Discover how advanced polymer composites are revolutionizing structural design with their innovative properties and unlocking limitless possibilities.

As a child, I was always fascinated by the intricate designs of buildings and bridges. I would spend hours staring up at towering skyscrapers, marveling at the engineering feats that made them possible.

But as I grew older and began to study the construction industry, I realized that there was still so much untapped potential for innovation in structural design.

That’s when I discovered advanced polymer composites – a revolutionary material that has been quietly transforming the way we build everything from airplanes to sports equipment. With their incredible strength-to-weight ratio and unmatched durability, these composites are unlocking new possibilities for architects and engineers around the world.

In this blog post, we’ll explore what makes advanced polymer composites so unique and how they’re being used to create some of the most innovative structures on the planet.

Whether you’re an industry professional or simply someone who appreciates good design, you won’t want to miss this exciting look into one of construction’s best-kept secrets!

Polymer Composite Basics

Polymer composites are a type of material made up of two or more components that work together to create a stronger, more durable substance. In the case of advanced polymer composites, these materials typically consist of a resin matrix reinforced with fibers such as carbon, glass or aramid.

What makes these composites so unique is their ability to combine the best properties from each component. The resin matrix provides excellent resistance to corrosion and chemicals while also being lightweight and easy to shape into complex forms.

Meanwhile, the reinforcing fibers add strength and stiffness without adding significant weight.

For years now, advanced polymer composites have been used in industries ranging from aerospace engineering to sports equipment manufacturing due in large part because they offer an unbeatable combination of strength-to-weight ratio and durability.

As I delved deeper into this fascinating field during my studies as an expert in construction industry design; it became clear that there was still so much untapped potential for innovation using this material – especially when it comes structural design!

Advanced Manufacturing Techniques

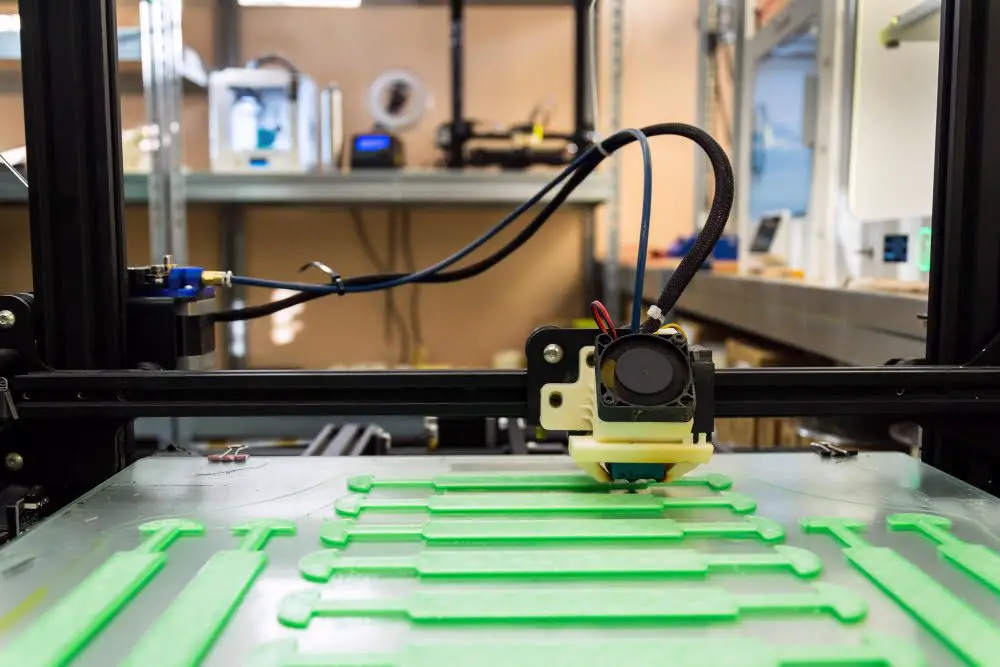

One of the key reasons why advanced polymer composites are so exciting is their compatibility with advanced manufacturing techniques. These materials can be molded into virtually any shape, allowing architects and engineers to create structures that were once thought impossible.

For example, in recent years we’ve seen the rise of 3D printing technology in construction. This technique allows for precise control over every aspect of a structure’s design and fabrication process, resulting in faster build times and reduced waste.

But it’s not just 3D printing that’s benefiting from these new materials – other techniques like injection molding and pultrusion are also being used to create complex shapes with incredible precision.

As an expert in the construction industry, I’m constantly amazed by how quickly technology is advancing. With each passing year, we’re seeing more innovative solutions emerge that push the boundaries of what was previously possible.

And as long as there are materials like advanced polymer composites available to us, I have no doubt that this trend will continue well into the future!

Innovative Structural Design

Innovative structural design is all about pushing the boundaries of what’s possible. It’s about finding new ways to create structures that are not only functional but also beautiful and sustainable.

And advanced polymer composites are playing a major role in this quest for innovation.

