Discover the benefits and applications of polymer coatings in construction, enhancing durability and aesthetics in modern building projects.

Key takeaways:

- Polymer coatings are made from durable polymers that protect surfaces.

- Different types of polymer coatings have specific benefits and applications.

- Factors like moisture, temperature, surface prep, UV exposure, and chemicals affect the performance of polymer coatings.

- Regular maintenance and innovations, like self-healing and smart coatings, contribute to the longevity and versatility of polymer coatings.

- Future trends include self-healing coatings, bio-based polymers, and smart functionality in polymer coatings.

Definitions and Composition of Polymer Coatings

Imagine wrapping your favorite couch in a clear plastic film to keep it free from dust and stains. Polymer coatings work much like this film, but for buildings and various surfaces, protecting them from damage, wear, and corrosion.

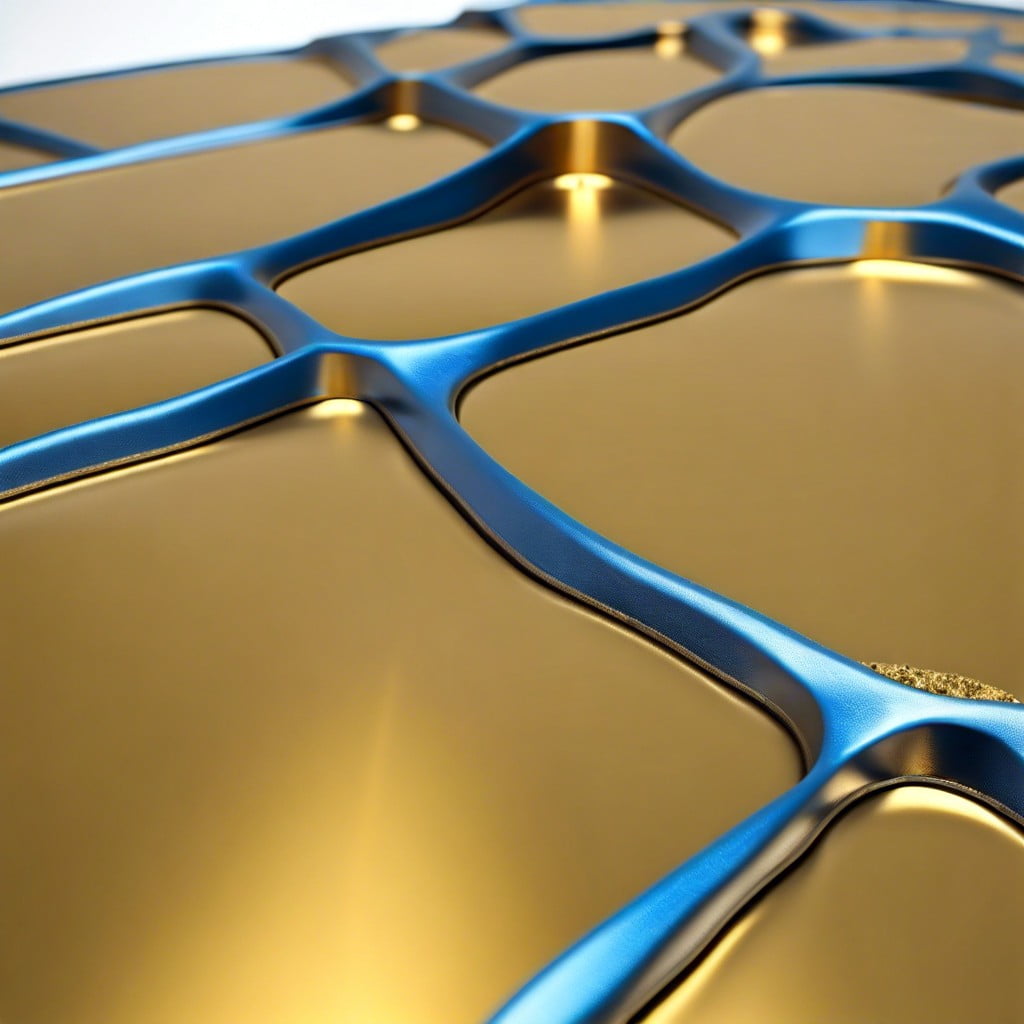

In essence, polymer coatings are coverings made from polymers, those long, repeating chains of small molecules chemists call monomers. When these monomers hitch a ride together, they form durable, flexible materials. Think of them as a team of acrobats, locking hands to create a strong, interconnected network.

Now, polymers come in all shapes and sizes, from natural rubber to synthetic plastics. In coatings, we often see epoxies, polyurethanes, and acrylics, each bringing its own set of characteristics to the table. An epoxy might offer a sturdy shield against chemicals, while a polyurethane coating could give you the elasticity to absorb impacts without a dent.

These coatings latch onto surfaces like a gecko to a wall, providing a protective layer that can resist moisture, fend off UV rays, and even prevent graffiti from becoming a permanent art exhibit on your building’s facade. It’s like giving your structure a superhero cape that guards against the elements.

