This informative article will clearly elucidate the fundamental aspects of monomers and polymers, their relationship, and their pertinent use in the construction industry.

Key takeaways:

- Monomers are basic building blocks of polymers

- Polymers are large molecules made up of repeating monomer units

- Monomers are smaller and simpler than polymers

- Monomers are more reactive than polymers

- Properties of monomers can be different from resulting polymers

Definition of a Monomer

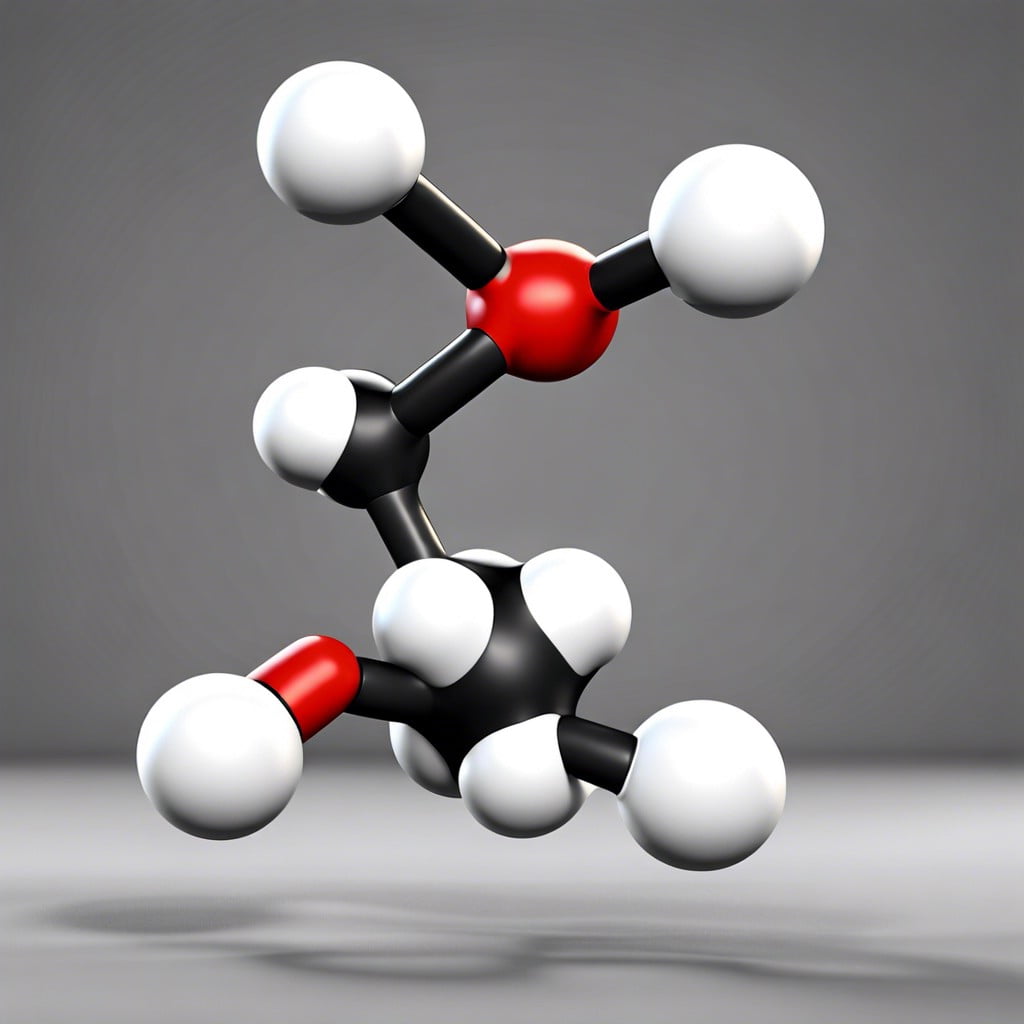

A monomer is the basic building block of polymers, consisting of small, simple molecules with the capacity to link up with similar units. Think of it like a single bead in a necklace, which when connected continuously forms a chain.

These monomers can join together through chemical reactions, typically requiring catalysts or specific conditions to proceed. Each type of monomer can contribute distinct properties to the resulting polymer, influencing its strength, flexibility, and resistance to chemicals and temperature.

Common examples include ethylene, which is used to make polyethylene plastics, and propylene, the base of polypropylene materials. In construction, monomers such as vinyl chloride are polymerized to form PVC, used extensively in pipes and home siding.

Understanding monomers is crucial, as they lay the groundwork for creating a wide array of materials essential to modern building technology.

Definition of a Polymer

Polymers are large, complex molecules made up of repeating structural units derived from simpler molecules known as monomers. They exhibit a wide range of physical and chemical properties, which are dictated by their specific structure and composition.

