If you are in search of reputable plastic injection molding companies in North Carolina, this blog post will provide you with valuable insights and recommendations.

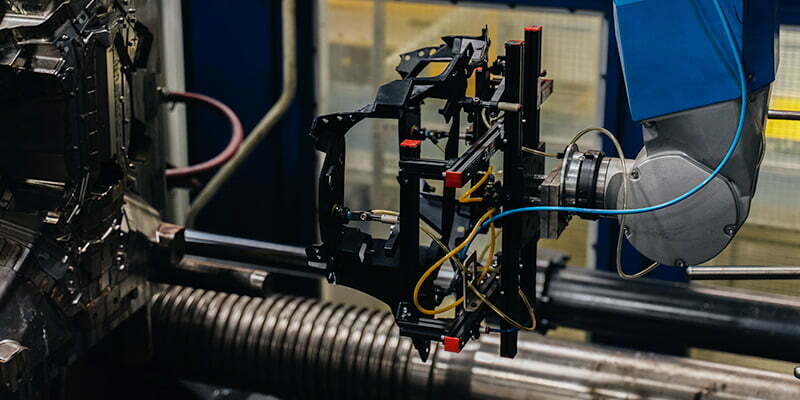

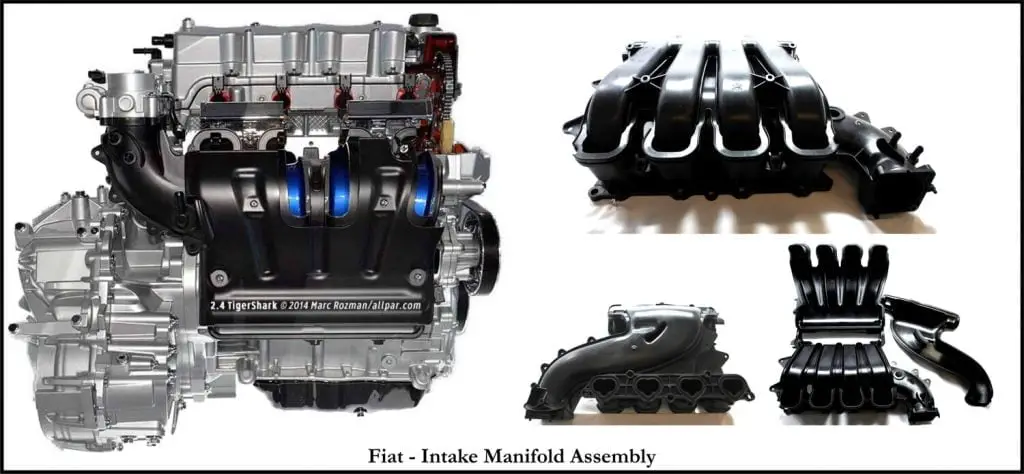

Plastic injection molding has revolutionized the manufacturing industry, providing a cost-effective and efficient method for producing high-quality plastic parts. In North Carolina, there is a booming market for such companies, catering to diverse industries such as automotive, electronics, and medical devices.

This blog post aims to explore the top plastic injection molding companies in North Carolina and highlight their key capabilities and specialties that make them stand out in this competitive landscape. So if you’re looking for a reliable partner to bring your plastic product ideas to life, keep reading as we delve into the world of injection molding in North Carolina.

Advanced Plastiform

Facebook page: Facebook

Services:

- Specializes in thermoforming and injection molding

- Works with companies from various industries

- Determines the right method of manufacturing for custom plastic components and products

- Ensures durable, long-lasting products that are accurate and consistent to approved designs

- Offers low per-unit pricing and fast lead times

Advanced Plastiform, Inc. Is a leading plastics engineering and manufacturing company specializing in thermoforming and injection molding.

They have a skilled team of engineers and designers who work closely with clients from various industries to determine the most suitable method for manufacturing custom plastic components and products. With a range of high-quality thermoplastic materials and injection presses up to 530 tons, they can deliver durable, accurate, and consistent products with fast lead times at competitive prices.

