Looking for plastic injection molding companies in Georgia? We’ve got you covered with a comprehensive list of top-notch providers in the state.

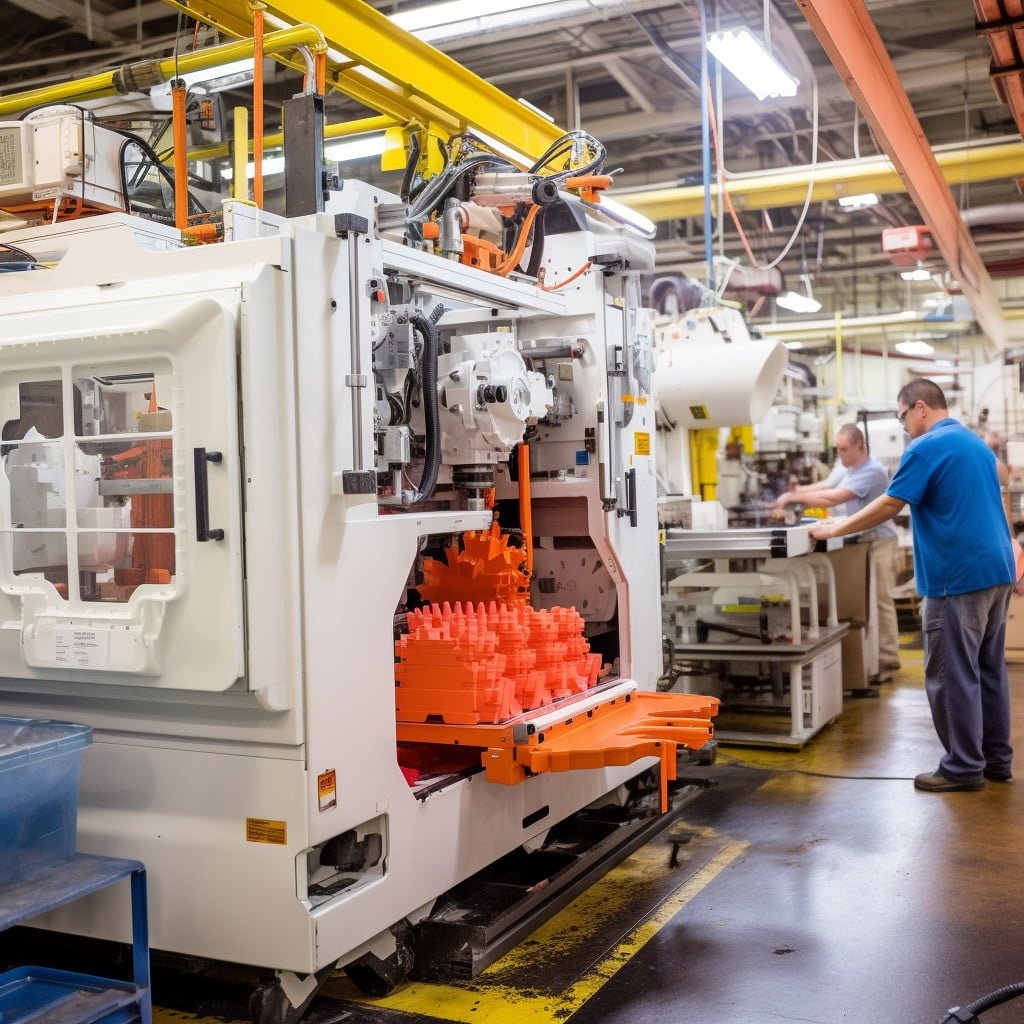

Plastic injection molding has become an integral part of the manufacturing industry, offering countless possibilities for creating complex and customized plastic components. In Georgia, a state known for its thriving business environment, several top-notch injection molding companies have emerged.

From their commitment to quality and technological advancements to their expertise in various industries, these companies are playing a pivotal role in shaping the future of manufacturing. Join us as we delve into the world of plastic injection molding companies in Georgia and discover why they are at the forefront of this innovative industry.

