Explore the fascinating world of superabsorbent polymers because their ability to absorb and retain huge amounts of liquid can revolutionize the construction industry.

Superabsorbent polymers are remarkable materials with the extraordinary ability to soak up and lock away copious amounts of water, much like a microscopic sponge that operates at the edge of material science and magic. These polymers, built primarily from polyacrylate compounds, boast a versatile array of structures and properties tailored for specific uses.

Whether transforming agriculture with water-conserving soil additives, elevating personal care products through high-performance absorbency, or revolutionizing waste management with their fluid-sequestering capabilities, superabsorbent polymers are hidden heroes in our daily lives.

This article shines a light on the intricate world of these polymers, detailing how their porous matrices function and where they make a profound impact across various industries—a treasure trove of insights for the curious mind seeking to understand these fascinating materials and their wide-ranging applications.

Key takeaways:

- Superabsorbent polymers can absorb and retain large volumes of water.

- There are different types of superabsorbent polymers with unique properties.

- The chemical composition of superabsorbent polymers consists of polyacrylate compounds.

- Superabsorbent polymers absorb liquids through their porous structure.

- Superabsorbent polymers have diverse applications in agriculture, personal care, industry, and waste management.

Overview

Superabsorbent polymers (SAPs) are materials with the extraordinary ability to absorb and retain large volumes of water or aqueous solutions, swelling to many times their original size. These cross-linked polymers turn water into a gel-like substance by forming hydrogen bonds with water molecules.

Due to their high absorbency relative to their mass, SAPs play a crucial role in products where liquid management is essential, such as diapers and hygiene products.

Because of their versatility, they are becoming increasingly important in innovative industries like agriculture for water conservation in soil. Versatile and efficient, their expanding use showcases a commitment to improving products that touch everyday life while also enhancing environmental sustainability.

