Learn about polymer fume fever, its symptoms, causes, and how to prevent it in construction environments.

Key takeaways:

- Polymer fume fever is caused by overheated plastics releasing fumes.

- Symptoms include fever, chills, body aches, and difficulty breathing.

- Prevent fume exposure through ventilation, PPE, temperature control, and training.

- Follow safety guidelines for workplace ventilation, PPE, temperature control, training, monitoring, and maintenance.

- Seek medical help if symptoms persist or worsen after exposure.

What Is Polymer Fume Fever?

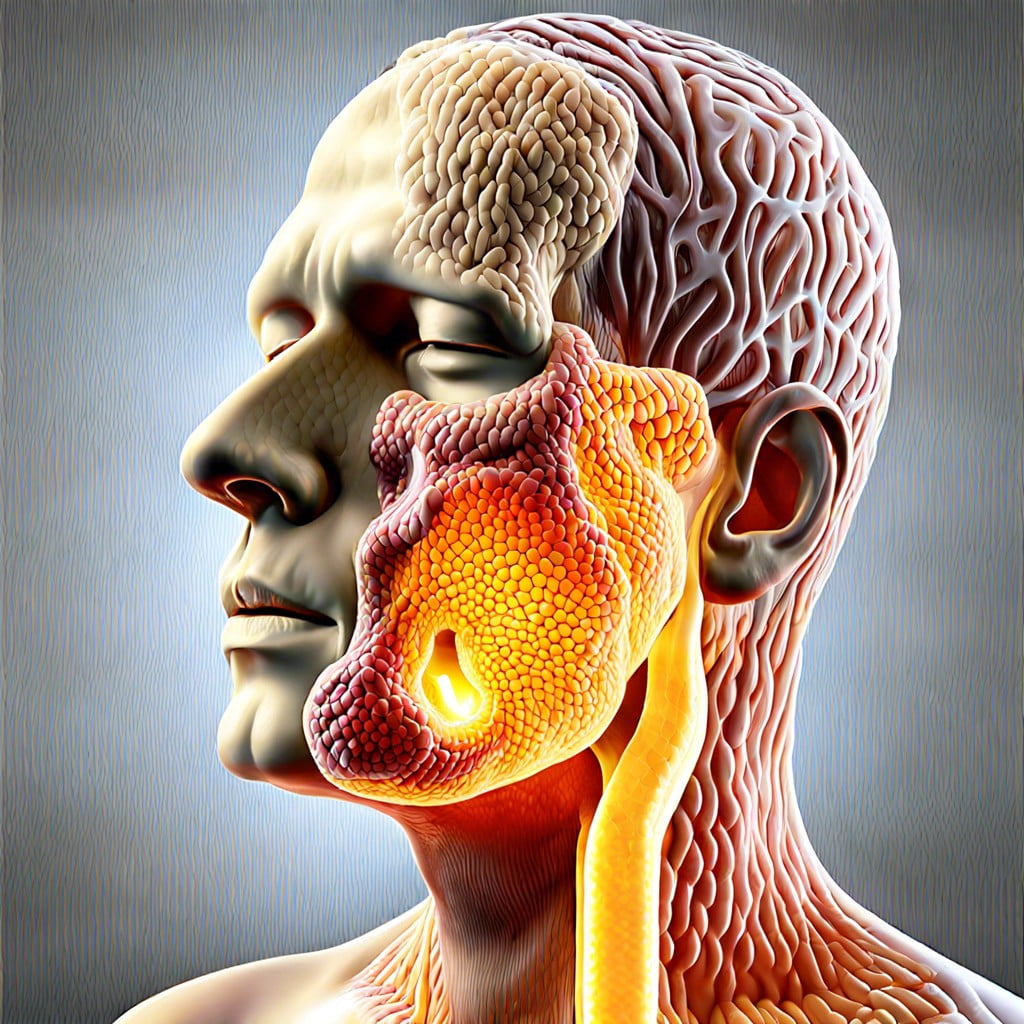

Polymer fume fever is an illness typically occurring after exposure to fumes released by certain heated plastics. Primarily linked with fluoropolymer-based materials like Teflon (PTFE), this condition emerges when these polymers are overheated and begin to degrade, releasing a fine particulate matter into the air.