Rosti

Services:

- Full-service injection molding and contract manufacturing of precision components & assemblies

- Extensive design for manufacturing (DFM) process

- Custom tool building services

- Advanced injection molding processes up to 1,100 tons

- Full-service assembly, heat staking, hot stamping, machining, riveting, solvent bonding, and more

Rosti North Carolina is a leading injection molding company with over 40 years of experience. They offer a full-service approach, providing precision components and assemblies to a global customer base.

Their 51,000 square foot facility houses advanced injection molding presses ranging from 35 to 1,100 tons, along with additional capabilities such as custom tool building services and comprehensive design for manufacturing (DFM) analysis. Rosti North Carolina’s expertise extends to various finishing processes, including assembly, machining, riveting, heat staking hot stamping, solvent bonding, and more.

PAM Injection Molding

Contact phone: (336) 668-0901

Services:

- Custom injection molding manufacturing

- Tooling support

- Warehousing

- Material handling

- Tooling maintenance, change-over, and repair

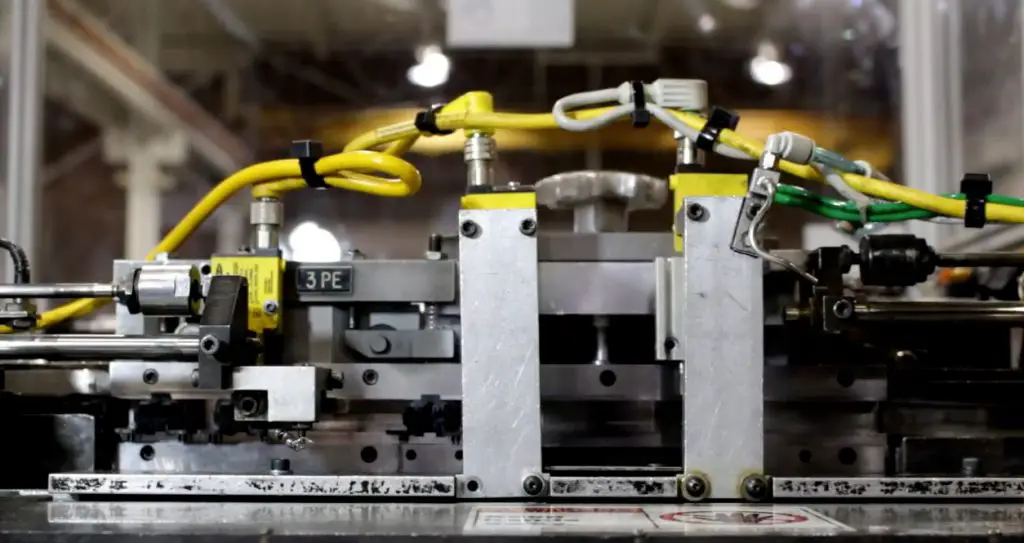

PAM Injection Molding Facility located in Kernersville, NC provides a comprehensive solution for custom injection molding needs, encompassing manufacturing, tooling support, and warehousing. With their all-electric molding presses ranging from 110 tons to 950 tons of clamping force, PAM embraces the latest manufacturing technology.

They prioritize quality and customer satisfaction through a separate material handling department and offer a complete tooling and machining facility equipped with various tool centers for preventive maintenance, change-over, and repair of customers’ tooling.

Sapona Plastics, LLC

Facebook page: Facebook

Services:

- Injection molding

- Assembly

- Decorating

- Tooling

- Lip Balm Containers

This injection molding company is a leading provider of high-quality injection molded products. They offer a wide range of services, including assembly, decorating, and tooling.

Their team is dedicated to delivering exceptional results and providing excellent customer service.

Blue Ridge Molding

Company: blueridgemolding.com

Services:

- Injection molding

- Assembly

- Special packaging

- Part design

- Tool design

Blue Ridge Molding is an injection molding company that offers a wide range of services including part and tool design, prototyping, hot stamping, special packaging, project management, warehousing, and assembly. They aim to establish a “True Partnership” with their customers by supplying high-quality plastic components on time and within budget.