Atlanta Molding

Services:

- Long-range production runs in the millions down to a few thousand parts

- Mold design and construction

- Injection molding

- Assembly and subassembly

- Packaging

Atlanta Plastic Injection Molding specializes in high-volume production runs, offering shot capacities ranging from 3 oz to 39 oz. They provide comprehensive services including mold design and construction, injection molding, assembly and subassembly, as well as packaging.

With a dedicated and experienced team of technicians, they strive for efficiency in production with minimal scrap. Working with a wide range of plastic resins, they are committed to meeting customer expectations while delivering quality parts on time at competitive prices.

Advanced Plastiform

Facebook page: Facebook

Services:

- Custom plastic product and part manufacturing

- Thermoforming and injection molding expertise

- Fast lead times

- Low per-unit pricing

- Accurate and high-quality products

Advanced Plastiform, Inc. Is a leading injection molding company that has been providing custom plastic products and parts to various industries since 1988.

With their state-of-the-art manufacturing hub in North Carolina, they specialize in thermoforming and injection molding processes, using innovative technology and equipment. Their experienced team of engineers and designers work closely with clients to deliver accurate, high-quality solutions with fast lead times and competitive pricing.

Serving customers not only in Georgia but also throughout the Southeast and Mid-Atlantic regions, Advanced Plastiform stays ahead of the competition through efficient practices and a strong commitment to customer service.

Accurate Plastics & Mold

Contact phone: (770) 867-6867

Facebook page: Facebook

Services:

- Concept development

- Prototypes

- Molds for injection molding

- Value-added services

- Quality management

Accurate Plastics & Mold Co. Is a family-owned injection molding company founded by Jeff Reuschle in 1991.

With over 80 years of combined industry experience, they are committed to providing customers with the highest quality products and excellent service at competitive prices. They offer design assistance, material recommendations, and ensure timely delivery of quality molded products for new product launches.

EVCO Plastics

Company: evcoplastics.com

Services:

- Plastic injection molding

- In-mold decorating/labeling (IML)

