Discover how polyethylene, the superhero of the polymer world, is used everywhere from plastic bags to bulletproof vests.

Key takeaways:

- Polyethylene is composed of carbon and hydrogen atoms in long chains.

- Polyethylene was created in 1933 and gained popularity post-World War II.

- There are different types of polyethylene, each with unique properties.

- Polyethylene is used in various applications such as shopping bags, toys, and plumbing systems.

- Polyethylene has environmental impacts due to its non-renewable origin and slow decomposition, but sustainable alternatives are being developed.

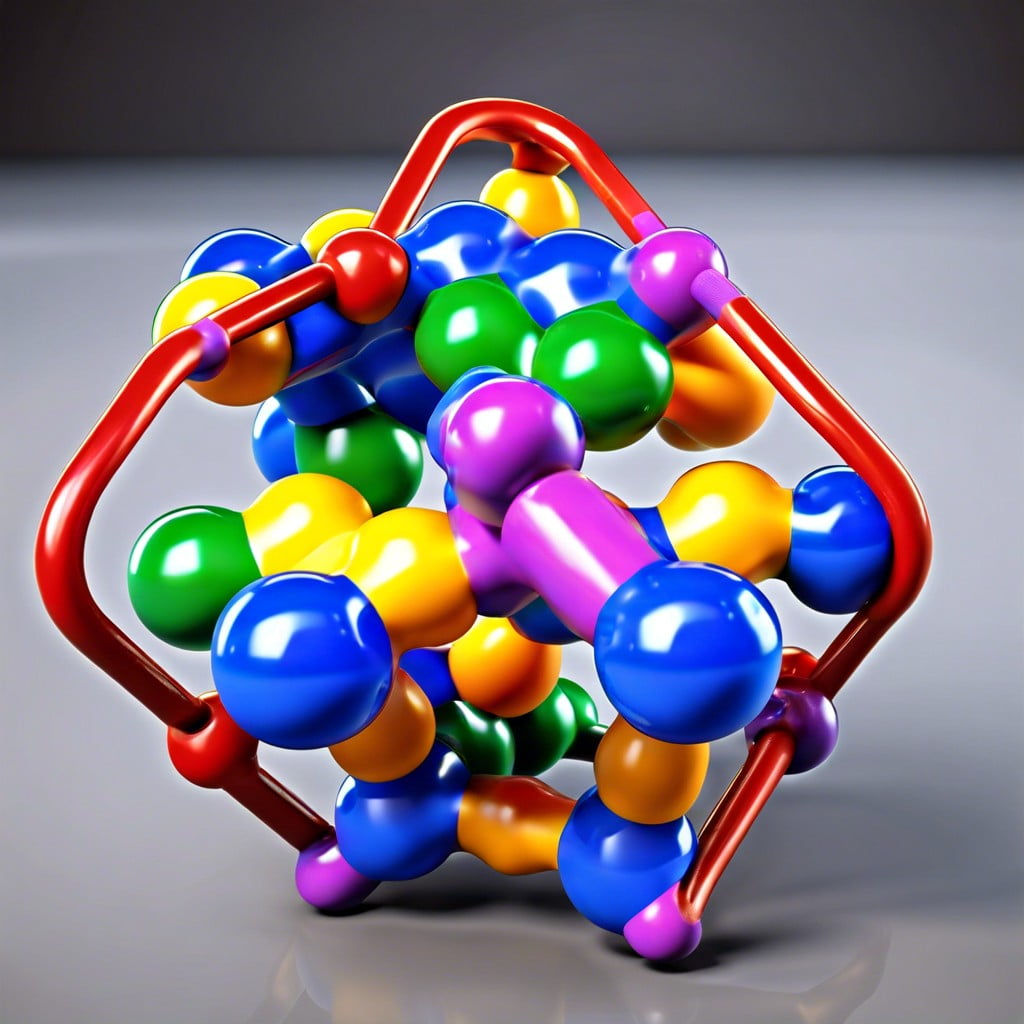

Chemical Composition and Molecular Structure

Polyethylene, affectionately known as PE, is like a Lego masterpiece on the molecular level. It’s primarily composed of carbon and hydrogen atoms. Picture each molecule as a long chain, where each link is a carbon atom flanked by hydrogen atoms – it’s a carbon-hydrogen tag team! These chains can vary in length and structure, which influences the properties of the final material.

