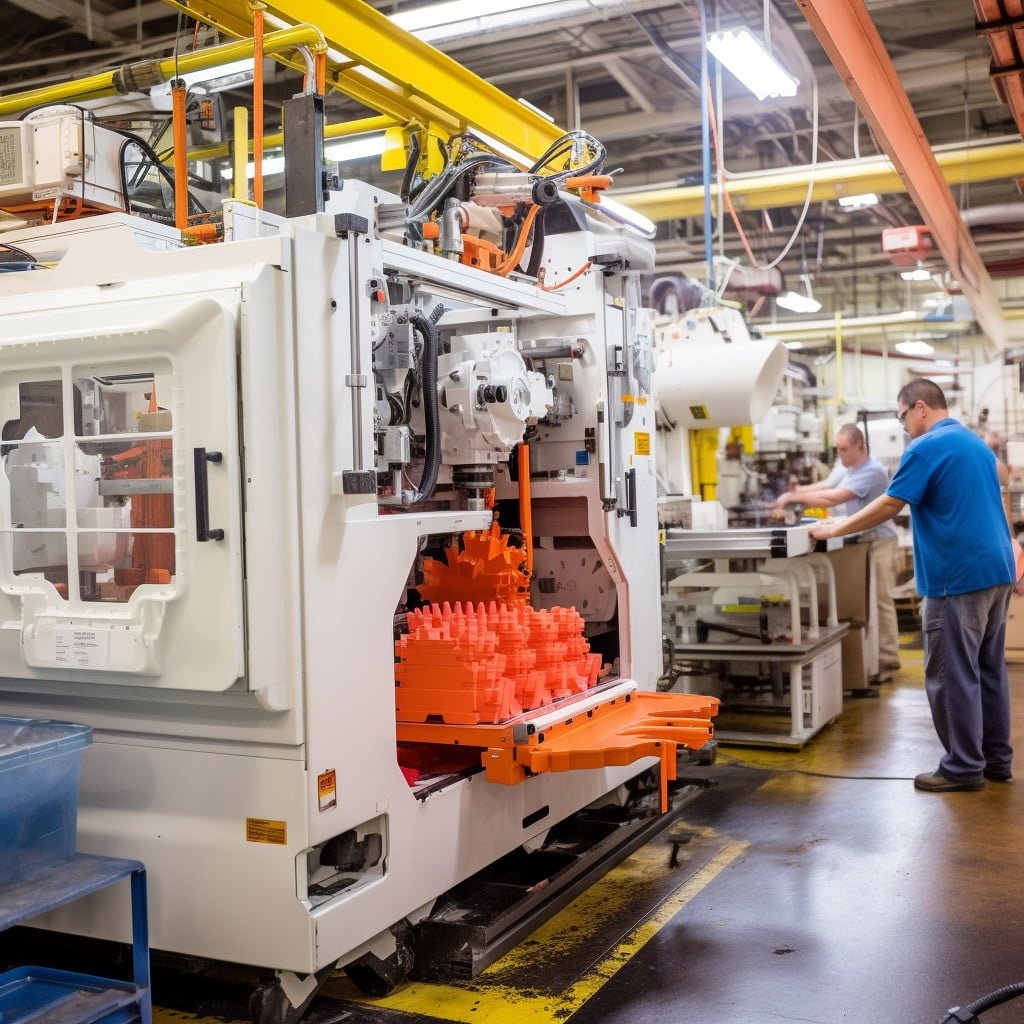

Plastic injection molding companies in Washington offer a range of high-quality manufacturing services for various industries.

Plastic injection molding companies play a critical role in Washington’s manufacturing sector. These companies bring innovative ideas to life by transforming melted plastic into high-quality products.

Whether you’re an entrepreneur with a groundbreaking concept or a business looking to streamline production, this blog post will guide you through the top plastic injection molding companies in Washington. From expertise to state-of-the-art facilities, discover how these industry leaders can meet your specific needs and propel your project towards success.

Get ready to delve into the world of plastic injection molding and unlock endless possibilities for your next big venture.

Piller Aimmco Plastics

Facebook page: Facebook

Services:

- Over Molding, Insert Molding & Encapsulation Molding

- Large & Small Part Injection Molding

- Thin Wall Injection Molding

- Low Pressure Injection Molding

- Complex / Tight Tolerance Injection Molding

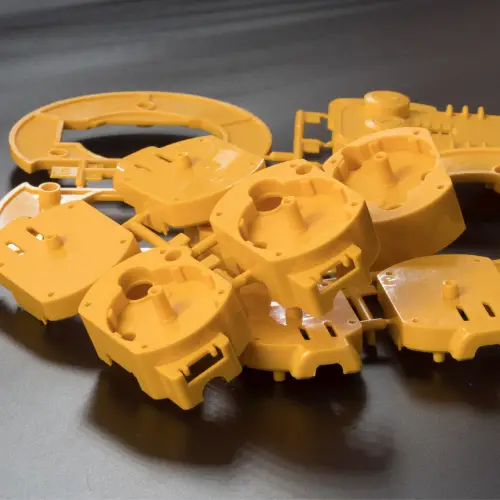

This injection molding company specializes in various molding techniques such as over molding, insert molding, and encapsulation molding. They are experienced in producing both large and small parts, including thin wall components.

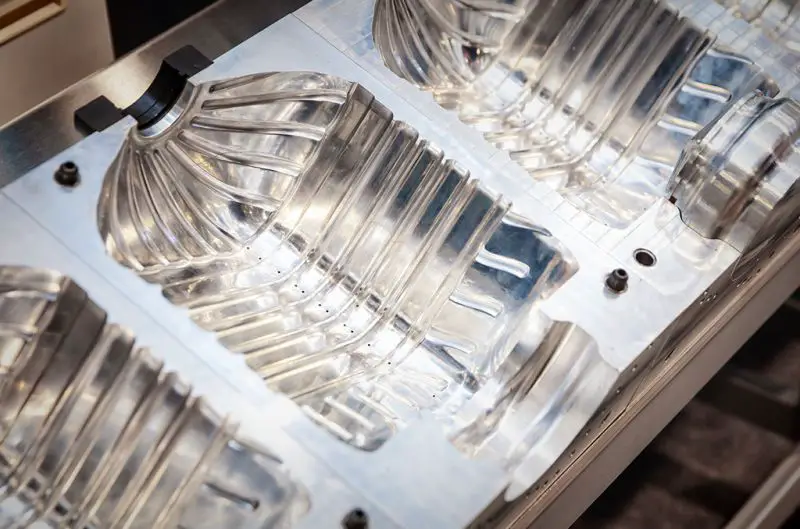

Their capabilities also include low pressure injection molding and complex/tight tolerance injection molding. They offer in-house mold design and construction services, quick turn injection mold manufacturing, plastic part design/engineering/3D modeling, prototyping/product development, fixture design/construction, secondary operations, program management, and industry-specific solutions for sporting goods & outdoor recreation, automotive & heavy trucking, medical devices & bio-technology; consumer electronics; industrial/agricultural; and aerospace/military sectors.

Rex Plastics

Services:

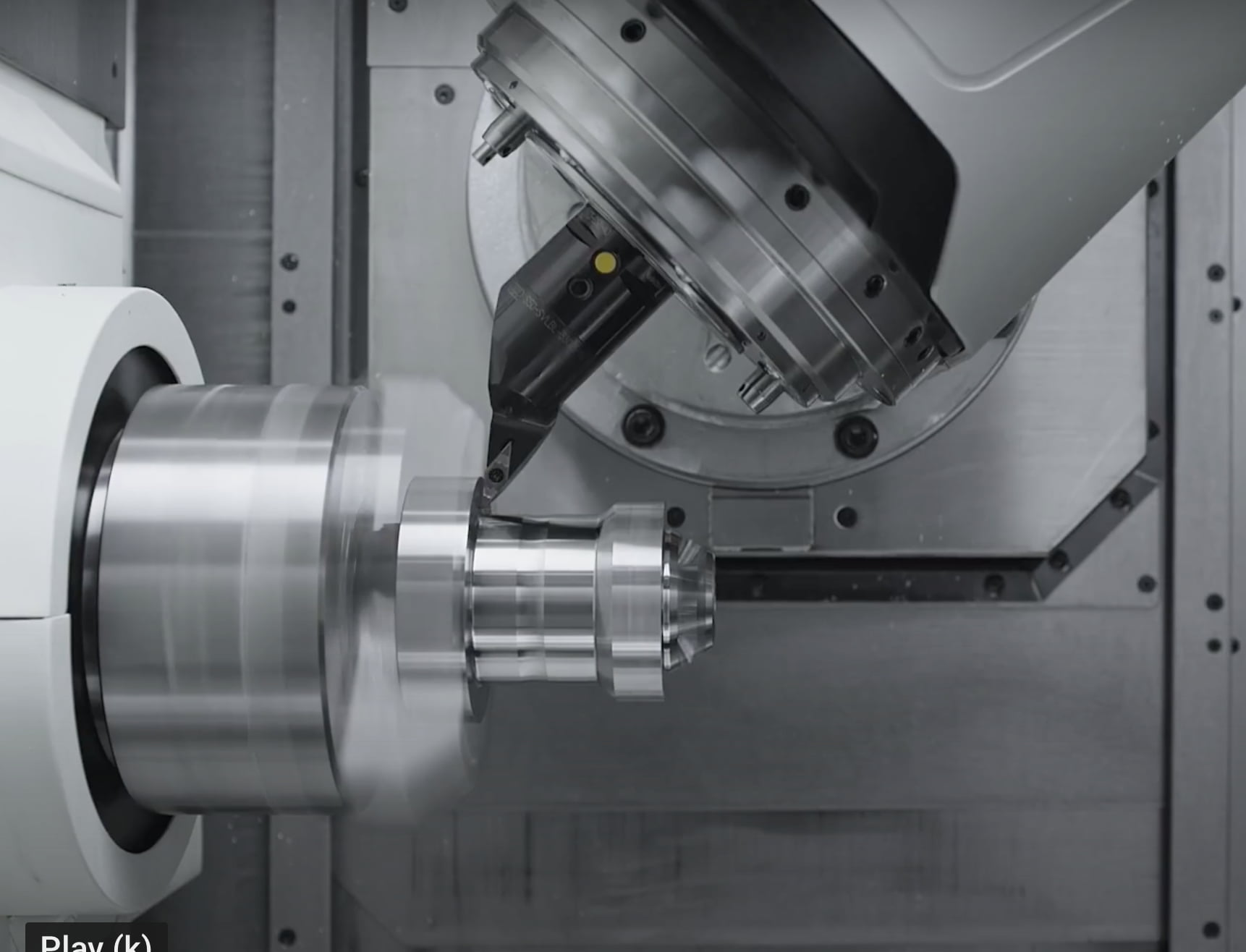

- Plastic injection molding services with machines ranging from 28 to 310 ton clamping force

- Shot capacity from less than a gram to 41 ounces per cycle

- Custom colors for plastic parts according to specifications

- Insert molding to integrate threaded brass inserts into plastic molded parts

- Over molding to combine different component materials into a single part

The injection molding company operates a plastics manufacturing facility with a team of experienced operators. Their state-of-the-art equipment ranges from 28 to 310 tons of clamping pressure, allowing for precise and efficient production.

With capabilities like custom colors, insert molding, and over molding, they offer comprehensive solutions tailored to meet specific requirements.

SEA-LECT Plastics

Company: sealectplastics.com

Contact phone: (425) 339-0288

Facebook page: Facebook

Services:

- Plastic injection molding

- Design services

- Product development

- Expert tooling

- Strong customer relationships

SEA-LECT Plastics Corporation is a leading injection molding company in the Pacific Northwest. With a strong focus on plastic injection molding, design, product development, and expert tooling, they provide high-value services to private companies, government entities, and partners.

Their skilled employees, improved processes, innovation mindset, and strong customer relationships set them apart in the industry.

Kaso Plastics

Facebook page: Facebook

Services:

- Comprehensive plastic injection molding capabilities

- Engineering and materials selection expertise

- Design and manufacturing of injection molded window and door hardware

- High quality and efficient production for any project

- Preferred vendor throughout the Northwest

KASO is a leading injection molding company known for their comprehensive plastic injection molding capabilities, guaranteeing high quality and efficient production for all projects. With expertise in engineering and materials selection, KASO has become a preferred vendor in the Northwest region.

They specialize in designing and manufacturing top-notch window and door hardware that prioritizes quality, performance, and aesthetics.

Retlaw Industries Inc

Company: retlawindustries.com

Contact phone: (888) 412-9088

Services:

- Custom Plastics Design & Engineering

- Tooling

- Molding

- Assembly

- Precision / Quality Prototyping

Retlaw Industries is a Wisconsin-based injection molding company with over 40 years of experience. They specialize in manufacturing high-quality thermoplastic components for a wide range of industries.

From adapters in Seattle to sprockets in Spokane, and rebar chairs and idler pulleys in Olympia, Retlaw Industries can custom design their products to meet specific needs. Contact them today for a free quote.

H&H Molds

Contact phone: (651) 859-8278

Services:

- Mold-making

- Plastic injection molding

- Engineering services

- Machining

- Quality control

This injection molding company is a full-service mold-making and plastic injection molding company that specializes in low volume, tight tolerance molding of engineering and commodity grade thermoplastic resins. With a strong focus on quality, continuous improvement, superior customer service, and engineering, they are able to provide cost-effective, high-quality products.

They have evolved into one of the largest professional mold making and plastic injection molding companies in the Pacific Northwest over three generations.

Pacific Injection Molding

Services:

- Production of high quality durable parts in rigid and elastomeric engineering thermoplastics

- Working with non-petroleum or bio-plastics base materials in production and 3D modeling

- Full-service support from concept to production

- Building customer ideas into reality

- Commitment to quality and customer satisfaction

Pacific Injection Molding Corporation (PIMC) is a leading injection molding company that specializes in manufacturing durable parts using rigid and elastomeric engineering thermoplastics, including bio-plastics. They provide full-service solutions from concept to production, ensuring high-quality results for their customers’ ideas.

Tamarack Industries

Services:

- Manufacturing products to customer specifications

- Part and mold design services

- Mold making services

- Injection molding services

- Secondary operations such as ultra-sonic welding, drilling, and assembly

This injection molding company specializes in inspiring creative partnerships through molded plastics. With their experience and capabilities, they provide comprehensive services including part and mold design, mold making, and plastic molding.

They pride themselves on good communication and teamwork to achieve quality custom molded parts for their customers, proudly made in the USA. They offer secondary operations such as ultra-sonic welding, drilling, and assembly to meet various manufacturing needs.

Ultra Polymers Injection Molding

Services:

- Highly engineered injection molded parts

- Insert molding

- Sonic welding

- Electro/electro-less nickel plating

- CNC adhesive bonding

Ultra Polymers Injection Molding, formerly known as Cascade Quality Molding, is a leading injection molding company based in Wenatchee, Washington. With their newly expanded 12,000 sq ft facility and modern 28 to 440-ton presses equipped with advanced features, they specialize in producing highly engineered injection molded parts using a wide range of materials.

Ultra Polymers offers specialized services such as insert molding, sonic welding, electroplating, adhesive bonding, and assembly methods to ensure high-quality products with traceability and consistency.

Molded Dimensions Group

Contact phone: (678) 902-7219

Facebook page: Facebook

Services:

- Custom molded rubber parts for various industries

- Molded, formed, and wrapped hoses for fluid and air movement

- Urethane molding with expertise in hand pouring and high-speed production

- Full-service offerings in plastic injection molding from idea to production

- Comprehensive process from initial project needs to product reliability and customer satisfaction

This injection molding company specializes in designing and manufacturing custom molded rubber parts, as well as molded, formed, and wrapped hoses for fluid and air movement applications. They also offer expertise in urethane molding, providing high quality finished products.

With their proficiency in plastic injection molding, they are able to provide full-service offerings from idea generation to production. Their process involves activating initial project needs and goals, developing the process with optimal materials and product samples, executing timely production and delivery based on customer demands, and performing for product reliability and customer satisfaction.

Custom Engineered Wheels Inc. (CEW)

Facebook page: Facebook

Services:

- Custom mold design and manufacturing

- Injection molding of plastic parts and products

- Precision and high-volume production capabilities

- Compliance with specifications and quality standards

- Expertise in various industries, including electronics, automotive, home appliances, housewares, medical, and aerospace.

Plastic injection molding is a widely implemented manufacturing process that has driven significant growth in the plastics industry. It involves melting plastic granules and injecting them into a custom-made mold cavity to cool and take shape.

The process is known for its precision, compliance to specifications, and ability to produce large quantities of parts consistently.

Mira Plastics

Company: miraplastics.com

Services:

- Injection molding of plastic products for various industries

- Operation of semi and automatic two-plate, three-plate, runner-less, and hydraulic core pull molds

- Utilization of cutting-edge robotics for parts removal

- Extensive experience with a wide range of injection molding materials

- Selection of optimum components for any project based on knowledge of material properties and processing parameters

Mira Plastics, a premier family-owned plastic injection molding company located in Fredon Township, New Jersey, has been providing high-quality products and services to various industries since 1955. Their state-of-the-art facility, spanning 62,000 square feet and conveniently accessible from major roadways and airports, houses advanced equipment including cutting-edge robotics for parts removal.

With expertise in operating different types of molds and a deep understanding of various materials and their properties, Mira Plastics stands out as one of the most trusted injection molding companies in the industry.

Altek, Inc

Facebook page: Facebook

Services:

- Custom injection molding

- Prototype development

- Mold design and manufacturing

- Secondary operations and assembly

- Quality control and testing

Altek, Inc. Is an injection molding company that specializes in providing high-quality manufacturing solutions for a wide range of industries.

With certifications and registrations since 2000, they pride themselves on their expertise, innovation, and commitment to customer satisfaction. Their website, designed by OLI Communications, showcases their capabilities and showcases a dedication to excellence.

Vision Plastics

Services:

- Injection molding

- Contract manufacturing

- Plastic assembly services

- Automation

- Custom end of arm tooling, fixturing, and molding automation

Vision Plastics is a plastic manufacturing partner that offers a comprehensive range of molding services. With ISO 9001:2015 certification and Lean Manufacturing methods, they provide high-quality products, minimal waste levels, and efficient manufacturing processes.

In addition to injection molding, they also offer specialized services such as custom tooling, fixturing automation, heat staking and ultrasonic welding, metrology with CMM equipment, Design for Manufacturing support, and mold flow analysis. Their in-house engineering team aims to surpass customer expectations in every aspect of custom molding projects.

Rainier Precision

Company: rainierprecision.com

Services:

- Custom Plastic Injection molding services

- Manufacturing of Dri-Z-Air dehumidification product

- Injection molding capacities ranging from 25 tons to 140 tons

- Re-work and secondary operations

- Color blending, tooling, part design, consultation, and insert molding

Rainier Precision is a renowned injection molding company that was established by J.W. Trosper more than 61 years ago in Seattle.

With expertise in custom plastic injection molding, they proudly serve customers throughout the United States and Canada. Operating out of Redmond, OR, they offer a wide range of capabilities including various injection molding capacities, re-work and secondary operations, color blending, tooling services, part design consultation, insert molding, and the ability to produce both small and large quantities of parts.

AIM Institute

Services:

- Educational and training courses rooted in research

- Problem-solving using critical thinking

- Knowledge and skills expansion

- Next level education and training for the plastic injection molding industry

- Diligent selection of training provider for employee education

The AIM Institute is an injection molding industry leader, offering educational and training courses designed to advance knowledge and skills in the field. With a focus on problem-solving through critical thinking, this institute provides the next level of education for those seeking to excel in the plastic injection molding industry.

Their dedication to workforce development sets them apart as a trusted training provider for both students and employers alike.

Recap