- Molded-in color

- Overmolding

- Insert molding

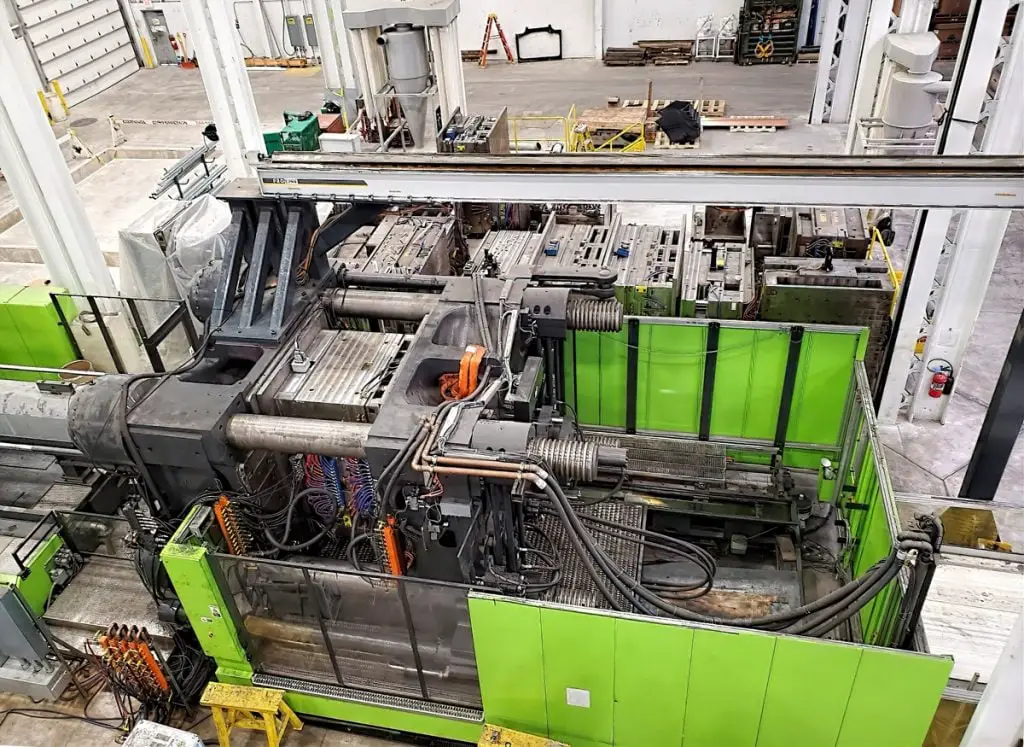

EVCO Plastics CAL1, located in Calhoun, Georgia, is a certified ISO 9001 injection molding company with a 110,000 square feet facility and 20 plastic injection molding machines. They specialize in various capabilities such as in-mold decorating/labeling (IML), molded-in color, overmolding, insert molding, gas assist molding, secondary operations, tool and mold building, large part molding, metal to plastic conversions, contract manufacturing, plastic packaging,and prototyping.

When plastics matter to your business and you need innovative solutions,EVCO is the trusted partner.

ADCO Plastics Corporation

Contact phone: (770) 425-1234

Services:

- Custom injection molded assemblies and parts manufacturing

- Serving various markets including medical, commercial, industrial, transportation, and retail

- Wide range of commodity grade and engineered resins and thermoplastic rubbers

- Agile customer responsiveness

- Value-added design and manufacturing

ADCO Plastics, located in Metro Atlanta, Georgia, is a trusted injection molding company with over 45 years of experience. Serving various industries such as medical, commercial, industrial, transportation, and retail markets, ADCO specializes in manufacturing custom injection molded assemblies and parts using a wide range of resins and thermoplastics rubbers.

With their agile customer responsiveness and powerful value-added design capabilities, ADCO stands out as a reliable provider of professional plastic injection molding services.

Murray Plastics

Services:

- Design & Engineering

- Molds & Tooling

- Injection Molding

- Quality Guarantee

- Latest Projects

Murray Plastics is a custom plastic injection molding company that offers design and engineering services, molds and tooling expertise, and high-quality injection molding solutions. With a commitment to providing excellent customer service, they work closely with clients to provide valuable insights and ideas for product improvement.

Their impressive portfolio includes projects in the film industry, welding industry, and military optics sector. Whether you’re looking for consultation or interested in becoming a vendor, Murray Plastics is ready to assist you with their founder-led United States manufacturing capabilities.

Peliton

Company: peliton.com

Services:

- Plastic injection molding

- Mold making

- Part assembly

- Packaging

- Machining

Peliton Plastics is a full-service plastic injection molding and manufacturing company based in Valdosta, Georgia. With a wide range of services including mold making, part assembly, packaging, machining, ultrasonic welding, and shipping, Peliton strives to deliver high-quality results at the lowest cost possible.

Founded in 1996 by Robert McKinnon with humble beginnings, Peliton now runs from a state-of-the-art 35,000 sq. Ft facility and continues to grow by providing dedicated customer service and turning ideas into successful finished products that meet customers’ expectations and specifications.

Custom Molding

Services:

- Custom plastic injection molding with machines ranging from 88 ton to 1500 ton capacity

- High pressure and low pressure structural foam molding options

- Daily capacities ranging from several hundred large parts to over 500,000 smaller parts

- In-house services including design and engineering, fully equipped tool rooms, and warehousing

- Integrated ISO 9001 quality control with additional services like press side packaging, hot stamping, and sonic welding available if needed

Plastic Industries, located in East Tennessee, is an injection molding company that offers same-day shipping to Georgia. With a wide range of plastic injection molding machines and daily capacities of several hundred large parts or over 500,000 smaller parts per day, they provide custom plastic injection molded products to customers across the southeast.

In addition to their manufacturing capabilities, Plastic Industries also offers design and engineering services, fully equipped tool rooms, warehousing facilities, integrated ISO 9001 quality control, press side packaging, hot stamping, and sonic welding.

