricks.

But as I grew older and learned more about the impact of plastics on our environment, my love for them began to fade.

Nowadays, as an expert in the construction industry, I’m always looking for ways to make buildings more sustainable and eco-friendly. And that’s why I’m excited to talk about biodegradable polymers.

These innovative materials are paving the way for a greener future in construction. They’re made from natural sources like cornstarch or sugarcane, which means they break down into harmless substances when disposed of properly.

In this article, we’ll explore what biodegradable polymers are, how they’re being used in construction today, and why they’re such an important part of our efforts to create a more sustainable world. So grab your hard hat and let’s get started!

Introduction to Biodegradable Polymers

Biodegradable polymers are a type of plastic that can be broken down by microorganisms into natural substances like water, carbon dioxide, and biomass. Unlike traditional plastics that take hundreds or even thousands of years to decompose, biodegradable polymers break down in just a few months to a few years.

As I mentioned earlier, these innovative materials are made from renewable resources like cornstarch or sugarcane. This means they have a much lower environmental impact than traditional plastics which rely on non-renewable fossil fuels for their production.

In the construction industry specifically, biodegradable polymers are being used as an alternative to conventional building materials such as concrete and insulation foam. They offer several benefits over their non-biodegradable counterparts including reduced waste generation during manufacturing and disposal processes.

Moreover, using biodegradable polymers in construction projects can help reduce greenhouse gas emissions associated with the production of conventional building materials while also promoting sustainable practices within the industry.

Overall it’s clear that biodegradable polymers hold great promise for creating more eco-friendly buildings without sacrificing quality or durability.

In fact many experts believe they could play an important role in paving the way towards greener future not only for construction but also other industries where plastic is widely used today!

Types of Biodegradable Polymers

When it comes to biodegradable polymers, there are several types that are commonly used in construction. One of the most popular is polylactic acid (PLA), which is made from cornstarch and sugarcane.

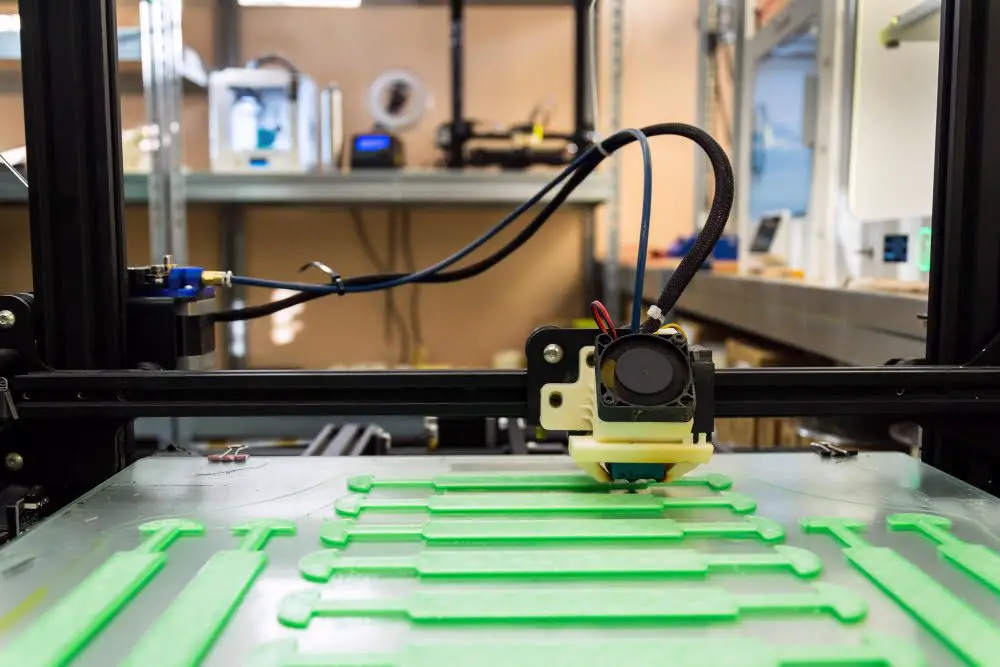

PLA can be used for a variety of applications, including packaging materials and 3D printing. Another type of biodegradable polymer is polyhydroxyalkanoates (PHAs), which are produced by bacteria when they consume organic material like sugar or starch.

PHAs have many potential uses in construction, such as coatings for wood products or binders for concrete. But why should we care about using these types of materials in construction? Well, traditional plastics take hundreds if not thousands of years to break down naturally.

This means that they accumulate in landfills and oceans where they harm wildlife and pollute our environment. By using biodegradable polymers instead, we can reduce our reliance on non-renewable resources while also minimizing waste production.

It’s a win-win situation: we get strong building materials without harming the planet!

Environmental Benefits

As we discussed earlier, biodegradable polymers are made from natural sources and break down into harmless substances when disposed of properly. This means they have a much lower impact on the environment than traditional plastics.

