Understand why acrylic polymer is the go-to material in construction because this versatile and durable material is revolutionizing the industry.

Acrylic polymers, the versatile materials derived from acrylic acid, stand out in the construction industry for their impressive blend of properties like exceptional clarity, enduring UV resistance, and robust chemical resistance.

Their molecular structure, featuring lengthy carbon chains and ester side groups, makes them a key ingredient in enhancing the performance of concrete and improving energy efficiency in buildings.

Whether applied in concrete mixtures to boost strength and durability, or used in paints, coatings, and adhesives to withstand harsh environmental conditions, acrylic polymers are integral to modern construction practices.

Dive into the world of acrylic polymers with us, where we’ll explore how these substances contribute to stronger, more sustainable infrastructures.

Key takeaways:

- Acrylic polymers are derived from acrylic acids, with long chains of carbons and ester side groups.

- Acrylic polymers have exceptional clarity, UV resistance, and chemical resistance.

- Acrylic polymers can be used in concrete, coatings, adhesives, and paints.

- Acrylic polymer enhances the strength and durability of concrete.

- Acrylic polymers contribute to energy efficiency and sustainability in construction.

What You Will Learn

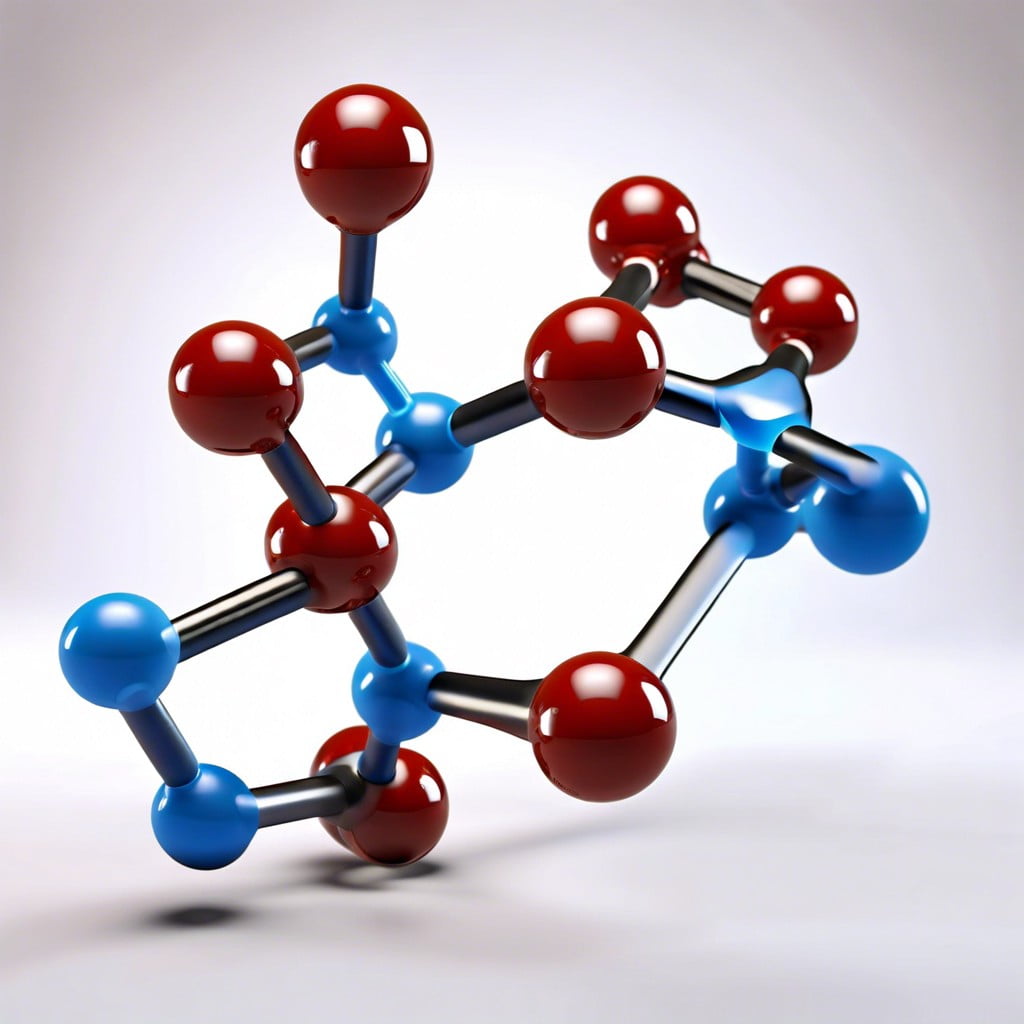

Chemical Composition of Acrylic Polymer

Acrylic polymers are derived from acrylic acids, particularly esters of acrylic acid and methacrylic acid. Their molecular structure mainly comprises long chains of carbons with side groups of ester. These chains are synthesized through a process called polymerization, where monomers (single, small molecules) join to form a large, repeating chain structure.

The unique arrangement of molecules in acrylic polymers gives them a clear, glass-like appearance and makes them highly resistant to UV light and weathering. Additionally, the presence of different side groups can tweak the polymer’s properties, such as flexibility, hardness, and adhesion, making acrylics versatile for various commercial and industrial applications.

Properties of Acrylic Polymer

Acrylic polymers are characterized by their exceptional clarity and brilliance, resembling glass but with greater durability and less weight. They exhibit high resistance to ultraviolet light and weathering, which protects them from sun damage and aging. Moreover, acrylics are known for their excellent optical clarity and can transmit or diffuse light effectively, making them ideal for various optical applications.

Their adaptability is reflected in a wide range of hardness and textures, from soft elastomers to tough, rigid plastics, allowing them to be tailored for specific construction needs. Acrylics maintain their color and shape over time, resisting the warping and discoloration that can occur with other materials.

Thermal stability is another key trait–acrylic polymers can withstand temperature fluctuations without compromising structural integrity. This material also boasts a high resistance to chemicals, oils, and greases, expanding its use to environments that are prone to such exposures.

