Let’s explore the latest breakthroughs in polymer insulation research and how they are revolutionizing construction.

From 3D printing to smart homes, there’s no shortage of innovation when it comes to building and design. But one area that has recently caught my attention is polymer insulation.

I remember working on a project where we had to insulate an old building with traditional materials like fiberglass and foam board. It was a messy and time-consuming process that required a lot of manual labor.

But now, with the latest breakthroughs in polymer insulation research, things are changing for the better.

In this blog post, I’ll be sharing some of the most exciting developments in polymer insulation research and how they’re impacting construction as we know it.

From improved energy efficiency to faster installation times, these breakthroughs are sure to make waves in the industry.

So let’s dive in!

Polymer Insulation Overview

Polymer insulation is a type of insulation material that has been gaining popularity in recent years due to its superior insulating properties and ease of installation.

Unlike traditional materials like fiberglass or foam board, polymer insulation is made from synthetic polymers that are designed to be lightweight, durable, and highly effective at reducing heat transfer.

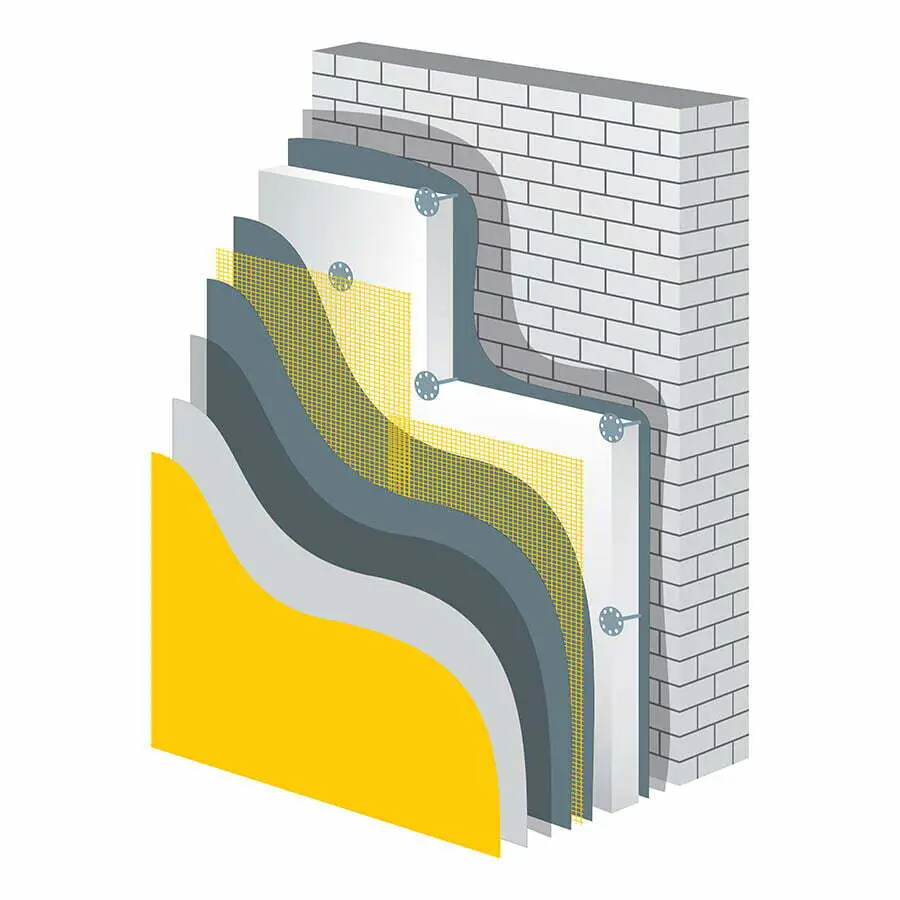

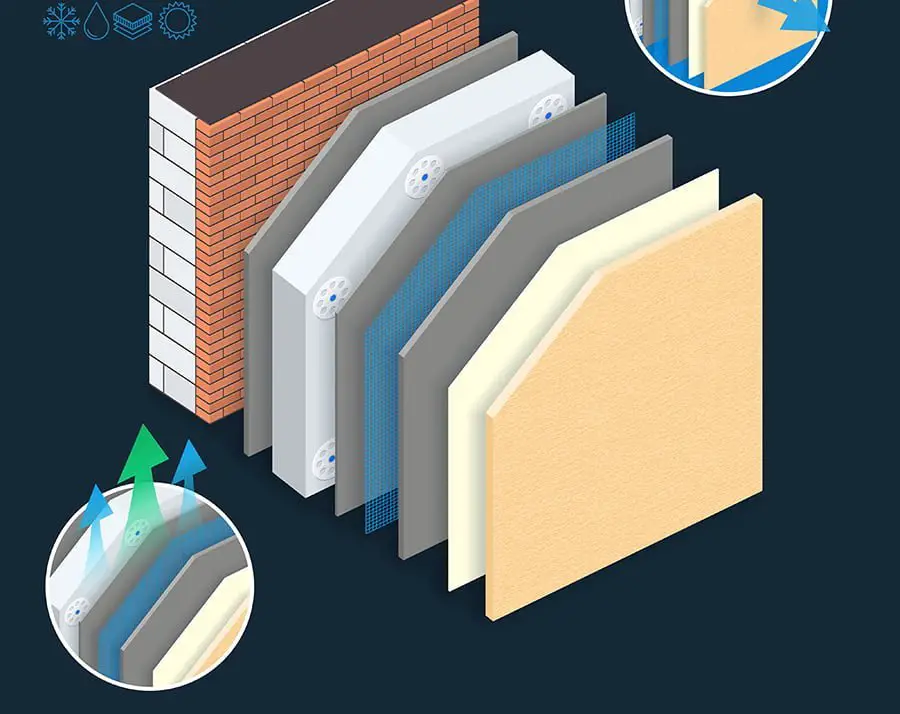

One of the most significant advantages of polymer insulation over other types is its ability to create an airtight seal around the building envelope.

This means that it can prevent air leaks and drafts from entering or escaping your home or building, which can significantly improve energy efficiency.

As I mentioned earlier in my story about working on an old building project with traditional materials like fiberglass and foam board – it was messy work! But now with advancements in polymer research technology – things have changed for the better.

The latest breakthroughs have led to even more efficient forms of this innovative material being developed which makes installation faster than ever before while still providing excellent thermal performance.