In construction, biodegradable polymers can be used in a variety of ways to reduce waste and promote sustainability. For example, they can be used as an alternative to traditional plastic packaging for building materials or as a replacement for non-biodegradable insulation materials.

But the environmental benefits don’t stop there. Biodegradable polymers also have the potential to reduce greenhouse gas emissions during production because they require less energy and resources compared to their petroleum-based counterparts.

By incorporating these innovative materials into our construction practices, we’re not only reducing our carbon footprint but also paving the way for a greener future where sustainable building practices are commonplace.

Applications in Construction

Biodegradable polymers are not just a buzzword in the construction industry. They have already found their way into various applications, from insulation to roofing materials and even concrete production.

For instance, biodegradable polymer-based insulation is an excellent alternative to traditional fiberglass or foam insulations that can release harmful chemicals during manufacturing and disposal. These eco-friendly insulations offer similar thermal performance while being recyclable or compostable at the end of their life cycle.

Roofing membranes made from biodegradable polymers are also gaining popularity due to their durability and resistance against UV radiation, water penetration, and fire hazards. Moreover, these materials can be easily installed without any specialized equipment or adhesives required for conventional roofing systems.

In addition to this, researchers have been exploring ways of incorporating biodegradable polymers into concrete production as a partial replacement for cement. This approach could significantly reduce carbon emissions associated with cement manufacturing while improving the overall strength and durability of concrete structures.

As we continue our efforts towards creating sustainable buildings that minimize environmental impact throughout its lifecycle – design through demolition – it’s clear that biodegradable polymers will play an essential role in achieving those goals.

Durability and Performance

When it comes to construction materials, durability and performance are key factors. After all, no one wants a building that falls apart after just a few years.

But some people might be skeptical about the durability of biodegradable polymers. Can they really hold up against traditional materials like concrete or steel? The answer is yes! In fact, many biodegradable polymers have been shown to have excellent strength and durability properties.

They can withstand heavy loads and extreme weather conditions just as well as their non-biodegradable counterparts. One example of this is in road construction.

Biodegradable polymer-based asphalt has been found to perform just as well (if not better) than traditional asphalt in terms of wear resistance and skid resistance. So if you’re worried that using biodegradable polymers means sacrificing performance or longevity, think again!

These innovative materials are proving themselves to be more than capable of holding their own in the world of construction.

Cost Analysis and Market Growth

While biodegradable polymers may seem like a no-brainer for their environmental benefits, some may wonder about the cost implications of using them in construction. The good news is that as technology advances and demand increases, the cost of these materials is becoming more competitive with traditional plastics.

In fact, according to a report by Grand View Research Inc., the global market for biodegradable polymers was valued at $1.2 billion in 2020 and is expected to grow at a compound annual growth rate (CAGR) of 14.5% from 2021 to 2028.

This growth can be attributed not only to increased awareness and concern for sustainability but also advancements in research and development that have led to improved performance characteristics such as strength, durability, flexibility, and heat resistance.

As more companies adopt sustainable practices across industries including construction – we can expect this trend towards greener alternatives like biodegradable polymers will continue its upward trajectory. It’s exciting times ahead!

Challenges and Limitations

While biodegradable polymers offer many benefits, they also come with their own set of challenges and limitations. One major challenge is that not all biodegradable polymers are created equal.

Some may only break down under specific conditions, such as high temperatures or certain types of bacteria. Another limitation is the cost.

Biodegradable polymers can be more expensive than traditional plastics due to the production process and sourcing of natural materials. However, despite these challenges, it’s important to remember that every step towards a greener future counts.

As builders and consumers become more aware of the impact we have on our environment, demand for sustainable building materials will continue to grow. Investing in research and development for better biodegradable polymer options while simultaneously improving waste management practices globally can pave a way towards a cleaner planet without sacrificing quality or safety in construction projects.

As an expert in this field myself – I am confident that by working together with industry leaders across various sectors including architecture firms & engineering companies alike; we can find innovative solutions which benefit both people & planet alike!

Case Studies in Green Building

As we discussed earlier, biodegradable polymers are a promising solution for creating more sustainable buildings. But how exactly are they being used in construction today? Let’s take a look at some case studies in green building.

One example is the Bullitt Center in Seattle, Washington. This six-story office building was designed to be one of the most energy-efficient and environmentally friendly structures ever built.

It features an innovative rainwater harvesting system, solar panels on the roof, and composting toilets that use biodegradable polymers instead of traditional chemicals.

Another notable project is The Edge in Amsterdam, which has been dubbed “the world’s smartest building.” This futuristic structure uses sensors to monitor everything from temperature and lighting to occupancy levels and air quality. And like the Bullitt Center, it also incorporates biodegradable materials into its design.

These examples demonstrate that using biodegradable polymers isn’t just good for the environment – it can also lead to more efficient buildings with lower operating costs over time. As technology continues to advance and awareness about sustainability grows among consumers and businesses alike, we can expect even more exciting developments in this area going forward.

Recap