From an acoustic standpoint, these polymers can dampen noise, contributing to more serene indoor environments. They are also non-toxic and can be safely used in various settings, aligning with health and safety considerations.

Lastly, their ease of fabrication and ability to be recycled make them a versatile and environmentally conscious choice for construction projects, embodying a harmony between functionality and eco-friendliness.

Production Process of Acrylic Polymer

Acrylic polymers are synthesized through a process known as polymerization, where monomer molecules, in this case, acrylic acid esters (like methyl methacrylate), react to form polymer chains.

Let’s break down this manufacturing process:

1. Initiation: The process starts with the generation of free radicals, typically from substances called initiators that decompose under heat or light.

2. Propagation: These free radicals attack the double bond in the monomer, adding the monomer to the radical to form a new radical. This step continues, adding monomers one by one to grow the polymer chain.

3. Termination: At some point, the growing chains will be terminated by various mechanisms, such as combining with another radical or by disproportionation. This halts the process, setting the polymer’s molecular weight.

The resulting substance can be tailored by controlling the reaction conditions—like temperature, pressure, and the ratio of reactants—to create various grades of acrylic polymer, each suited for specific applications. Advanced techniques, such as emulsion polymerization, also allow for the production of water-soluble acrylic polymers used in environmentally friendly coatings and adhesives.

Acrylic Polymer in Construction

In the world of construction, the versatility of acrylic polymer is harnessed to enhance building materials and techniques. Its clear, thermoplastic nature means it can be molded into a range of shapes, and once set, it becomes highly resistant to impact and weathering.

Incorporating acrylic polymer into concrete, for instance, improves its compressive and tensile strength. This modified concrete can withstand heavy loads and resist hairline cracks, extending the structure’s lifespan. Moreover, as a bonding agent, acrylic ensures that repair materials adhere strongly to existing concrete surfaces, making it ideal for restoration work.

In exterior applications, water-resistant properties are a boon. Acrylic coatings not only prevent water ingress but also allow buildings to ‘breathe,’ reducing the risk of mold and damp. This is especially beneficial for structures exposed to harsh weather conditions.

Acrylic is also valuable for its transparency and light-transmitting qualities. It can be used to create windows and skylights that are much more durable and resistant to UV radiation than traditional glass, all while providing excellent clarity.

Furthermore, its application is not limited to solid forms. Acrylic polymer emulsions are widely used in paints, offering enhanced color retention, easier application, and quick drying times.

Utilizing acrylic polymer in construction leads to safer, more durable, and aesthetically pleasing buildings, showcasing its remarkable application in modern architecture and construction projects.