In fact, some new formulations are so easy-to-use they don’t require any special equipment at all! With these developments happening right now within our industry – we’re excited about what’s next for construction using Polymer Insulation technology.

Recent Breakthroughs

Thanks to recent advancements in polymer insulation research, construction professionals now have access to a range of new materials that offer improved performance and efficiency.

One such breakthrough is the development of aerogel-based insulation, which has been shown to provide superior thermal protection compared to traditional materials like fiberglass or foam board.

Aerogels are highly porous solids with low density and excellent insulating properties. They’re made by removing the liquid from a gel through supercritical drying, leaving behind an extremely lightweight material that’s up to 99% air. This makes them ideal for use in building applications where weight is a concern.

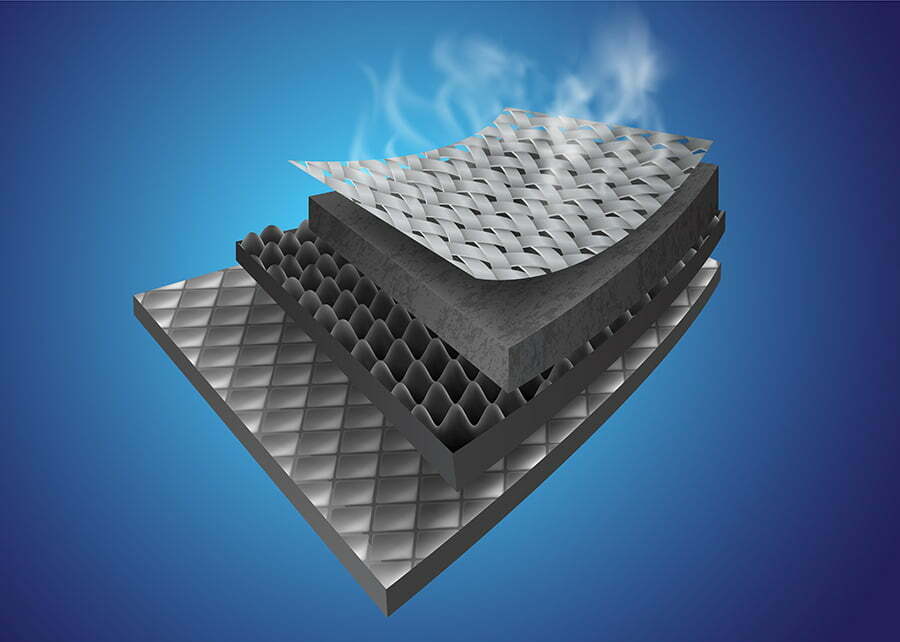

Another exciting development in polymer insulation research is the use of phase-change materials (PCMs) as part of composite insulation systems. PCMs are substances that can absorb or release large amounts of heat energy when they change from one state (solid/liquid/gas) to another at specific temperatures.

By incorporating PCMs into composite panels alongside other insulating materials like polyurethane foam or mineral wool, researchers have been able to create products with enhanced thermal storage capacity and reduced temperature fluctuations inside buildings – leading not only better energy efficiency but also increased comfort levels for occupants.

These breakthroughs represent just some examples among many others currently being explored by scientists around the world who seek ways improve upon existing technologies while reducing environmental impact – all while making life easier for those working on construction sites!

Enhanced Thermal Performance

One of the most significant benefits of polymer insulation is its enhanced thermal performance. Traditional insulation materials like fiberglass and foam board have been used for decades, but they often fall short when it comes to energy efficiency.

Polymer insulation, on the other hand, has a much higher R-value (a measure of thermal resistance) than traditional materials.