TerBeek Molding & Tool

Services:

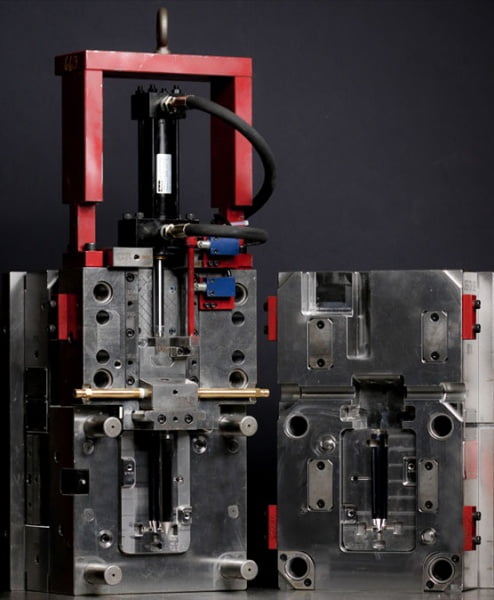

- High-precision mold manufacturing services for various industries

- Fabrication of robust molds for long-term production

- Specialization in designing and producing tight-tolerance plastic injection molds

- Serving industries such as medical device, technical automotive, food packaging, general industrial, and consumer product

- Operating from a new, modern, climate-controlled, 22,000 sq. ft. facility in Peachtree City, Georgia

TerBeek Molding & Tool is a privately held injection molding company based in Peachtree City, Georgia. Established in 2005 by industry veterans Brian and John TerBeek, the company specializes in designing and producing high-precision plastic injection molds for various industries including medical device, automotive, food packaging, general industrial, and consumer products.

With a new, modern facility spanning 22,000 square feet just south of Atlanta, their talented team of professionals delivers robust molds with tight tolerances for long-term production. Contact them today at [email protected] or call (678) 519-1917 or (678) 489-5902 to learn more about their services.

20/20 Custom Molded Plastics

Contact phone: (419) 485-2020

Facebook page: Facebook

Services:

- High pressure injection molding

- Structural foam molding

- Structural web/gas assist molding

- Engineering and tooling services

- Quality assurance and secondary services

This injection molding company specializes in high and low pressure injection molding, with a focus on developing and improving applications for cost reduction. Their product development team integrates design, engineering, and quality control disciplines to ensure superior part performance and cost effectiveness.

They have multiple locations across Ohio, Indiana, and Georgia.

Advanced Molding Inc

Contact phone: (678) 840-8087

Services:

- Custom plastic injection molding services

- Specialization in intricate and large component parts

- Production using engineering and commodity grade resins, as well as thermoplastic rubbers and elastomers

- Focus on producing high-quality parts on time and at a competitive cost

- Ability to meet a variety of injection molding needs with a range of 14 machines from 60 tons to 400 tons capacity

Advanced Molding, Inc. Is a reputable injection molding company based in Georgia that has been providing custom plastic injection molding services since 2002.

With expertise in the Medical, Electrical, Construction, Telecommunications, and Recreational Industries, they specialize in producing intricate and large component parts using a range of resins and elastomers. Equipped with 14 state-of-the-art machines ranging from 60 to 400 tons capacity, they prioritize delivering high-quality products on time and at competitive prices to ensure customer success.

Premier Plastic Molding & Tooling, Inc

Company: premierplasticmolding.com

Contact phone: (678) 425-6959

Services:

- Plastic injection molding

- Tooling design and manufacturing

- Custom plastic part manufacturing

- Accurate and precise manufacturing processes

- Convenient location near Atlanta, Georgia

The Atlanta-based company is a leading expert in plastic injection molding and tooling. Known for their precision and expertise, they specialize in producing custom plastic parts with utmost accuracy.

SPF Plastic Group

Facebook page: Facebook

Services:

- Custom molding services

- New product development

- Contract manufacturing options

- Competitive pricing

- Dedicated customer service

SPF Groups is a reliable and experienced injection molding company that offers contract molding services, with machine clamp sizes ranging from 300 to 1800 tons. They provide excellent quality and service to meet customers’ custom molding needs.

SPF offers branding options, daily QC programs, in-house tool repair shop, material recycling/grinding, preventative maintenance programs, and more. Their specialized expertise helps companies create high-quality plastic solutions for various industrial applications.

