Discover how synthetic polymer proteins blend biology with materials science, offering revolutionary improvements in various industries including health, construction, and beyond.

Key takeaways:

- Synthetic polymer proteins enhance construction and health industries.

- Hybrids combine biological and synthetic materials uniquely.

- Stimuli-responsive hybrids change behavior based on environment.

- Polymer shells protect proteins and improve delivery.

- Polymer-streptavidin system enables precise drug delivery.

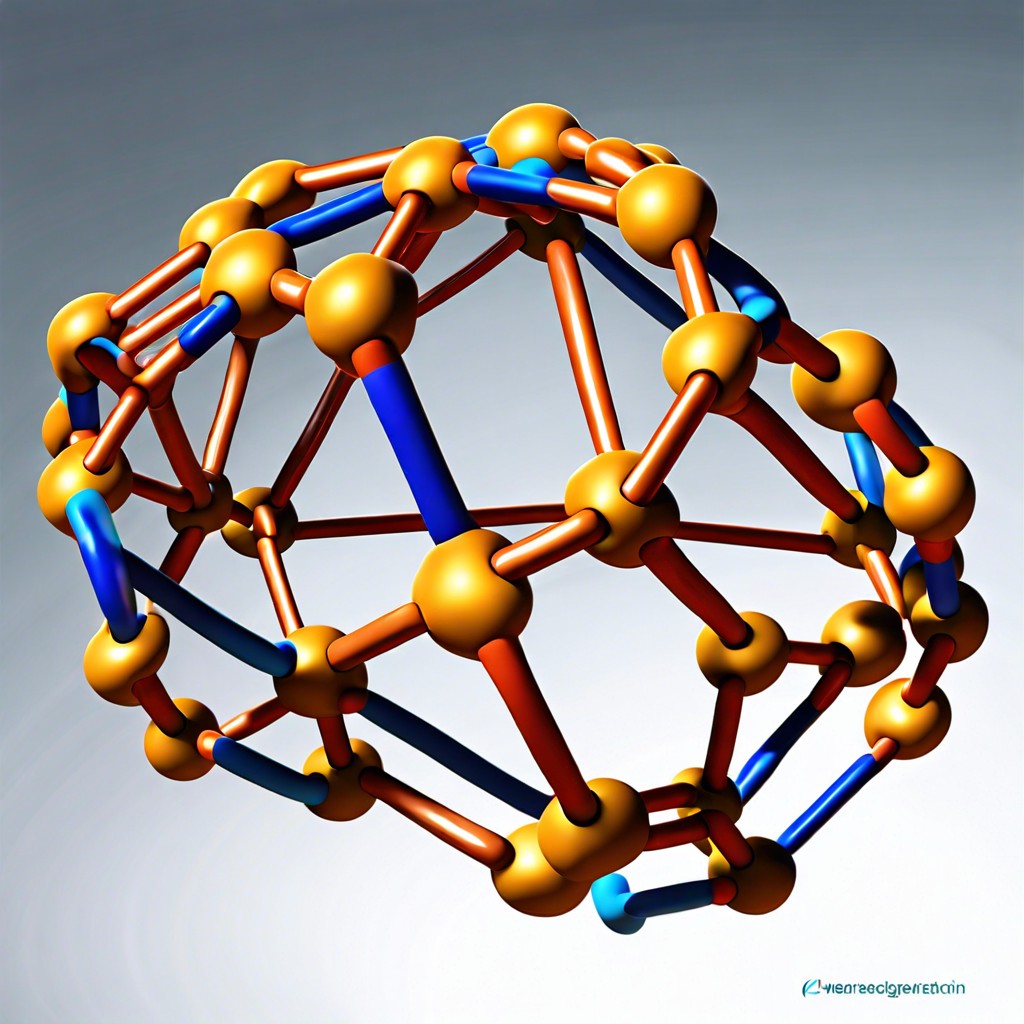

Single Chain Protein-polymer Hybrids

These hybrids combine the best of proteins and polymers into a single molecule. They have unique characteristics thanks to the marriage of natural and synthetic components.