Located in Conover, NC, they provide custom injection molding solutions to meet the demanding requirements of manufacturing operations.

Mack Molding

Company: mack.com

Facebook page: Facebook

Services:

- Plastic Injection Molding

- Design/Development

- Prototyping

- Finishing

- Contract Manufacturing

This injection molding company specializes in a range of services including design/development, prototyping, plastic injection molding, finishing, sheet metal work, machining, contract manufacturing and more. With multiple divisions and expertise in various industries such as medical, industrial, transportation and consumer goods, they offer a comprehensive approach to their clients’ manufacturing needs.

They also provide additional resources through their website including press releases, newsletters and blog posts.

RJG, Inc

Company: rjginc.com

Facebook page: Facebook

Services:

- Technical and non-technical training courses for production of thermoplastic injection molded components

- Hands-on, practical applications in injection molding and DECOUPLED MOLDING® processes

- Comprehensive coverage of molding machine construction, process parameter selection, mold temperature control, material handling, and use of additives

- Online version of the course available for remote learning

- Prerequisite online Math for Molders course or minimum score on the online assessment

This four-day course is designed for individuals involved in the production of thermoplastic injection molded components, providing practical applications and hands-on training. It covers topics such as molding machine construction, process parameter selection, mold temperature control, material handling, and the use of additives for consistent component quality.

Participants will gain knowledge on machine elements, dimensional control of components, and different material types. Prior completion of a Math for Molders course or passing an online assessment is required.

Custom Molding

Services:

- Plastic injection molding machines ranging from 88 ton to 1500 ton

- High pressure and low pressure structural foam capabilities

- Daily capacities ranging from several hundred large parts to over 500,000 smaller parts per day

- In-house services including design and engineering, fully equipped tool rooms, and warehousing

- Integrated ISO 9001 quality control and additional services such as press side packaging, hot stamping, and sonic welding

Plastic Industries, located in East Tennessee, is a leading injection molding company with a wide range of capabilities. With plastic injection molding machines ranging from 88 ton to 1500 ton and daily capacities that can reach over 500,000 parts per day, they offer efficient manufacturing options for both large and small projects.

In addition to their manufacturing facilities, Plastic Industries also offers design and engineering services, in-house tool rooms, warehousing, ISO 9001 quality control, press side packaging, hot stamping, and sonic welding. They pride themselves on their ability to ship products quickly and easily throughout North Carolina cities such as Raleigh, Charlotte,Greensboro,Wilmington,and many more.

Stanford Manufacturing

Services:

- Affordable and high-quality injection molding services

- Expertise in addressing and resolving quality issues

- Commitment to customer satisfaction and addressing concerns

- Inclusive and supportive work environment for employees

- Ability to work with existing molds and provide improvements

Stanford Manufacturing is a customer-centric injection molding company that focuses on delivering affordable, high-quality products and services. With a commitment to extreme customer satisfaction, Stanford Manufacturing empowers its employees in an inclusive and stable environment while consistently addressing and resolving any concerns or issues raised by their clients.

Atlas Precision Plastics

Facebook page: Facebook

Services:

- Full-service plastic injection molding

- In-house design and tool building capability

- Specialization in precision injection mold tooling for various industries

- Assistance with product design, material selection, prototype development, mold design, and mold flow

- Superior customer service and state-of-the-art equipment

Atlas Precision Plastics is a full-service injection molding company with expertise in designing and building precision injection mold tooling. They serve a range of industries including healthcare, automotive, telecommunications, industrial, and electrical markets.

Atlas Precision Plastics is committed to providing high-quality products with advanced technology and exceptional customer service.

R&D Plastics

Services:

- Custom plastic injection molding

- Assembly, part decorating, and secondary operations

- Parts design and material selection assistance

- Prototyping services

- High-quality standards with precise tolerances using commodity or engineered/exotic material

R&D Plastics is a service-first custom plastic injection molding manufacturer that has been providing a comprehensive range of plastic parts manufacturing methods for over 30 years. They offer assembly, part decorating, and secondary operations, and their team works closely with clients to provide solutions, assist with parts design and material selection, and recommend manufacturing methods.