Benefits of Acrylic Polymer in Concrete

Integrating acrylic polymer into concrete mixtures enhances material characteristics in several compelling ways:

- Improved Adhesion: The polymer increases the concrete’s adhesion to different surfaces, making it particularly useful for repair projects or when applying overlays.

- Flexibility: Unlike traditional concrete, acrylic-modified concrete exhibits greater flexibility, reducing the risk of cracking under stress or thermal expansion.

- Water Resistance: The waterproof nature of acrylics translates into concrete that resists moisture penetration, safeguarding against water damage and corrosion of embedded steel reinforcements.

- Abrasion Resistance: Surfaces with acrylic polymer are more resilient to wear and tear, extending the lifespan of floors and pavements.

- Enhanced Aesthetics: Acrylic polymers can improve the finish of concrete, providing a smooth surface that can be pigmented for a variety of colors and textures.

- Cure Time: The curing time of concrete can be significantly reduced when acrylic polymers are used, facilitating quicker construction turnarounds.

By bringing these benefits to the table, acrylic polymers offer innovative solutions for contemporary construction challenges, combining aesthetics with performance.

Acrylic Elastomers and Their Properties

Acrylic elastomers, a specialized group within the acrylic polymers family, boast remarkable qualities that make them ideal for various applications. They are characterized by:

- Exceptional Weatherability: These materials resist degradation from prolonged exposure to sunlight, UV rays, and extreme weather conditions, ensuring longevity in outdoor settings.

- Heat Resistance: Withstanding high temperatures, acrylic elastomers are suitable for applications where thermal stability is essential.

- Oil and Fuel Resistance: This property makes them a preferred choice in the automotive industry for seals and gaskets.

- Flexibility: Maintaining elasticity, they can accommodate movement and settling in construction materials without cracking.

- Transparency and Clarity: When needed, they can be produced to be clear, which is advantageous for applications like outdoor lighting fixtures.

These inherent properties allow acrylic elastomers to contribute significantly to the durability and functionality of the building materials in which they’re incorporated.

Applications of Acrylic Polymer in Construction

Acrylic polymers have found their way into various construction applications owing to their versatility and durability. These applications include:

- Concrete Additives: By incorporating acrylic polymers into concrete mixtures, builders can improve flexibility, reduce cracking, and enhance overall structural integrity.

- Waterproof Coatings: Applied as sealants over surfaces, these polymers create a water-resistant barrier, protecting buildings from moisture damage.

- Roofing Materials: Acrylic coatings on roofs reflect sunlight, thereby reducing interior temperatures and energy costs associated with cooling.

- Joint Compounds: The flexibility of acrylic polymers ensures that joint compounds for drywalls remain durable, withstanding movement and temperature changes without failing.

- Adhesives: Because of their strong bonding properties, acrylic adhesives are used for a variety of materials like tiles, wood panels, and flooring.

- Paints and Primers: Acrylic-based paints and primers offer excellent coverage, quick drying times, and resistance to peeling or chipping.

- Protective Finishes: Outdoor fixtures and furnishings often receive an acrylic finish to prevent degradation from UV exposure and weathering.

By integrating acrylic polymers into these aspects of construction, builders achieve high-performance structures that stand the test of time.

Advantages of Acrylic Polymer Over Traditional Materials

Acrylic polymer stands out due to its exceptional qualities, offering a range of advantages in construction applications:

– **Weather Resistance**: It withstands prolonged exposure to sun, rain, and freezing temperatures, ensuring longevity. – **Color Stability**: Structures painted or coated with acrylic retain their vividness, resisting fading and discoloration. – **Adhesion**: It adheres well to various substrates, which means coatings and paints stay firmly in place on different surfaces. – **Flexibility**: Its flexibility allows it to accommodate slight movements in buildings without cracking. – **Environmentally Friendly**: Water-based acrylics are low in volatile organic compounds (VOCs), contributing to a healthier environment. – **Ease of Application and Cleanup**: Tools and surfaces can be cleaned with water, simplifying the construction process. – **Transparency and Clarity**: In applications like windows and light fixtures, it maintains clarity and transmits light effectively.These features make acrylic polymer a versatile and dependable choice for modern construction, enhancing the durability and aesthetic appeal of structures.

