This article delivers a clear comparison between lithium-ion and lithium-polymer batteries, outlining their individual characteristics, advantages and disadvantages to aid your understanding and decision making.

Key takeaways:

- Lithium-ion batteries use liquid electrolytes; lithium-polymer batteries use solid or gel-like polymer electrolytes.

- Lithium-ion batteries generally have higher energy density than lithium-polymer batteries.

- Lithium-ion batteries are generally less expensive to produce than lithium-polymer batteries.

- Lithium-polymer batteries have an edge in safety due to their solid or gel-like electrolytes.

- Advancements in battery technology include solid-state batteries, silicon anodes, and lithium-sulfur batteries.

Chemistry of Lithium-ion and Lithium-polymer Batteries

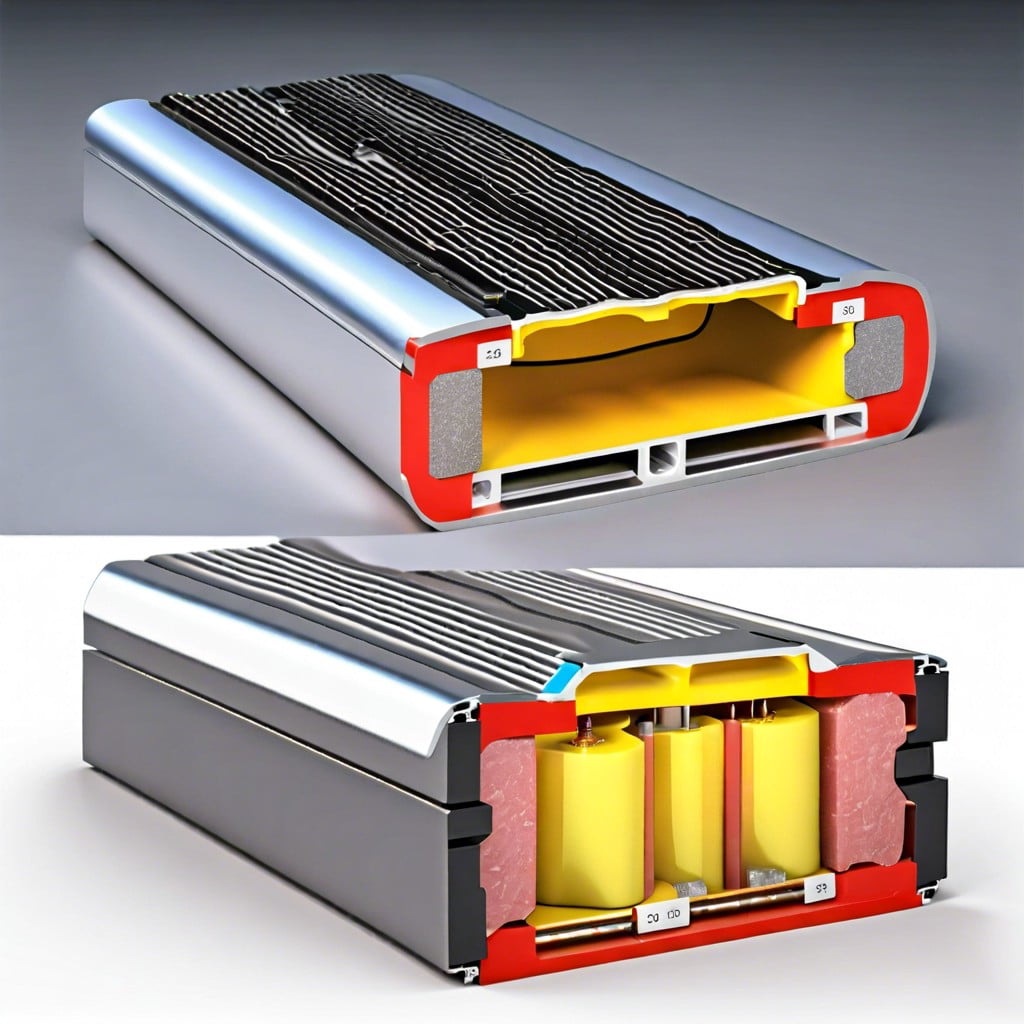

Lithium-ion batteries, or Li-ion, and lithium-polymer batteries, or LiPo, both employ lithium as their primary element but compose their electrolytes differently. Li-ion batteries rely on a liquid electrolytic solution, facilitating the flow of lithium ions between the anode and cathode during charge and discharge cycles.

In contrast, LiPo batteries use a solid or gel-like polymer electrolyte. This polymer base can be shaped more flexibly, allowing the battery to be thinner and lighter. This adaptability also means LiPo batteries can be custom-crafted to fit specific shapes, an advantage in space-constrained applications.

Both battery types transfer lithium ions during operation, which is the core mechanism powering electronic devices. However, the solid-state nature of the polymer electrolyte in LiPos offers a theoretical improvement in safety due to its resistance to leakage compared to the liquid electrolytes in Li-ion batteries.