First, the protein backbone. This provides specific biological functions. Think enzymes that speed up chemical reactions.

Now, the polymer tail. It offers additional functionality. It can improve stability, solubility, or even make the molecule responsive to environmental changes.

Here’s the fun part: you can tailor these hybrids. You want a molecule that only responds to light? No problem. Prefer one that’s more resilient to temperature changes? Done.

In essence, you’re creating a Swiss Army knife of molecules.

But wait, how do you get these two to stick together? Enter the world of clever chemistry. Methods like click chemistry help link the protein and polymer precisely, ensuring they work harmoniously, without being like oil and water.

Stimuli Responsive Hybrids

These hybrids are like mood rings but for science—changing their behavior based on the environment they’re in. They can morph in response to temperature, pH, light, or even specific chemicals. Here’s the scoop:

They can expand or contract with temperature changes, a bit like woolly sweaters on laundry day. When it’s hot, they might stretch out, and when it’s cold, they tighten up.

pH-responsive hybrids act like chameleons with the right pH level. In acidic or basic conditions, they alter their structure, impacting their activity.

Light-responsive hybrids are the sunbathers of the group. With exposure to particular wavelengths of light, their shape and function can flip, useful for controlled drug delivery.

Chemical stimuli responses make these hybrids act like selective doormen. Introduce a specific chemical, and they change, allowing certain molecules to pass through or be sequestered.

In essence, these hybrids are like the shape-shifters of materials science!

Polymer Shell Protein Core

Imagine a party where the guest of honor is a tiny protein, and it’s wearing a fabulous, protective polymer shell like an invisible cloak. This combo of polymer shell and protein core is engineered for specific tasks, and it’s not just about looking good.

- Polymers help in:

- Stability: The polymer shell protects the delicate protein from environmental stress, like a superhero suit against oxidation or heat.

- Delivery: It can guide the protein to the right location, navigating through a chaotic body environment like a GPS app.

- Functionality: The shell can be designed to respond to external stimuli, releasing the protein only when needed, like popping out of a surprise cake when the spotlight hits.

In essence, it’s about blending the best of both worlds: the efficiency and specificity of proteins with the robustness and versatility of polymers. A dynamic duo, like Batman and Robin, but in the microscopic world.

Non-covalent Conjugation

In non-covalent conjugation, proteins and polymers bind together without forming actual chemical bonds. Think of it like holding hands without the superglue.

Here are some key points:

- Hydrogen Bonding: This type of bond is pretty much like a firm handshake. It’s not too weak or too strong but just right to hold the polymer and protein together.

- Electrostatic Interactions: Opposites attract, right? In this case, positive and negative charges from the protein and polymer cling together like magnets.

- Hydrophobic Interactions: Water-fearing parts (hydrophobic) of both the polymer and protein tend to stick together, much like introverts at a big party.

It’s a bit like dating – no long-term commitment, but still strong enough to stick around and make things interesting.

Polymer-Streptavidin System

The Polymer-Streptavidin system is like the ultimate matchmaking service in the world of polymers and proteins. Streptavidin is a protein known for its strong affinity to biotin (think of biotin as the Velcro of the biochemistry world).

This system uses non-covalent bonds, which means no complicated chemistry sets are needed—just good old-fashioned molecular attraction. Here’s a quick rundown:

- High Affinity: Streptavidin is practically glued to biotin, with a bond that’s one of the strongest in nature.

- Versatile: Polymer chains can easily be attached to Streptavidin, turning it into a multifunctional hub.

- Efficient: It can help deliver drugs or other molecules precisely where they’re needed, making it a favorite in medical research.

Imagine Streptavidin wearing a polymer jacket, ready to go on a mission. This makes it incredibly useful in a variety of applications, from diagnostics to therapeutics. It’s protein-polymer synergy at its finest.

Recap