Acrylic Polymer Coatings for Buildings

Acrylic polymer coatings are a popular choice for protecting and enhancing buildings due to their unique properties. They create a durable layer that resists weathering, ultraviolet light, and chemical exposure.

Here are some key aspects:

- Weather Resistance: Designed to withstand extreme temperatures, these coatings maintain their integrity, preventing cracks and peeling.

- Color Retention: They have excellent color retention capabilities, which keep buildings looking fresh and reduce the need for frequent repainting.

- Adhesion: With exceptional adhesive properties, they bond well to various substrates, including concrete, wood, and metal, ensuring a long-lasting finish.

- Breathability: The coatings are permeable, allowing building materials to “breathe” and moisture to escape, thus reducing the risk of mold and mildew growth.

- Application Ease: They can be easily applied using brushes, rollers, or sprayers, making them a practical option for both new construction and renovation projects.

- Low VOC Emissions: Acrylic polymer coatings typically have lower volatile organic compound (VOC) emissions, making them an environmentally friendlier option for building exteriors.

Together, these factors make acrylic polymer-based coatings an effective option for building maintenance, adding both aesthetic appeal and protective functionality.

Water-Based Acrylic Polymer Adhesives

These adhesives are a blend of acrylic polymers suspended in water, offering a strong, durable bond once the water evaporates.

Due to the absence of volatile organic compounds (VOCs), they are more environmentally friendly than solvent-based alternatives.

They adhere well to a variety of surfaces, including metals, plastics, and wood, making them versatile for different construction needs.

Their flexibility allows them to withstand movement and temperature changes without cracking or weakening.

The fast setting time and ease of application, often with a spray gun or brush, facilitate efficient workflow on construction sites.

When cured, they resist moisture and UV light, enhancing the longevity of bonded structures exposed to the elements.

It’s important to apply these adhesives to clean, dry surfaces for optimal adhesion and performance.

Acrylic Polymer Emulsions for Paints

Acrylic polymer emulsions serve as the backbone for many paint formulations, providing a blend of durability and aesthetic appeal. Upon drying, the water in the emulsion evaporates, leaving behind a film of closely packed polymer particles that coalesce into a solid layer. This process imparts several key benefits to the paints:

1. Enhanced Color Retention: These emulsions help paints resist fading and yellowing over time, ensuring long-lasting vibrant colors on various surfaces.

2. Improved Adhesion: The unique properties of the polymer allow the paint to adhere better to different substrates, reducing the likelihood of peeling or blistering.

3. Water-Resistance: Being inherently resistant to water, once dried, paints based on acrylic emulsion can form a barrier that protects surfaces from moisture ingress.

4. Flexibility: Acrylic paints remain flexible upon drying, which minimizes the risk of cracking and allows for movement within the painted surface without damage.

5. Eco-Friendly Option: Water-based acrylics emit lower levels of volatile organic compounds (VOCs) compared to solvent-based options, making them a safer choice for the environment and for indoor air quality.

6. Variety of Finishes: Depending on the formulation, acrylic emulsions can produce a range of finishes from high gloss to matte, offering versatility for different design preferences.

7. Quick Drying Times: The fast drying nature of these paints allows for quicker recoating and job completion, a valuable feature for both DIY enthusiasts and professional painters.

Comparison: Acrylic Emulsion Paint Vs. Plastic Emulsion Paint

Understanding the differences between acrylic and plastic emulsion paints can help you make informed choices for your construction or renovation projects.

Composition: Acrylic emulsion paints are water-based and have acrylic polymer as their binding agent, offering strong, flexible coatings. Plastic emulsion paints, often referred to as vinyl paints, use polyvinyl acetate as the binder.

Durability: Acrylic paints typically outperform plastic emulsions when it comes to resistance to weathering and ageing. They adhere well to surfaces and are less prone to cracking or chalking over time.

Color Retention: Acrylic formulations tend to hold their pigment better, ensuring the paint maintains its original hue for longer periods compared to plastic emulsions, which might yellow or fade faster.

Washability: Acrylic paints are easier to clean, allowing walls and surfaces to withstand regular washing without the paint coming off, a feature that might not be as strong in plastic emulsion paints.

Price: Due to their enhanced properties, acrylic emulsion paints are usually more expensive than their plastic-based counterparts.