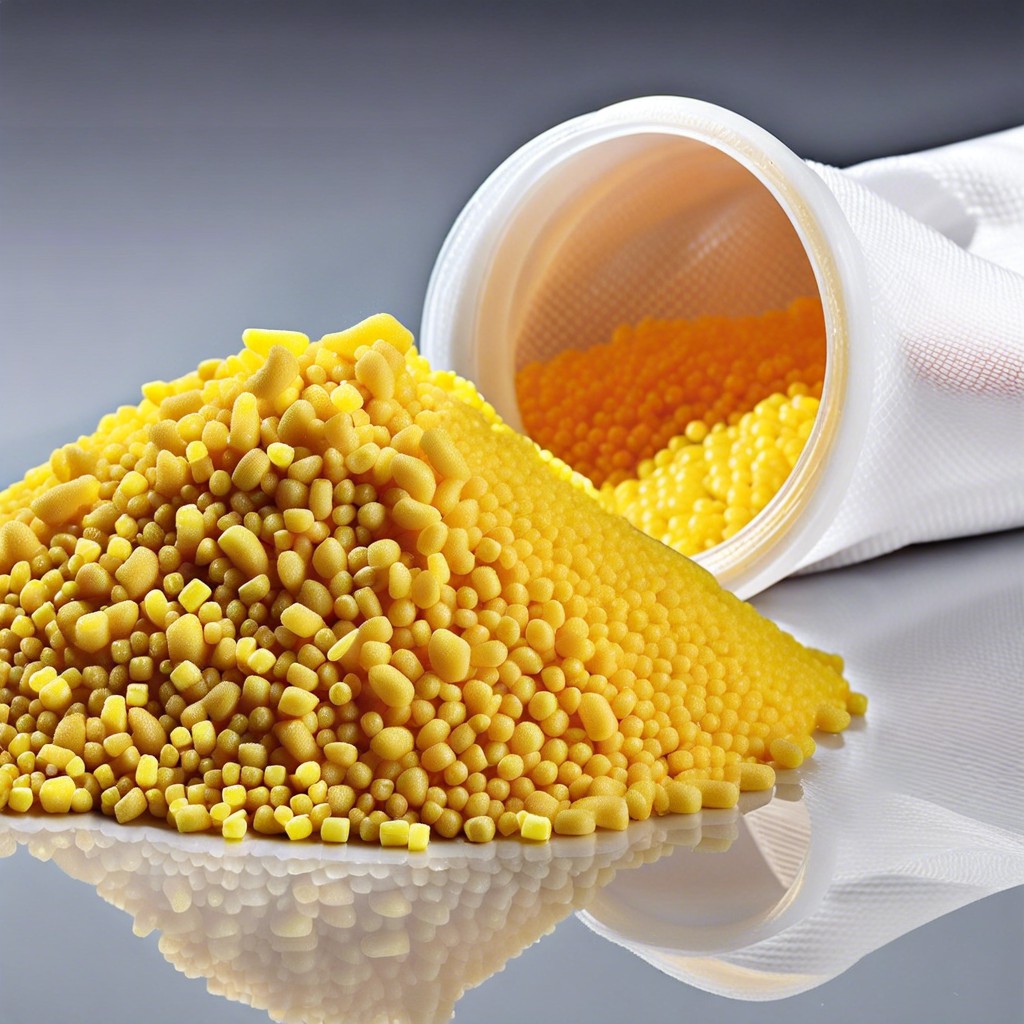

Types of Super Absorbent Polymer

Superabsorbent polymers (SAPs) are broadly classified by the type of polymer chain they contain. Each category has unique properties that lend themselves to specific applications.

1. Sodium Polyacrylate: This is the most common type of SAP found in everyday products like baby diapers and adult incontinence pads. Sodium polyacrylate can absorb many times its weight in water, turning into a gel-like substance upon absorption.

2. Polyacrylamide Copolymers: Often used in agriculture, these polymers enhance soil’s water retention capability, helping plants resist drought conditions. Their network structure is tailored to release water gradually.

3. Polyvinyl Alcohol (PVA): PVA-based SAPs are recognized for their strength and abrasion resistance, making them suitable for industrial applications where mechanical stress is a consideration.

4. Starch-Grafted Copolymers: Consisting of natural starch and synthetic polymers, these SAPs are biodegradable, offering an eco-friendlier option with applications ranging from agriculture to packaging materials.

5. Cellulose-Based Polymers: Derived from cellulose, these SAPs are also biodegradable and are often used in medical applications due to their biocompatibility.

Each SAP type can be tailored during synthesis to optimize performance characteristics such as absorption capacity and rate, swelling pressure, and gel strength for its intended use.

