This article examines the role of polymers in the interaction with lipids, offering insights into their applications and benefits in various industries.

Key takeaways:

- Polymers for lipids have hydrophobic and hydrophilic components.

- Polymers can self-assemble into bilayer structures like lipids.

- Functionalized polymers can mimic lipid properties for specific applications.

- Lipid-polymer hybrids combine fluidity of lipids with robustness of polymers.

- Polymer mimetics of cell membranes offer biocompatibility and functionality.

Structure and Properties of Polymers for Lipids

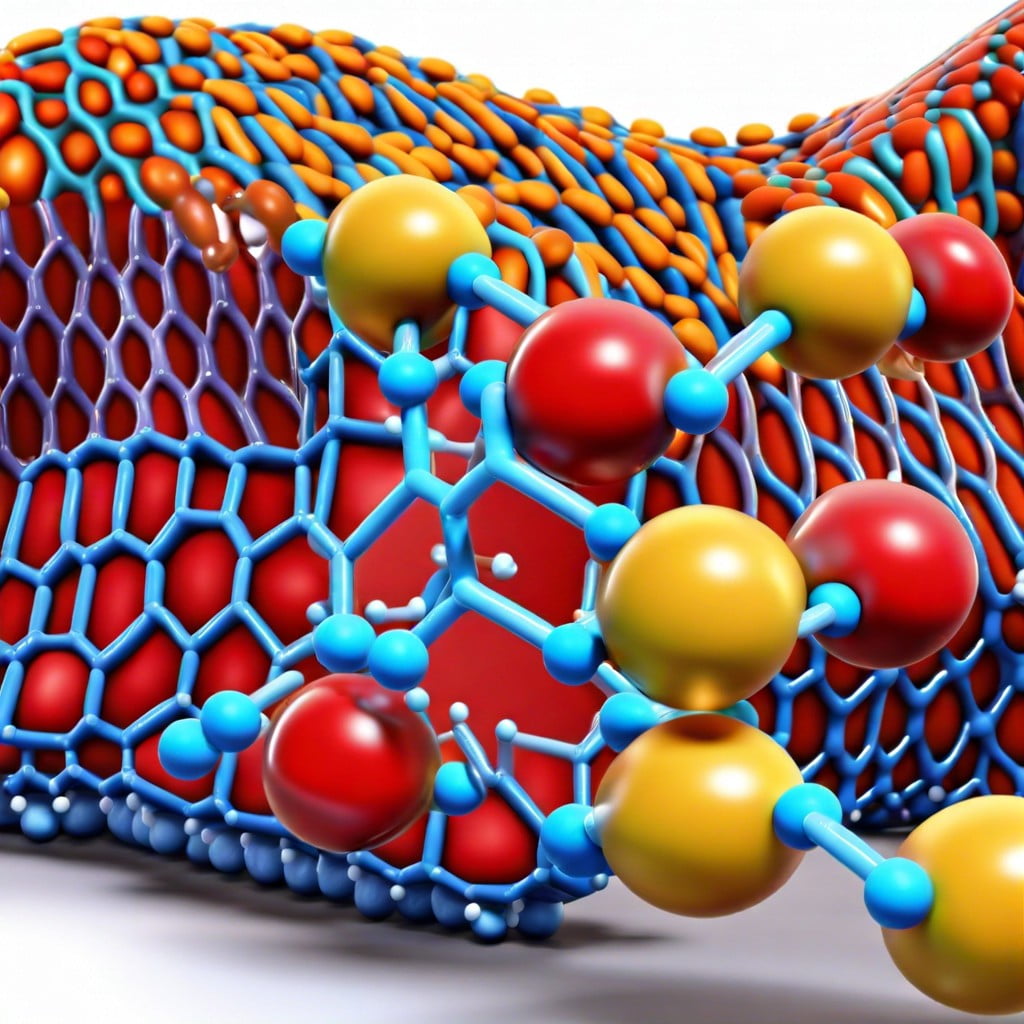

Polymers designed to interact with lipids often mimic the structure and behavior of natural lipid molecules. The polymer chain typically includes a hydrophobic (water-repellent) segment analogous to the lipid tail, which provides compatibility with lipid environments. Meanwhile, a hydrophilic (water-attracting) segment can replicate the head of a lipid, allowing for interaction with aqueous substances. The structural design of such polymers plays a pivotal role in their ability to form stable structures, such as vesicles or micelles, which can encapsulate substances, much like lipid bilayers do in cell membranes.

Key points in understanding these polymers include:

- The amphiphilic nature: They contain both hydrophobic and hydrophilic components.

- Self-assembly: Under certain conditions, they can spontaneously form ordered structures, similar to lipids forming bilayers or vesicles.

- Tailorable properties: By adjusting the length and composition of the polymer chains, their properties can be fine-tuned for specific applications.

- Compatibility with lipids: These polymers can integrate with natural lipids, leading to hybrid systems with unique functionalities.

Such polymer structures are not only fascinating for their biomimicry but also for their potential in targeted drug delivery, sensors, and other biotechnological applications.

