This article discusses the characteristics, method of production, and various uses of Polyetherimide (PEI), a high-performance polymer, in the construction sector and beyond.

Key takeaways:

- PEI exhibits high thermal stability (up to 170°C)

- PEI is inherently flame-resistant

- PEI has excellent strength, rigidity, and chemical resistance

- PEI has outstanding electrical insulation properties

- PEI has various construction applications, including structural components, electrical insulation, fire-resistant coatings, and chemical piping

Properties of PEI

PEI, short for polyetherimide, exhibits remarkable characteristics that make it an exceptional choice for various demanding construction applications. Here are some key points highlighting its properties:

- High thermal stability allows PEI to maintain its integrity in environments with temperatures of up to 170°C, ensuring durability under thermal stress.

- Inherent flame resistance means it doesn’t easily ignite and often meets aviation and automotive flammability standards without the need for additives.

- Strength and rigidity are central to PEI’s appeal; it can withstand significant loads and maintain its shape, vital for structural components.

- PEI’s excellent chemical resistance protects it against degradation from common solvents and fuels, which is crucial for long-lasting installations.

- Outstanding electrical insulation properties enable its use in electrical and electronic applications, providing safety and reliability.

- The transparency of certain PEI grades allows for the creation of components requiring visual inspection or light transmission without sacrificing material strength.

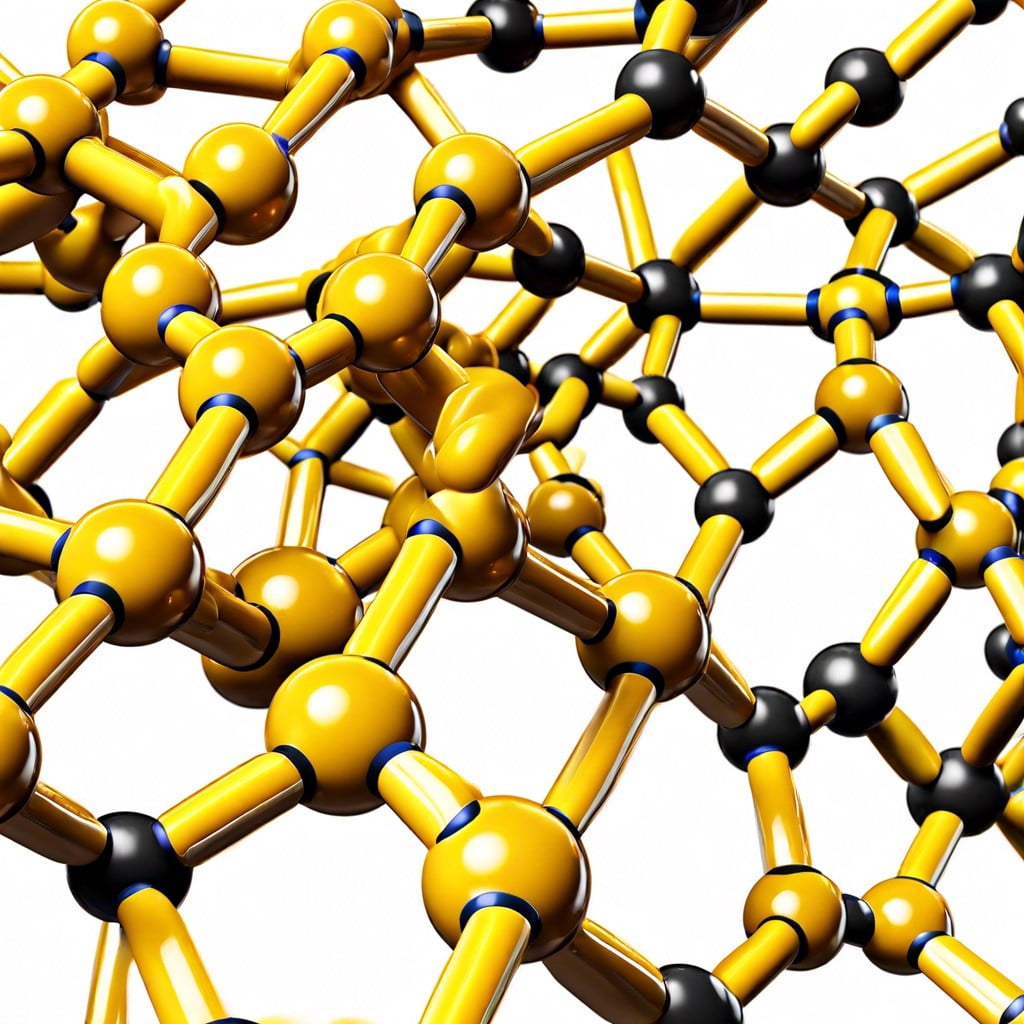

Synthesis of Polyetherimide

Polyetherimide (PEI) is a high-performance engineering thermoplastic created through a chemical reaction between bisphenol A and methylene dianiline in the presence of an acid chloride. This process, known as polycondensation, occurs at elevated temperatures and produces a polymer chain with repeating imide groups.