I remember working on a project where we had to insulate an old building with fiberglass batting. Despite our best efforts, we couldn’t get the R-value high enough to meet modern energy codes without adding more layers or thicknesses – which would have added time and cost.

But with polymer insulation’s superior thermal performance properties, buildings can be insulated more effectively while using less material overall. This not only saves money in terms of material costs but also reduces heating and cooling expenses over time by keeping indoor temperatures stable year-round.

Improved Fire Resistance

One of the most significant breakthroughs in polymer insulation research is improved fire resistance. Traditional insulation materials like fiberglass and foam board are highly flammable, which can be a major safety concern for buildings.

However, with the latest advancements in polymer technology, manufacturers have been able to create insulation products that are much more resistant to flames.

I remember working on a project where we had to install traditional fiberglass insulation in an old building that was being renovated into apartments. The local fire department required us to add extra sprinklers and other safety measures because of how easily the material could catch on fire.

But now, with new polymer-based insulations available on the market such as polyisocyanurate (PIR) or phenolic foam (PF), builders can achieve better thermal performance without sacrificing safety standards. These materials have been tested extensively under high heat conditions and have shown remarkable resistance against flames compared to their traditional counterparts.

This improvement enhances building safety and reduces insurance costs for property owners since they will no longer need additional coverage due to potential hazards caused by flammable insulating materials used before these recent developments came about.

Eco-friendly Materials

One of the most significant benefits of polymer insulation is its eco-friendliness. Traditional insulation materials like fiberglass and foam board can be harmful to the environment, as they release toxic chemicals during production and installation.

On the other hand, polymer insulation is made from recycled materials and has a much lower carbon footprint.

I remember working on a project where we had to remove old fiberglass insulation that was causing health problems for occupants due to poor air quality. It was an eye-opening experience that made me realize how important it is to use sustainable building materials.

With advancements in polymer technology, we now have access to even more eco-friendly options for construction projects. For example, some companies are using plant-based polymers instead of petroleum-based ones in their products.

Not only do these new developments benefit the environment by reducing waste and emissions, but they also provide better performance than traditional insulations. Polymer insulations offer higher R-values (a measure of thermal resistance), meaning buildings can retain heat better without relying on energy-intensive heating systems.

With sustainability becoming increasingly important in construction practices today – it’s exciting news that there are innovative solutions available such as eco-friendly polymer insulations!

Cost Efficiency Analysis

One of the most significant benefits of polymer insulation is its cost efficiency. Traditional insulation materials like fiberglass and foam board can be expensive, especially when you factor in installation costs.

But with polymer insulation, the installation process is much faster and requires less labor, which translates to lower overall costs.

In fact, a recent study conducted by the Department of Energy found that using spray polyurethane foam (SPF) insulates 30% to 40% better, making it cost-effective. This means that you are saving money on installation costs upfront and your monthly utility bills over time.

But it’s not just homeowners who stand to benefit from this cost efficiency analysis; contractors and builders will also see savings in material and labor costs when using polymer insulation products. With faster installation times comes increased productivity for workers, allowing them to take on more projects or complete jobs quicker than before.

It’s clear that advancements in polymer insulation research have significantly impacted construction by providing a more affordable option for both residential and commercial buildings while still maintaining high-quality performance standards.

Construction Applications

Polymer insulation has a wide range of applications in the construction industry. One of the most significant benefits is its ability to improve energy efficiency, which can lead to lower heating and cooling costs for building owners.

This is achieved through its high R-value, which measures how well it resists heat flow.

But that’s not all – polymer insulation also offers faster installation times compared to traditional materials like fiberglass or foam board. This means that construction projects can be completed more quickly and efficiently, saving time and money in the process.

I remember working on a project where we had to insulate an old building with traditional materials like fiberglass and foam board. It was a messy and time-consuming process that required a lot of manual labor.

But now, with polymer insulation technology advancements such as spray-on application methods available on the market today; things are changing for better.

In addition to these benefits, polymer insulation is also lightweight yet durable making it ideal for use in various types of buildings including residential homes or commercial structures alike. Overall Polymer Insulation Research breakthroughs have made this material one worth considering when planning your next construction project!

Future Prospects

Looking ahead, the future prospects for polymer insulation are incredibly promising. As more research is conducted and new breakthroughs are made, we can expect to see even greater advancements in this field.

One area that researchers are currently exploring is the use of nanotechnology in polymer insulation. By incorporating nanoparticles into the material, it’s possible to create an even more effective insulator with improved thermal conductivity and durability.

Another exciting prospect for polymer insulation is its potential use in sustainable construction practices. With a growing focus on reducing carbon emissions and promoting eco-friendly building methods, there’s a need for materials that can help improve energy efficiency while also being environmentally responsible.

I’m excited about what lies ahead for polymer insulation research and how it will continue to impact construction as we know it. From faster installation times to improved energy efficiency and sustainability practices – these breakthroughs have already begun transforming our industry – but there’s still so much more potential waiting to be unlocked!

Recap