Energy Density Comparison

Both lithium-ion and lithium-polymer batteries store and release energy by moving lithium ions between the anode and cathode. The energy density of a battery tells us how much power it can store relative to its size or weight, a crucial factor in applications where space and weight are limited, such as in mobile phones or electric vehicles.

Lithium-ion batteries have a liquid electrolyte solution that allows ions to flow between electrodes. They generally offer a higher energy density, which means they can store more energy per unit of weight than lithium-polymer batteries.

Lithium-polymer batteries, on the other hand, use a polymer gel as their electrolyte. This gel can be thinner and shaped more flexibly, which is advantageous for custom battery shapes, although their energy density tends to be slightly lower than that of their lithium-ion counterparts.

However, technology advances are closing the gap, with some lithium-polymer designs now approaching the energy densities of lithium-ion batteries. This convergence creates exciting opportunities for innovation in device design and energy storage capacity.

Cost Differences

Lithium-ion batteries are generally less expensive to produce than their lithium polymer counterparts. The price differential stems from several factors:

- Manufacturing Complexity: Lithium-ion battery production is a more mature process with standardized manufacturing techniques. In contrast, lithium polymer batteries require a more specialized manufacturing process that can add to the cost.

- Material Availability: The materials used in lithium-ion batteries, like liquid electrolytes, are more readily available and hence cheaper compared to the solid polymer electrolyte needed for lithium polymer batteries.

- Economies of Scale: Since lithium-ion batteries have been around longer, they benefit from larger production scales, which drives down costs. Lithium polymer batteries have not yet achieved the same level of mass production.

- Market Presence: Lithium-ion batteries are widespread in consumer electronics, electric vehicles, and other applications, fostering competitive pricing. Lithium polymer batteries are used in niche markets and often in custom designs, which don’t lend themselves to cost reductions through large scale manufacturing.

It is important to note that as technology and manufacturing methods improve for lithium polymer batteries, the cost is expected to decrease, potentially making them more competitive with lithium-ion batteries over time.

Safety and Stability

Lithium-ion batteries include a liquid electrolyte that can pose a risk if the battery is damaged, potentially leading to leaks or fires. Manufacturers incorporate safety features to minimize these risks, but the liquid nature of the electrolyte remains an inherent vulnerability.

On the other hand, lithium-polymer batteries use a solid or gel-like electrolyte, reducing the chances of leakage. Their more stable chemistry allows for a flexible, lighter, and potentially more rugged construction, which can better withstand physical stress. It’s this trait that often gives lithium-polymer batteries an edge in safety.

However, it’s important to note that both battery types have built-in safeguards and are generally considered safe for everyday use when properly handled and maintained.

Advancements and Future of Battery Technology

With rapid technological advancements, the future of battery technology is promising, as it moves towards achieving higher energy densities, faster charging, longer lifespans, and improved safety. Here are some key developments:

- Solid-state batteries: The shift from liquid electrolytes to solid conducts could greatly enhance safety by reducing the risk of leaks and fires.

- Silicon anodes: Replacing graphite anodes with silicon could lead to batteries with much higher capacities, as silicon can hold more lithium ions.

- Lithium-sulfur batteries: This next-generation technology promises higher energy density and lower costs, potentially overcoming the limitations of current lithium-based batteries.

- Recycling technology: As battery usage grows, improving recycling methods is crucial for sustainability and resource recovery.

- Wireless charging: While not directly related to battery composition, advancements in wireless charging infrastructure could impact how and where batteries are used and charged.

These innovations strive to keep pace with the increasing demands of electronic devices, electric vehicles, and large-scale energy storage solutions.

FAQ

Which is better lithium polymer or lithium ion?

Lithium-ion batteries are better than lithium-polymer batteries due to their higher power levels, making them more suitable for high-power usage.

Do lithium-polymer batteries last long?

Yes, lithium-polymer batteries last relatively long, typically around 10 to 17 months with daily charging, however, their lifespan can be extended with proper handling.

Can I replace lithium polymer with lithium ion battery?

Yes, you can replace a lithium polymer battery with a lithium ion battery due to similar voltage and larger capacity, however, the charging time may be comparatively longer.

Can I use a lithium polymer charger for a lithium ion battery?

Yes, a lithium polymer charger can often be used for a lithium ion battery due to their similar charging requirements.

What are the safety concerns around using lithium ion and lithium polymer batteries in construction?

Safety concerns around using lithium-ion and lithium polymer batteries in construction include the risk of fire and explosion due to overheating or physical damage, potential exposure to toxic materials upon rupture, and environmental damage related to improper disposal.

How do the energy densities of lithium ion and lithium polymer batteries compare?

Lithium polymer batteries typically have a lower energy density than lithium-ion batteries.

Is there a significant cost difference between lithium ion and lithium polymer batteries in the construction sector?

Yes, lithium-ion batteries are typically more cost-effective than lithium polymer batteries in the construction sector.

Recap