Located in Flat Rock, NC, R&D Plastics specializes in cost-effective molding solutions for small- to medium-volume requirements while maintaining high-quality standards and precise tolerances. They also offer valuable add-on services to accelerate product launch and ensure customer satisfaction.

Locust Plastics, Inc

Company: locustplastics.com

Contact phone: (912) 311-1356

Services:

- Custom injection molding services

- Highest standards in quality

- Excellent customer service

- On-time delivery

- Wide range of capabilities

Locust Plastics, Inc. Is a custom injection molding company that prides itself on delivering the highest standards in quality, customer service, and punctual delivery.

With a wide range of manufacturing capabilities and advanced molding equipment, they are dedicated to meeting their customers’ exact specifications. Located at 630 Industrial Ave., Salisbury, NC 28144 and accessible via phone at 704-636-2742 or fax at 704-636-2746, their website showcases their offerings for potential clients.

Glenn Mauser Plastics

Company: glennmauserplastics.com

Services:

- Custom injection molding

- Hosiery hooks and hangers

- Injection molded hair picks

- Injection molded part trays

- Injection molded plastic baskets

Glenn Mauser Plastics in Conover, North Carolina specializes in custom injection molding. They offer a variety of products including hosiery hooks & hangers, portable storage units, molded handy compartments, injection molded part trays, plastic baskets, and hair picks.

For more information or inquiries, contact Glenn Mauser at 828-464-8996.

Wilbert Plastic Services

Contact phone: (866) 273-1810

Services:

- Molding capability ranging from 100 Ton to 3500 Ton

- Multi-material, two-shot plastic injection molding

- In-mold labeling

- MuCell microcellular foam injection

- Long fiber glass molding

Wilbert Plastic Services is an injection molding company with industry-leading engineering insight and advanced manufacturing capabilities. They provide a wide range of injection molding services, including multi-material, two-shot plastic injection molding, in-mold labeling, MuCell microcellular foam injection, and more.

With four U.S. Plants and a headquarters in Belmont, North Carolina, they cater to OEMs throughout North America and ship plastic components globally.

Quality Plastics

Contact phone: (828) 652-1190

Services:

- High quality injection molding services for a wide range of commercial applications

- Product development, design, prototype manufacture, material selection, tooling, and final production process support

- Manufacturing of custom injection molds varying in size and complexity

- Production of thick sectioned large parts and intricately designed small precision parts

- Manufacture of high quality products for the RV and camping industry under the brand “Campers Friend”

Quality Plastics CMI is a full-service injection molding company with over two decades of experience in providing high-quality injection molding services. They specialize in serving a wide range of commercial applications, from swimming pools to aircraft.

With their expertise in product development, design, prototype manufacture, material selection, tooling, and final production process, Quality Plastics is the perfect partner for all your injection molding needs. In addition to their services, they also manufacture their own high-quality products for the RV and camping industry under the brand “Campers Friend”.

Located in North Carolina’s Blue Ridge Mountains, Quality Plastics expertly produces custom injection molds of varying sizes using rigid and elastomeric thermoplastics.

Superior Tooling

Services:

- Plastic Injection Molds

- Die Cast Dies

- Fixtures

- Precision Machining

- Validation

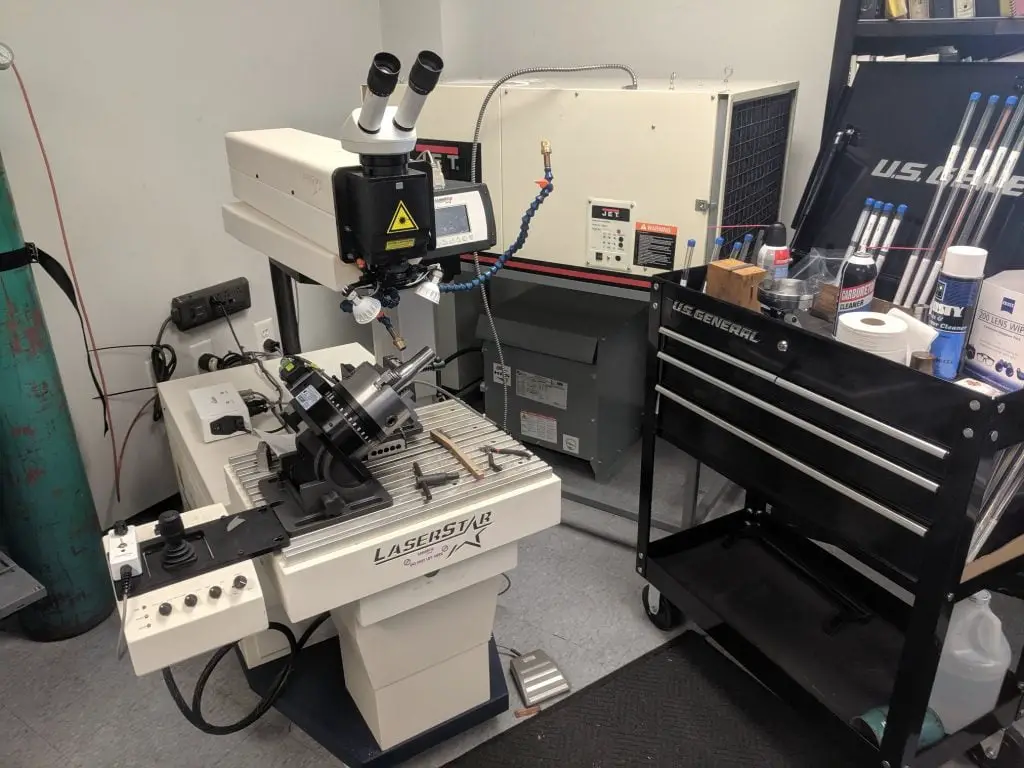

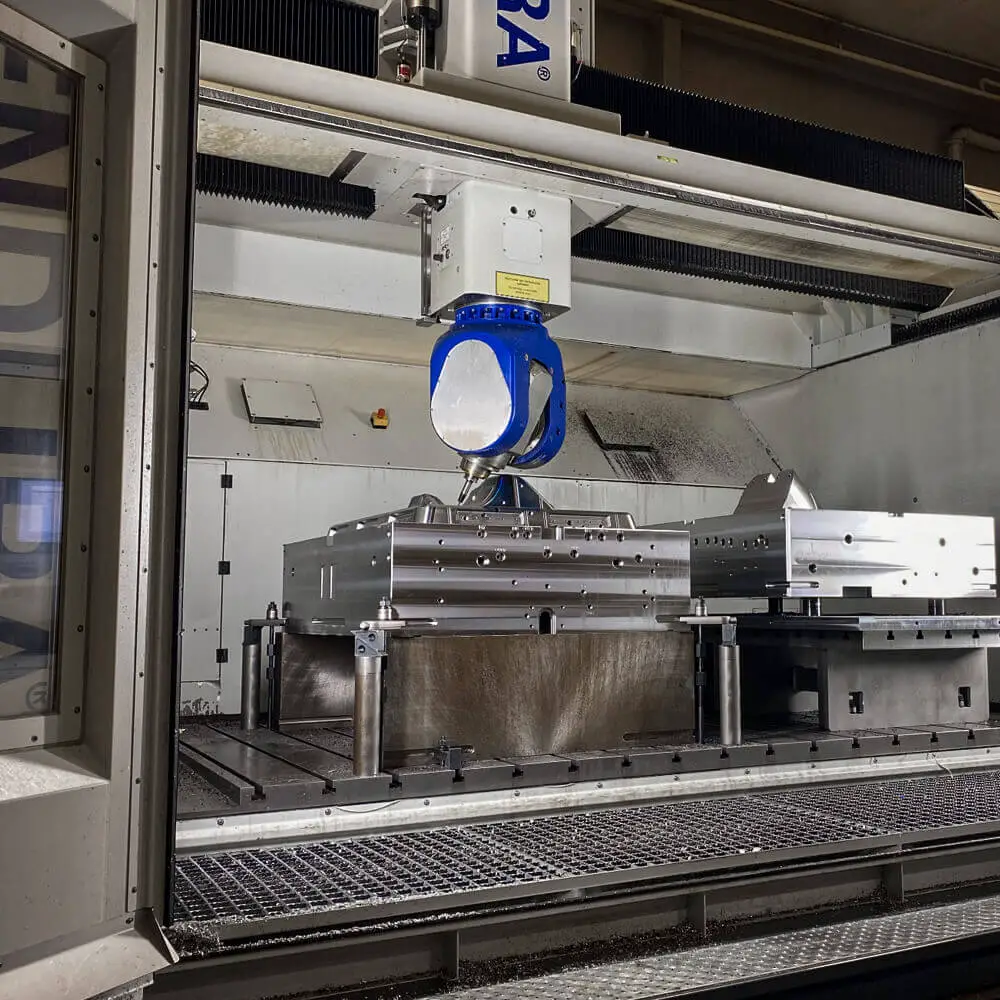

Superior Tooling, Inc. Is an injection molding company founded in 1985 with a focus on quality tooling manufacture.

They aim to be an industry leader in plastic injection molds by utilizing expert craftsmen and state-of-the-art technology. Their commitment to continuous improvement helps them earn new business while maintaining long-term client satisfaction.

DeltaMold

Company: deltamold.com

Services:

- Manufacturing, sampling, and repair of high-quality injection molds

- Designing and developing plastic injection, compression, and stack molds

- RIM tooling services

- 3D modeling for product viability assurance

- Manufacturing and tool feasibility studies

Delta Mold, Inc. Is a leading injection molding company based in Charlotte, NC.

With 45 years of experience, they specialize in the design and development of high-quality injection molds for various industries. They offer manufacturing, sampling, repair services, as well as feasibility studies and production services.

Known for their culture of collaboration and employee care, Delta Mold sets itself apart by prioritizing relationships and providing great opportunities to its employees and customers alike.

Quantum Plastics

Facebook page: Facebook

Services:

- Plastic injection molding

- Over molding

- Insert molding

- Assembly services

- Secondary operations (hot-stamping, sonic welding, kitting, packaging, fulfillment, contract manufacturing)