Application: Both can be applied to a wide range of surfaces, including plaster, brick, and concrete, but acrylics have an edge in overall performance, especially in exterior settings.

Each type has its merits, and the best choice will depend on the specific requirements of your project, such as the need for outdoor durability or a tighter budget.

Acrylic Polymer and Sustainability in Construction

In the realm of sustainable construction, acrylic polymers contribute significantly to green building practices. Here are some ways in which they support eco-friendly construction:

- Energy Efficiency: With excellent thermal properties, acrylic-based materials help in reducing the energy consumption of buildings. They contribute to insulation, which keeps interiors comfortable and cuts down on heating and cooling requirements.

- Longevity: The durability of acrylics means less frequent replacements, thus conserving resources and reducing waste. This aligns with the principles of sustainable development by extending the lifecycle of construction materials.

- Reduced VOC Emissions: Water-based acrylic polymers emit low levels of volatile organic compounds (VOCs), making them a healthier choice for indoor environments and minimizing air pollution.

- Recyclability and Waste Reduction: Some acrylic products are recyclable, which minimizes their footprint by allowing the materials to be repurposed at the end of their life cycle.

- Reflective Roof Coatings: Acrylic coatings on roofs reflect sunlight and reduce heat absorption, which can lower urban heat islands and contribute to energy savings.

- Compatibility with Other Sustainable Materials: Acrylics can be combined with sustainable materials, amplifying their green benefits. For example, they are often used in composites with recycled plastics or glass fibers.

In sum, the integration of acrylic polymers in construction supports the drive for sustainability by enhancing energy efficiency, durability, and material efficiency while also reducing environmental impact.

Maintenance and Durability of Acrylic Polymer Products

Acrylic polymers boast impressive durability, requiring minimal maintenance over their lifespan. They resist weathering, UV radiation, and chemical attack, which means they don’t yellow, become brittle, or lose their strength easily when exposed to the elements.

Here are some key points regarding their maintenance and longevity:

- Cleaning: Simple cleaning methods involving water and mild detergent are usually sufficient, keeping the appearance fresh and vibrant without the need for aggressive chemicals.

- Resistance: Acrylics are inherently moisture-resistant, preventing mold growth and reducing maintenance associated with moisture damage.

- Repair: Minor scratches and damages can often be easily repaired with polish or by a filler material, which seamlessly blends with the existing structure.

- Paintability: If a color refresh is desired, they readily accept paints and coatings, without peeling or blistering, when the appropriate products are used.

- Longevity: Acrylic polymer products generally maintain their integrity for decades, contributing to lower life-cycle costs compared to materials that require frequent repairs or replacements.

This strong performance in various conditions makes them a top choice for a range of construction applications, from sealants to paints and beyond.

Safety and Handling of Acrylic Polymers in Construction

Safety measures are vital when working with acrylic polymers to ensure a risk-free construction environment. These materials require careful handling:

- Ventilation: Use in well-ventilated areas to minimize inhalation of fumes.

- Protective Equipment: Wear gloves, safety goggles, and respirators as needed to prevent skin and eye contact and inhalation of particles.

- Correct Mixing: Follow manufacturer guidelines for mixing polymer solutions, as incorrect proportions can affect setting times and strength.

- Storage: Store acrylic polymers in a cool, dry place, away from direct sunlight and extreme temperatures to prevent degradation.

- Disposal: Dispose of any waste material according to local environmental regulations to prevent ecological harm.

- Spill Management: Quickly clean up spills using absorbent materials to prevent slips and potential chemical reactions with other substances on the site.

By adhering to these precautions, workers can handle acrylic polymers efficiently while maintaining a safe construction site.

The Role of Acrylic Polymer in GFRC (Glass Fiber Reinforced Concrete)

Acrylic polymers play a pivotal role in enhancing the performance of Glass Fiber Reinforced Concrete (GFRC), a material renowned for its strength and versatility in the construction industry.

Here are some key points that illustrate the contributions of acrylic polymers in GFRC:

- Flexibility and Toughness: The incorporation of acrylic polymers allows GFRC to maintain robustness while offering greater flexibility compared to traditional concrete. This improved elasticity reduces the risk of cracking under stress or during transport.

