This article provides an overview of lipid polymers, showcasing their structure, uses, and examples in everyday applications.

Key takeaways:

- Lipid polymers are biodegradable and environmentally friendly materials.

- They possess unique properties, such as biocompatibility and barrier properties.

- Lipid polymers have versatile applications in medical devices, food packaging, and cosmetics.

- They can be synthesized through polymerization, interfacial polymerization, and enzymatic synthesis.

- Future trends in lipid polymer research include biodegradable materials, medical applications, and energy storage.

Definition of Lipid Polymers

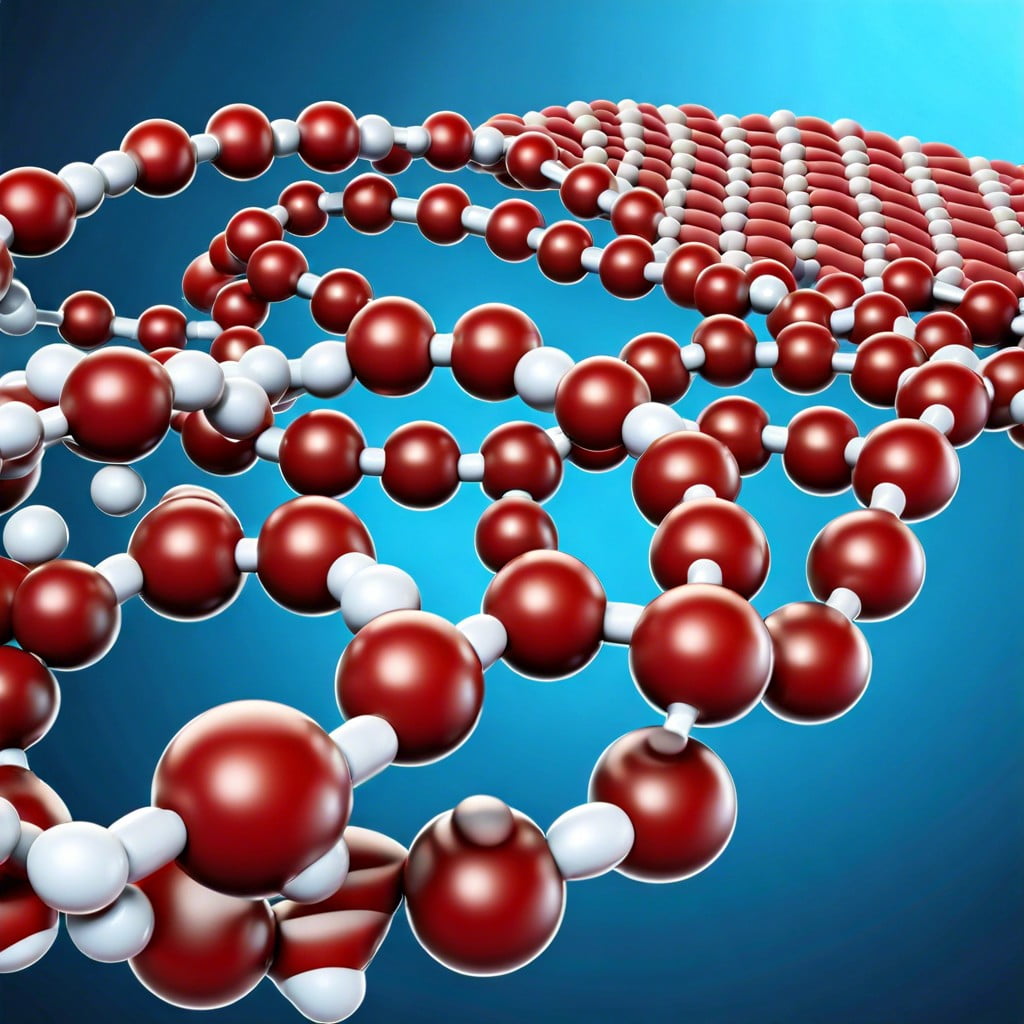

Lipid polymers are fascinating materials composed of long chains of lipid molecules. Unlike traditional polymers, which are generally hydrocarbon-based, lipid polymers are formed from lipids—molecules that are predominantly fatty acids or their derivatives. The building blocks of life, such as fats, oils, waxes, and certain vitamins, fall into this category. These polymers occur naturally in the cell membranes of living organisms.