The Raleigh Division of this injection molding company specializes in providing plastic injection, over molding, and insert molding solutions for the industrial and consumer industries. They offer a range of secondary operations such as assembly, hot-stamping, sonic welding, kitting, packaging, fulfillment, and contract manufacturing.

The company ensures high-quality standards through a three-level approval process before production and regular inspections during production to maintain consistency. They also stock inventory in-house for high-volume products and strive to meet customer deadlines with efficient production scheduling.

Thunderbird Molding

Services:

- Custom Injection Molding

- Mold Design and Tooling

- Clean Room

- Integrated Materials

- Quality Control

Thunderbird Molding is an injection molding company with multiple state-of-the-art facilities located in Elkhart, IN, Shelbyville, IN, Clearwater, FL, Elgin IL, and Greensboro, NC. They specialize in custom injection molding and offer services such as mold design and tooling, clean room manufacturing, integrated materials processing, quality control, and finishing services.

With a focus on industries like automotive, medical, military and defense, aerospace, technology and consumer goods; Thunderbird Molding is dedicated to providing superior products through ongoing investments in technologies and processes.

Cape Fear Mold & Tool Co., Inc

Company: capefearmold.com

Services:

- Plastic injection mold manufacturing

- Precision tool manufacturing

- High precision component manufacturing

- Complex mold building

- Wire EDM services

Cape Fear Mold & Tool Co., Inc. Is a highly regarded plastic injection mold and precision tool shop that specializes in manufacturing plastic injection molds and high precision components.

With over twenty years of industry experience and a strong reputation for delivering top-quality tooling, Cape Fear Mold & Tool Co., Inc. Has become a trusted name in the field.

Central Carolina Products

Services:

- Custom Injection Molding

- Assembly

- Decorative Coating

- Tooling Support

- Design and Development

Central Carolina Products, Inc. Is a minority-owned injection molding company headquartered in Burlington, NC.

With over 25 years of experience, they are ISO 9001:2015 registered and specialize in custom injection molding of thermoplastics. In addition to assembly and decorative coating services, they offer comprehensive engineering assistance and support to ensure the highest quality products that meet customer expectations.

Serving both domestic and international markets, CCP, Inc. Prides itself on providing made-in-the-USA manufacturing with convenient access to transportation channels for efficient delivery.

North Carolina Molding Manufacturer

Company: nist.gov

Facebook page: Facebook

Services:

- Plastic injection molding for the biological pharmaceutical industry

- Plastic injection molding for the automotive and heavy truck appliance industry

- Plastic injection molding for the outdoor lawn equipment industry

- Plastic injection molding for the aerospace industry

- Integrated and innovative plastics solutions for leading companies in various industries

Core Technology is a plastic injection molding supplier located in Greensboro, North Carolina. They serve several industries including pharmaceutical, automotive, heavy truck appliance, outdoor lawn equipment, and aerospace.

Their strategy focuses on providing integrated and innovative plastics solutions to prominent customers such as Merck, Pfizer, BMW Manufacturing, Volvo, Mack Trucks, Volvo Cars, Husqvarna and more. In addition to their existing capabilities in manufacturing, they have sought training from the NC State Industry Expansion Solutions (IES) to further enhance their skills and expertise in pharmaceutical manufacturing.

Bull Engineered Products

Contact phone: (704) 504-0300

Services:

- Full service, turnkey injection molding

- Design and rapid prototyping

- Assembly and delivery management

- Meeting tight tolerances

- ISO registered company since 2008

Bull Engineered Products is a full-service injection molding company based in Charlotte, North Carolina. With expertise in design, rapid prototyping, assembly, and delivery, they offer a comprehensive parts program while ensuring the tightest tolerances are met.

As an ISO registered company since 2008, Bull Engineered Products is committed to providing high-quality parts at competitive prices and continually seeks ways to improve their business. With facilities spanning 19,000 square feet and a range of specialized capabilities including tight tolerance molding, die cutting, ultrasonic welding, pad printing, and quality laboratory services; Bull Engineered Products stands out as a leader in the industry.

Conover Plastics

Services:

- Custom plastic injection molding

- Design of parts, tooling, and mass production of molded products

- Expertise in molding various commodities and engineered plastics

- Customer-focused approach and commitment to success

- Use of thirteen injection molding machines with various tonnage and shot weights

Conover Plastics is a leading custom plastic injection molding company that specializes in design, mold fabrication, and the production of various commodities and engineered plastics. With over 45 years of experience, their expert team manages projects from concept to finished product with meticulous attention to detail.

They have a range of injection molding machines with different tonnage and shot weights to meet any customer’s needs. Conover Plastics is dedicated to customer success and delivering high-quality products that satisfy customers locally and globally.

H & R CUSTOM INJECTION MOLDING, INC

Company: usaopps.com

Services:

- Injection molding services

- Custom mold design and manufacturing

- Prototype development

- Production of plastic parts

- Quality control and inspection

This injection molding company provides a range of products and services, catering to government bids and contracts. Their expertise lies in manufacturing molded products with high precision, while ensuring quality and meeting the specific requirements of their clients.

With a strong reputation in the industry, they are dedicated to delivering exceptional results for their customers.

CDM Tool & Manufacturing

Contact phone: (262) 673-5620

Services:

- Custom precision mold design and manufacturing

- Multiple/Complex Action Molds

- Stack Molds

- Gas Assist Molds

- Two Shot Molds

CDM Tool & Manufacturing is a trusted mold maker for plastic injection molding. With over 60 years of industry experience, they design and build custom precision molds for businesses seeking high-quality plastic injection molds.