- Adhesion Properties: Acrylic polymers enhance the bonding between glass fibers and the concrete matrix, which translates to a higher tensile strength for the composite material. This strong bond ensures the structural integrity of GFRC components.

- Weather Resistance: GFRC components containing acrylic polymers demonstrate excellent weather resistance. They withstand harsh environmental conditions, including UV exposure, extreme temperatures, and moisture, making them ideal for outdoor applications.

- Improved Workability: The addition of acrylic polymers makes the GFRC mixture more workable, allowing for intricate shapes and fine details in architectural elements. This ease of molding and sculpting opens up creative possibilities for designers.

- Curing Efficiency: Unlike traditional concrete that requires ample time to cure, GFRC with acrylic polymers can cure more rapidly and effectively, helping to speed up construction timelines.

Incorporating acrylic polymers into GFRC significantly boosts the material’s performance, ensuring that it meets the dynamic needs of modern construction projects, from enhanced durability to creative design flexibility.

Standards and Specifications for Acrylic Polymer in Construction Materials

Ensuring the quality and performance of acrylic polymers in construction materials relies on adhering to set standards and specifications.

ASTM International provides various protocols to test for properties like viscosity, tensile strength, and adhesion. ASTM D4802, for instance, covers acrylic plastic materials.

ISO standards, including ISO 7823-1, -2, -3, detail requirements for general-purpose acrylic sheets, considering characteristics such as optical and mechanical properties.

EN standards from the European Committee for Standardization assess aspects such as the reaction to fire and the durability of acrylic products used in construction.

Local Building Codes often reference these standards to set minimum performance criteria for construction materials, including those incorporating acrylic polymers.

Compliance with these standards is critical for manufacturers, as it directly relates to the safety, durability, and sustainability of the construction projects in which acrylic polymers are utilized. Manufacturers and engineers must familiarize themselves with these standards to ensure the materials they use or produce meet the necessary quality benchmarks.

Future Trends in Acrylic Polymer Application in Construction

The continuous advancements in material science forecast an exciting future for the use of acrylic polymers in construction.

- Smart Polymers: Researchers are exploring stimuli-responsive acrylics that change properties in response to environmental conditions, potentially leading to self-healing materials or structures that adapt to changing loads or temperatures.

- Green Chemistry: There’s a push towards more eco-friendly production processes, using bio-based monomers to create acrylic polymers, reducing the carbon footprint associated with construction materials.

- Enhanced Performance Composites: Combining acrylic polymers with other materials aims to produce composites with superior strength, durability, and resistance to environmental stresses, improving the longevity of structures.

- Nanotechnology Integration: At the nano-scale, acrylic polymers may be manipulated to create coatings and additives with improved thermal insulation, UV resistance, and antimicrobial properties, providing added functionality to construction materials.

- 3D Printing: With the rise of 3D printing in construction, acrylic polymers are being tailored for use in this technology, allowing for more complex architectural designs and rapid on-site production of building components.

These trends represent a fraction of the potential that acrylic polymers hold as a pivotal element in the future of sustainable and innovative construction methodologies.

FAQ

What is acrylate polymer used for?

Acrylate polymers have a diverse range of applications including the production of coatings, paints, sealants, adhesives, textile fibers, printing inks, superabsorbent materials for diapers, thermoplastic elements, and advanced biomedical technologies.

Are acrylic polymers safe?

Acrylic polymers, such as Poly Methyl Methacrylate (PMMA), are generally considered safe due to their low toxicity, although they do contain minimal levels of residual monomers and process chemicals that may leach out during handling and use.

Is acrylate a plastic?

Yes, acrylate, specifically in the form of polymethyl methacrylate (PMMA), is considered a type of plastic.

Is acrylic a synthetic polymer?

Yes, acrylic is a synthetic polymer.

How are acrylic polymers produced?

Acrylic polymers are produced through a process called free-radical polymerization, where monomers like methyl methacrylate are reacted, typically with an initiator such as benzoyl peroxide, to form long polymer chains.

What are the primary characteristics of acrylic polymers?

Acrylic polymers are primarily characterized by their exceptional durability, transparency, weather resistance, and flexibility.

How does the use of acrylic polymers benefit the construction industry?

The use of acrylic polymers in construction provides benefits such as improved durability, water resistance, and flexibility, thereby enhancing the overall quality and longevity of structures.

Related reading: