Stone polymer composite (SPC) flooring is an innovative solution that combines the durability of stone with the versatility of plastic, and this article will guide you through its benefits, applications, and maintenance tips.

Key takeaways:

- SPC flooring combines the durability of stone with plastic versatility.

- UV layer protects against discoloration and extends lifespan.

- Wear layer guards against scratches, ideal for high foot traffic areas.

- Core layer offers durability, stability, and acoustic properties.

- Bottom layer provides comfort, sound absorption, and moisture resistance.

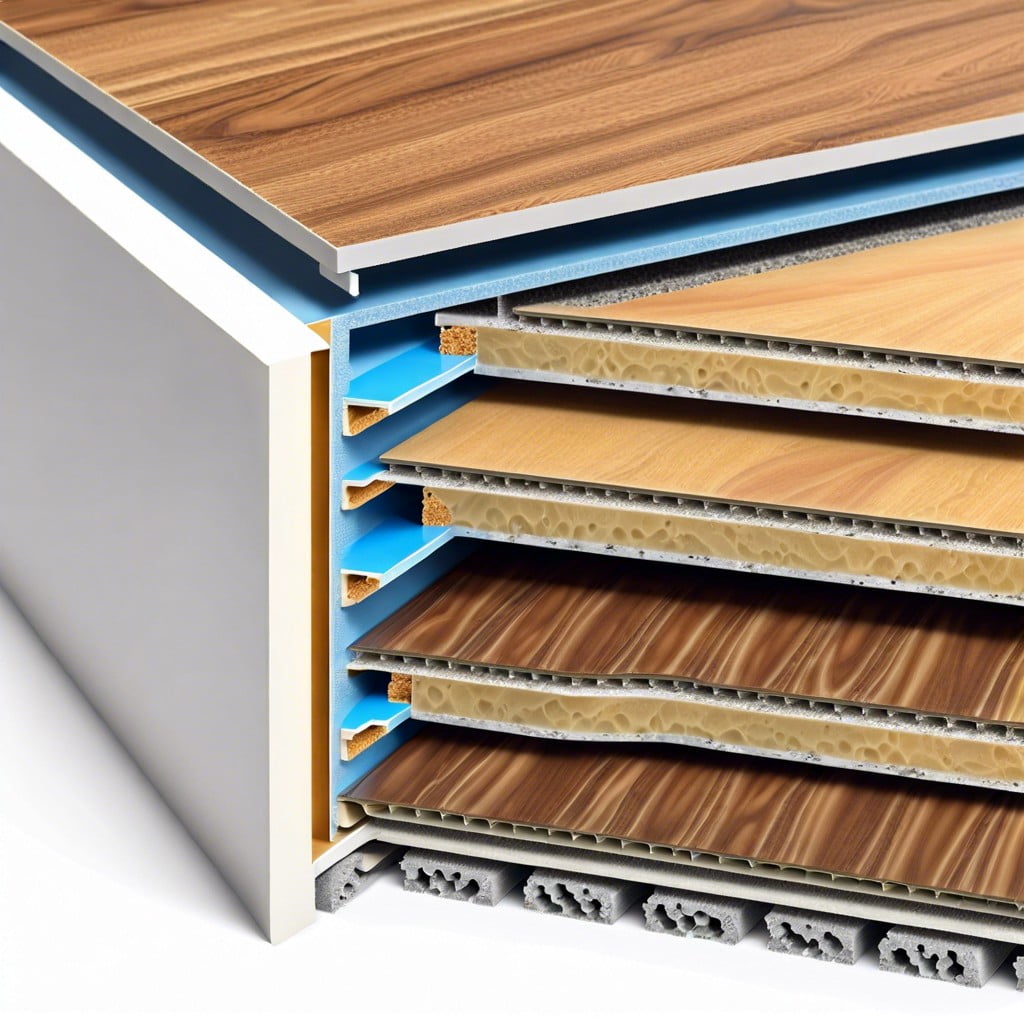

Understanding the Composition of SPC Flooring

Stone polymer composite (SPC) flooring is known for its robust layers, each with a distinct role. At the top, the UV layer acts as the first line of defense against fading and surface wear. Below it, the wear layer, usually made of transparent vinyl, enhances durability and protects against scratches and stains.