Key points illustrating the synthesis process:

- Temperature Control: Conducted at high temperatures, typically around 300°C, ensuring the reaction progresses efficiently.

- Chemical Reactants: Bisphenol A and methylene dianiline are combined to create the polymer backbone, while an acid chloride acts as a linker between these two compounds.

- Polymerization Technique: The polycondensation reaction leads to the growth of polymer chains, establishing the high-strength molecular structure characteristic of PEI.

- Reaction Environment: Performed under a carefully controlled atmospheric condition, typically an inert gas like nitrogen to prevent unwanted side reactions.

- Production of Amorphous Polymer: The result is a thermoplastic with an amorphous structure, granting PEI its high heat resistance and mechanical strength properties.

The precise conditions under which this synthesis occurs are critical to the final properties of the PEI produced. Understanding these steps is crucial for those working with this material to tailor it to specific construction applications, ensuring reliability and safety of the structures it is used in.

Applications of PEI in Construction

Polyetherimide (PEI) is a versatile high-performance polymer broadly utilized for its thermal stability, mechanical strength, and flame resistance. Within the construction industry, PEI finds its place in a range of applications due to these properties.

It’s commonly used in high-stress structural components that require durability and reliability over a long lifespan. For instance, it’s often chosen for insulating elements in both electrical and thermal contexts because of its excellent insulative properties.

Its inherent flame retardancy also makes it a valuable material in fire-resistant coatings and films applied to various building materials as a safety measure. PEI’s transparency to microwave radiation sees it used in radome construction, essential for protecting sensitive equipment without interfering with signal transmission.

Furthermore, its resistance to a wide spectrum of chemicals allows it to be included in piping and fittings in industrial buildings, ensuring safe transport of corrosive substances. In sum, PEI’s assortment of physical and chemical characteristics make it an important polymer in crafting safer, more efficient, and durable construction materials.

Processing Techniques for PEI

Polyetherimide (PEI) is versatile and can be molded into various shapes thanks to its thermoplastic nature, which softens when heated and hardens upon cooling. Here are some common processing techniques:

Injection Molding: Ideal for high-volume production of intricate designs, PEI is heated and injected into molds. This method ensures precise dimensions and is cost-effective for large runs.

Extrusion: PEI is pushed through a die to create continuous shapes like pipes, rods, and sheets. This process is well-suited for making profiles with consistent cross-sections.

Thermoforming: Sheets of PEI are heated until pliable, then formed over molds. Once cooled, they retain the new shape. This is great for creating large panels and complex contours.

Machining: In cases where molding isn’t feasible, PEI can be cut, drilled, or milled. While this method is more labor-intensive, it allows for custom fabrication of parts.

Each technique requires precise control of temperature and handling to maintain PEI’s mechanical and thermal properties. Understanding these methods is crucial for anyone looking to utilize PEI in their construction projects.

Recycling and Sustainability Aspects of PEI

Polyetherimide (PEI) distinguishes itself with a balance of workable characteristics and environmental considerations. Regarding recycling, PEI can be reprocessed and molded into new shapes, albeit with some potential loss of performance. Thermal degradation is a concern during multiple heating cycles, so recycling protocols must be designed carefully.

On the sustainability front, PEI’s durability means products last longer, reducing the need for frequent replacements. This longevity is a plus for sustainability as it decreases waste and resource consumption over time.

Additionally, PEI’s production requires energy, like all plastics, yet its robustness can lead to thinner, lighter components, translating to energy savings in transport and installation in construction projects.

Life cycle assessments are valuable in understanding the total environmental impact of PEI, from raw material extraction through to end-of-life disposal or recycling, enabling better choices for eco-conscious construction applications.

FAQ

What is PEI polymer?

PEI polymer, also known as ULTEMTM plastic, is an amorphous thermoplastic characterized by its high mechanical strength and rigidity, sharing similar physical properties to polyarylsulfones.

What is polyethylenimine used for?

Polyethylenimine is primarily used for the complexation and transfection of DNA into various cell lines and tissues both in vitro and in vivo.

What is PEI made of?

PEI, also known as Polyetherimide, is made via a polycondensation reaction between tetracarboxylic dianhydride (derived from bisphenol A and phthalic anhydride) and m-phenylene diamine.

Does PEI dissolve in water?

Yes, polyethyleneimine (PEI) does dissolve in water.

What are the mechanical properties of PEI polymer?

The mechanical properties of PEI (Polyetherimide) polymer include high tensile strength, excellent dimensional stability, and outstanding heat and flame resistance.

How does the thermal stability of PEI compare to other polymers?

Polyetherimide (PEI) has greater thermal stability than most polymers, maintaining characteristics up to temperatures of 170℃ – 200℃.

Can PEI polymer be used in 3D printing applications?

Yes, PEI (Polyetherimide) polymer can be effectively used in 3D printing applications due to its strength, heat resistance, and high dimensional stability.

Recap