The Chemical Composition of SAP

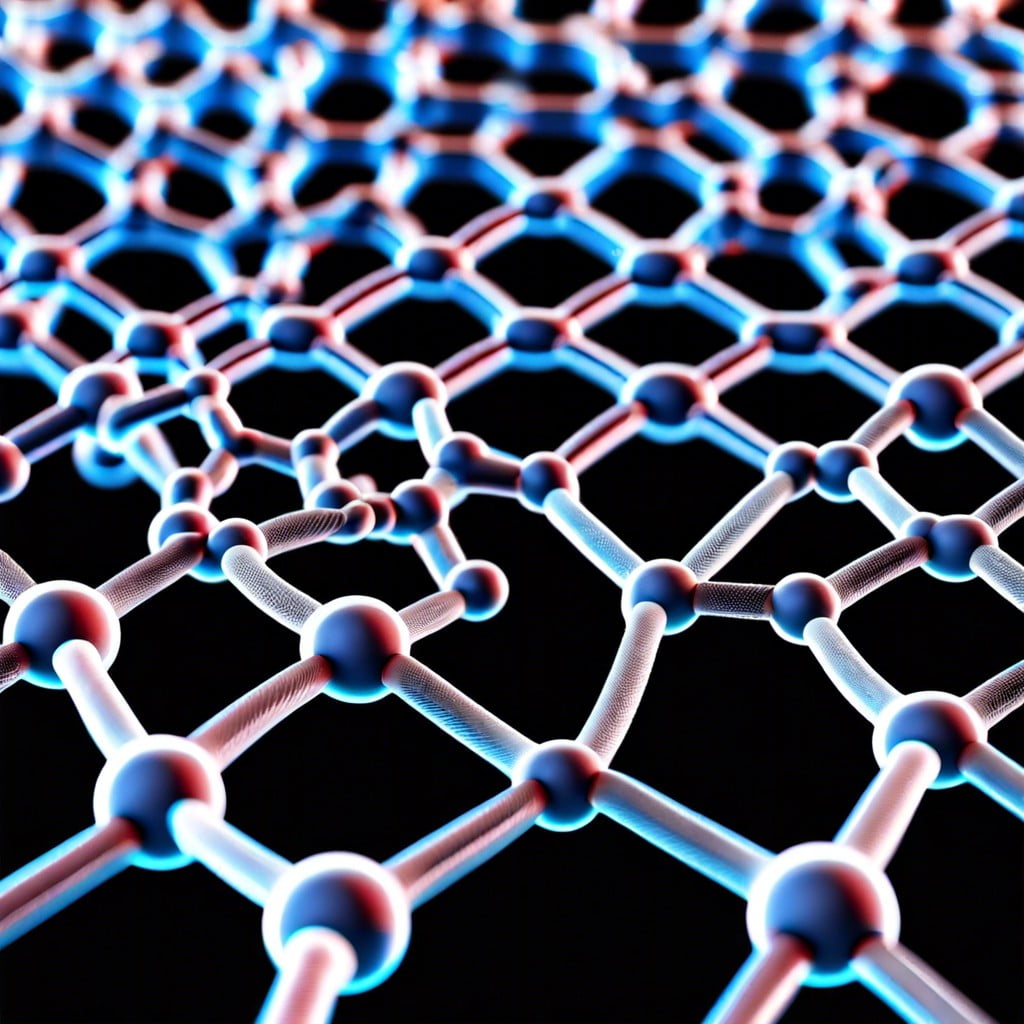

Superabsorbent polymers (SAPs) are primarily made up of polyacrylate compounds, which are cross-linked networks of polymer chains that have the remarkable ability to absorb and retain large volumes of water. Here’s a breakdown of the key components:

- Polyacrylate: This is a type of polymer that’s derived from acrylic acid, a substance commonly used in the manufacturing of plastics. Polyacrylate is the backbone of most SAPs, providing the structure that absorbs water.

- Cross-linkers: These are chemicals that bond individual polyacrylate chains together, creating a three-dimensional network. It’s the density of these cross-links that determines how much liquid the SAP can absorb. Fewer cross-links mean a looser network with more space for water, while more cross-links create a denser, less absorbent material.

- Sodium ions: Sodium polyacrylate, a common form of SAP, contains sodium ions. These ions help to enhance the absorbency by facilitating the movement of water into the polymer network.

- Functional groups: The acrylic acid chains feature carboxyl groups (-COOH). When these come into contact with water, they ionize and become negatively charged, which in turn attracts water molecules.

This composition enables SAPs to absorb up to several hundred times their own mass in water, which makes them invaluable in applications where liquid management is crucial.

Mechanism of Absorption

Superabsorbent polymers (SAP) have the remarkable ability to soak up vast amounts of liquid relative to their mass. This is possible due to their unique structure, which is made up of long chains of molecules interlinked in a network. This network is highly porous, allowing liquid to enter and be retained within the structure.

At the molecular level, the chains contain a significant number of hydrophilic groups. These are parts of the molecules that are attracted to water, enabling the polymer to draw in and hold moisture. When liquid encounters the SAP, it’s rapidly absorbed and distributed throughout the polymer network, turning the SAP from a dry, granular solid into a gel-like substance.

The absorption mechanism involves swelling as the liquid is taken in, and the polymer expands to many times its original size. This expansion is constrained by the cross-linked nature of the polymer, which also ensures that the SAP does not dissolve in water. Electrostatic charges within the polymer play a vital role in maintaining the structure’s integrity and supporting its absorption capacity.

Temperature and the quality of the liquid, such as salt concentration, can influence the absorption capacity and rate. SAP can absorb more in distilled water compared to saline water, as the presence of ions in saline can interfere with the absorption process.

Important Characteristics of Superabsorbent Polymers

Superabsorbent polymers (SAPs) are notable for their prowess in absorbing and retaining liquid, showcasing the ability to hold many times their own weight in water. This capacity is due to their hydrophilic, or water-loving, polymer chains, which swell as they come into contact with moisture.

Key features include:

- High Absorption Rate: SAPs rapidly soak up fluids, a quality that is particularly useful in products like diapers or for controlling spills.