One example of this can be seen in the construction of the world-famous Millau Viaduct bridge in France. This stunning structure spans over 2 miles across a deep valley, making it one of the tallest bridges on earth.

But what makes it truly remarkable is its use of advanced polymer composites.

The bridge’s designers used these materials to create an innovative cable-stayed system that allowed them to reduce both weight and wind resistance while maintaining incredible strength and durability. The result was a breathtaking feat of engineering that has become an icon for modern architecture around the world.

But it’s not just bridges where we’re seeing these materials being used – they’re also being incorporated into everything from high-rise buildings to sports stadiums, creating structures that are stronger, lighter, and more efficient than ever before.

As we continue to explore new possibilities with advanced polymer composites, there’s no telling where our imaginations will take us next – but one thing is certain: when it comes to innovative structural design, these materials will play a crucial role in shaping our future built environment for years to come!

Material Properties & Performance

Advanced polymer composites are a class of materials that have been engineered to possess unique properties and performance characteristics. These composites consist of two or more constituent materials, typically a reinforcing fiber and a matrix material, which work together to create an end product with superior strength, stiffness, and durability.

One of the key advantages of advanced polymer composites is their high strength-to-weight ratio. This means that they can support heavy loads without adding unnecessary weight to the structure.

For example, in aerospace applications such as aircraft wings or fuselages made from these composite materials can significantly reduce fuel consumption by decreasing overall weight.

Another important property is their resistance against corrosion and fatigue damage compared to traditional building materials like steel or concrete. Advanced polymer composites are also highly resistant against environmental factors such as moisture absorption which makes them ideal for use in harsh environments like offshore oil rigs.

Innovative structural designs using advanced polymer composite technology have already begun popping up around the world – from bridges spanning vast distances across rivers & valleys; sports stadiums with retractable roofs; even skyscrapers reaching new heights while maintaining stability during earthquakes!

As we continue exploring this exciting field further throughout this article series on “Advanced Polymer Composites: Unlocking The Potential For Innovative Structural Design,” you’ll discover how these remarkable materials are changing our understanding about what’s possible when it comes down designing structures for tomorrow’s world!

Aerospace & Automotive Applications

One of the most exciting applications for advanced polymer composites is in the aerospace and automotive industries. These materials are incredibly lightweight, yet strong enough to withstand extreme conditions – making them ideal for use in aircraft and spacecraft components, as well as high-performance cars.

In fact, many modern airplanes are now built with composite materials instead of traditional metals like aluminum. This not only reduces weight but also improves fuel efficiency and reduces maintenance costs over time.

The Boeing 787 Dreamliner is a great example of this trend – it’s made up of more than 50% composite materials by weight!

Similarly, automakers have been using advanced polymer composites to create lighter vehicles that can still meet safety standards. For instance, BMW’s i3 electric car features a carbon fiber reinforced plastic (CFRP) passenger cell that provides excellent protection while keeping the vehicle’s overall weight low.

As we continue to push the boundaries of what’s possible with these innovative materials, we’re sure to see even more impressive applications emerge across various industries. From bridges and buildings to sports equipment and medical devices – there seems no limit on how far these polymers can take us!

Renewable Energy Integration

One of the most exciting applications of advanced polymer composites is in renewable energy integration. As we continue to shift towards a more sustainable future, it’s becoming increasingly important to find ways to incorporate clean energy sources into our existing infrastructure.

That’s where these composites come in – their lightweight and durable properties make them ideal for creating wind turbine blades that can withstand even the harshest weather conditions.

In fact, researchers at Sandia National Laboratories have been working on developing new composite materials specifically designed for wind turbines. By using advanced modeling techniques and testing methods, they’ve been able to create blades that are not only stronger than traditional fiberglass ones but also more efficient at capturing wind power.

But it’s not just limited to wind turbines – solar panels can also benefit from the use of advanced polymer composites. These materials can be used as protective coatings or substrates for solar cells, helping them last longer and perform better over time.

As we look towards a future powered by renewable energy sources, it’s clear that innovative structural design will play a crucial role in making this transition possible.

With the help of advanced polymer composites, architects and engineers have an exciting new tool at their disposal – one that could unlock endless possibilities for sustainable construction projects around the world.

Infrastructure Advancements

One area where advanced polymer composites are making a significant impact is in infrastructure advancements. From bridges to tunnels, these materials are being used to create structures that are stronger, lighter and more durable than ever before.

For example, the Pulaski Skyway in New Jersey was recently renovated using advanced polymer composites. The bridge’s original steel beams were replaced with composite ones that weigh 50% less but have the same load-bearing capacity as their heavier counterparts.

This not only made the renovation process faster and more cost-effective but also extended the lifespan of the bridge by reducing corrosion.

Another impressive application of these materials can be seen in underground tunnel construction. By using composite reinforcement bars instead of traditional steel ones, engineers can create tunnels that are resistant to corrosion from water or chemicals commonly found underground while still maintaining structural integrity.

As we continue to push boundaries with innovative structural design solutions like those enabled by advanced polymer composites, it’s exciting to think about what other possibilities lie ahead for our built environment!

Recap