Their capabilities include multiple/complex action molds, stack molds, gas assist molds, two-shot molds, insert molding/overmolding, high-pressure injection molding, and low-pressure injection molding. Contact them to start your next custom mold project.

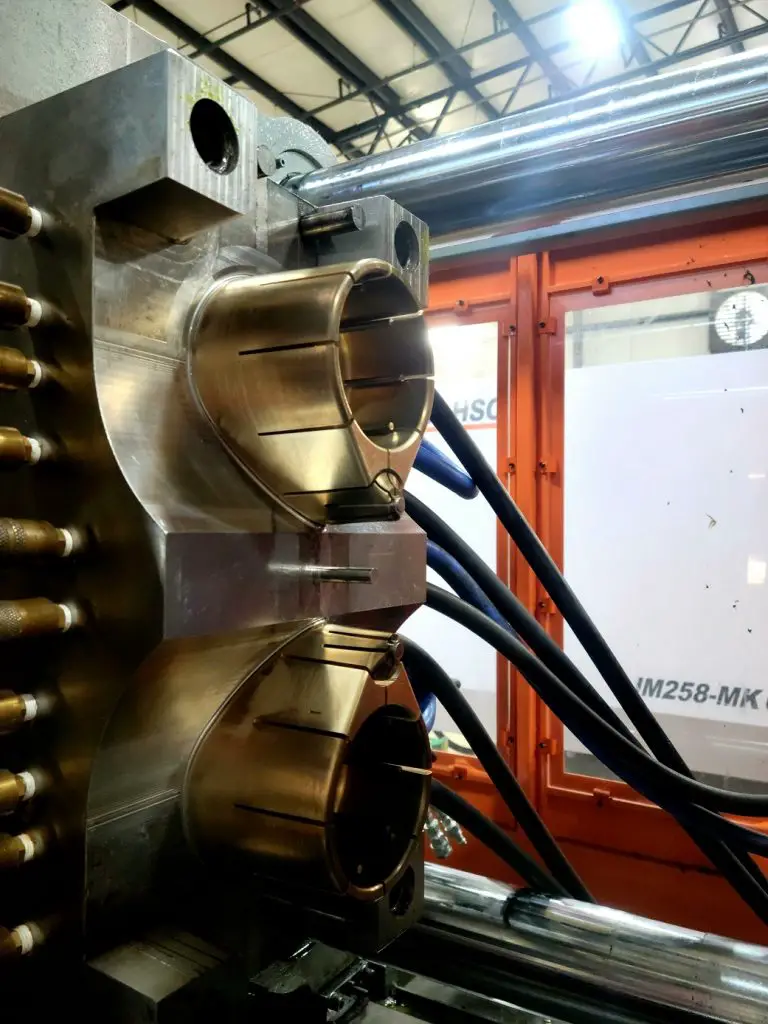

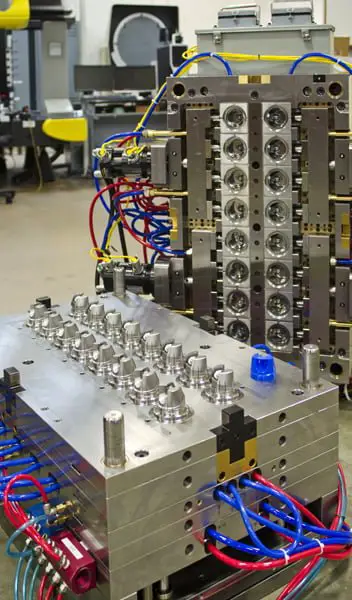

Plastic injection molding is a highly efficient process that involves melting plastic pellets and injecting the molten plastic into a mold under pressure to form the final product. The durable molds used in this process are typically made of steel (hardened or pre-hardened), aluminum, or beryllium-copper alloy and can be used for over one million cycles.

Recap