- Retention Capacity: Unlike sponges, SAPs lock in moisture, preventing it from being easily squeezed out.

- Swelling: When SAPs absorb water, they expand significantly. This swelling is reversible; they return to their original size as they dry out.

- Thermal Resistance: Many SAPs can maintain their structure and functionality over a range of temperatures.

- Chemical Stability: These materials are usually inert, meaning they don’t react with other chemicals and thus maintain their absorbing properties across various conditions.

- Biocompatibility: Certain SAPs are safe for use in applications that require contact with the human body, such as in sanitary products or wound dressings.

These characteristics make SAPs versatile, enabling their use in contexts that demand a combination of durability, reliability, and safety in water absorption and retention.

Uses of Super Absorbent Polymer

Superabsorbent polymers (SAPs) have revolutionized the way we manage liquids in various products and industries:

- In agriculture, SAP enhances soil quality by retaining moisture, reducing the need for frequent watering, and improving plant growth.

- They are essential in personal care items like diapers and adult incontinence products, where they absorb and lock away fluids efficiently.

- SAP is used in the medical field for wound dressings that require high absorbency to manage exudate and promote healing.

- These polymers play a critical role in flood control; water-swollen bags create quick and effective barriers against rising floodwaters.

- The food packaging industry uses SAPs to absorb excess moisture, ensuring freshness and preventing spoilage.

- In cable manufacturing, SAPs are applied within cables to block water penetration, providing protection and maintaining cable integrity.

SAPs are versatile and provide solutions where liquid management and control are crucial.

SAP in Agriculture

Superabsorbent polymers offer innovative solutions in agriculture, with their incredible ability to retain water proving transformative for soil quality and plant growth. They absorb moisture many times their own weight and release it gradually, which benefits crops in several ways:

- Water conservation: They significantly reduce the need for frequent watering by retaining moisture in the soil.

- Improved soil structure: Mixing SAP with soil can enhance aeration and root penetration, leading to healthier plants.

- Enhanced nutrient retention: These polymers hold onto nutrients, preventing them from leaching away from plant roots.

- Drought management: In arid areas, SAPs help maintain moisture levels, allowing crops to survive prolonged dry spells.

- Seedling survival: SAPs can be used during planting to ensure seedlings have the critical water needed to establish themselves.

Their application in agriculture showcases a step forward in resource management, improving crop yields while fostering sustainable farming practices.

SAP in Personal Care Products

Superabsorbent polymers (SAP) have become a staple in the world of personal care products due to their remarkable ability to absorb and retain liquid. Here are several points to explain how SAP is utilized in personal care items:

1. Diapers and Adult Incontinence Products: SAP is a critical component in diapers for both babies and adults. It helps in absorbing urine and turning it into gel, which prevents leakage and keeps skin dry.

2. Feminine Hygiene Products: SAP is used in sanitary pads and tampons where it effectively absorbs menstrual fluid, again minimizing leakage and enhancing comfort.

3. Wound Care: In some advanced wound dressings, SAP helps in managing exudates from sores or injuries, thereby promoting a better healing environment.

4. Cosmetics: Within cosmetic products like face masks and hydrating patches, SAP’s absorbency is employed to deliver moisture and active ingredients to the skin for longer periods.

The incorporation of SAP in personal care products improves user experience by boosting performance in terms of absorption, providing comfort, and preventing potential skin irritations caused by wetness. With its hygienic benefits, SAP has become essential in the manufacture of products designed for convenience and health.

SAP in Industrial Applications

Within the industrial sector, superabsorbent polymers (SAP) play a vital role in multiple applications due to their exceptional absorption capabilities:

- Cable Wrapping – SAPs are used to prevent water from penetrating and damaging underground power cables. When wrapped around the cables, the polymer swells upon contact with moisture, creating a barrier against water infiltration.

- Flood Control Products – They are incorporated into sandbag alternatives which are lightweight and easy to transport. Upon contact with water, they expand, blocking floodwaters more efficiently than traditional methods.

- Packaging Material – In the packaging industry, SAPs protect goods by absorbing condensation or leaks that may occur during shipping, especially for moisture-sensitive products.