The core is where SPC gets its name; it’s made from a mixture of natural limestone powder, polyvinyl chloride, and stabilizers, providing the floor with its strength and rigidity. This dense core makes the flooring less susceptible to expansion or contraction with temperature changes.

Finally, the bottom layer, or backing layer, comprises foam or cork, offering additional sound insulation and a bit of cushioning underfoot. This layer also helps to smooth out minor subfloor imperfections. Understanding these components gives insight into why SPC flooring is a robust and practical choice for various environments.

The UV Layer

At the apex of the layered structure, a transparent coating referred to as the UV layer offers essential protection against discoloration caused by sunlight. Acting as a shield, this layer blocks ultraviolet radiation that can fade colors over time. Additionally, it contributes to the durability of the flooring by resisting stains and providing an easy-to-clean surface. This feature not only preserves the aesthetic appeal of the floor but also extends its lifespan by minimizing wear and tear from daily foot traffic. Its inclusion is a thoughtful design consideration that maintains the floor’s appearance and functionality long-term.

The Wear Layer

The wear layer is a key player in safeguarding your floor against everyday wear and tear. Think of it as your floor’s personal bodyguard. This transparent, durable coating is directly above the core layer. It’s designed to resist scratches, scuffs, and stains, making it ideal for areas with high foot traffic.

Its thickness can vary; the thicker the wear layer, the more durable the flooring will be. Floors in commercial spaces often have a thicker wear layer to withstand heavy use. For residential spaces, a thinner layer may suffice, offering protection while being cost-effective.

Additionally, this layer contributes to the floor’s overall texture and feel underfoot. It can be embossed to enhance its realistic look, simulating textures like wood grain or stone, offering both beauty and brawn.

When selecting SPC flooring, consider how the space will be used to ensure your wear layer provides the necessary protection for your investment.

The Core

At the heart of SPC flooring lies its core layer, a dense, rigid mix that differentiates it from other flooring options. This core is fundamentally composed of limestone powder and stabilizers, which are blended to create a solid foundation that imparts several key characteristics.

Firstly, the core’s robust structure offers remarkable durability. It can withstand heavy foot traffic and resists denting, making it ideal for both residential and commercial spaces with high activity.

Additionally, the core contributes to the flooring’s dimensional stability. Unlike traditional hardwood, SPC flooring doesn’t warp or buckle under temperature fluctuations and high humidity levels, thanks to its resistance to expansion and contraction.

Another benefit of this core is its acoustic properties. It has the inherent ability to mute sound, providing a quieter environment compared to other hard surfaces.

Finally, with the core’s composition, SPC flooring remains thinner and lighter, which facilitates transportation and installation without compromising on toughness. This combination of lightness and strength makes SPC flooring a versatile and practical choice for modern construction needs.

The Bottom Layer

The bottom layer of SPC flooring serves as a solid foundation, stabilizing the planks and ensuring the durability of your floor. Typically made from foam or cork, it offers several benefits:

- Comfort and Insulation: This layer provides a softer surface underfoot, making it more comfortable to walk on compared to traditional hard floors. The cushioning also helps in keeping the floor warm, acting as an insulator against cold subfloors.

- Sound Absorption: Thanks to its composition, the bottom layer effectively reduces noise levels. It dampens the sound of footsteps and contributes to a quieter, more serene living environment.

- Moisture Barrier: By resisting water seepage, it protects the core from moisture damage, which is particularly vital in areas prone to spills or with high humidity.

Carefully engineered to complement the other layers, the bottom layer plays a crucial role in the overall performance and longevity of SPC flooring.

Recap