Parkway Products, LLC

Company: parkwayproducts.com

Contact phone: (774) 862-7380

Services:

- High Performance Polymer Molding using Ultra Polymers such as Torlon®, Ultem™, Amodel®, Ryton®, and PEEK™

- Molding parts for Aerospace & Defense, Industrial, Energy & Infrastructure, and Automotive markets

- Lightweight parts that can withstand high stress, high pressure, and high temperature

- Compounds with Carbon-fiber, Glass-fiber, or Aramid-fiber reinforcements for optimal mechanical properties

- Secondary operations including machining and dual disc grinding for a complete solution

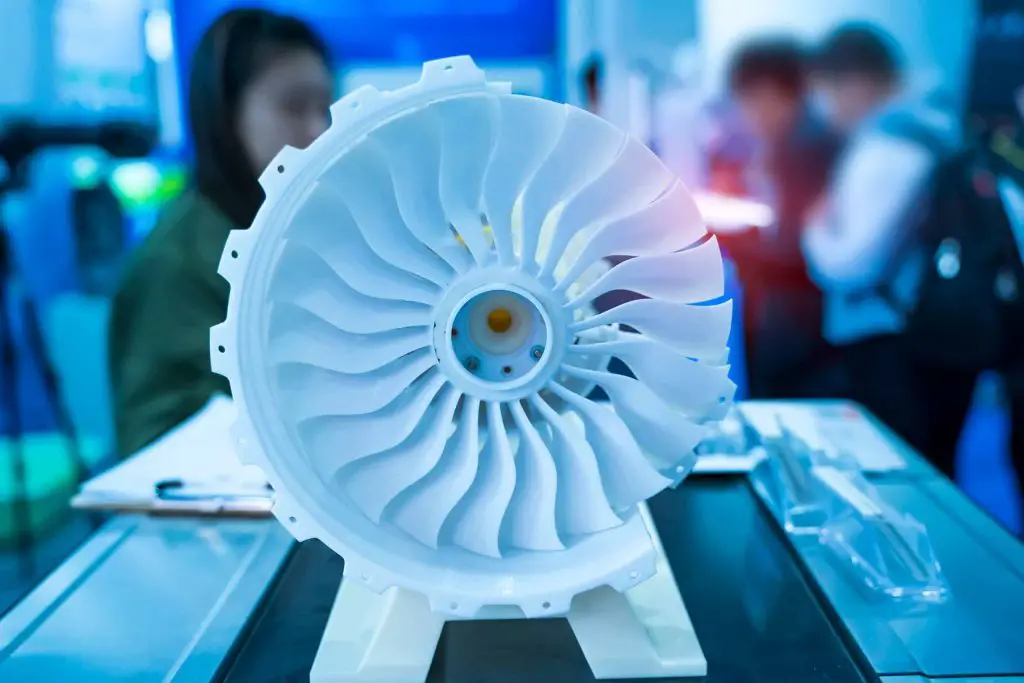

Parkway, an injection molding company with locations in Atlanta, Georgia and Machesney Park, Illinois, specializes in High Performance Polymer Molding. They offer dedicated facilities for molding parts using Ultra Polymers such as Torlon® (PAI), Ultem™ (PEI), Amodel® (PPA), Ryton® (PPS), and PEEK™.

These materials are chosen for their lightweight properties and ability to withstand high stress, pressure, and temperature. Parkway also provides secondary operations like machining and dual disc grinding to deliver comprehensive solutions to their customers in various industries including Aerospace & Defense, Industrial, Energy & Infrastructure, and Automotive markets.

RPM Fast

Contact phone: (470) 264-1680

Services:

- Fast turnaround on injection molded parts using various materials and tools

- Capable of complex tool designs

- Additional services including two-shot molding, family tools, inserts, multi-cavity tools, insert molding, pad printing, ultrasonic welding, and assembly

- Domestic options available, including ITAR compliance

- Request a quote and contact information provided

This injection molding company offers fast turnaround on a variety of parts using Aluminum, P20 Steel, and Steel Tools. They provide T1 samples within 12 days and can complete full production in 25 days.

With expertise in complex tool designs, they also offer additional services such as two-shot molding, family tools, inserts, multi-cavity tools, insert molding, pad printing, ultrasonic welding, and assembly. Domestic options are available including ITAR compliance.

To request a quote or find their contact information visit their website.

Plastics and Innovations

Services:

- Pre-production and design services

- Prototyping services

- Mold making for mass production

- Production of plastic parts

- Quality assurance and adherence to strict standards

This injection molding company specializes in providing pre-production and design services, which typically take 2 to 3 weeks to complete. They offer prototyping to test initial concepts before proceeding with mass production.