- Water-blocking Tapes – Used within the telecommunications industry, SAP-infused tapes prevent water from spreading along optical fibers, thus safeguarding signal integrity.

- Firefighting – SAPs are added to water used in firefighting to enhance its effectiveness. The polymers help retain water in the target area, reducing the amount of water needed and the risk of water damage.

By incorporating SAPs, industries optimize product functionality, improve safety measures, and contribute to more efficient processes, making these polymers a key to innovation and problem-solving in industrial applications.

Application in Waste Management

Superabsorbent polymers (SAPs) play a pivotal role in enhancing the efficiency and cleanliness of waste management systems. Here’s how these innovative materials contribute:

- Liquid Waste Solidification: SAPs can solidify liquid waste, reducing spillage risk during transport and disposal.

- Odor Control: By absorbing moisture, SAPs help in controlling foul odors emanating from waste.

- Medical Waste Management: In healthcare settings, they solidify biohazardous fluids, making handling and disposal safer.

- Sanitation Products: SAPs are key in manufacturing diapers and adult incontinence products, improving hygiene and comfort.

- Landfill Management: Their use in landfills minimizes leachate formation, thus reducing potential soil and groundwater contamination.

Through these applications, SAPs contribute to more sustainable and effective waste management practices.

Environmental Impact and Biodegradability

Superabsorbent polymers (SAPs) are primarily made from polyacrylate compounds, which yield long-lasting, non-biodegradable materials. This durability contributes to SAP’s effectiveness but also raises questions about their environmental impact.

Non-Biodegradability: Conventional SAPs do not easily break down in natural environments. Disposed of in landfills, they can persist for years.

Soil Absorption: When used in agricultural applications, the non-biodegradable nature of SAPs can lead to soil accumulation over time, potentially affecting soil health and permeability.

Microplastic Pollution: As SAPs degrade physically, they can release microplastics, which are a concern for aquatic and terrestrial ecosystems.

Biodegradable Alternatives: Research is ongoing to develop SAPs from biodegradable materials like polysaccharides, which can minimize long-term environmental impacts.

Life-Cycle Assessment: Evaluating the full environmental footprint of SAPs involves examining raw material extraction, production, usage, and end-of-life disposal.

Understanding and mitigating the environmental impact of SAPs is crucial, and the development of eco-friendlier alternatives is an essential step toward sustainability.

The Benefits of Superabsorbent Polymers

Superabsorbent polymers (SAPs) offer a multitude of advantages, particularly in their capacity to absorb and retain large volumes of liquid relative to their own mass. Here are some key benefits:

1. Efficient Water Retention: SAPs can absorb water up to several hundred times their weight, making them ideal for maintaining moisture in products like diapers or agricultural soils.

2. Reduced Watering Frequency: In agriculture, SAPs reduce the need for frequent watering, as they slowly release stored water, thus conserving water resources and saving time.

3. Enhanced Soil Quality: Incorporating SAPs into soil can improve its structure and porosity, promoting aeration and preventing soil compaction.

4. Leakage Prevention: By converting liquid into gel, SAPs prevent leakages in products like food packaging, providing a cleaner and safer user experience.

5. Cost-effective: Despite their advanced functionality, SAPs can be cost-effective by reducing the frequency of product changes or applications—like in diapers or agricultural use.

6. Waste Minimization: SAPs contribute to waste reduction by enabling products to be thinner and lighter, thus requiring less material for construction and decreasing post-use waste volume.

Each of these benefits stems from the remarkable ability of SAPs to interact with water, making them versatile solutions in numerous industries.

The Safety of Superabsorbent Polymers

Concerns about the safety of materials used in everyday items are legitimate, especially those that come into direct contact with human skin or are part of environmental management systems. Generally, superabsorbent polymers are considered safe for use in various applications:

1. Non-Toxicity: Most superabsorbent polymers are made from chemicals that, once polymerized, become largely inert and non-toxic. This means they do not react chemically in harmful ways with other substances.

2. Minimal Skin Irritation: In personal care products like diapers and sanitary pads, they are used in forms that typically do not cause skin irritation. Nevertheless, it’s crucial for manufacturers to follow strict quality control to ensure the polymers’ purity and safety.