These molecular chains are not just randomly tossed together; they have a well-structured architecture. Some chains are like straight, obedient school kids in a line (high-density polyethylene), and others are more like a conga line at a party, a bit all over the place (low-density polyethylene). This structure determines everything from strength to flexibility in the final products. And just think, all these microscopic interactions are what make your everyday plastic items possible!

History of Polyethylene

Polyethylene, quite the accidental superstar of the polymer world, came into being in 1933 thanks to two enterprising chemists, Eric Fawcett and Reginald Gibson, at ICI in England. Initially, their creation didn’t cause much stir—it was the result of applying extremely high pressure to ethylene, a rather unassuming gas, and voila, a waxy resin they couldn’t find much use for at the time.

However, post World War II, the material’s true potential began to shine. It started to replace conventional materials in cables, toys, and containers because of its stellar insulation properties and mighty resilience. The demand skyrocketed, establishing polyethylene as a household name and a fundamental part of modern living. So, next time you crack open a plastic bottle or stumble over a child’s toy, tip your hat to the twist of fate that brought polyethylene into our lives!

Types of Polyethylenes

Just like in your favorite ice cream shop, polyethylene comes in several flavors, each with its own special twist!

High-Density Polyethylene (HDPE) is the tough guy. Think of it like the durable, hard plastic used in milk jugs and detergent bottles. It’s stiff, strong, and a little stubborn to bend, making it great for products that need to withstand pressure.

Low-Density Polyethylene (LDPE) is the more flexible family member. This type is softer and more pliable, kind of like the plastic wrap you use to cover your leftovers or the bags that magically stretch to fit all your groceries.

Linear Low-Density Polyethylene (LLDPE) combines the best of both worlds. It’s got more strength than LDPE but is more flexible than HDPE. Imagine an athlete who’s both strong and agile – that’s LLDPE for you!

Cross-linked Polyethylene (PEX) is the cousin who always seems to have everything together, especially when handling extreme temperatures. From radiant floor heating to hot and cold water plumbing, PEX doesn’t sweat under thermal stress.

Each type of polyethylene has its unique properties and preferred uses, making sure that there’s one to meet nearly any challenge you can throw at it in the world of materials.

Applications of Polyethylene

Polyethylene is like the Swiss Army knife of polymers, popping up everywhere in our daily lives due to its versatility and durability. Here’s a peek at how and where this overachieving material makes your life easier:

First, let’s talk shopping bags and packaging films. Thanks to its strong, lightweight properties, polyethylene helps you carry groceries without a wardrobe change from a spilled milk catastrophe.

Next up, toys. Ever wondered why your kid’s toys endure despite numerous crash tests against your living room walls? You guessed it—polyethylene. Its resilience and safe chemistry are why it’s favored for everything from action figures to teething rings.

In the construction world, polyethylene shows off its toughness and moisture resistance in pipes and plumbing systems. No more nightmares about burst pipes and indoor rainstorms!

Outdoor gear, like garden furniture and storage containers, also benefits from this material. It doesn’t mind the weather, whether it’s sunbathing on a hot day or surviving a snowstorm.

And there you have it—a snapshot of polyethylene at work. Next time you encounter any of these items, you’ll know there’s a bit of polymer magic at play!

Environmental Impact

Polyethylene, while super useful, isn’t exactly Mother Nature’s best friend. It comes mostly from non-renewable fossil fuels, and although it’s recyclable, it often ends up in landfills where it’s not exactly quick to say goodbye—taking hundreds of years to decompose. Plus, its production process is thirsty for energy and emits greenhouse gases.

On the upside, polyethylene’s durability can be a plus. Products made from it tend to have a longer life, reducing the waste cycle. Innovations are also on the horizon, aiming to produce polyethylene from more sustainable sources like sugarcane, which could sweeten its environmental footprint!

Recap