Located in Mableton, GA, they conform to strict quality standards and produce a variety of plastic parts.

Recreational Group

Facebook page: Facebook

Services:

- Injection molding

- In-Mold Labeling

- Color Molding

- Contract Manufacturing

- Specialized landscape design and architecture services through Lanmark Designs

CH3 is an injection molding company founded by industry experts who saw the need for improved quality and cost control in a more sustainable operation. They prioritize consistency in high-quality production, cost management, and on-time delivery.

Recognized as a Top 25 World Class Processor by Plastics Technology Magazine, CH3 offers injection molding services along with in-mold labeling, color molding, and contract manufacturing capabilities. Located in Dalton, GA and Orlando, FL, they are dedicated to providing excellent customer service and innovative solutions to fulfill project requirements.

Underwood Mold Co

Contact phone: (770) 926-2465

Services:

- Custom injection molding services

- Mold design and fabrication

- Extensive line of packaging products (aerosol caps, pails, and lids)

- Full in-house tool shop for PM & repair

- Engineering services (tooling, design & development)

Underwood Mold is a well-established injection molding company based in metro Atlanta. With over 50 years of experience, they are known for providing high-quality injection molds and molded products to their clients.

Their services include custom injection molding, mold design and fabrication, as well as a range of packaging products such as aerosol caps, pails, and lids. They have an extensive in-house tool shop for PM & repair and offer a wide range of press sizes for assembly and secondary operations.

With their expertise in engineering resins and their capabilities in tooling, design, and development, Underwood Mold can provide custom solutions to meet clients’ specific requirements.

The Rodon Group®

Company: rodongroup.com

Facebook page: Facebook

Services:

- Plastic Injection Molding

- Custom Plastic Injection Molding

- Standard Parts

- Parts Gallery

- Varying materials and surface finishes for custom injection molding

This injection molding company specializes in custom plastic injection molding, offering a wide range of materials to suit different applications. They provide various thermoplastics such as ABS for flexibility and impact strength, LDPE and HDPE for versatility and moisture resistance, PC for durability and transparency, nylon for electrical properties and heat resistance, HIPS for impact resistance and food-grade components, and PP for chemical resistance and high melting point.

Jabil

Facebook page: Facebook

Services:

- Accelerated Product Introduction

- Design, Decoration & In-Mold Labeling

- High Cavitation Injection Molding

- High Precision Injection Molding

- Sustainable Packaging

Jabil Atlanta is a leading injection molding company offering thermoplastic polymer solutions for diverse packaging applications. With capabilities such as accelerated product introduction, high cavitation and precision injection molding, design and in-mold labeling, as well as sustainable packaging options, Jabil assists customers in bringing innovative products to market quickly and reliably.

Leveraging a massive global network of 250,000 professionals across more than 100 strategic sites worldwide, Jabil provides comprehensive services that range from design and manufacturing to supply chain management for various industries. Their expertise ensures optimized designs, rapid prototyping, superior product quality through advanced automation technologies, stringent validation methods, intelligent digital supply-chain solutions for sourcing materials and reaching target markets effectively.

Thomson Plastics

Facebook page: Facebook

Services:

- Broad press capability ranging from 66 tons to 4400 tons of clamp force

- Expertise in producing medium and large-sized parts

- Ability to achieve demanding surface finishes, including Class-A, high gloss, and clear acrylic

- Gas-assisted injection molding for large, dense parts with a hollow inside

- Cost-saving initiatives for weight reduction and cycle time reduction

TPI is an injection molding company with a wide range of press capabilities, from 66 tons to 4400 tons of clamp force. They specialize in producing medium and large-sized parts with exceptional surface finishes, including Class-A, high gloss, and clear acrylic.

TPI also offers gas-assisted injection molding for large, dense parts with hollow interiors. Their expertise in this process allows for weight reduction and cycle time reduction, with the ability to update facilities quickly and safely deliver Nitrogen gas directly to machines.

Furthermore, recent investments have been made to enhance high pressure gas control equipment for improved performance.

Recap