3. Compliance with Standards: Superabsorbent polymers must conform to regulatory standards for safety. This includes the U.S. Food and Drug Administration (FDA) for polymers used in medical devices or sanitary products.

4. Safe Disposal: When disposed of, they do not leach harmful substances into the environment as they retain their absorbed liquids securely, which prevents the immediate release of potentially contaminating substances.

5. Allergy Considerations: While allergies to these polymers are rare, it is recommended that individuals with sensitive skin or predisposition to allergies review product materials to avoid potential reactions.

It should be noted that though the granular form of superabsorbent polymers poses a choking hazard if swallowed, this risk is easily mitigated by responsible product design and use. Always follow usage instructions, especially in products like toys that may expand with moisture, to ensure safety.

Major Manufacturers of Superabsorbent Polymer

The production of superabsorbent polymers is dominated by a few key players in the chemical industry. Among them, BASF SE, headquartered in Germany, is noted for its high-quality sodium polyacrylate-based polymers, often used in hygiene products. Nippon Shokubai Co., Ltd., a Japanese firm, is another leading manufacturer with a strong emphasis on research and innovation, improving absorbency rates of their products.

South Korea’s LG Chem Ltd. is recognized for its focus on eco-friendly superabsorbent polymers, addressing environmental concerns tied to SAP production and use. Evonik Industries AG, also from Germany, contributes with its expertise in acrylic acid-based polymers which form the basis of many SAPs.

In the United States, manufacturers such as SNF Holding Company play a significant role, primarily specializing in polyacrylamide co-polymers which cater to a diverse array of applications beyond personal care items, extending to agriculture and industrial processes.

These manufacturers are crucial as they set industry standards, push the boundaries of SAP technology through continuous research, and drive sustainability within the market.

Market Trends and Future Outlook

The demand for superabsorbent polymers is on the rise, largely driven by an increasing global focus on hygiene products such as adult incontinence pads and baby diapers. This uptick in usage is also a reflection of a growing population and a rise in the standard of living in developing countries, where such products are becoming more commonly used.

In agriculture, the effects of climate change are propelling the need for more efficient water retention solutions, positioning superabsorbent polymers as a critical tool for water-stressed regions looking to enhance crop yields with minimal water usage.

Innovations in polymer technology are paving the way for the development of biodegradable superabsorbent polymers. Such advancements are anticipated to mitigate environmental concerns associated with traditional SAPs and align with the global push towards sustainable materials.

The healthcare sector also presents new opportunities for SAP applications due to their potential in wound care products, offering improved absorption and better healing environments.

Investments in research and development by key market players are expected to introduce more advanced SAP products, which will expand their functionality and application range.

Overall, the market trend for superabsorbent polymers signals robust growth and an evolving landscape that will likely cater to the needs of various industries while also focusing on sustainability and environmental concerns.

FAQ

What is a superabsorbent polymer?

A superabsorbent polymer is a material that has the capacity to absorb and retain large quantities of water relative to its own mass.

Is superabsorbent polymers safe?

Superabsorbent polymers are considered safe, as confirmed by experts in toxicology, general medicine, nursing, and paediatrics.

What are the benefits of superabsorbent polymer beads?

Superabsorbent polymer beads are highly beneficial as they’re eco-friendly, non-toxic, possess impressive water absorption ability and holding capacity in the soil, and can retain and release approximately 95% of water relative to their weight.

What is superabsorbent polymer in agriculture?

Superabsorbent polymers in agriculture are materials that can absorb and retain large amounts of water, up to 400-500 times their weight, and slowly release it to plant roots, thereby reducing water loss through leaching and evaporation.

How does superabsorbent polymer improve soil quality for agriculture?

Superabsorbent polymers improve soil quality for agriculture by absorbing and retaining large quantities of water and nutrients, increasing the soil’s moisture content, and reducing the need for frequent irrigation.

What are the main uses of superabsorbent polymers in the construction industry?

Superabsorbent polymers are mainly used in the construction industry for self-healing concrete, moisture barriers, reservoirs for slow release of chemicals and water, and to control dust on construction sites.

Are there any potential environmental impacts associated with the use of superabsorbent polymers?

Yes, the use of superabsorbent polymers may potentially contribute to environmental issues due to their non-biodegradable nature and the emission of greenhouse gases during their production.

Recap