Polymers can be natural, like cellulose in plants and DNA in our bodies, or synthetic, such as nylon or polystyrene.

These materials are central to our daily life due to their versatility. They are used in everything from clothing and packaging to construction materials and high-end technology.

The repeating units, the monomers, are covalently bonded to form a long and linear or branched and networked chain.

Degree of polymerization, the number of monomers linked together in a polymer, is a key factor in determining a polymer’s properties. For instance, with a higher degree of polymerization, polymers typically become tougher and more durable.

Moreover, the shape and function of a polymer are influenced by how these monomer units are arranged – whether in a straight chain, branched, or cross-linked into a network.

Understanding polymers is essential because it gives insight into how materials behave in different conditions and how they can be manipulated or processed for specific applications in construction, from providing insulation and structural support to waterproofing surfaces.

Differences Between Monomers and Polymers

Monomers are the fundamental building blocks of polymers. They are simple molecules with a reactive group that allows them to bond with other monomers. Polymers, on the other hand, are complex structures composed of long chains of monomers linked together.

Key points to consider in the differentiation are:

- Size: Monomers are smaller compared to the much larger polymers they create.

- Complexity: A monomer is a single unit with a simple structure, while a polymer is made up of many monomer units and has a more complex structure.

- Reactivity: Monomers are typically more reactive than polymers, as they need to be able to connect to each other to form larger chains.

- Properties: The properties of a monomer can be vastly different from the properties of the polymer it forms. While a monomer might be a liquid or gas, the resulting polymer might be a solid with diverse characteristics necessary for specific applications in construction, like strength, elasticity, or resistance to heat and chemicals.

How Polymers Form

Polymers take shape through a process called polymerization, where monomers, the basic building blocks, link together. Think of it like a train, with each car being a monomer; when connected, they form a long chain, which is the polymer.

There are two primary pathways to polymer formation:

- Addition Polymerization: Here, monomers simply add to a growing chain one by one without the loss of any atoms, like adding beads onto a string. This happens when monomers have unsaturated bonds (double or triple bonds) which open up and attach to other monomers.

- Condensation Polymerization: In this method, monomers join together with the elimination of a small molecule, such as water. This can be imagined as two people holding hands while tossing away a tennis ball. It typically involves a series of step-by-step reactions between bi-functional or multi-functional monomers.

Polymerization can be initiated by heat, light, or catalysts, which provide the necessary energy to start and sustain the reaction. Control over this process allows for the creation of polymers with desired attributes, tailored for various applications in construction and beyond.

Examples of Monomers and Polymers

Ethylene, a gas composed of two carbon atoms double-bonded to each other and each attached to two hydrogen atoms (C2H4), acts as the fundamental building block for polyethylene, familiar to many as a component in plastic bags and bottles.

Vinyl chloride is another key monomer, which when polymerized forms polyvinyl chloride (PVC), extensively used for pipes, cable insulation, and clothing.

Styrene, a liquid monomer, is the precursor to polystyrene, a solid polymer we often see as foam cups and insulation material.

Bisphenol A (BPA), when combined with other chemicals, produces polycarbonate, a tough and durable plastic used in eyewear lenses, medical devices, and water bottles.

Terephthalic acid and ethylene glycol are monomers that create polyethylene terephthalate (PET), commonly used to make food and drink packaging due to its strong barrier properties.

Through understanding how these various monomers link to create polymers, we can better grasp the versatility of materials that build many of the everyday products we use.

FAQ

Which best explains the difference between a monomer and a polymer?

A monomer is a single molecular unit that can bind to other similar units to form a polymer, which is a complex structure comprising multiple interconnected monomers.

What is a monomer?

A monomer is an atom or small molecule that bonds together to create more complex structures known as polymers.

What turns a monomer into a polymer?

A monomer turns into a polymer through a process called dehydration synthesis, where the monomers combine using covalent bonds, creating larger molecules as polymers and producing water as a byproduct.

What is monomer and polymer plastics?

Monomer plastics are very tiny particles that, when linked together in a chain, form polymer plastics.

How are polymers applied in the construction industry?

Polymers are applied in the construction industry primarily as adhesives, sealants, coatings, foams, and as a component of composite materials to enhance durability, resistance, flexibility, and efficiency in buildings.

What role does polymerization play in the creation of plastic materials?

Polymerization plays a crucial role in the creation of plastic materials as it involves the bonding of monomers to form a complex structure known as polymer, which constitutes the basis of all plastic materials.

What are the environmental impacts of using polymer materials in construction?

The use of polymer materials in construction can lead to environmental impacts such as resource depletion from petroleum extraction, greenhouse gas emissions during production, and waste accumulation after disposal due to their non-biodegradable nature.

Recap