In this article, you will gain a detailed understanding of protein polymers and their significant applications in various fields.

Key takeaways:

- Protein polymers have diverse structures and functions.

- They are strong, flexible, and environmentally friendly.

- Protein polymers are biocompatible and biodegradable.

- Polymer-protein hybrids combine the best of both worlds.

- Ongoing research focuses on tissue engineering and sustainable materials.

Understanding Protein Polymers

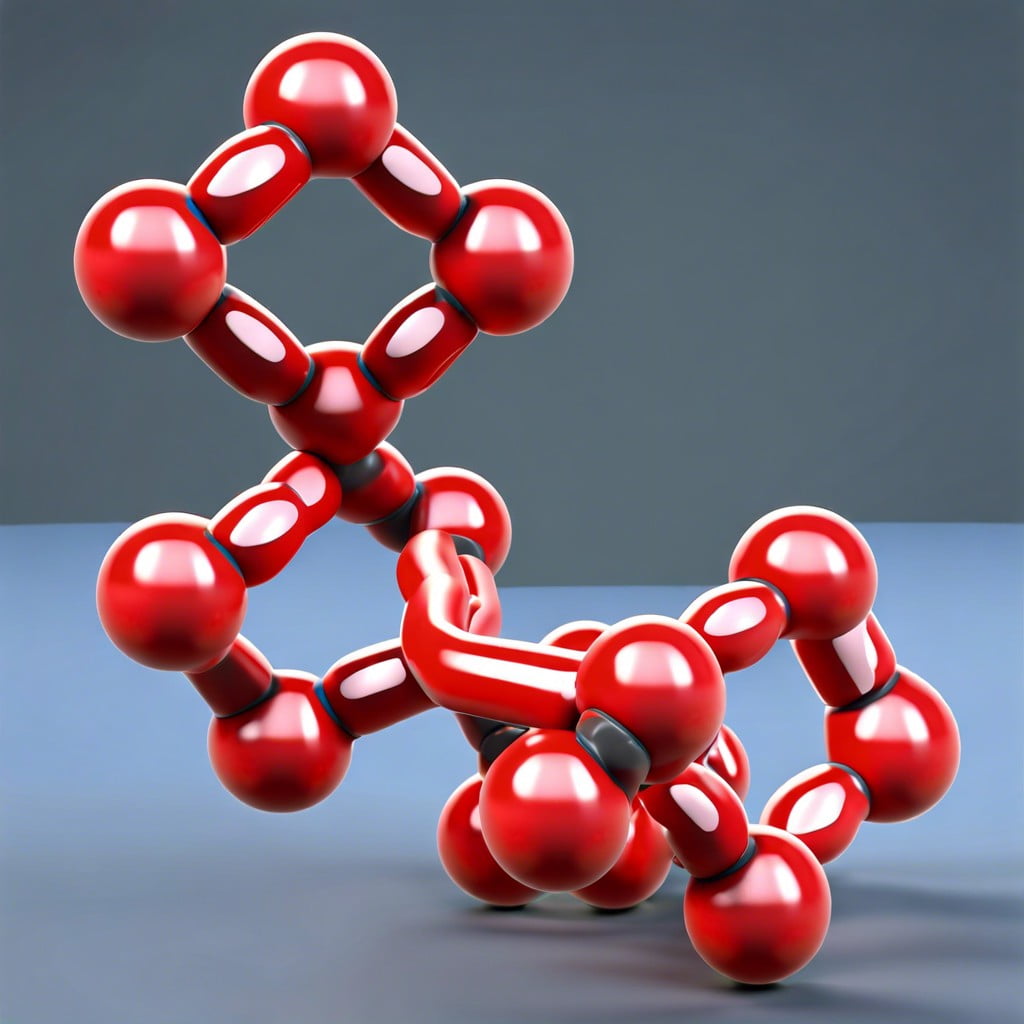

Protein polymers are macromolecules composed of amino acid building blocks, linked together by peptide bonds in a specific sequence. They are naturally occurring in living organisms and play vital roles, such as forming structural components or facilitating biological functions.

Some points to understand about these polymers:

- The sequence of amino acids determines the polymer’s structure and function.

- The structure can be simple with linear chains or complex with three-dimensional shapes.

- Their ability to self-assemble into specific structures underpins their use in construction, medicine, and other fields.

In construction, the inspiration from nature’s protein polymers leads to materials that are strong, resilient, and environmentally friendly. Understanding the fundamentals of protein polymers opens doors to innovative material design and sustainable solutions.