Types and Benefits of Polymer Coatings

Polymer coatings come in various forms, each serving a specific purpose. Epoxy coatings, known for their durability, create a hard shell on floors in commercial spaces, making them resist wear and tear like a champ!

Then there’s polyurethane, the flexible friend that can take a hit and bounce back, ideal for surfaces that need some give, like outdoor equipment that braves the elements.

And we can’t forget acrylics; think of them as the sunscreen of coatings. They fend off UV rays to keep colors vibrant on cars and buildings, making faded hues a thing of the past.

Silicone coatings are the unsung heroes in high-heat areas. They stand up to temperatures that would make most materials throw in the towel.

The benefits? Well, they’re a mighty bunch. These coatings can extend the life of materials, saving money and hassle in the long run. They’re also quick-change artists, sprucing up surfaces with a new color or finish faster than you can say “renovation.” Plus, they bring peace of mind, adding fire resistance and making cleaning a breeze.

Whether shielding a skyscraper from the sun’s harsh glare or keeping a bridge stable and strong, polymer coatings are the silent guardians of our buildings and structures. With each type, we give our constructions their best fighting chance against the everlasting battle with the elements.

Application and Factors Affecting Performance

Slapping on a coat of polymer isn’t just about making things look spiffy—it’s a science. Like solving a Rubik’s cube, multiple factors align to affect how well your polymer coating sticks around and does its job. Picture this: You’ve got a skyscraper exposed to the rage of the sun, the slap of the wind, and the occasional tantrum from the rain. That building needs a superhero shield, and that’s where polymer coatings swing into action.

Moisture is like that uninvited guest at a picnic—it’s everywhere, and too much of it can spoil the party. Too damp, and your coating might throw in the towel before it even begins. Humidity, I’m looking at you.

Temperature swings are like mood swings—too extreme, and things might crack under pressure. You want your polymers to keep their cool in the heat and not get brittle when the thermometer drops.

Here’s another brain teaser: surface prep. Think of it as trying to paint over a dusty chalkboard. The base material needs to be squeaky-clean, or your polymers are just going to peace out.

UV exposure’s no joke either. Sunlight might be great for beach days, but your polymers think otherwise. Too much UV, and your coating might go from vibrant to washed-out faster than last season’s jeans.

Lastly, chemicals lurking around are like spies from a rival camp. Certain substances can infiltrate and lead to early retirement for your polymer coating. So, you’ve got to know the enemy and pick a polymer that can handle the espionage.

Put all these factors in your toolbox, and you’re more Sherlock than Clouseau at this coating game. Keep them in check, and you’ve got a polymer pal that sticks around through thick and thin—or should I say through heat and rain?

Maintenance and Innovations in Polymer Coatings

Taking care of polymer coatings is a walk in the park. A bit of soap and water, and you’ve got yourself a surface that looks as good as new. No elbow grease required! They’re like that high-quality paint on your walls that just needs a gentle wipe to keep the colors vibrant. Regular maintenance not only keeps them looking sharp but also extends their lifespan. A stitch in time saves nine, or in this case, a quick clean prevents coating calamities!

But wait, there’s more. Innovation hasn’t taken a backseat in the polymer coating express. Scientists are on a roll, mixing up concoctions that would make even a barista jealous. For instance, they’ve cooked up self-healing coatings – think of them as the Wolverine of polymers, bouncing back from scratches without a fuss. And then there are the smart coatings, changing their behavior with temperature, ready to become the chameleons of the construction world.

Expect to see more eco-friendly options pop up on the market, with researchers busy as bees looking for sustainable ingredients. These green warriors are set to reduce our carbon footprint one coat at a time.

In short, it’s an exciting time for anyone with a roof overhead or a wall to paint. Tomorrow’s polymer coatings aren’t just a protective layer; they’re a superhero cape for buildings that come with their own set of superpowers.

Future Trends and Case Studies in Polymer Coatings

As we peer into the crystal ball of upcoming developments, self-healing coatings are causing quite the stir. Imagine a world where a scratched car heals itself like new. It’s not science fiction; researchers are dabbling with materials that recover from damage when exposed to certain stimuli, such as heat or light.

On the sustainability front, the push for greener construction has spawned bio-based polymers. Instead of relying on petroleum, these coatings use renewable resources like plant oils. The cherry on top? They offer comparable, if not superior, performance to traditional options.

Then there’s the smart functionality bandwagon. Coatings that change color with temperature or give a heads-up on structural damage are inching from prototypes to practical solutions. Talk about coatings that don’t just sit pretty but also keep an eye out for you!

Now, let’s splash a bit of reality onto these futuristic paints with some case studies. Picture the Golden Gate Bridge, swathed in a high-performance polymer coating that battles corrosion and withstands the relentless onslaught of salt and fog. Or think about hospitals, where antimicrobial polymer coatings are the unsung heroes, keeping surfaces free from pesky germs.

The fusion of function and innovation in polymer coatings is not just about making things last longer; it’s about making them smarter and kinder to our planet. Keep your eyes peeled; the next big thing in coatings might just be around the corner.

Recap