Use of Polymers to Mimic Lipid Bilayers

Polymers are adept at imitating the structure of lipid bilayers, which are fundamental components of cell membranes. This mimicry is significant for several applications, from drug delivery systems to constructing artificial cells.

Here are key points explaining how polymers are utilized for this purpose:

- Selection of Polymers: Scientists choose specific polymers that have amphiphilic characteristics, meaning they contain both hydrophilic (water-attracting) and hydrophobic (water-repelling) segments. This dual nature allows the polymers to self-assemble into bilayer structures akin to natural lipids.

- Self-Assembly: When amphiphilic polymers are placed in an aqueous environment, they spontaneously arrange themselves into bilayer sheets or vesicles, creating a barrier that separates two aqueous compartments. This self-assembly process is crucial as it parallels how lipid molecules organize to form cell membranes.

- Functional Mimicry: These synthetic bilayers can host a variety of functional groups or proteins, acting as scaffolds for biochemical processes, just as lipid bilayers do in nature. This allows researchers to study membrane-associated phenomena in a controlled environment.

- Tunable Properties: Unlike natural lipids, synthetic polymers can be engineered to have specific functionalities, sizes, and mechanical properties. This tunability is essential for customizing the bilayer for specific research needs or applications.

By harnessing the versatility of polymers, scientists are able to create models that closely resemble the natural functions of lipid bilayers, opening up new possibilities in biomedical research and nanotechnology.

Functionalization of Polymers With Lipid-like Properties

Polymers can be tailored to display characteristics similar to lipids, broadening their utility in various applications. Through a process called “functionalization,” specific chemical groups are added to the polymer backbone, which can adjust their behavior to more closely resemble that of lipids.

Here are key points regarding this transformation:

- Hydrophobic and Hydrophilic Balance: Like lipids, which have both water-loving (hydrophilic) and water-fearing (hydrophobic) parts, polymers can be functionalized to have similar amphiphilic qualities. This balance is crucial for creating self-assembling structures that mimic lipid behavior.

- Insertion of Fatty Acids: Fatty acids are a central component of lipids. By grafting these fatty acids onto polymer chains, the polymers obtain properties like increased flexibility and compatibility with biological systems.

- Surface Modification: The surfaces of polymers can be coated with lipid-like layers to promote interaction with biological entities, such as proteins or cells, facilitating applications like drug delivery or tissue engineering.

- Bulk Modifications: Embedding lipid-like molecules within the polymer matrix can alter the bulk properties, potentially leading to materials with enhanced biocompatibility or biodegradability.

By incorporating these lipid-like properties, polymers become more functional in biological environments, opening new doors in biomedical research and material science.

Synthesis of Lipid-Polymer Hybrid Materials

Lipid-polymer hybrid materials combine the fluidic nature of lipids with the robustness of polymers. Developing these hybrids often involves the tethering of lipid molecules to a polymer backbone or the encapsulation of lipids within a polymer matrix.

Here’s how these materials are typically synthesized:

Tethering Method:

This process attaches lipid chains onto polymers through chemical reactions, creating a modified polymer with lipid-like side chains. Scientists often employ techniques like “click chemistry” for efficient bonding.

Self-Assembly:

Lipids and amphiphilic copolymers can self-organize into structures such as micelles or bilayers in aqueous environments. This spontaneous formation is driven by the hydrophobic and hydrophilic parts seeking to minimize energy by reducing contact with water.

Solvent Casting and Evaporation:

A solution of lipids and polymers is cast onto a surface, and as the solvent evaporates, a thin film forms. This film can rearrange further upon hydration, more closely resembling natural lipid arrangements.

Electrospinning:

A technique where a polymer-lipid mix is exposed to a high voltage to create fine fibers. These fibers can encapsulate lipids, resulting in a material with unique surface properties and encapsulation capabilities.

These methods have enabled the creation of novel materials with applications in drug delivery systems, tissue engineering scaffolds, and biosensing technologies.

Biology: Cell Membrane Mimetics Using Polymers

Polymers that mimic cell membranes offer innovative solutions for various biological applications. These synthetic structures can replicate the essential features of lipid bilayers, which are the fundamental components of cell membranes. Their design allows for the incorporation of specific proteins and other molecules, paving the way for targeted drug delivery and therapeutic interventions.

Here are some key points to understand the concept:

- Self-assembly: Just like lipids form membranes through self-assembly, certain polymers are designed to spontaneously organize into structures resembling the lipid bilayers.

- Biocompatibility: These polymers are engineered to be biocompatible, which means they can interact with living tissue without causing harm, making them suitable for medical use.

- Functionalization: By attaching functional groups, these polymers can be made to perform specific roles, such as recognizing and binding to certain cell types or triggering responses under particular conditions.

- Stability: Compared to natural membranes, polymer mimetics can offer enhanced stability, which is beneficial for applications that require longevity, like in controlled-release drug systems.

- Customizability: The chemical structure of polymers allows precise control over their properties, enabling the creation of tailored membrane systems for specialized tasks in biotechnology and medicine.

Recap