Key Characteristics of Protein Polymers

Protein polymers boast a unique combination of properties that stem from their natural origin. They exhibit remarkable structural diversity thanks to the 20 different amino acids that can be combined in various sequences. This diversity allows for a vast range of functional capabilities, such as responsiveness to pH, temperature, and other environmental triggers.

These polymers are inherently strong yet flexible, a consequence of the intricate folding patterns and intermolecular interactions between amino acid chains. The strength and flexibility endow them with the ability to perform a multitude of roles within biological systems, such as catalyzing reactions or providing structural support.

Moreover, their functionality can be finely tuned. By altering the amino acid sequence, the physical and chemical properties of the resultant protein polymer can be custom-designed. This opens up possibilities for creating materials with specific characteristics suitable for targeted applications in construction and beyond.

In construction, these characteristics translate into materials that can adapt to changing conditions, potentially leading to smarter, more resilient structures.

Biocompatibility and Biodegradability

Protein polymers naturally integrate with biological systems, showing minimal adverse reactions when introduced to the body. This unique feature makes them ideal candidates for medical applications, such as tissue engineering and drug delivery systems. Additionally, they are inherently biodegradable, breaking down into harmless, natural substances. This property is particularly valuable in minimizing environmental impact, as it avoids the persistent waste issues associated with many synthetic polymers.

- These materials can mirror the body’s own substances, resulting in fewer immune responses.

- When used in medical implants, they gradually dissolve, reducing the need for surgical removal.

- Their decomposition products are often amino acids, which the body can easily reabsorb or safely eliminate.

- The rate of biodegradation can be tailored, allowing for controlled release of drugs or gradual replacement by natural tissue.

Synthesis of Polymer-Protein Hybrids

Creating polymer-protein hybrids involves fusing the functional properties of proteins with the durability and flexibility of synthetic polymers. The process often uses genetic engineering to insert specific sequences into proteins that enable them to bond with synthetic polymers. Alternatively, chemical methods can directly join polymers to proteins at designated points.

These hybrids are crafted to retain the biological activity of the protein while enhancing stability and resilience, characteristic of synthetic polymers. Often used in medical applications, these materials can mimic natural tissues, promote healing or serve as scaffolds in tissue engineering.

The effectiveness of a hybrid is greatly influenced by the method of synthesis, which ensures that the protein’s active sites remain unblocked and the polymer maintains its structural integrity. This strategic combination opens the door to innovations in drug delivery systems, biosensors, and regenerative medicine.

Current Research and Development in Protein Polymer Technology

Scientists are at the forefront of exploring the potential of protein polymers in various applications. They are engineering these macromolecules for use in tissue engineering, where they can promote cellular growth and repair. The focus here is on tailoring the polymers to mimic the extracellular matrix, providing a scaffold that encourages tissue development.

Researchers are also enhancing the strength and responsiveness of protein polymers. They’re blending them with synthetic materials to create composites with improved mechanical properties suitable for construction purposes. This also involves developing stimulus-responsive protein polymers that can change properties in response to environmental triggers, opening doors for smart materials in building technology.

Drug delivery is another area of active development. Protein polymers are being tailored to carry therapeutic agents and release them at controlled rates, directly to the target site, minimizing side effects and improving efficacy.

Biotechnological advancements are equally instrumental, as scientists use genetic engineering to produce protein polymers with precise sequences and structures, paving the way for materials with unprecedented performance characteristics.

Furthermore, sustainability issues are being addressed by devising methods to produce protein polymers from renewable resources, ensuring that their use in construction and other industries aligns with the growing emphasis on environmental responsibility.

FAQ

What are the 4 polymers of proteins?

The four examples of protein polymers include haemoglobin, gelatin, enzymes, and antibodies.

Does protein represent a polymer?

Yes, proteins are considered polymers as they are composed of amino acids linked together.

What are the 4 types of polymers?

The four types of polymers are natural polymers, synthetic polymers, addition polymers, and condensation polymers.

Is protein a natural polymer?

Yes, protein is a naturally occurring polymer.

What are the distinctive properties of protein polymers in construction?

Protein polymers in construction are renowned for their exceptional adhesive properties, high tensile strength, and impressive biodegradability.

How does protein as a natural polymer compare to synthetic polymers?

Proteins, as natural polymers, are biodegradable and renewably sourced, contrasting with synthetic polymers which are typically more durable and resistant, and can potentially create environmental issues due to their non-degradability.

How is protein polymerization manipulated in the construction industry?

Protein polymerization is manipulated in the construction industry mainly to create high-strength materials and coatings leveraging the natural, self-assembling structures of certain proteins.

Recap