- Key points to consider:

- Lipid polymers are mostly biodegradable, making them environmentally friendly.

- They possess unique properties, including biocompatibility, which is essential for applications in medical devices and drug delivery systems.

- Due to their structure, lipid polymers can form different shapes and sizes, offering versatility in various applications.

Overall, their structure and biological origin offer a range of functionalities that synthetic polymers might not easily replicate.

Characteristics of Lipid Polymers

Lipid polymers are celebrated for their versatility in both structure and function, influenced by the nature of the fatty acids and glycerol components. Here’s how their properties stand out:

**Biodegradability**: They breakdown naturally, making them environmentally friendly. This quality is essential, considering the current focus on sustainable materials in numerous industries.

**Biocompatibility**: Since they are essentially fats similar to those found in human bodies, lipid polymers are less likely to cause reactions. This makes them ideal for medical applications, from drug delivery systems to tissue engineering.

**Barrier properties**: Lipid polymers create effective barriers against water vapor and oxygen, which is crucial in food packaging to maintain freshness and in pharmaceuticals to protect sensitive products.

Each characteristic opens a door to innovative uses in various fields, supporting advancements and satisfying specific needs with precision.

Industrial Uses of Lipid Polymers

Lipid polymers are gaining popularity due to their biocompatibility and biodegradability, making them ideal for a variety of industrial applications. Here’s how they are currently being utilized:

Firstly, in the medical field, lipid polymers are used to create small drug delivery systems that can precisely target diseased cells without affecting healthy ones. This precision reduces side effects and improves the efficiency of treatments, particularly in cancer therapy.

Secondly, the cosmetics industry employs lipid polymers in the production of skin care products. Their ability to form protective barriers while also delivering nutrients directly to the skin enhances moisturizers and anti-aging creams.

Lastly, in the food packaging sector, lipid polymers offer an eco-friendly alternative to conventional plastics. They help extend the shelf life of perishables by preventing oxygen penetration and maintaining optimal humidity levels around the food.

Each of these applications demonstrates the versatility and functional adaptability of lipid polymers in meeting specific industrial needs.

Methods of Synthesizing Lipid Polymers

Creating lipid polymers involves a few key techniques that transform basic lipid structures into functional, long-chain molecules.

- Polymerization:

- This method involves linking lipid molecules together through chemical reactions. By applying catalysts and adjusting conditions like temperature and pressure, the lipids bond, forming a stable polymer chain. This process is akin to stringing beads onto a thread, where each lipid molecule is a bead.

- Interfacial Polymerization:

- Here, the reaction takes place at the interface between two different phases, typically water and oil. Lipid monomers are dissolved in both phases, and when they meet at the interface, they polymerize. Similar to drawing a line in the sand, this method clearly defines where the polymerization occurs.

- Enzymatic Synthesis:

- This uses enzymes as biological catalysts to join lipid molecules. This method is highly specific and can be conducted under milder conditions, reducing energy usage and potentially harmful byproducts. It’s similar to using a precision tool, ensuring that each connection in the polymer is correctly aligned.

By understanding these methods, scientists and engineers can manipulate lipid properties for desired applications in industries such as biomedicine and electronics.

Future Trends in Lipid Polymer Research

Researchers are continuously pushing the envelope to uncover new and exciting applications for lipid polymers. As we look to the future, several key areas of focus emerge:

Biodegradable materials are gaining traction, especially in reducing plastic waste. Lipid polymers are prime candidates for creating environmentally friendly alternatives to conventional plastics.

Medical applications are expanding rapidly. The inherent biocompatibility of lipid polymers makes them ideal for drug delivery systems and regenerative medicine. Scientists are exploring innovative ways to use these materials in targeted therapy and tissue engineering.

Energy storage is another promising field. Lipid polymers could play a crucial role in improving the efficiency and capacity of batteries, a vital component in the quest for sustainable energy solutions.

With ongoing advancements in technology and a growing understanding of molecular interactions, we can expect to see lipid polymers playing a significant role in many cutting-edge industries. Exciting times lie ahead as we continue to unravel the potential of these versatile materials.

Recap