Inhalation of these particulates can trigger an immune response similar to the flu. It’s important to note that the fever isn’t caused by the polymer itself, but rather from the complex mixture of compounds formed during the thermal decomposition. Essentially, it’s the body’s reaction to inhaling these byproducts that leads to the symptoms associated with polymer fume fever.

Despite its name, the condition is not limited to industrial settings. It can occur in any environment where fluoropolymers are present and can be accidentally overheated, such as in kitchen scenarios with non-stick cookware. Being informed about the materials that can cause this illness is a crucial step in recognizing the risk and ensuring safety.

Symptoms of Polymer Fume Fever

Polymer fume fever is often mistaken for a common flu because the symptoms are quite similar. Individuals affected by this condition typically experience fever, chills, and body aches. Additionally, they may report a feeling of tightness in the chest and may have trouble breathing deeply. These symptoms usually develop several hours after exposure to the fumes and often resolve within 48 hours if further exposure is avoided.

In some cases, people might also feel a sore throat coming on, accompanied by headaches and a general sense of tiredness or weakness. The condition can vary in intensity, with some experiencing mild discomfort while for others, the symptoms might be more severe and alarming.

While these symptoms can be unsettling, it is crucial to recognize them early to ensure proper measures are taken to prevent further exposure and to seek medical attention if necessary.

Prevention of Polymer Fume Fever

Maintaining a safe working environment is crucial for preventing the inhalation of hazardous fumes. Here are some proactive measures:

- Use polymers in well-ventilated areas to disperse fumes. Installing exhaust systems and fans can aid in ventilation.

- Whenever possible, substitute high-risk polymers with less toxic alternatives that do not produce harmful fumes upon heating.

- Personal protective equipment (PPE), such as respirators with filters specifically designed to capture polymer fumes, should be worn.

- Regular equipment maintenance ensures that machinery used to heat or process polymers is functioning correctly, reducing the risk of excessive fume production.

- Adhering to recommended temperatures for polymer processing limits the production of fumes. Avoid overheating materials.

- Conducting training sessions educates employees on the risks of polymer fumes and the importance of using protective gear and proper handling techniques.

- Implementation of strict safety protocols, including regular air quality checks, helps identify and mitigate exposure risks promptly.

Occupational Safety Guidelines

Ensuring workplace safety is a critical step in preventing polymer fume fever. Here are practical measures to follow:

- **Proper Ventilation: **

- Facilities must be equipped with effective ventilation systems to disperse fumes. This can include local exhaust ventilation at the point of emissions.

- **Use of Personal Protective Equipment (PPE): **

- Appropriate PPE, such as respirators, should be provided to employees handling polymers. These should meet the standards set by occupational health authorities.

- **Temperature Control: **

- Avoid overheating polymer materials during processing. Monitor machinery and use controls that prevent excessive temperatures that can cause fume production.

- **Training: **

- Workers should receive comprehensive training about the hazards of fumes and how to minimize exposure. This includes the proper use of equipment and PPE.

- **Routine Monitoring: **

- Regular workplace air monitoring can identify the presence and concentration of hazardous fumes. This identifies risks and helps in implementing timely interventions.

- **Maintenance: **

- Regularly check and maintain equipment to ensure it is in good working condition and does not pose a risk of overheating.

These safety protocols can significantly mitigate the risks associated with polymer fumes and safeguard the health of employees.

When to Seek Medical Help

If you experience symptoms such as fever, shortness of breath, tightness in the chest, or flu-like effects after exposure to polymer fumes, it’s important to act promptly. Initial symptoms can escalate quickly, and medical intervention may be needed to prevent complications. Contact a healthcare provider if symptoms persist for more than 24 hours or worsen over time. It’s essential to mention any recent exposure to polymer fumes to help with diagnosis and treatment. Remember, protecting your health should always be a priority, especially in environments where exposure to polymer fumes is a risk.

Recap